Previous Published Projects:

In-Work Projects:

Future Projects:

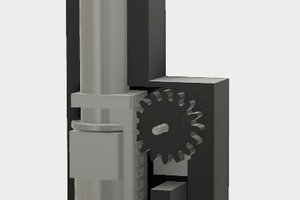

- 3D print new fish feeder tray

- Servo controlled fish feeder

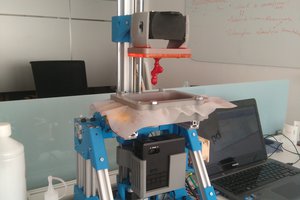

- Collect soil moisture data and publish to cloud, control plant watering

- Wifi Light Switch w/motion sensor

- 3D print enclosure for 120v AC to 5V converter.

- Upgrades to Adafruit LED Goggles project

- Adding built-in battery charger

- Adding enclosure with on/off switch

2017 Maker Events Attended:

- An Evening with Ultimaker @ SoDo Makerspace - Feb 25th

- Seattle Mini Maker Faire Launch Party @ SoDo Makerspace - April 18th

- Maker Faire Bay Area (Friday Volunteered, Saturday Attended) - May 19-21

Upcoming Events (I plan to attend):

- Seattle Mini Maker Faire - Sept 16-17

- Hackaday Superconference - Nov 11-12

Eric Moyer

Eric Moyer

Sam Ettinger

Sam Ettinger

Giovanni Leal

Giovanni Leal

Jaime García

Jaime García

CriptasticHacker

CriptasticHacker

ssfs