Game programming is hard. Sure, you can easily throw together something in RPGMaker, RenPy or Unity3D, and it's great -- but you don't actually know how it works inside. There is a certain skill required to go from scratch, write your own main loop, handle events, push the pixels, etc. Incidentally, the same exact skills are required when programming any other interactive system, such as a graphical user interface, an automatic appliance, a mobile art installation or... a robot! Those are going to be much more common in our lives soon. If we want to stay in control, we need to be able to program them ourselves, and for that we need those skills. They empower us and give us back the control over the technology.

One great tool for teaching it is PyGame -- which is a library, and not a game engine, so it forces you to attend to all those pesky details of game engine internals yourself. Which is a bit difficult, of course, but ultimately very useful. But even if you play with PyGame on the Raspberry Pi, it's still a very complicated and difficult to understand system. The learning curve is steep, and debugging is hell.

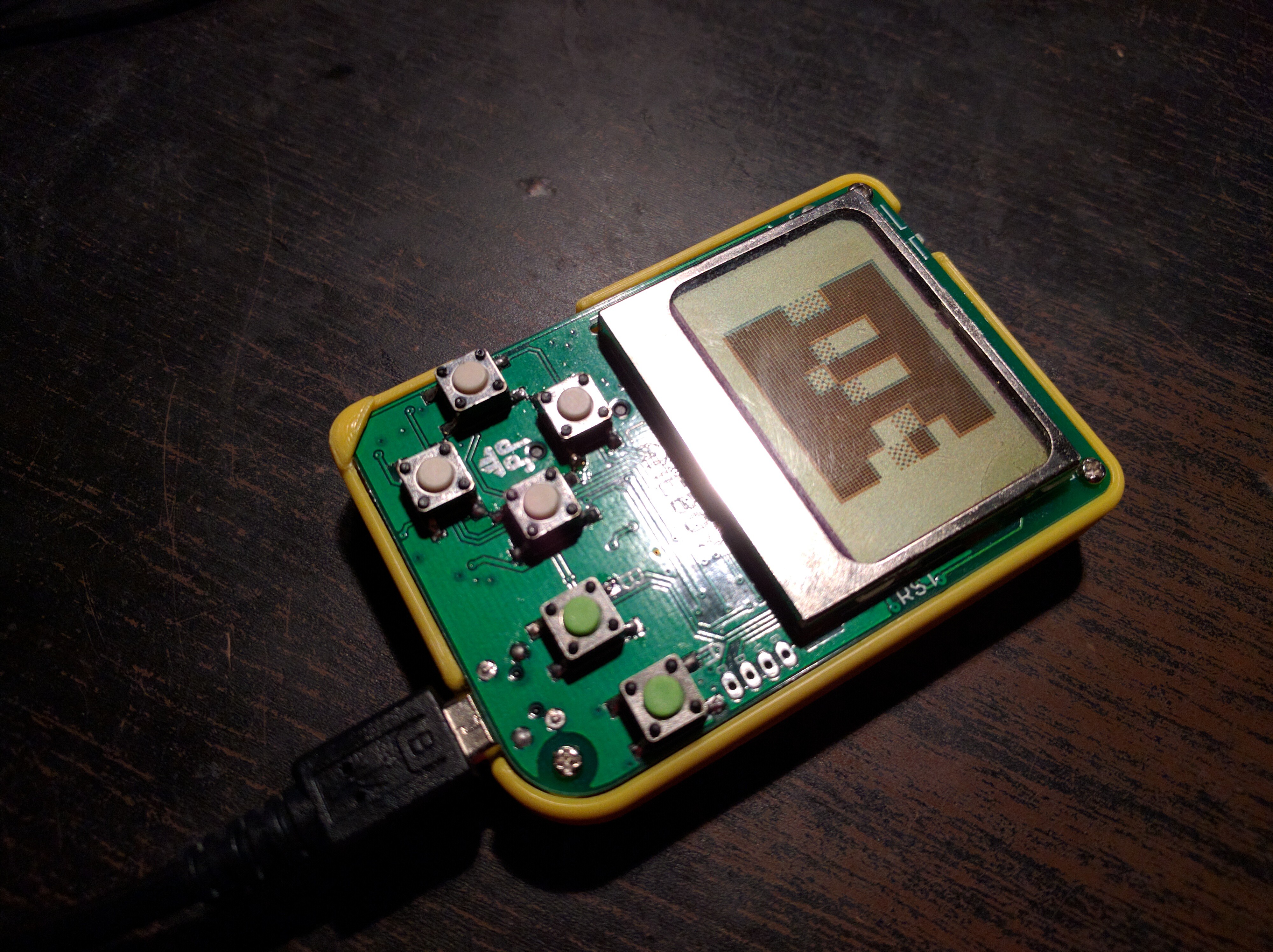

Enter MicroPython, and one of its flavors, CircuitPython. It's written by the people at Adafruit with the education in mind, but it runs on infinitely simpler devices than your average computer. Devices which you can't break easily, because reflashing the program will reset them to a known good state. Devices which run on batteries for hours, and which you can carry in your pocket. Devices, for which there is a plethora of add-ons and sensors that you could make use of in your game.

