Circuit theory:

- Inductive Switched-Mode Power Supply:

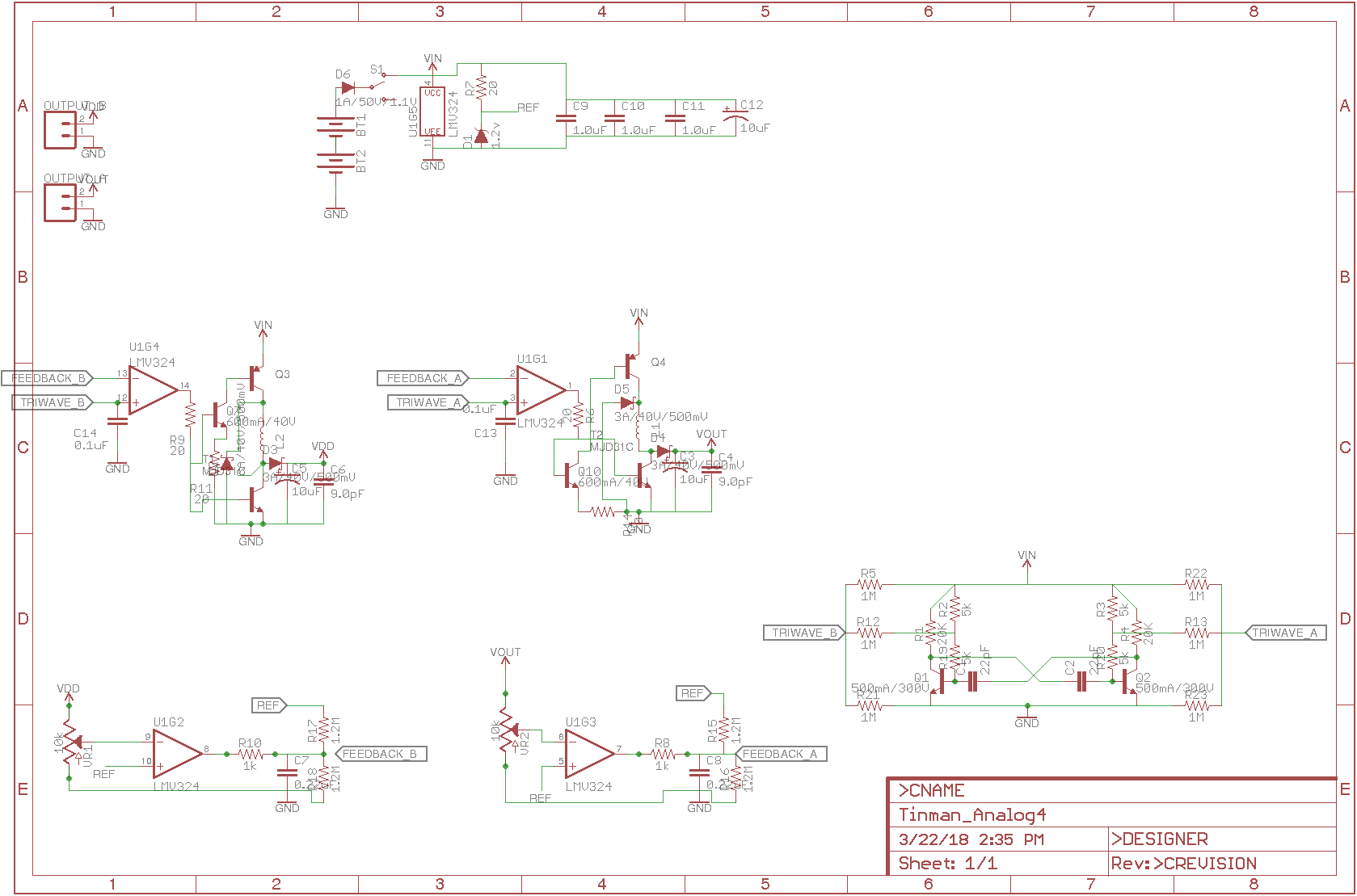

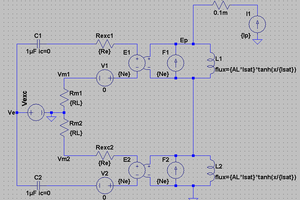

- In broad terms, an inductive SMPS is a circuit that takes advantage of an inductor's tendency to work against changes in current -- so if you switch current on, it will briefly create a voltage going the opposite direction, and if you cut off the current, it will continue to push current forward very briefly. There are three distinct methods of exploiting this effect: the Boost, Buck, and Boost-Buck converters.

