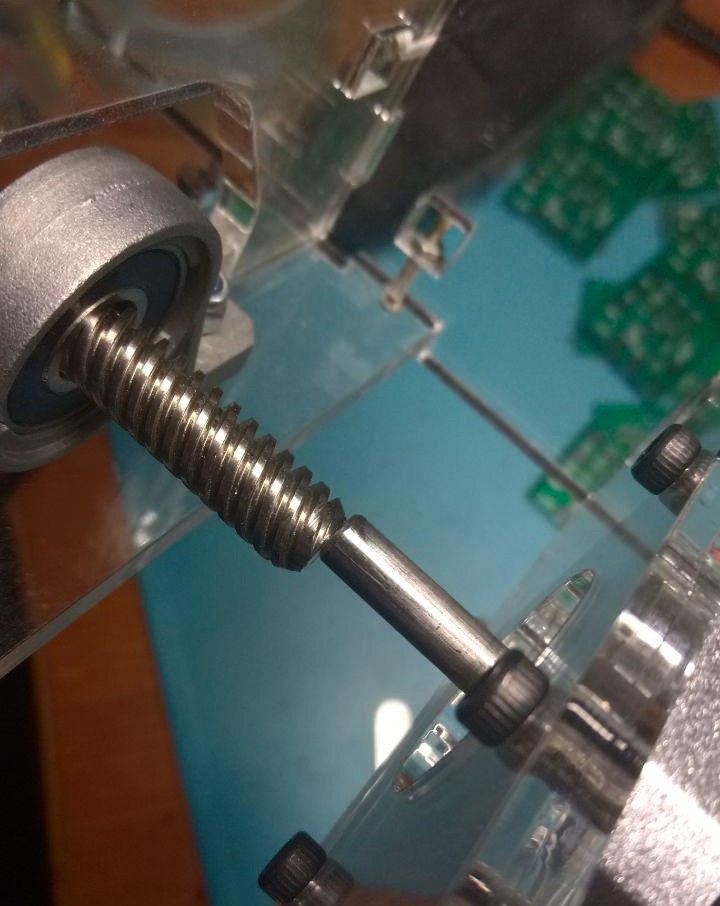

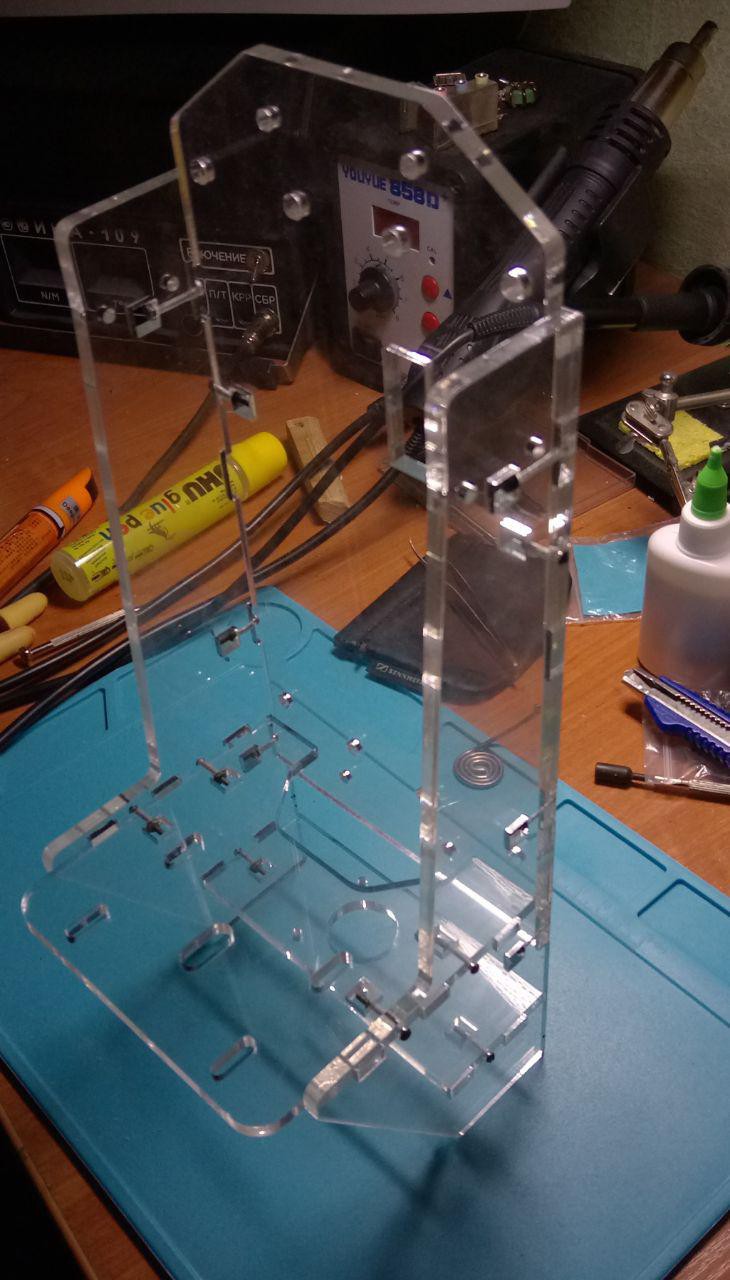

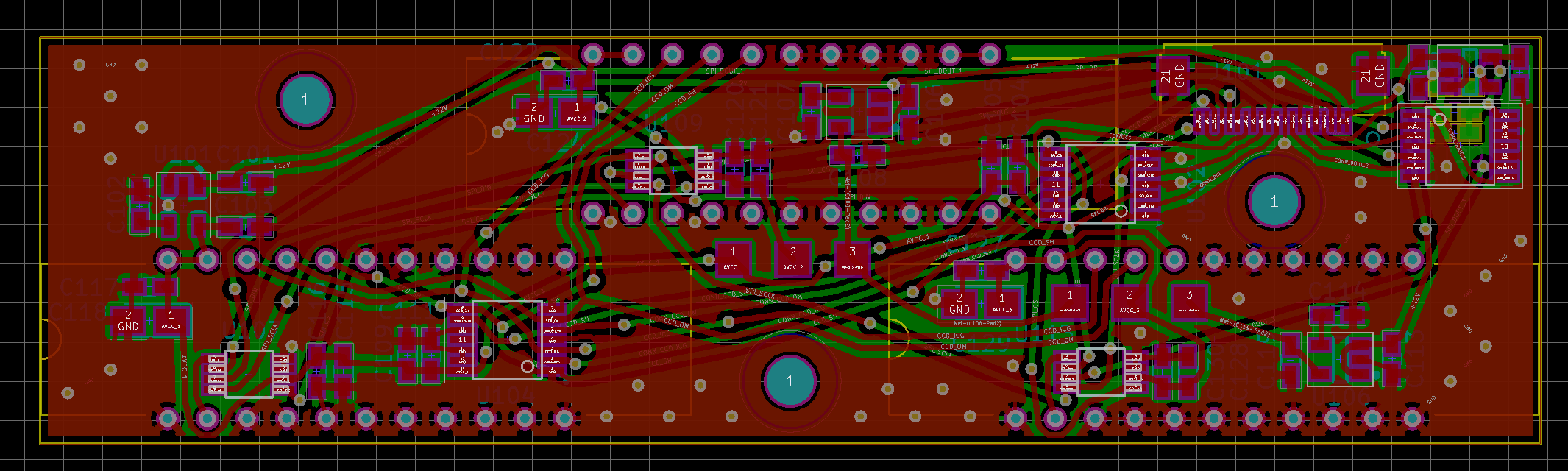

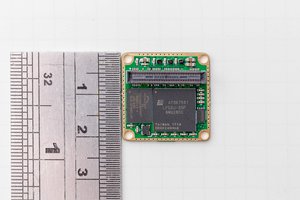

As for now, capture PCB are on their way, and the acrylic frame has been laser-cut and assembled. The goal is to assembly everything and then think about acquiring an FPGA board.