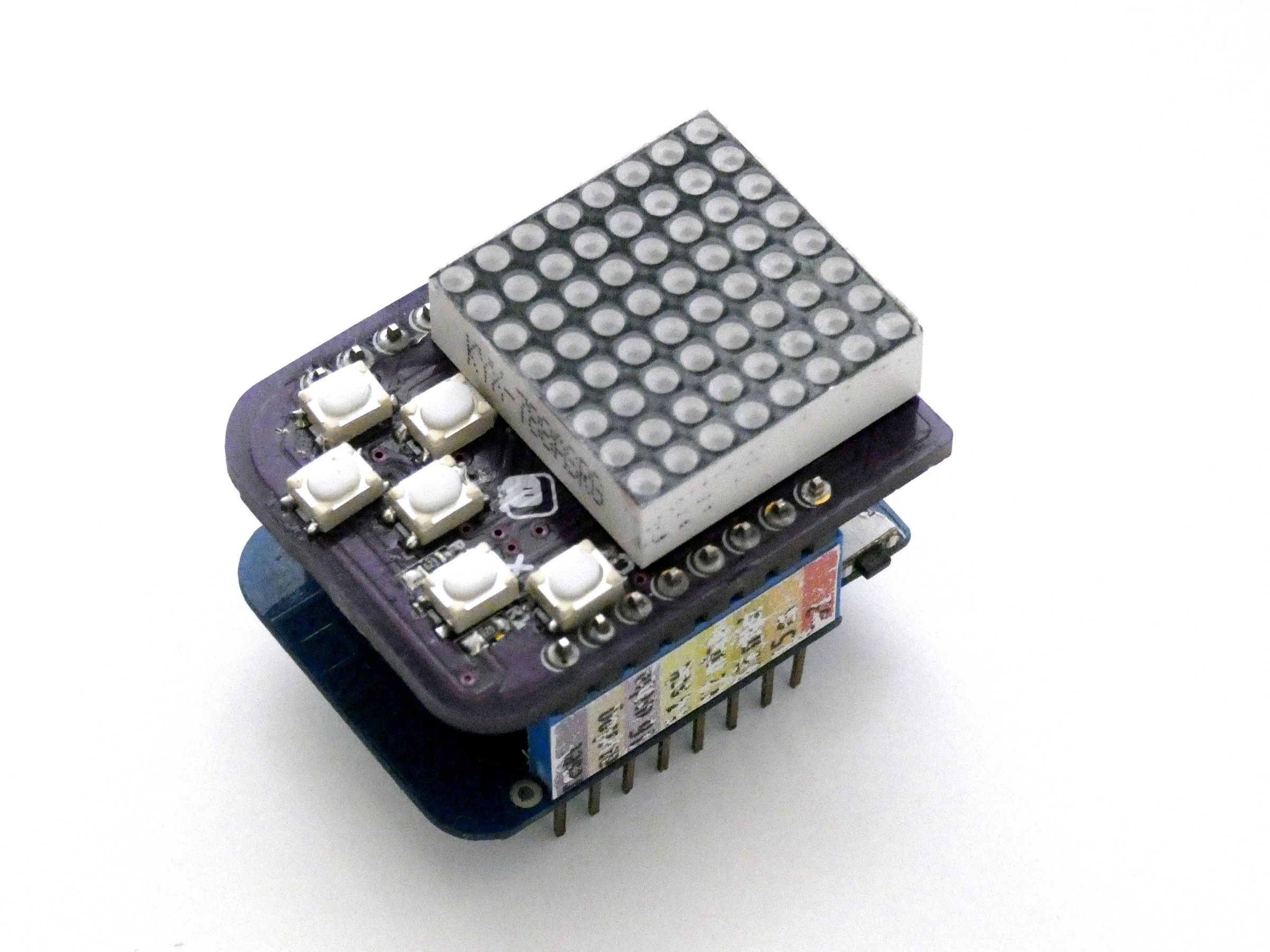

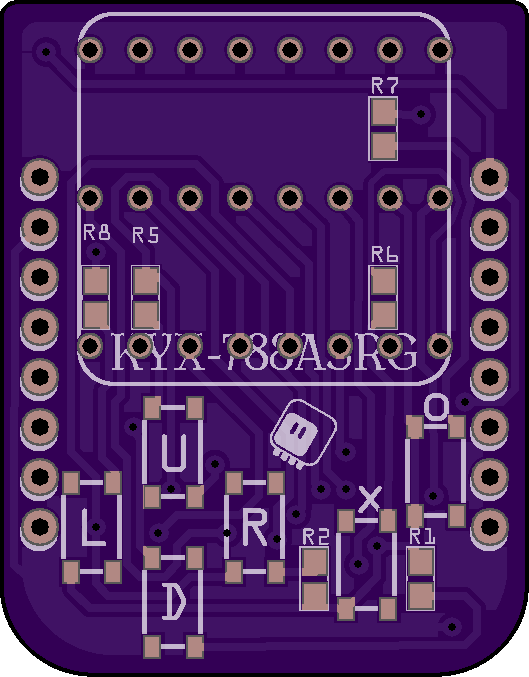

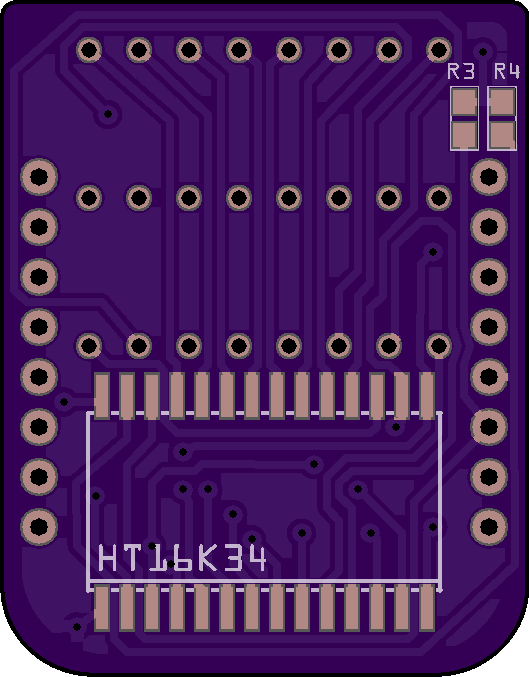

