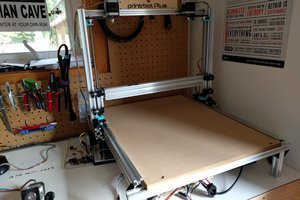

This project uses 3/4" aluminum square tube which is a common hardware store item. It differs from other 3d printers because of its high level of stiffness for such a low cost, and the modular design that is easily upgraded.

Another 3d Printer. But Better?

This project has been moved to my website at codyswain.net

James Dietz

James Dietz

John Opsahl

John Opsahl

Alex Anderson

Alex Anderson