Why I made this

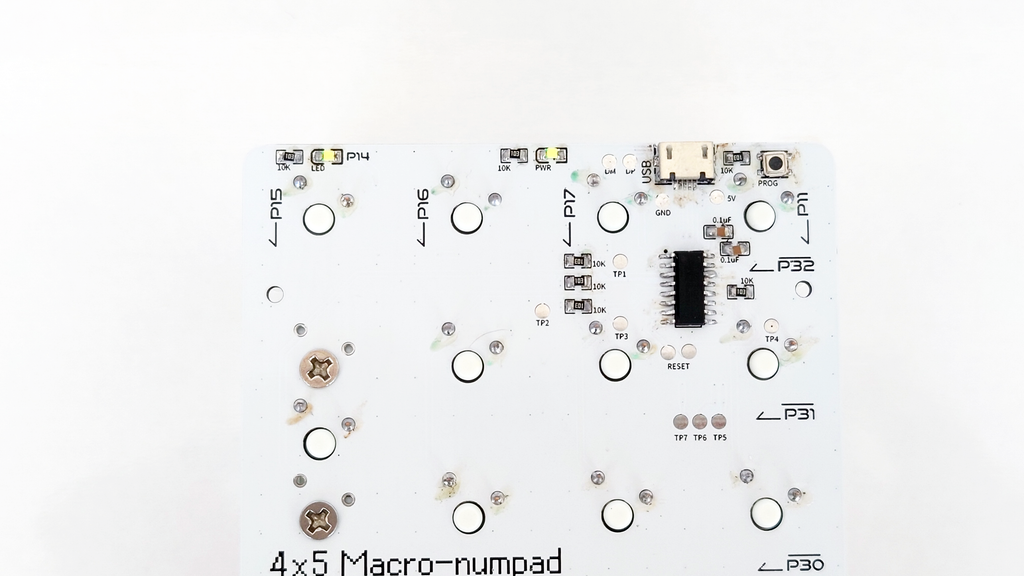

A few months ago, I developed and open source the 4xMacropad, a $3 macropad made using CH552G. After seeing much of the feedback from the internet, I notice I can better utilize this chip to make a keyboard with more keys. That is why I am trying to make a numpad in order to use 100% potential of this particular chip.

There are lots of good looking mechanical numpad out there with cool designs. But most of them falls into the 40 - 50 USD range (for DIY kits). That is why when I am deciding this numpad, my goal is to make it as cheap as possible, while maintain the good features from the previous builds:

- Arduino Programmable

- Cheap and easy to make

- Little to no change in BOM list

While improving some designs that was most commented agaist

- Swap out the mini USB port

After a few weeks of trial and error, I finally get a numpad made with the identical BOM list (actually this numpad has less SMT parts than the pervious 4xMacropad build) and successfully make it cost under $10 USD.

How this design turns out to be bad for international shipping (and for sale)

If you are also an Instructable reader, you will notice this post is slightly different than the one I wrote on Instructable. The reason is I do not have enough confident in shipping them out if I put it on hackaday (and Tindie). I have make a few sales on Tindie, but I lose money on both of the keyboard I sold. That is because of the design is not optimized for international shipping.

You see, international shipping have strict limits on size and weight of an item. And shipping the original design via parcel will cost much more than the keyboard itself, making it cannot compete with other options on the market.

In summary, international shipping prefer sizes around 15 - 20cm x 9 - 12cm with height around 4 - 6cm. You can wrap it in cardboard box or paper parcel, it doesn't really matters. Only if I optimized the macropad to the required size, I can easily ship it to Europe (from Asia) for less than 3 USD (for the slowest shipping method) or less than 5 USD to the US (also the slowest shipping method).