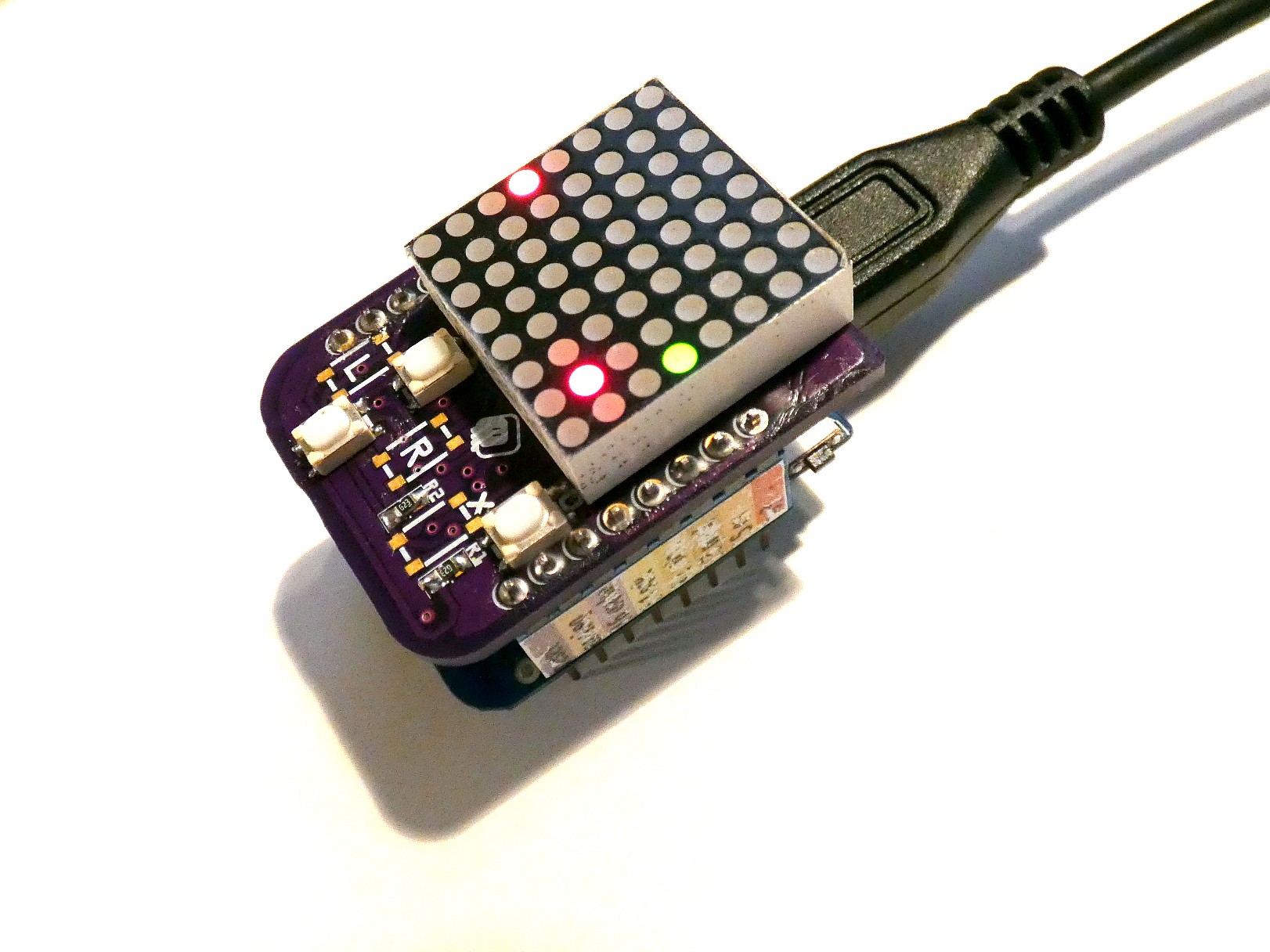

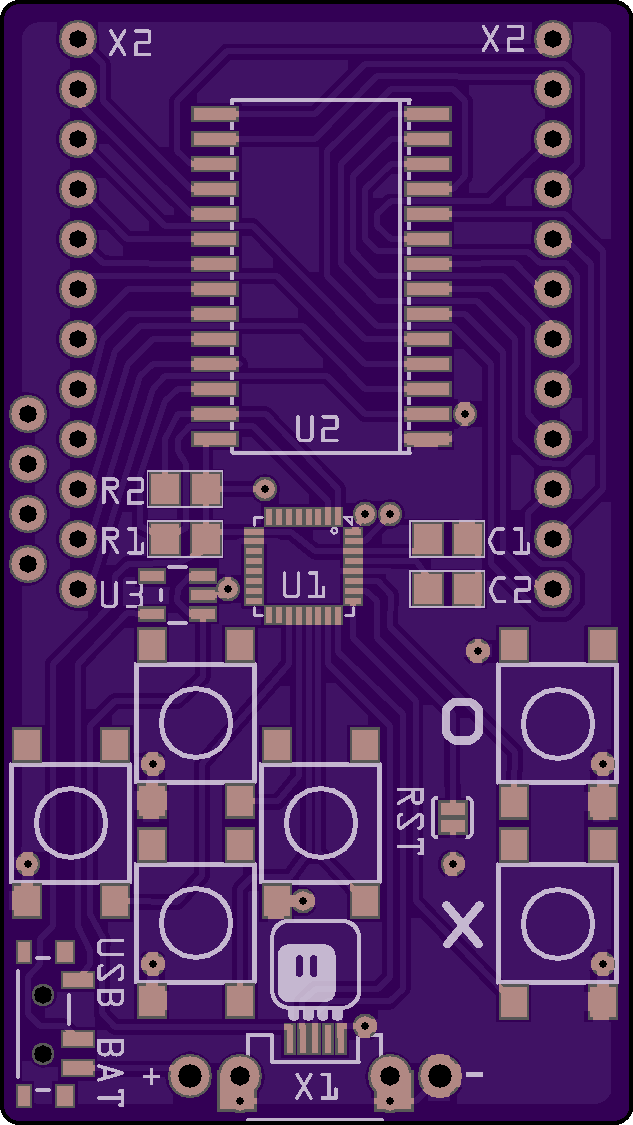

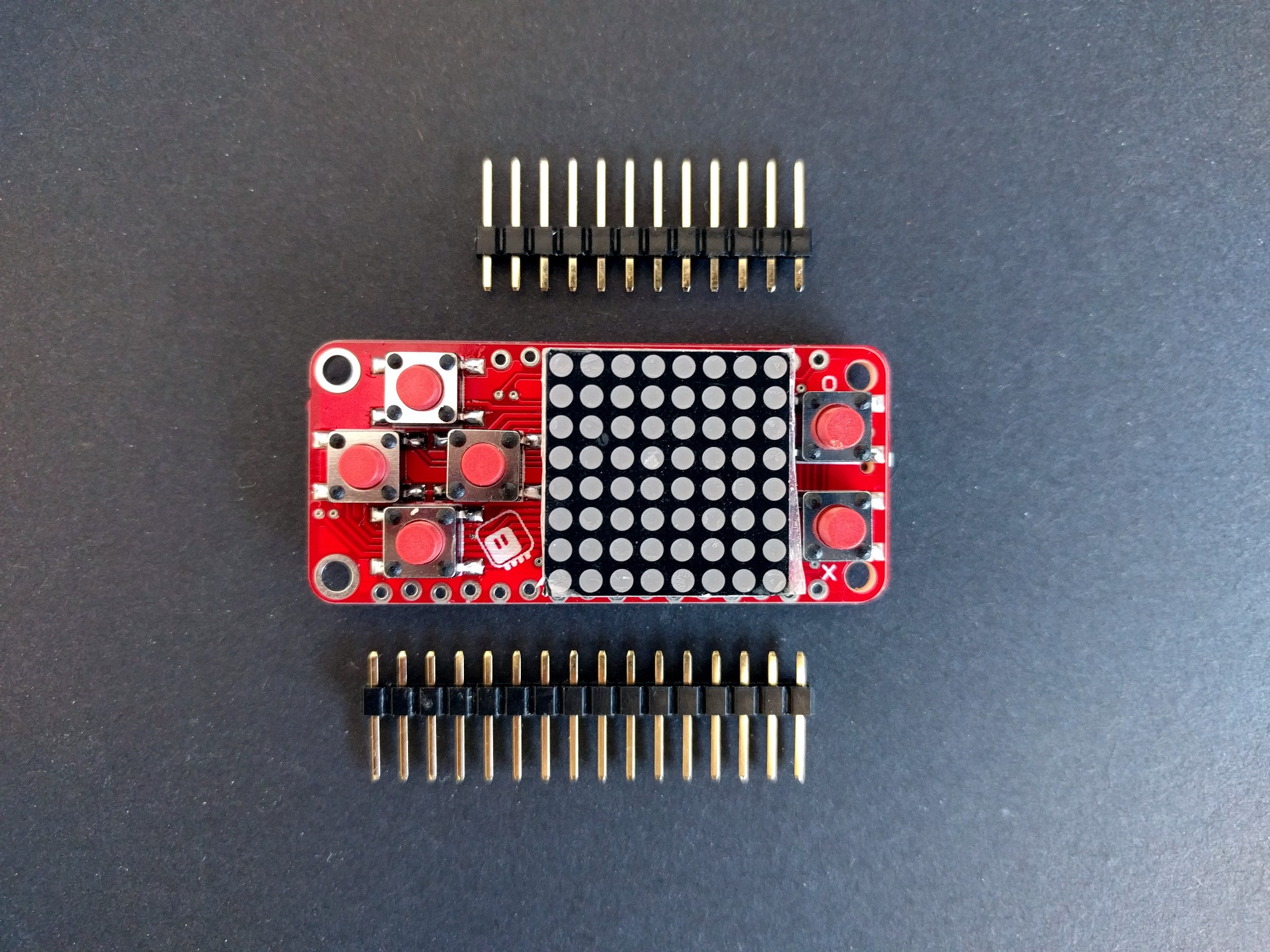

