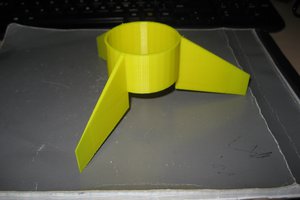

Attached are some pictures of the hinge (left). The first pictures shows the broken hinge, the second one the repaired hinge with the 3D printed part and the third one depicts the hinge with the original part.

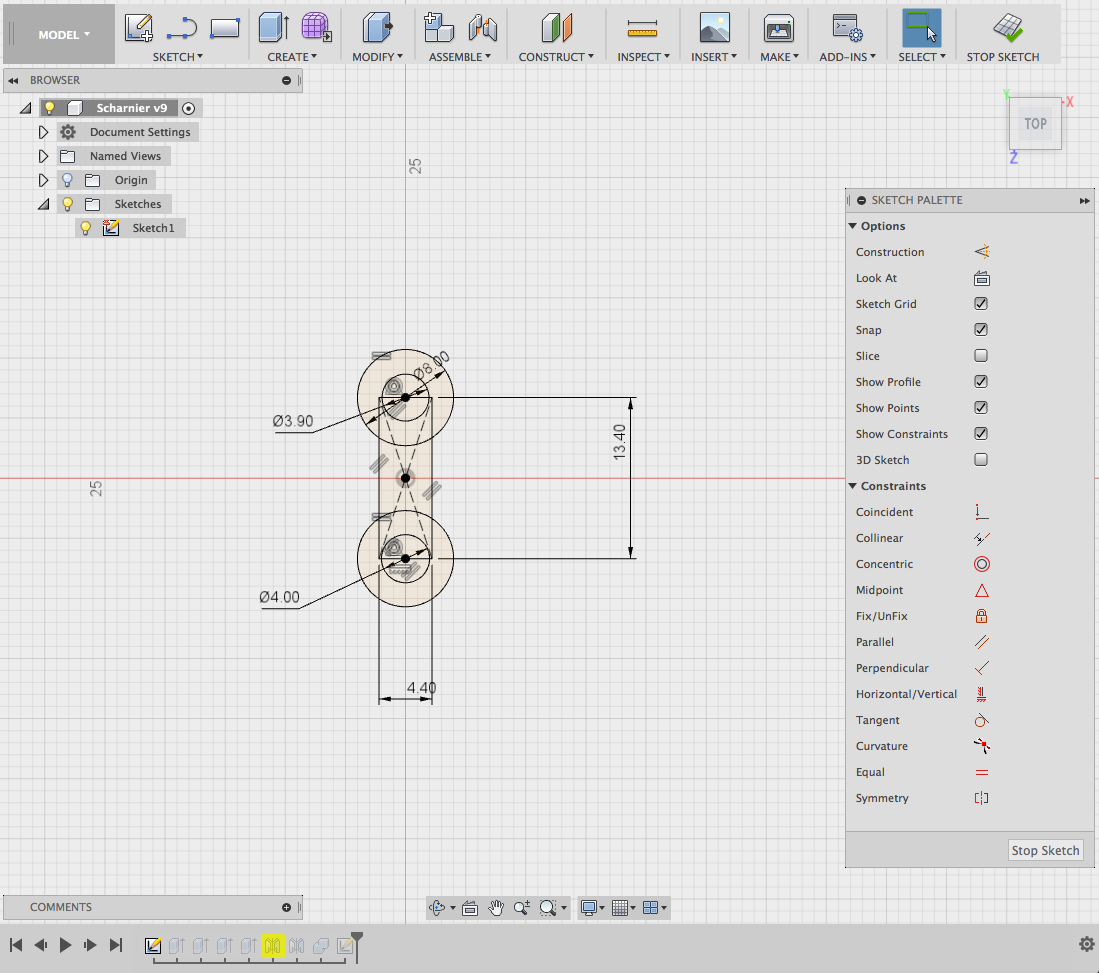

I measured the original hinge with my calliper and set up the model accordingly. The sketch consists of only basic shapes of multiple circles and a connector.