How I solve the international shipping issue with engineering

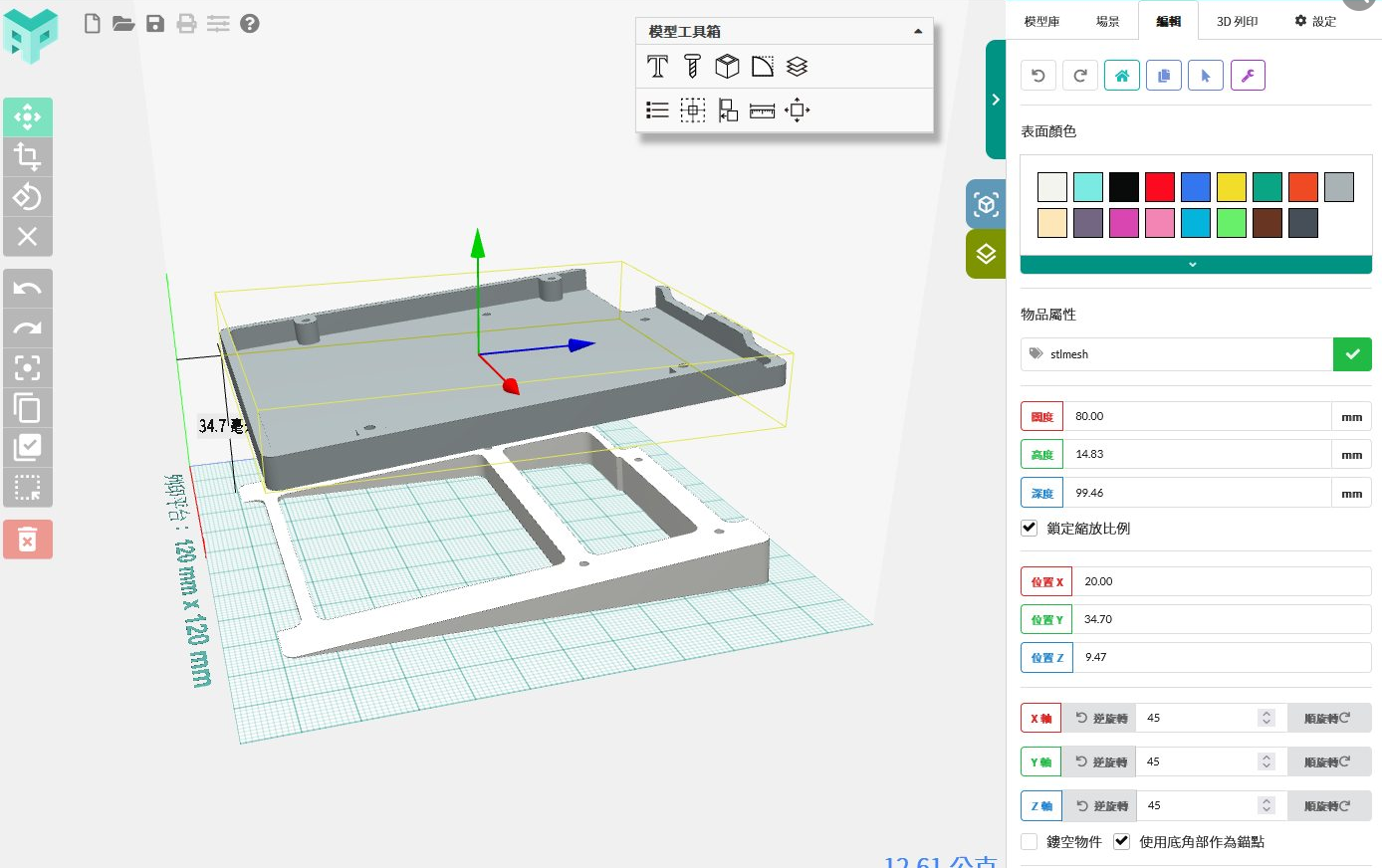

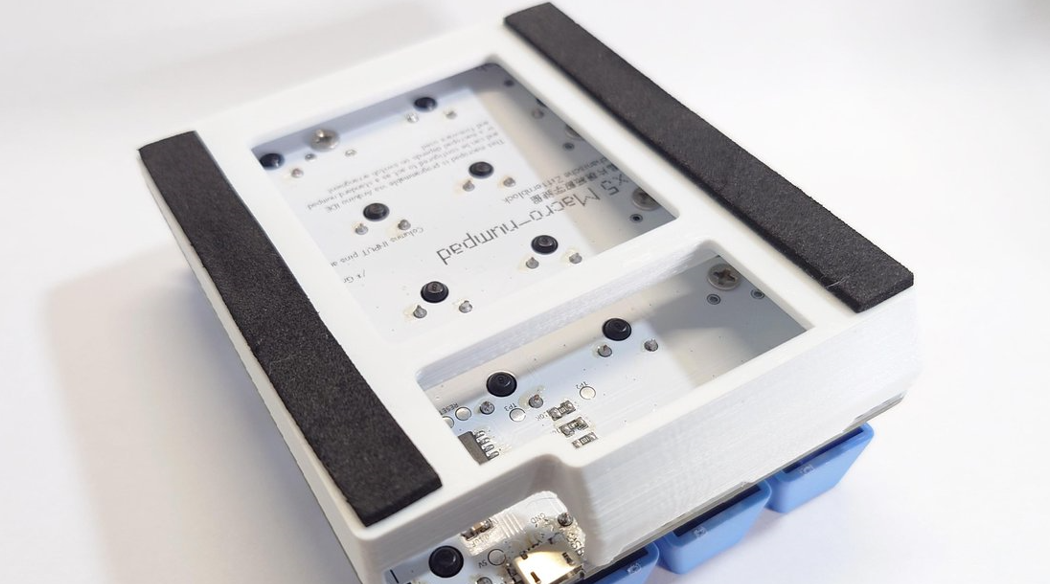

Eventually, I solved this be reducing the weight of the numpad to < 500g with some optimized 3D printed parts and wrapping materials.