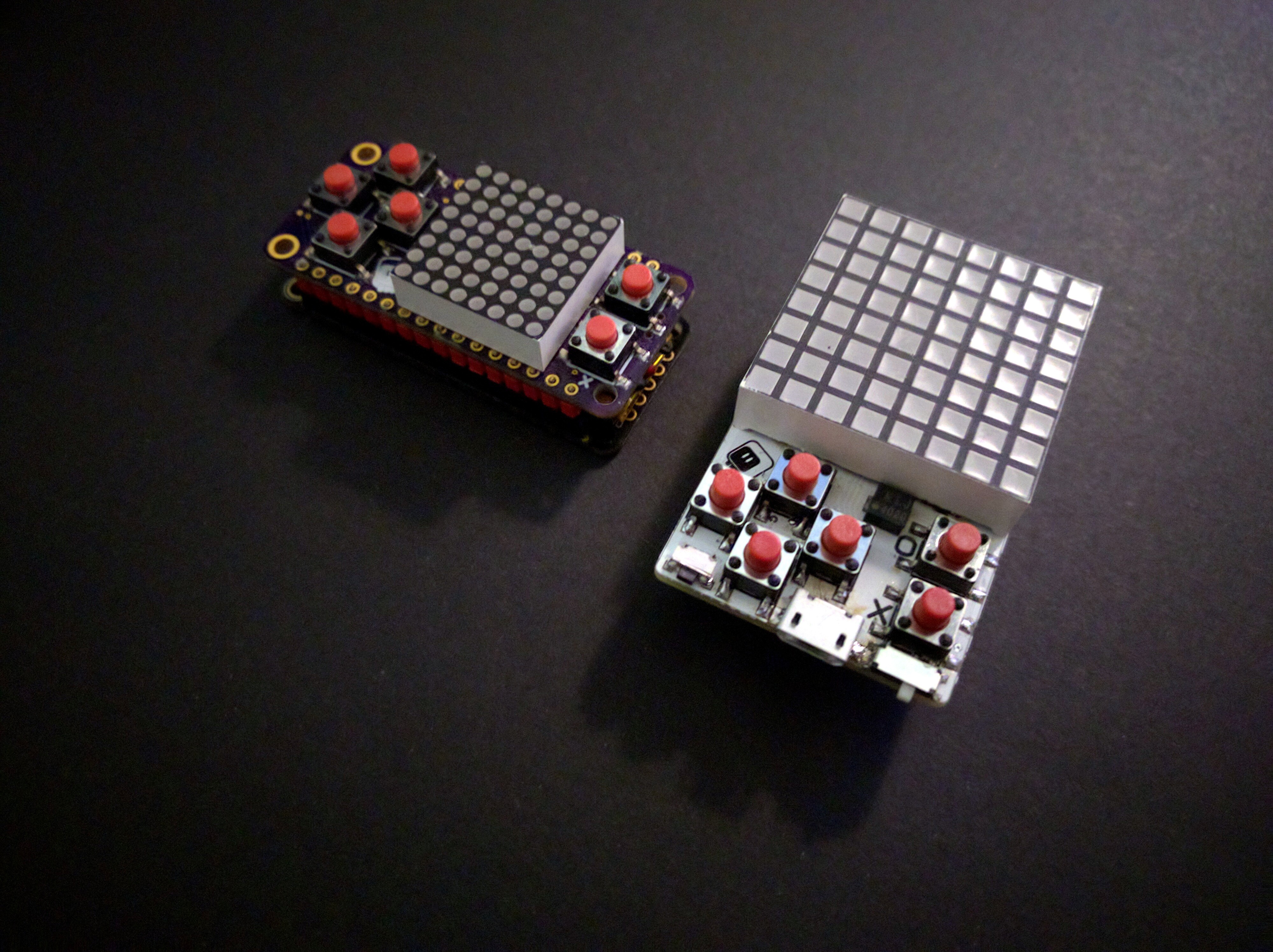

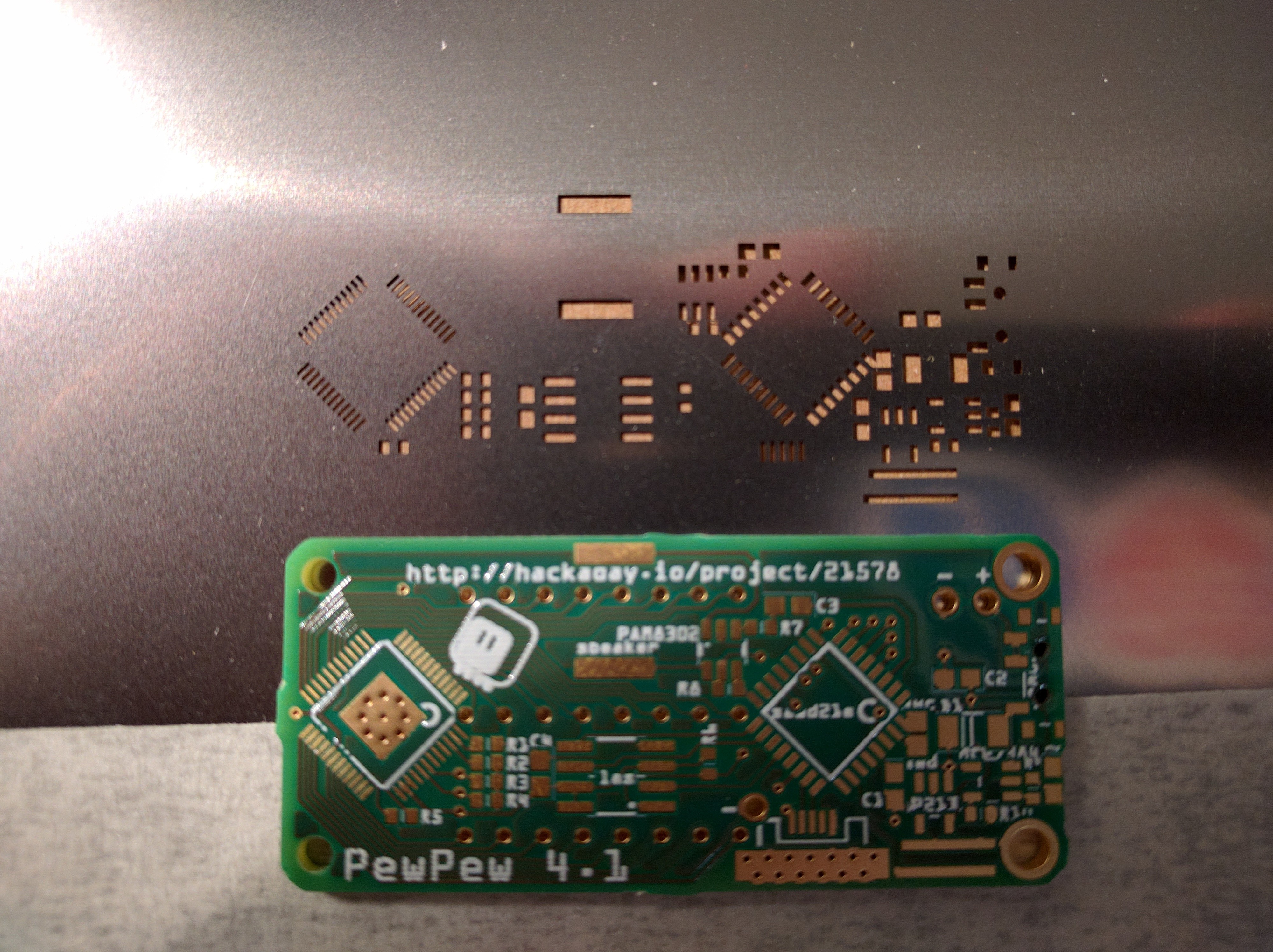

