There is a 1 MByte SPI flash memory on board which allows either data storage for very low duty cycle BLE radio transmission and/or to store a firmware upgrade for OTA reprogramming of the STM32L4.

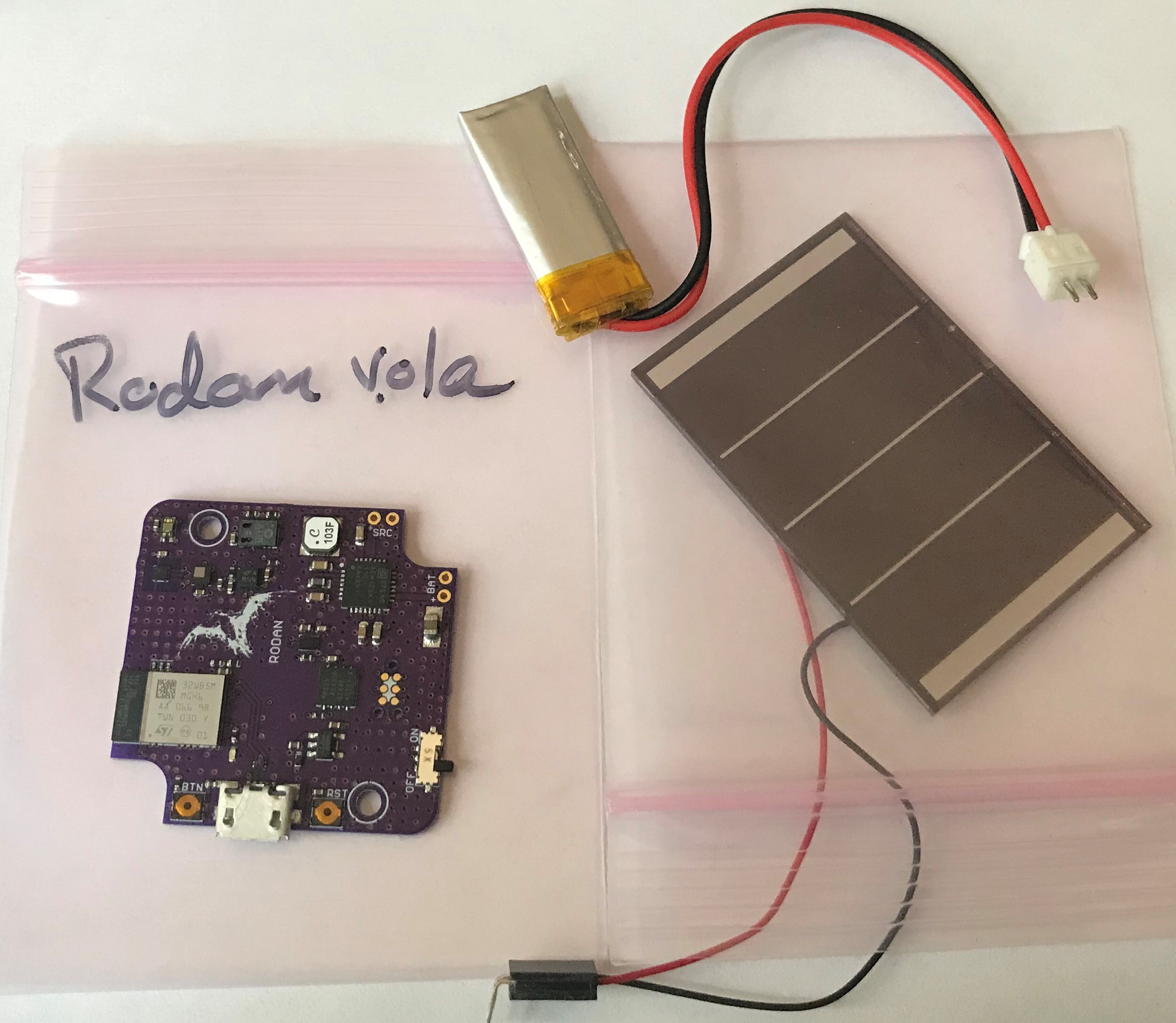

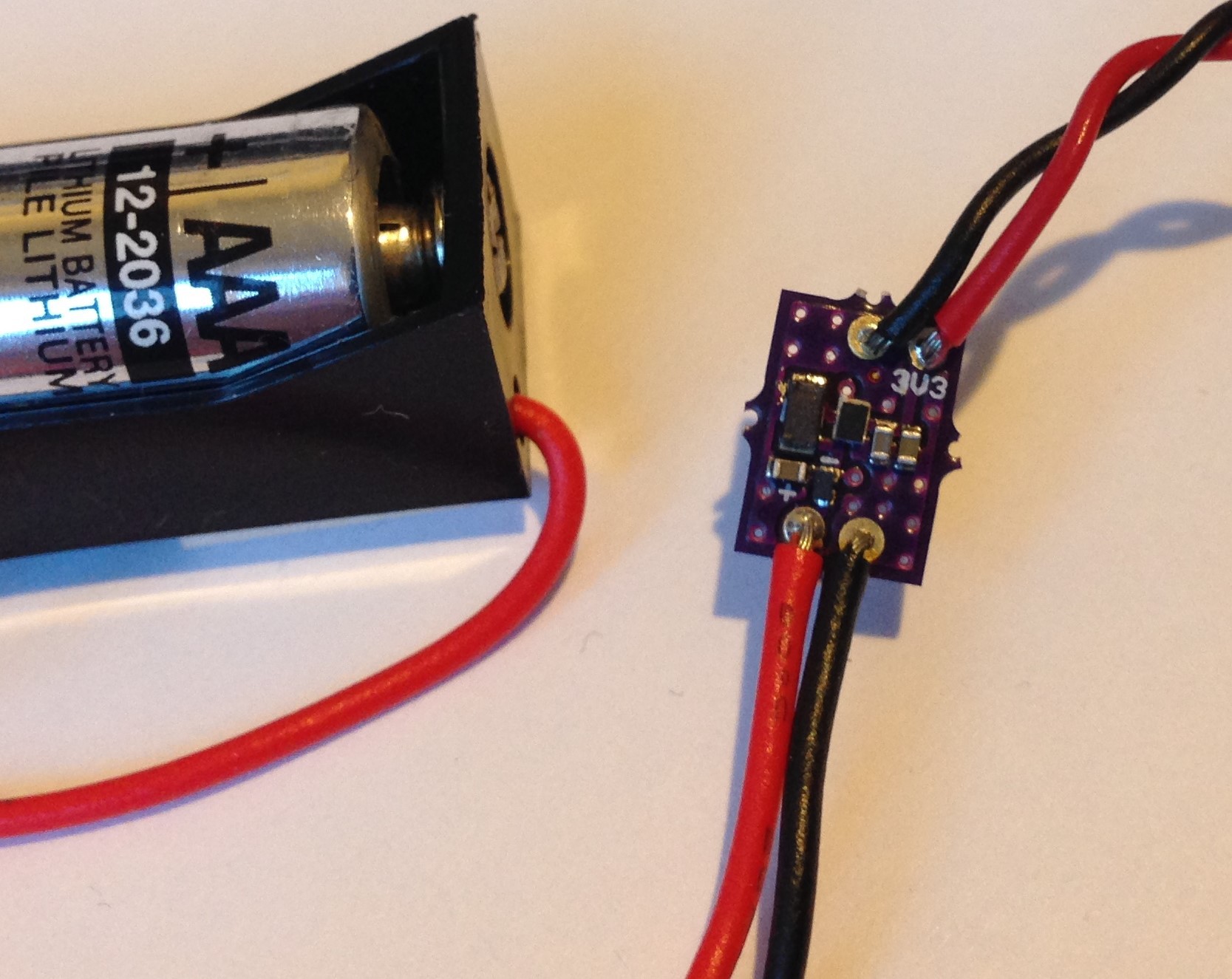

There is a MAX1555 LiPo battery charger on board, a power switch that controls the enable on the NCV8170 LDO, and 3V3, GND, SDA, and SCL are exposed as through holes on the board for ease of testing and in case another I2C sensor needs to be added.

The pcbs are available at OSH Park in the shared space.

Arduino-programmable STM32L432 development boards can be purchased here.