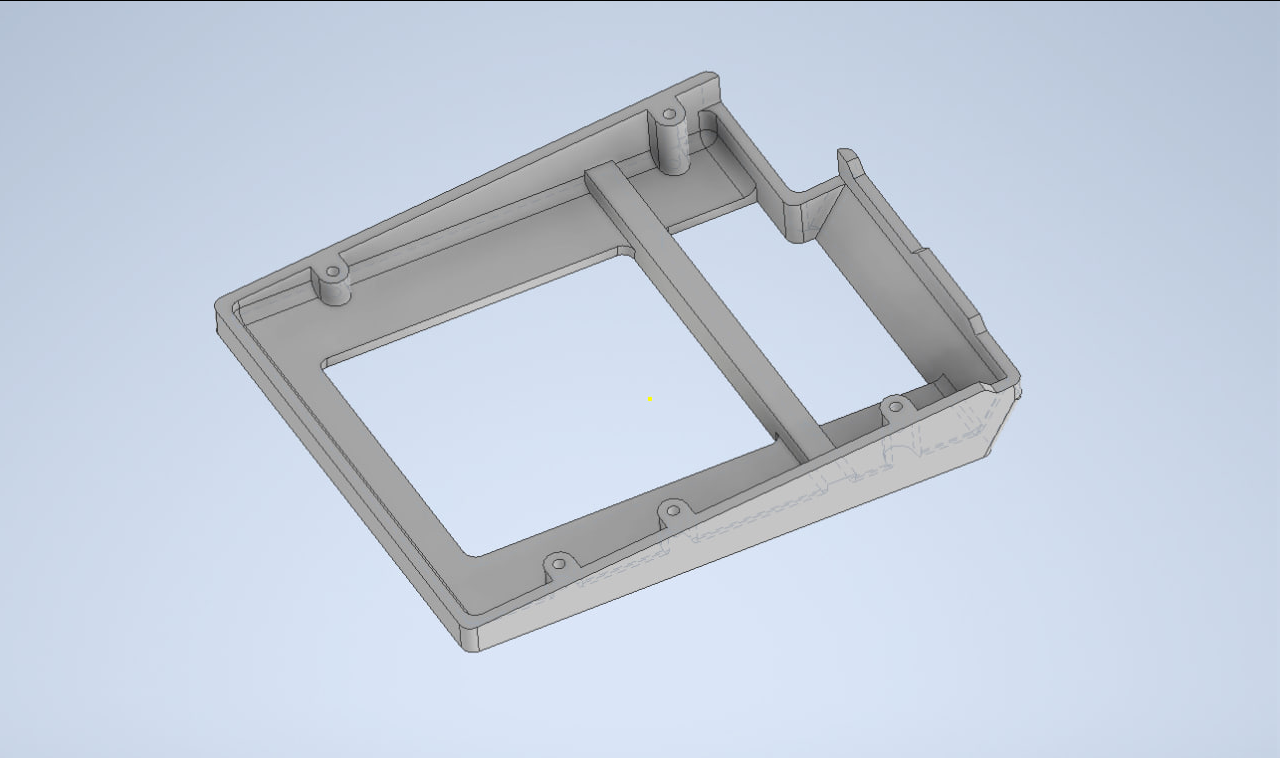

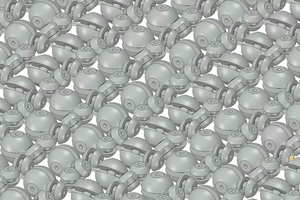

New design, which save much more materials (and weight) in shipping

New design, which save much more materials (and weight) in shippingAfter the base design is optimized, not even you can see through the bottom PCB which makes it much cooler (new vs old)

I also swapped out the foam case (which is a really nice fake leather container that I ordered from a case maker, but this add too much weight to the parcel) to a standard international shipping Y5 cardboard box.

These changes allows me to reduce the price of each units from 30+ USD to 23+ USD each (because of the shipping cost). Now this is finally ready to be put on hackaday and see how people reacts to the optimized design :D

tobychui

tobychui

Nathan Brown

Nathan Brown

Brien Allison

Brien Allison

finallyfunctional

finallyfunctional

Vaibhav Chhabra

Vaibhav Chhabra

how fast is this dev?

power is good for mobile dev?