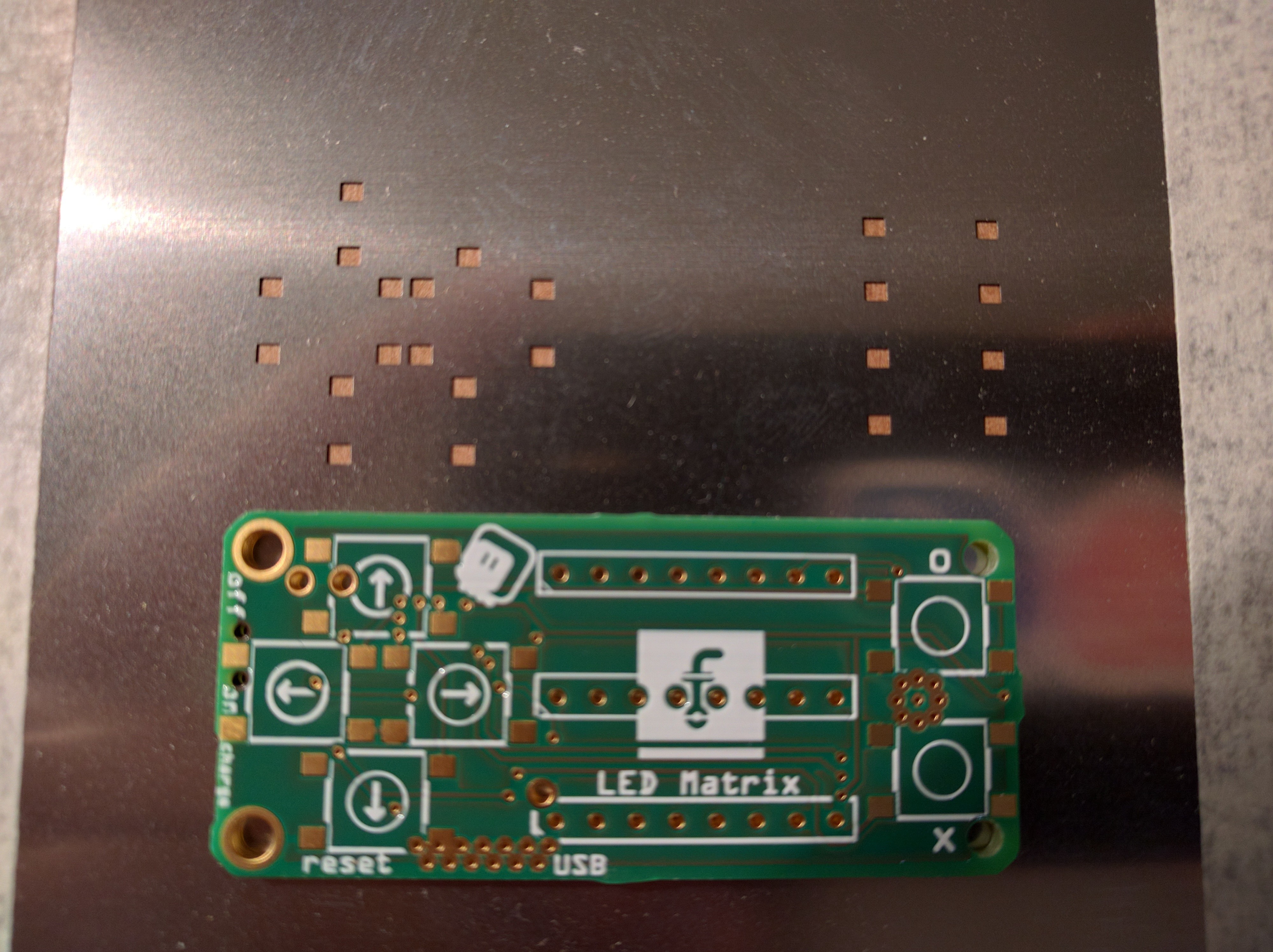

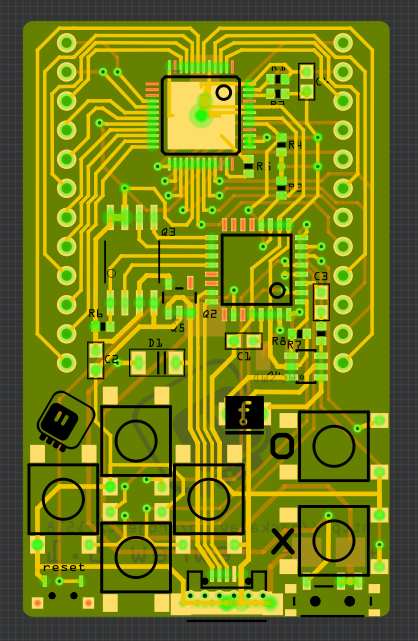

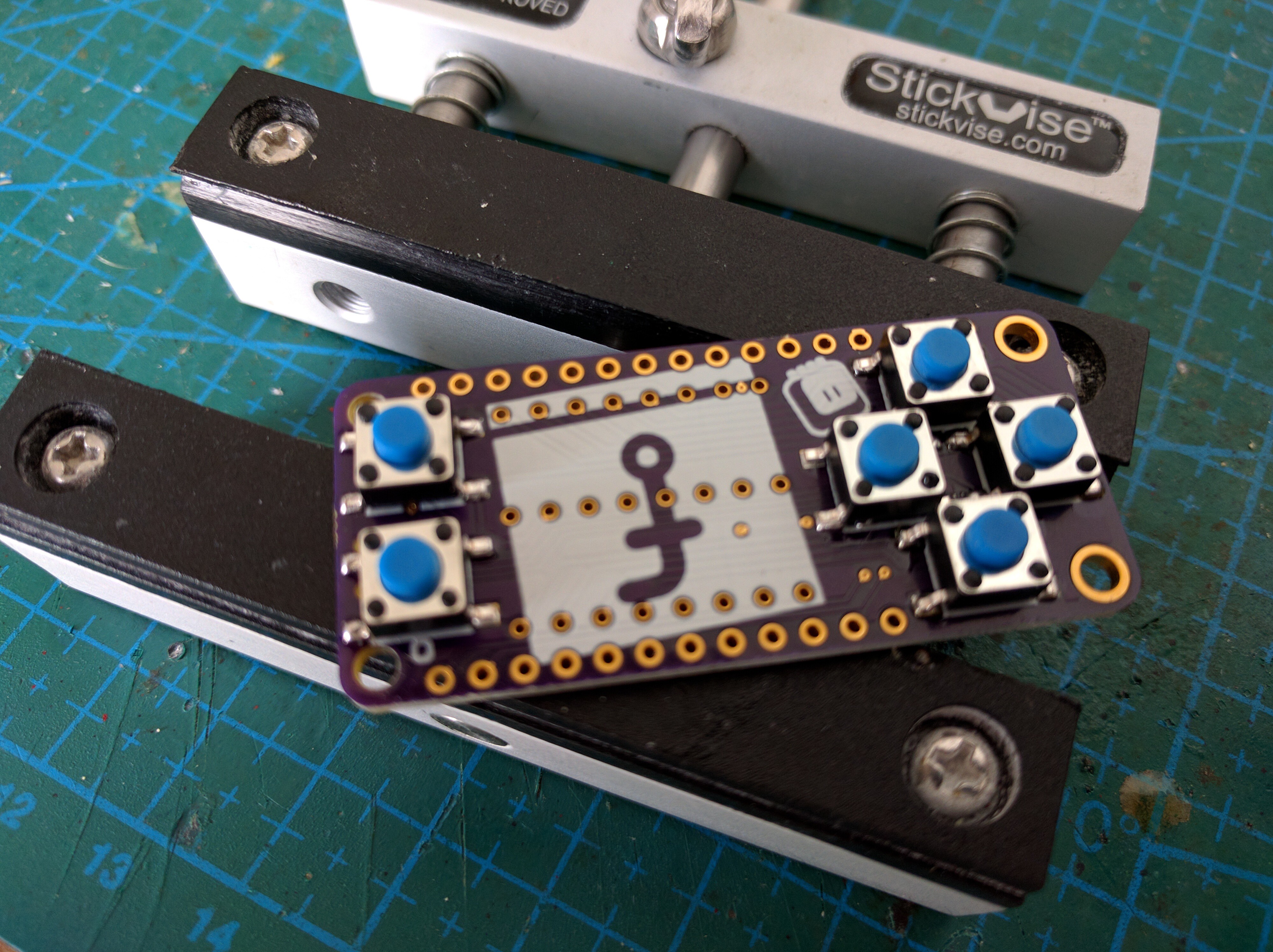