Update February 12, 2017

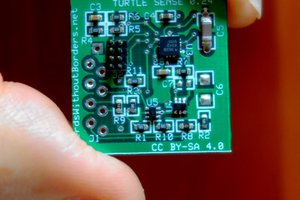

I assembled the first three pcbs I received from OSH Park. and on at least one of them I got almost everything working. Assembly was difficult since the board is crowded on both sides with not a lot of edge to grab onto. I guess this is the price of a small, compact board with lots of sensors!

I verified that the STM32L4 can be programmed via the USB using the Arduino IDE, of course, and that I can blink the on-board led on pin 13, read the internal temperature sensor and VDD voltage, as well as get time and date from the embedded RTC.

I also verified that the BME280 pressure/humidity/temperature sensor, ICS43434 microphone, 1 MByte SPI flash, and MPU6500 accel/gyro work as expected.

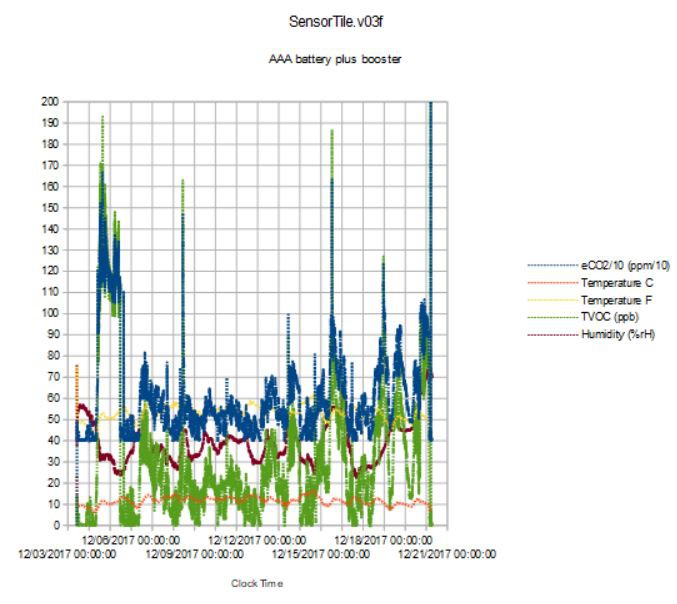

I had a bit of trouble with the CCS811 air quality sensor, partly because it is new to me and mostly because the land pattern is pretty tight for a LGA package. I might have to redo the footprint to make it more likely to make a good connection to the board. Of the three boards I (partially) assembled, one has a short between 3V3 and GND due to the poor soldering of the CCS811, one functions well enough but the I2C address of the CCS811 is 0x5B when it should be 0x5A since I set the ADO pin to GND in the design. So there is obviously some kind of connection problem on that one too. The third one seems fine, the I2C address of the CCS811 is 0x5A as it should be. I can't get proper data out of either of these last two and the heater current shows zero Amps and the heater voltage shows 0.83 V so the heater circuit doesn't seem to be working properly. I have asked AMS for access to the application notes so I can figure out how to properly configure this sensor.

The battery charger works as does the battery voltage monitor connected to an ADC of the STM32L432. The 12-bit ADC makes it possible to detect changes in battery voltage of 0.01 V, so one can watch the battery voltage slowly rise in just a few minutes as it charges. The temperature measured by the BME280 and internal STM32L432 temperature both rise several degree when the battery is being charged. I guess this draws a lot of current through the MAX1555 (~100 mA IIRC).

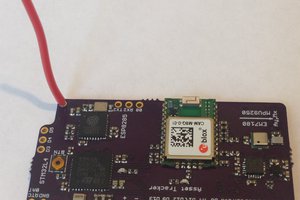

The Rigado BLE module is missing since Digikey won't have them in stock for another week or two. I have two samples from Rigado I assembled into breakouts for testing; I suppose I could harvest one of these to add to the Sensor Tile but I think I will just wait to get a real supply of them.

So what is the rationale for these sensors, are they chosen at random? Not really. The device will find first applications in sensing emplaced capital machinery. The idea is that there are a lot of expensive industrial machines operating in production lines that do not have adequate monitoring of their function and performance. Or such data needs to be manually accessed and printed out of a controller designed twenty years ago, etc. So this sensor tile is designed to be mounted to these machines, and return data wirelessly, automatically, and remotely. So it has to last a long time on a LiPo battery, has to send data that can be funneled up to the cloud or to a server, and has to measure things worth knowing.

