Having been standing outside, the Y Axis wasn't running smoothly. I worried, that I had to use a NEMA34 motor for driving this axis. Adding a 1.8 kg motor costing $200 wasn't on the top of my list, so I started looking into how, the Y Axis was constructed. Whereas the X Axis runs directly on the belt, the Y Axis seems to run using a magnetic transmission (for keeping dust etc. off the Y Axis belt). Designing a short arm, which could be screwed on to the Y Axis, I found, that it only required a 0.250Nm forced to move it. After cleaning and oiling the linear rails of the Y Axis, the axis ran much better and with much less force, making it more likely to be able to run using a standard NEMA23 motor.

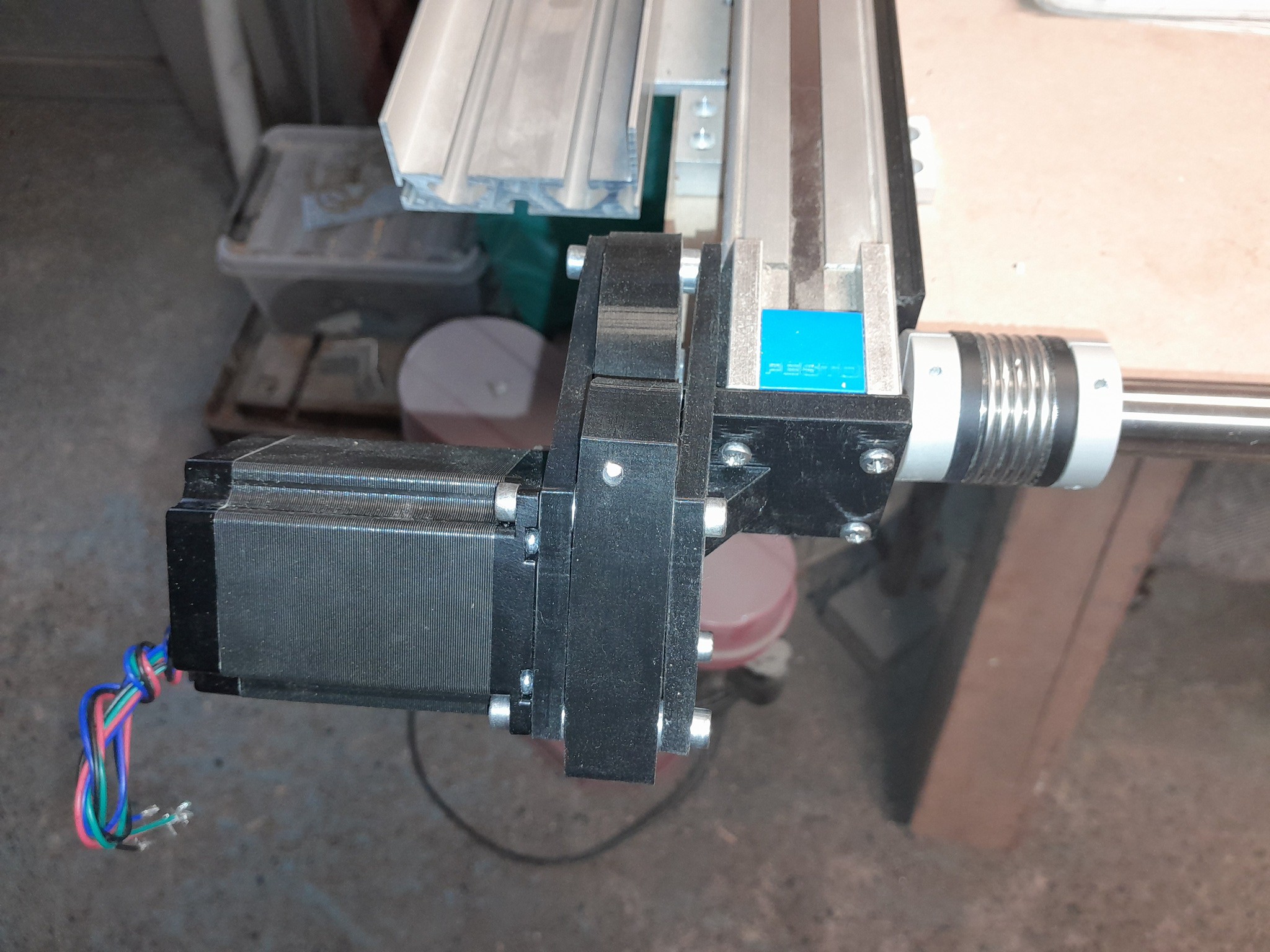

I designed a demo fixture for a NEMA23 stepper motor with 1:3 gearing using Belts and Pulleys. PLA version seems to fit, except for a 2 degree slope, which has been compensated for prior to printing it in PETG.

Huge thanks to www.makersupplies.dk (Martin) for his suggestions on how to begin this work and material choices.

Rui Caldas

Rui Caldas

jvsalatino

jvsalatino

jupdyke

jupdyke