However, as of yet, there is no game library and/or add-on that would allow to easily create games in CircuitPython. This project is an attempt to fix this.

deʃhipu

deʃhipu

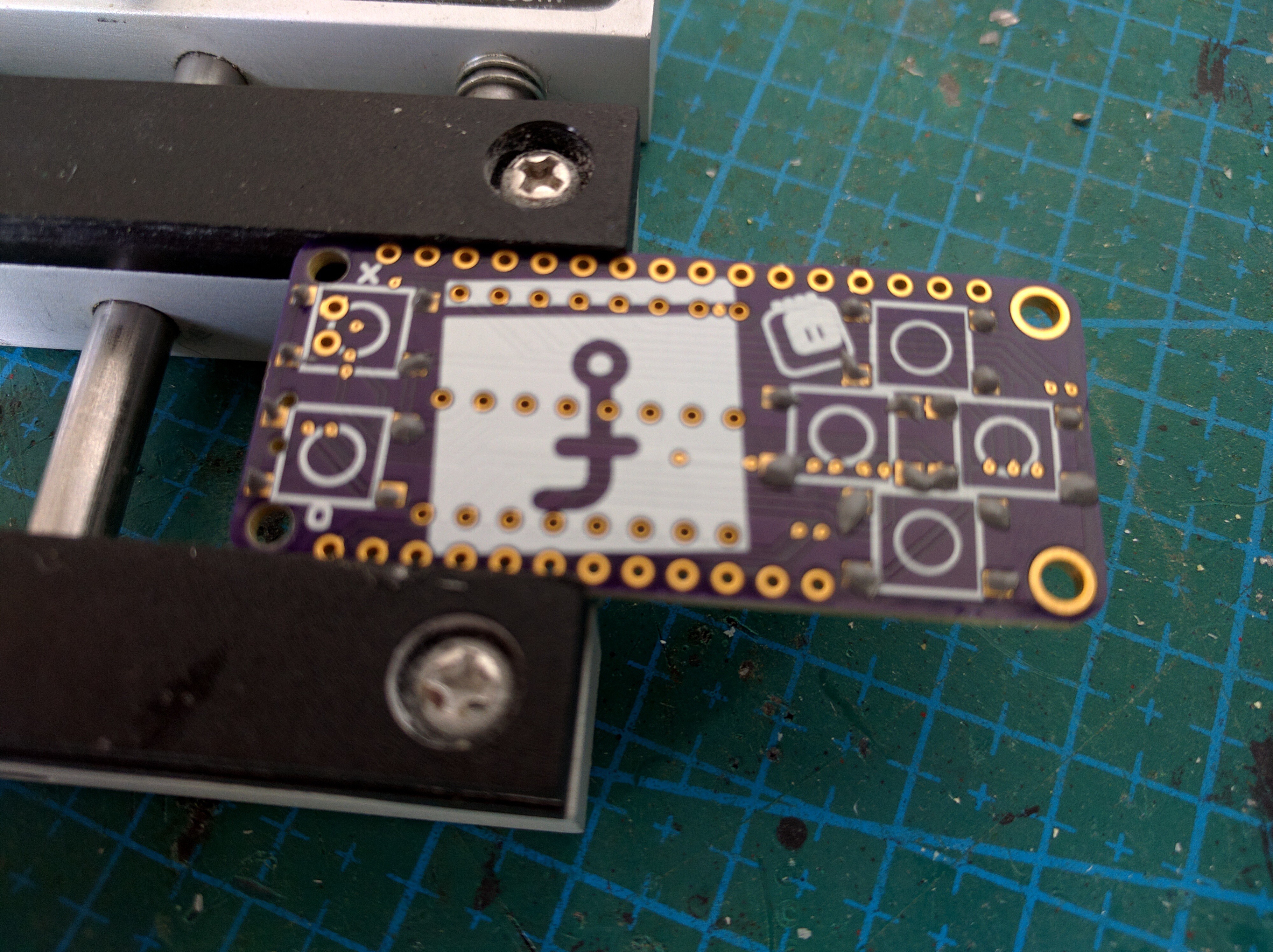

Did you customize your Feather board to have the female header row pointing to the top. My Feather came only with regular male pin headers?