There are a lot of ways this could be done, but I decided to leverage the work I have done in other projects, so the design is an opto-isolated triac AC power switch controlled by an ATTiny9.

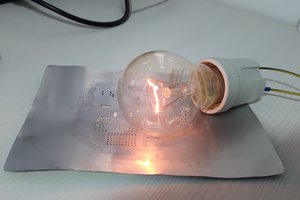

The ATTiny needs a 5 volt power supply, so that requires an isolated AC/DC power supply module - ironically the most expensive component of the entire build. The ATTiny9 is set up with one of its I/O lines connected to a button (other side of the button to ground), a second as the opto-isolator driving line, and a third driving a chassis mounted LED. There is a pilot light hooked up to the output to act as a power indicator. If you're still working after 25 minutes, the warning LED will begin to blink. If you push the button while the warning light is blinking, the timer will be reset without turning the power off. If you push the button while the warning light is not blinking, the power will go out. If you do nothing after 5 minutes of the warning light blinking (30 minutes from power-up), the light will go out.

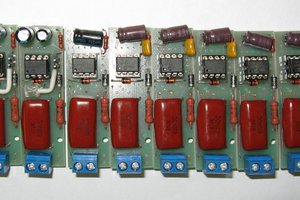

The triac circuit is one half of the Toast-R-Reflow power switching board. It uses a MOC-3020 opto-isolated triac driver and a BTA-20 triac. The board in this case is routed for a design maximum of 600W. At that sort of power, the BTA-20 will only be expected to dissipate about 5 watts of heat, which should be easy to sink through a finned heat sink. There's a snubber on the output to protect against unintended operation with inductive loads, and there's a beefy parallel load resistor to prevent leakage through the triac from lighting the power light dimly when it's turned off.

As with all HV designs, care must be taken to insure the correct current capacity for the load-bearing traces and to pay heed to creepage and clearance distances. It's also a good idea to draw a solid divide between the HV and logic portions of the circuit, with only isolated components allowed to bridge the line.

For the chassis, there is a panel-mounted IEC C14 inlet, plus an NEMA 5-15 outlet. The hot and neutral lines of each will go to dedicated connectors on the board. The pilot light is wired separately to the outlet hot and neutral. The two grounds are tied together and to a lug on the chassis. The button and warning LEDs mount at some distance away from the AC connections and tie to the logic part of the board.

Nick Sayer

Nick Sayer

trax

trax

fool

fool

bryan.lowder

bryan.lowder

I was a bit worried when I saw you bolted the triac directly to the case. But when I look up the part, I saw it is an insulated one so all good ;)

Is there a particular reason, why you use a triac here instead of a relay?