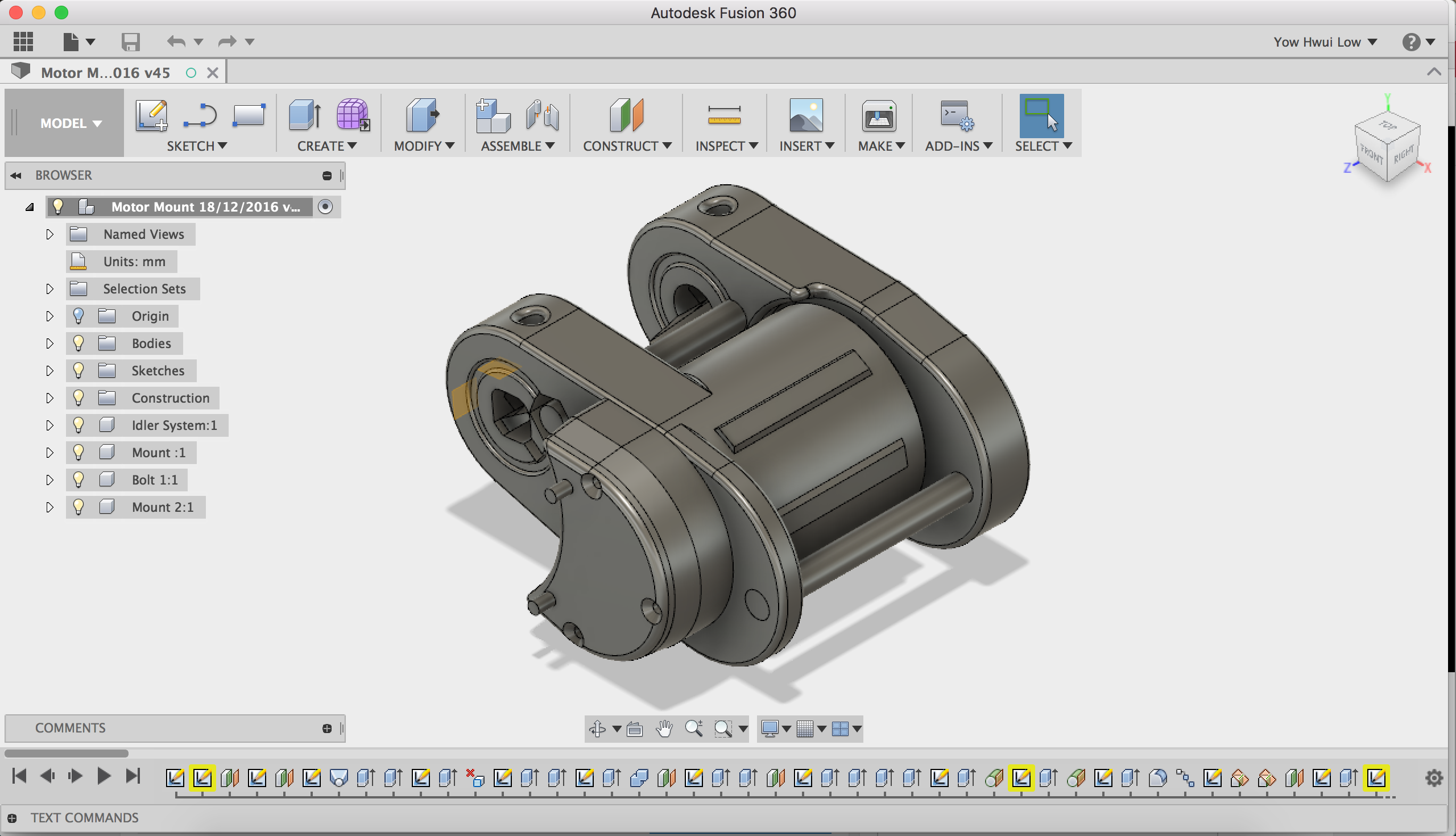

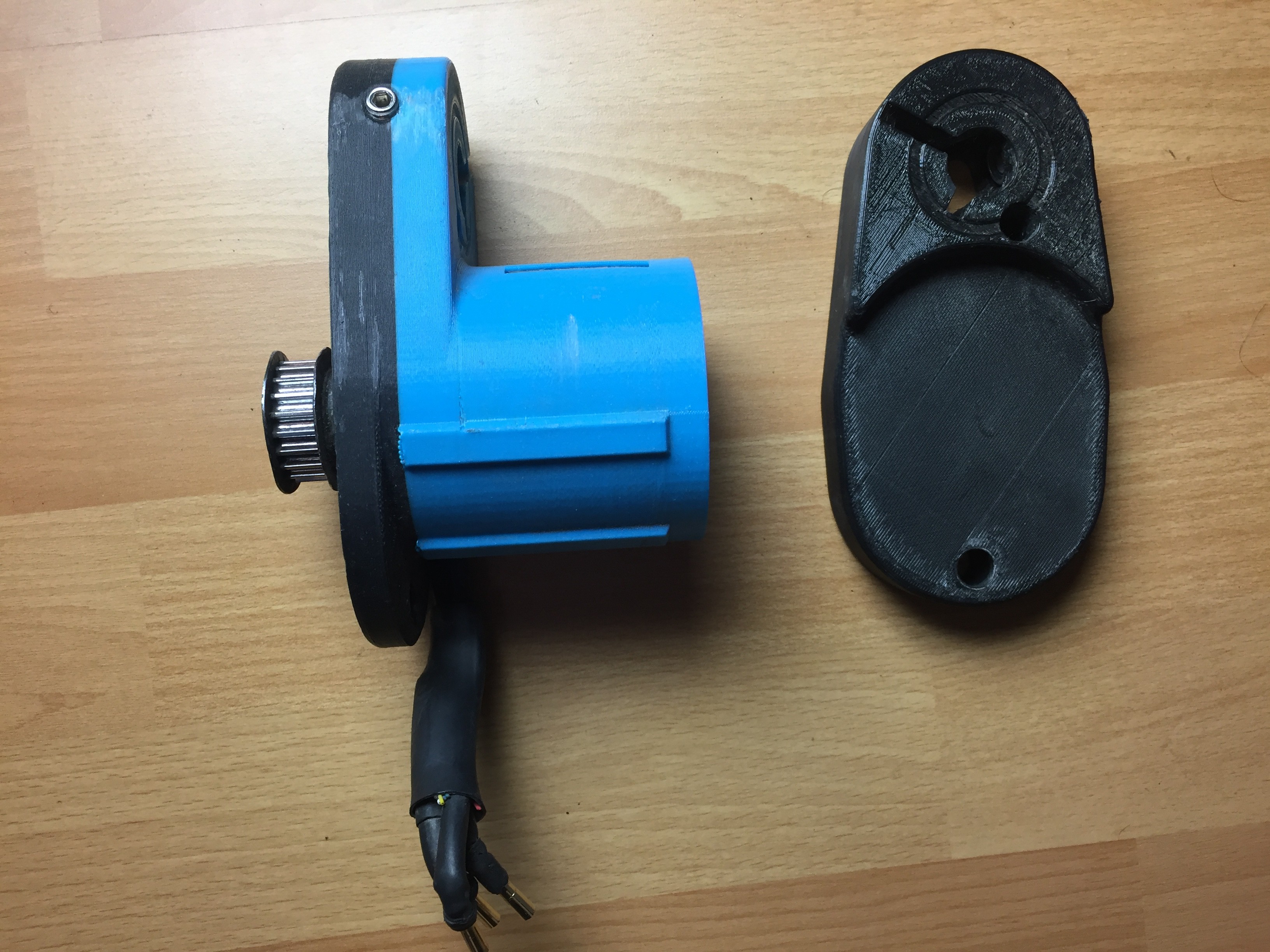

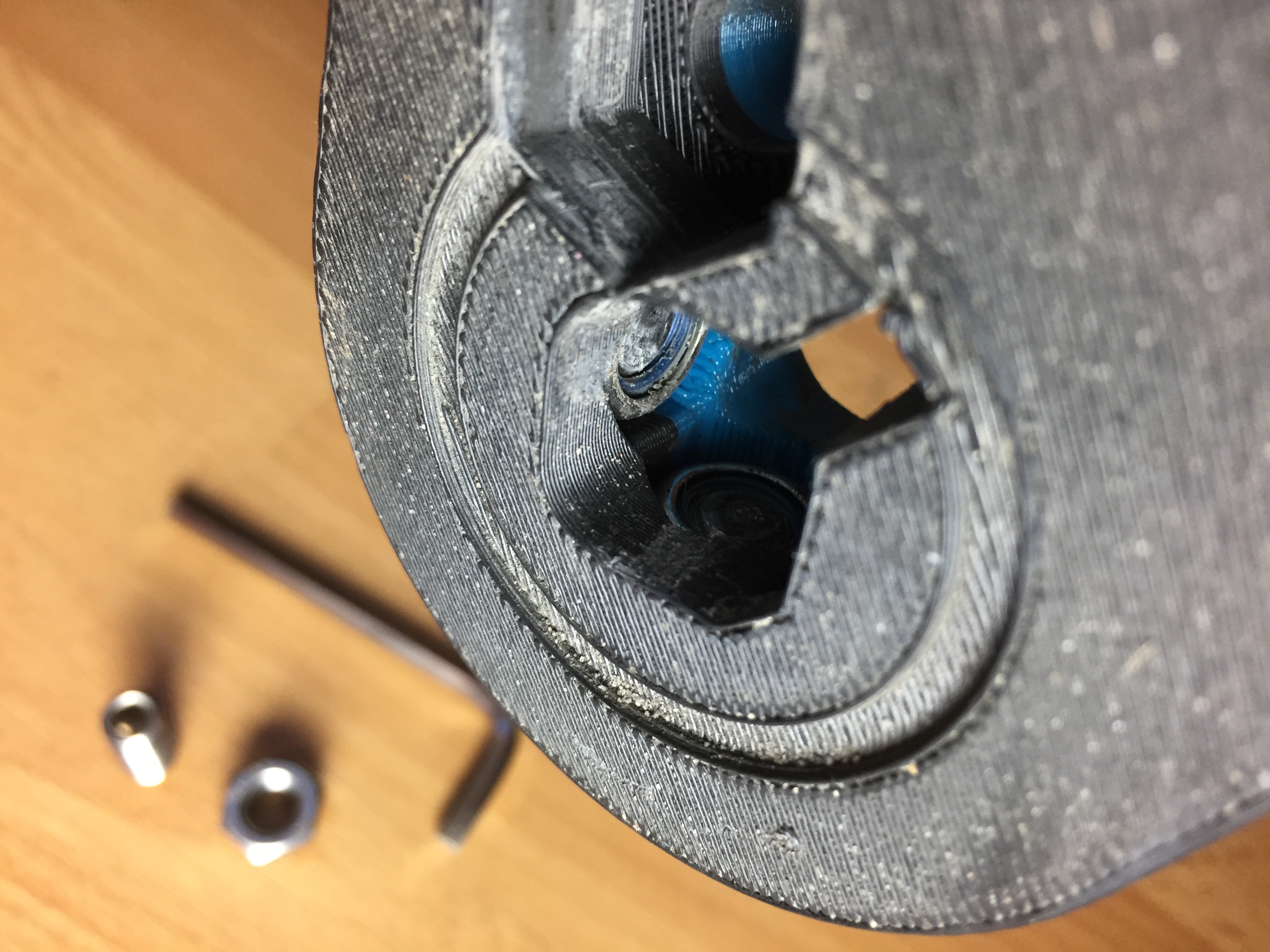

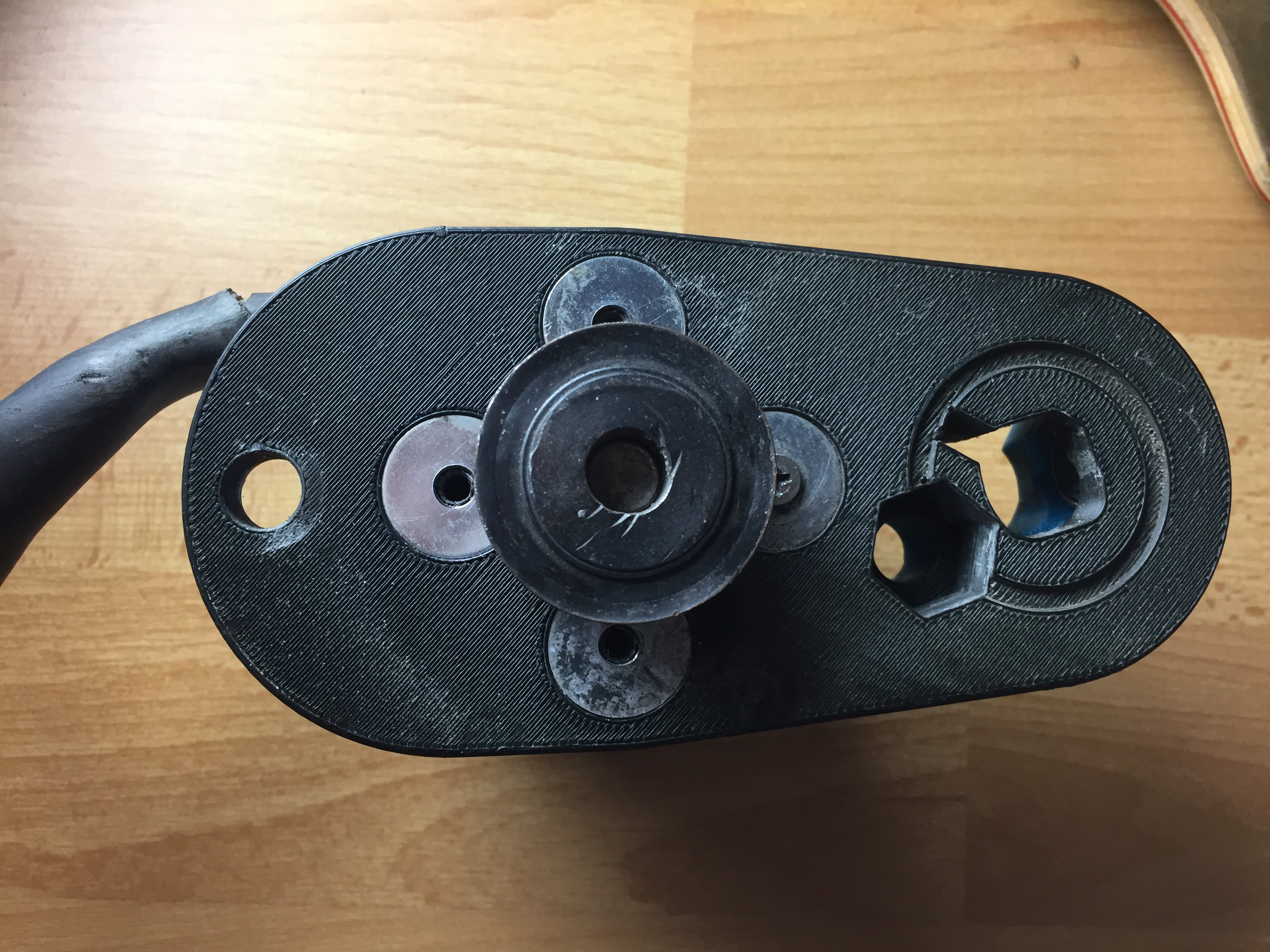

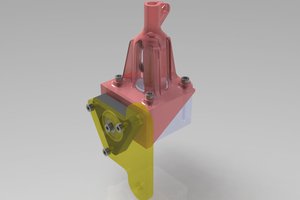

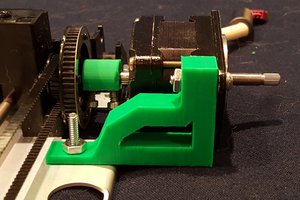

The goal was to design a 3D-printable motor mount which is robust and strong enough to withstand large forces even during hard braking. The electric longboard has since replaced my bicycle as my main transportation device. As of March 2017, the electric longboard has covered over 150 km. I constantly dis- and reassemble the motor mount to clean the components and also to make sure that there are no hidden fractures. So far it is holding up and I will continue to monitor the mount during the entire test phase of 1 year.

3D-Printed Electric Longboard

Fully 3D-printable electric longboard drivetrain with built-in idler system.

yowhwui

yowhwui

Sir Michael II

Sir Michael II

Ivan Stepaniuk

Ivan Stepaniuk

Luc JOB

Luc JOB

Rocketburns

Rocketburns

how much does it cost to make this?

i have had plans to convert old scooters for ages