DISCLAIMER

USE AT YOUR OWN RISK. This guide assumes that you are qualified to work with AC and DC systems. Always be save, follow the appropriate standards and consult an electrician before commissioning. I do not take responsibility for any harm or damage resulting from following this guide.

Saving the planet ... sort of

There are many reasons to build off-grid solar systems - saving the planet, independence from the utility and/or government organisations, prepping for the next dooms-day scenario. Mine is a bit less dramatic ...

I own two EVs (30kWh fully electric and 12kWh hybrid) that need charging somehow. Unfortunately, my garage is about 100m away from my house which is the only meaningful source of power in the close vicinity. The neighbouring house does provide AC power to all garages powering lights and electric garage-door openers, however, the 60year old electrical installation will probably burst into flames if subjected to multiple kW of continuous power draw.

This left me with a few options:

- A: Run about 80m of cable over multiple rooftops with the additional complexity of digging through 10m of communal asphalt

- B: Run about 80m of cable through multiple gardens (incl. trees and bushes) and dig through 5m of communal asphalt

- C: Digging up the entire foot path in the middle and then some asphalt (not really an option)

- D: Produce power locally and hope for the best

After multiple talks with my neighbours, expressing a varying degree of enthusiasm for vandalising their properties, I opted for option D.

Component choices

First step was to map out the available area on my garage and select some PV panels to utilise the space as good as possible. I opted for 550W panels from JaSolar that are roughly 2mx1m in size. The initial plan was to lay them all flat to minimise installation effort but unfortunately I am rubbish at measuring. Hence, I was forced to tilt two of the panels to stay within the bounds of the garage. I told myself later that this would improve yield in winter (ha). The panels are connected in series and generate about 350V of open circuit voltage (again - be save - see disclaimer). I also provided earthing to all panels via a 16mm2 coper lead.

Next step was to chose a stationary battery that matches the PV output and the size of the EV batteries. Here I tried to strike a balance between providing a meaningful amount of storage and having enough current to feed the wallbox. Also, I wanted to use a 48V LFP (lithium iron phosphate) battery as high voltage (batteries) as well as MNC chemistry (nickel manganese cobalt) is scary. After some research I opted for a 6.14kWh 48V LFP battery incl. BMS (battery management system) from Papool. These batteries can deliver 100A DC which gives us a comfortable 4,8kW charging/discharging power. Delivery was about 2 months - overall the battery appears to be pretty solid so far. (5,12kWh version shown here)

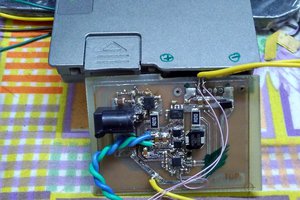

Choosing the PV charger & inverter that matches the charging power of the electric vehicle and the PV installation was next. My first attempt consisted of a cheap Esmart 3 PV charger and a cheap 2kW 48V 230V inverter.

Unfortunately this lead to two complications: 1. the Esmart 3 charger went up in a big cloud of smoke at half PV output although I limited the PV open circuit voltage to the recommended 150V by connecting 2x3 panels in parallel. And 2. the DATOUBOSS 48 V to 230 V 2kW Pure Sine Wave inverter that I selected was drawing too much current when switched on, causing the battery to go into an short-circuit error state.

Unfortunately this lead to two complications: 1. the Esmart 3 charger went up in a big cloud of smoke at half PV output although I limited the PV open circuit voltage to the recommended 150V by connecting 2x3 panels in parallel. And 2. the DATOUBOSS 48 V to 230 V 2kW Pure Sine Wave inverter that I selected was drawing too much current when switched on, causing the battery to go into an short-circuit error state.

So I went want back to the drawing board and finally settled on an all-in-one Growatt SPF 3500 ES inverter. This inverter can accept about 4.5kW of PV power and provide about 3.5kW of AC power including a build in 48V battery option. This matches my system rather well as the maximum allowable single phase AC power for the wall-box is about 3,6kW....

Read more » Dominic Buchstaller

Dominic Buchstaller

Simen Sollihøgda

Simen Sollihøgda

x-labz

x-labz

ric866

ric866

Kumar, Abhishek

Kumar, Abhishek

Nice project, congratulations! One general question, probably a stupid question. In a system like this, would it be not posible to skip the conversion to AC and back to DC to charge the car? I don't know if there are technical reasons for this, or just that the available components work this way.