Scanning Digital Back for a Large Format Camera

Uses linear CCD and Zynq SoC

Vlad Ivanov

Vlad Ivanov

As for mechanical parts, they were on their way too, but the shipping company managed to lose them. Now I have to wait until Aliexpress buyer protection takes place so I can get a refund and reorder.

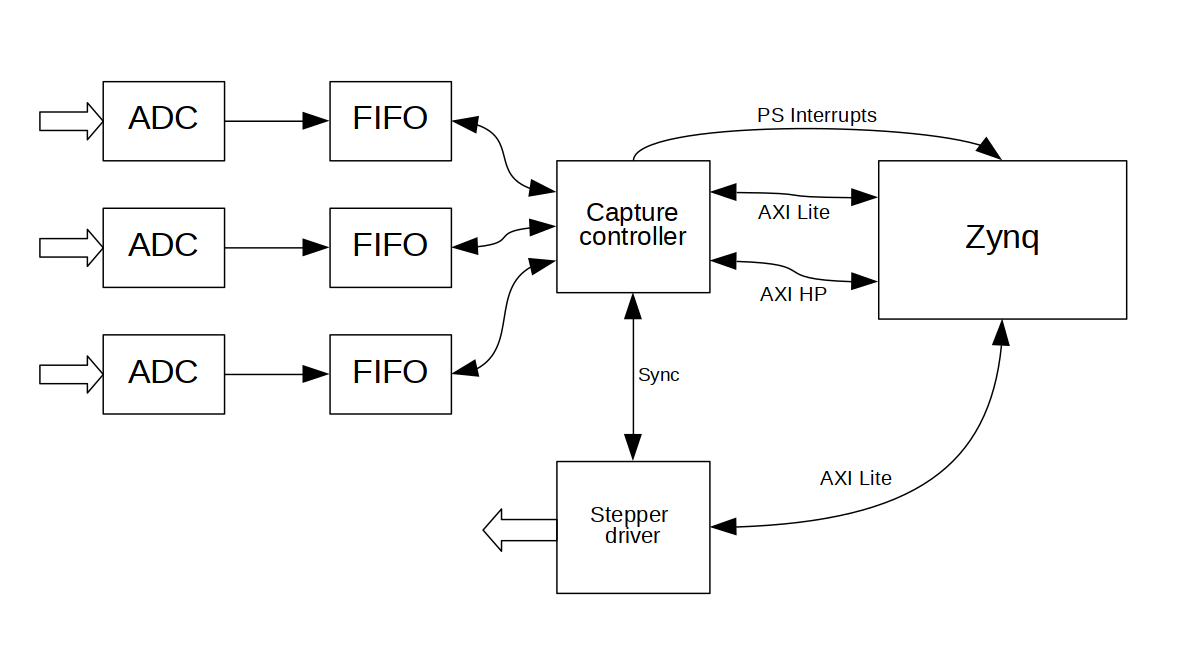

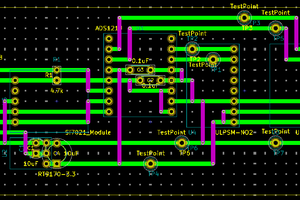

As for mechanical parts, they were on their way too, but the shipping company managed to lose them. Now I have to wait until Aliexpress buyer protection takes place so I can get a refund and reorder. On this diagram, Zynq refers to the Processing System block inside the SoC. As you can see, there are three ADCs, which output 12-bit samples. Samples from each one of them are stored in a small FIFO buffer. The capture controller module scans each FIFO periodically and, once there is enough data, submits a number of transfers through AXI HP interface. Using FIFOs allows us to account for system bus availability and also to store data in bursts, which is faster, especially on some low-budget Zynq boards.

On this diagram, Zynq refers to the Processing System block inside the SoC. As you can see, there are three ADCs, which output 12-bit samples. Samples from each one of them are stored in a small FIFO buffer. The capture controller module scans each FIFO periodically and, once there is enough data, submits a number of transfers through AXI HP interface. Using FIFOs allows us to account for system bus availability and also to store data in bursts, which is faster, especially on some low-budget Zynq boards.

greg davill

greg davill

Mike Teachman

Mike Teachman

Michael Delaney

Michael Delaney

Michael Welling

Michael Welling