One thing worth knowing is whether the machine is operating or not. This is easy to tell just be monitoring the vibrations detected by the accelerometer, which tend to have normal modes at the 60, 120, and 240 Hz supply voltages of AC motors that run them. In...

Read more » Kris Winer

Kris Winer

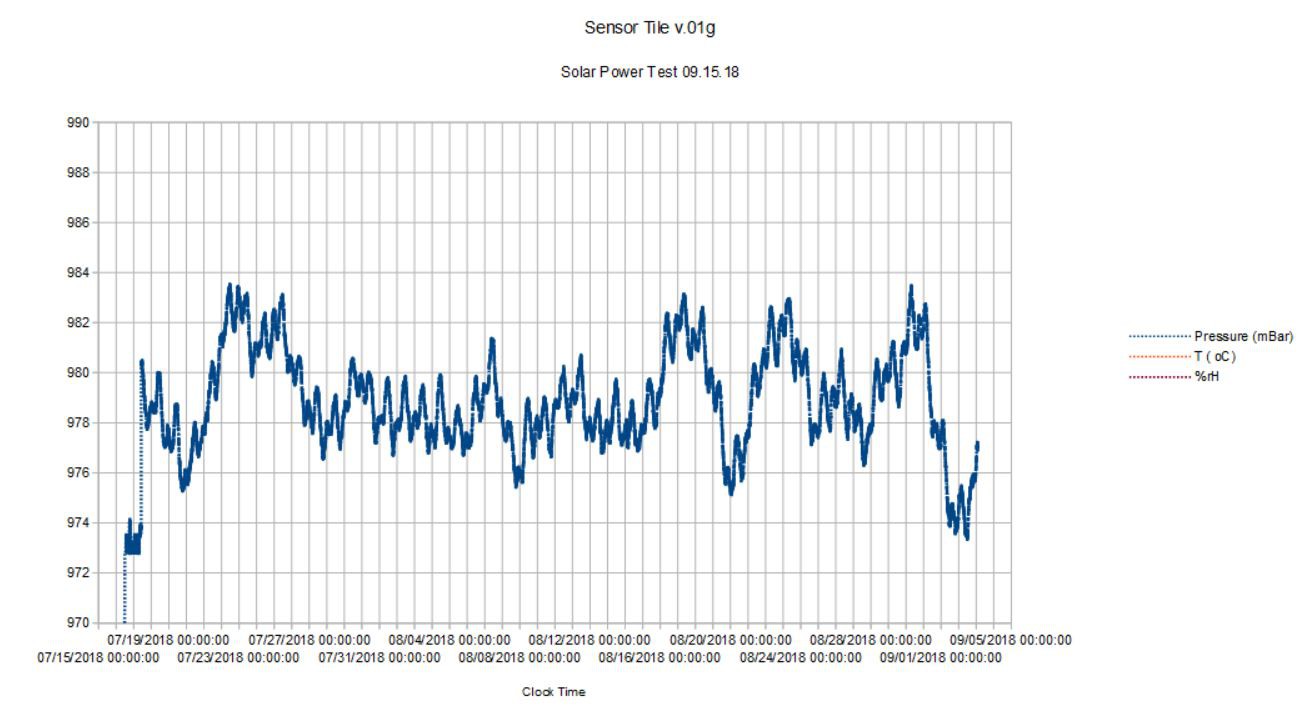

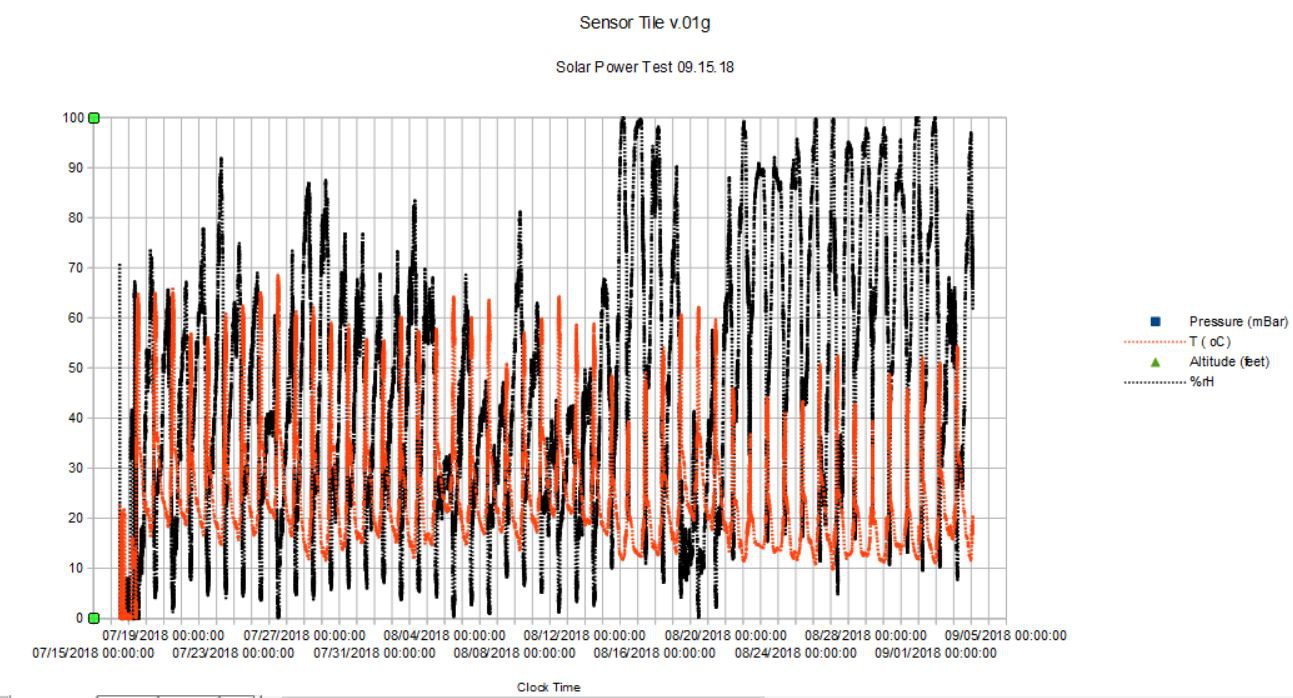

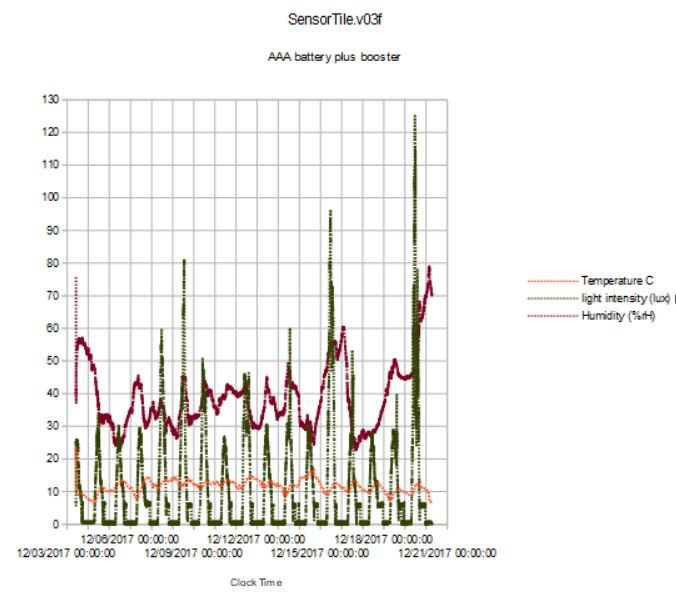

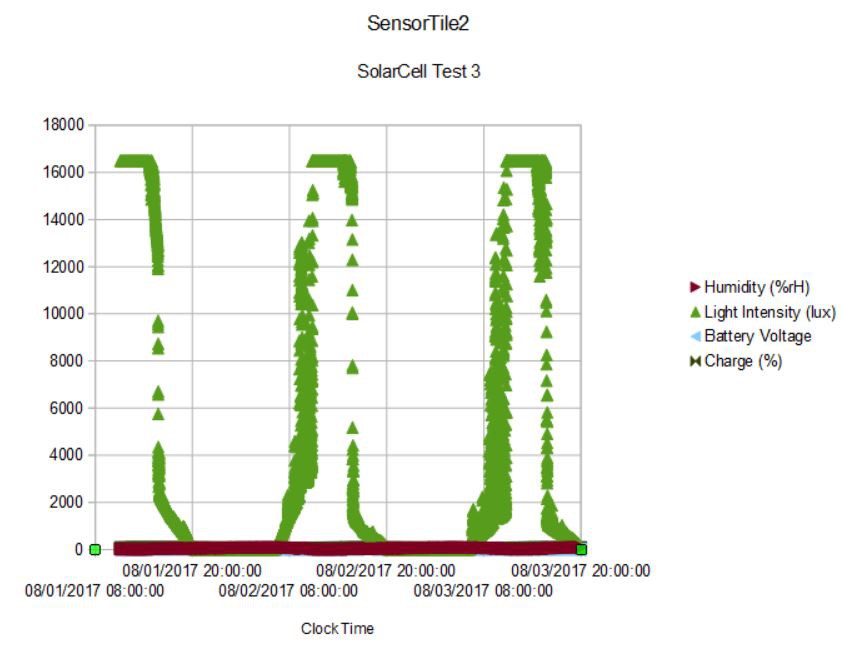

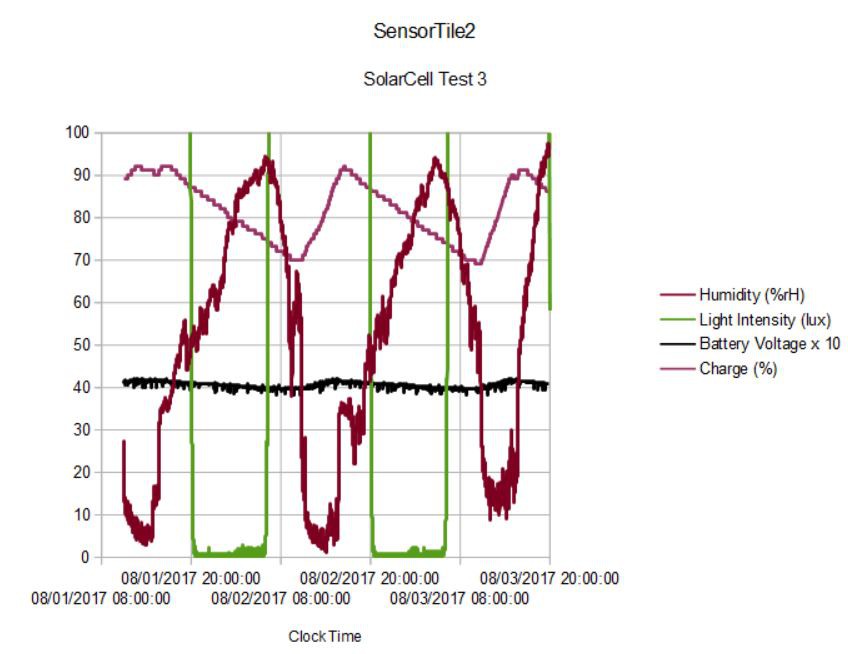

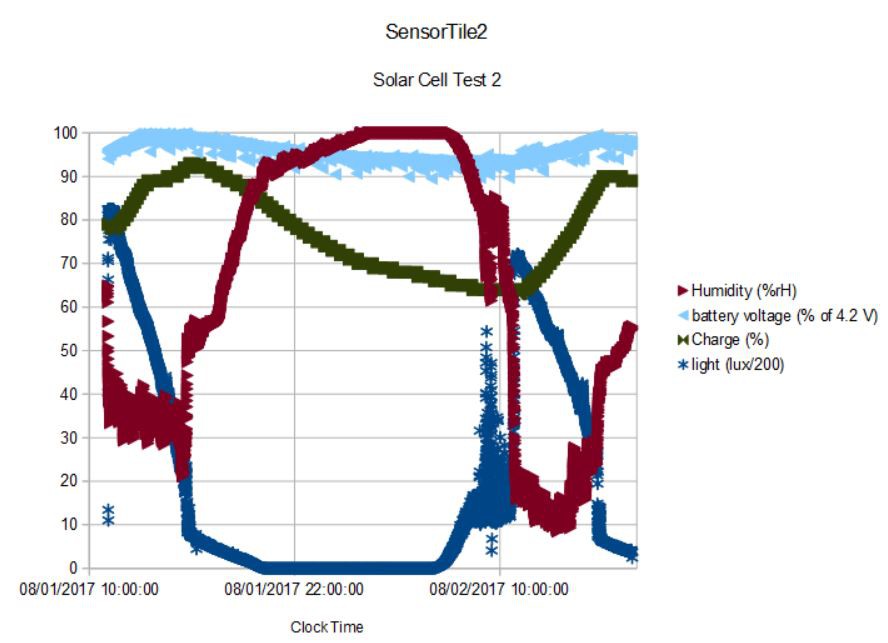

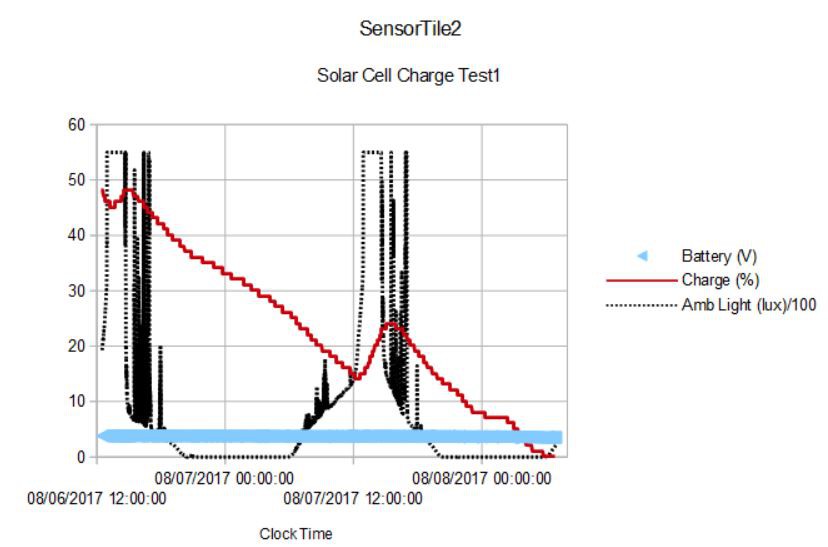