- The Boost Converter steps voltage up at the expense of current. In this configuration, an inductor is connected to a current source, and a switch (usually a transistor) is used to alternately allow current to flow through the inductor from input voltage to ground and then block the flow of current, forcing the energy stored in the inductor to flow through the output circuit. A blocking diode allows the higher voltage created to flow to the load, and then prevents it from flowing back into the source once the power in the inductor is exhausted.

- The Buck Converter steps voltage down while increasing current, by alternately allowing current to flow from the source through the inductor to the load and then blocking the current source, with a diode allowing the energy stored in the inductor to continue to flow with the source current switched off.

- In broad terms, an inductive SMPS is a circuit that takes advantage of an inductor's tendency to work against changes in current -- so if you switch current on, it will briefly create a voltage going the opposite direction, and if you cut off the current, it will continue to push current forward very briefly. There are three distinct methods of exploiting this effect: the Boost, Buck, and Boost-Buck converters.

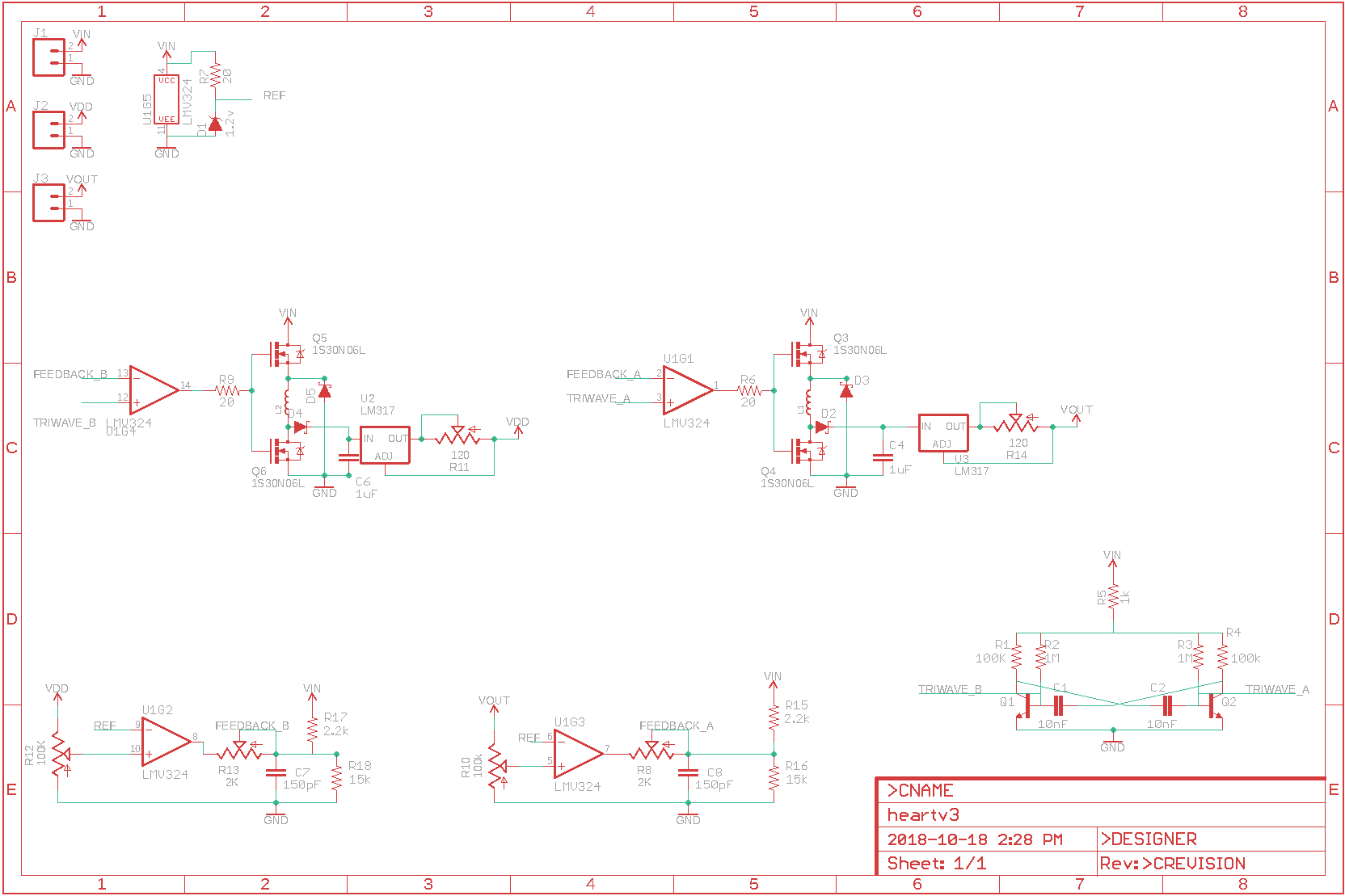

- Oscillator

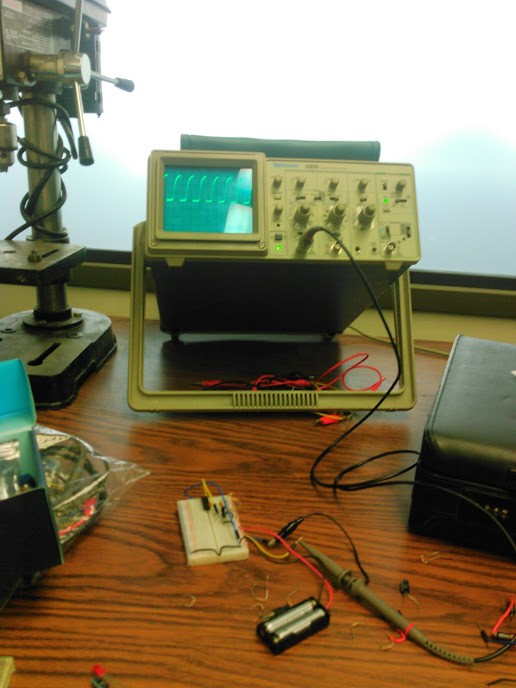

- The oscillator used in this circuit is just a BJT astable multivibrator, with the oscillation frequency set by the RC constant on each half of the multivibrator (see the instructions for the specific formula). This would normally yield two complementary symmetrical square waves, but the RC integrators between the multivibrator and the op-amp transforms this output into a sawtooth wave. In the Op-Amp, each sawtooth wave is compared to a feedback-controlled voltage (see below), which determines the exact pulse width of the output square wave fed into the transistors driving the boost or buck converter.

- Because the two sawtooth waves are complementary (meaning that when one rises to its peak, the other falls to its trough), the two boost converters' power draw cycles will be staggered, reducing the burden on the power source (except in the case of very heavy power usage, in which case each converter's duty cycle exceeds 50%, however even then the time that both inductors are drawing power should be relatively brief.)

- Feedback system

- The difficulty in real-world power supply designs is that the load, or the device you are powering, usually will draw different currents (which looks like changing its resistance) at different times, and greater current draw causes the effective voltage between the source and ground to decrease. To combat this, the power supply needs a feedback system that will respond to the changing resistance and increase or decrease the power that it supplies.

Jakob Wulfkind

Jakob Wulfkind

Yann Guidon / YGDES

Yann Guidon / YGDES

jbb

jbb

CaptMcAllister

CaptMcAllister

Elia

Elia