In direct sunlight, the ambient light sensor is pegged at 5500 lux (the VEML6040 has a maximum range of 16500 lux for integration time of 40 ms, whereas in this experiment I am using 160 ms*) so the actual intensity could be higher, but the direct sun only lasts ~3 hours or so at this window sill location. The BQ25504 definitely works, as the slight rises in charge level indicate while the sunlight is available. The half-charged 105 mAH LiPo battery lasted 43 hours which translates into ~1.2 mA average power usage. Really ~0.9 mA when we subtract off the 280 uA for the BQ25504 battery OK led. And this is a significant improvement over the 1.5 mA average power usage I was seeing without the BQ25504. Even the ~1.2 mA with OK led is better than the 1.57 mA I estimated above, so this likely means the actual light intensity is ~30% higher than the clipped peak measured. So likely closer to 7000 lux.

In direct sunlight, the ambient light sensor is pegged at 5500 lux (the VEML6040 has a maximum range of 16500 lux for integration time of 40 ms, whereas in this experiment I am using 160 ms*) so the actual intensity could be higher, but the direct sun only lasts ~3 hours or so at this window sill location. The BQ25504 definitely works, as the slight rises in charge level indicate while the sunlight is available. The half-charged 105 mAH LiPo battery lasted 43 hours which translates into ~1.2 mA average power usage. Really ~0.9 mA when we subtract off the 280 uA for the BQ25504 battery OK led. And this is a significant improvement over the 1.5 mA average power usage I was seeing without the BQ25504. Even the ~1.2 mA with OK led is better than the 1.57 mA I estimated above, so this likely means the actual light intensity is ~30% higher than the clipped peak measured. So likely closer to 7000 lux.

Samuel Wantman

Samuel Wantman

Thanks. The Ladybug (STM32L432 development board) is available on Tindie but the STM32L4(32) Sensor Tile is just one of my hobby projects. I have another sensor tile design that uses LoRa radio instead of BLE. This STM32L4 Sensor Tile is open source and you can have pcbs made by OSH Park if you want to try assembling some of your own.