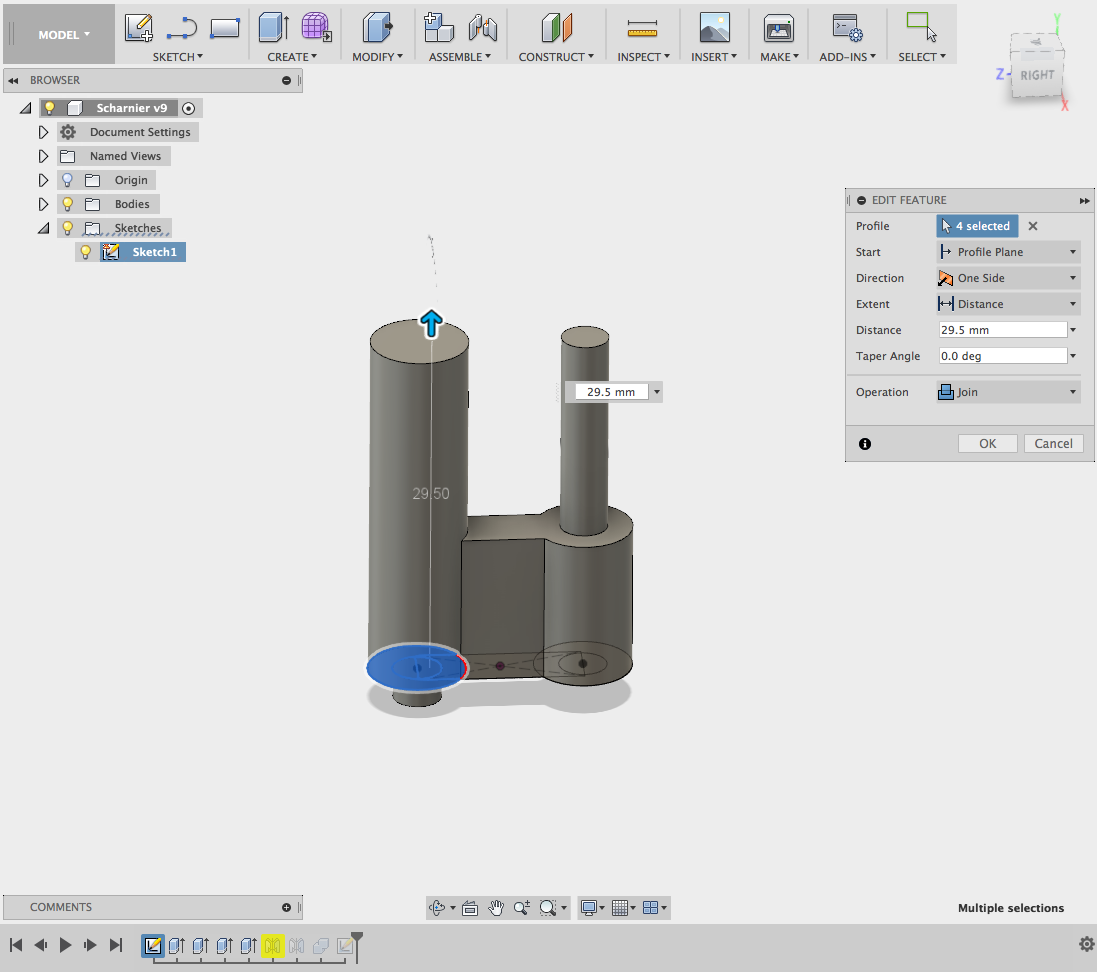

The barbell shape was extruded 29.5mm and a knob on one side was attached. This knob connects to the handle. The smaller bar is clipped directly to the toolbox and it is the section which allows the hinge to rotate.

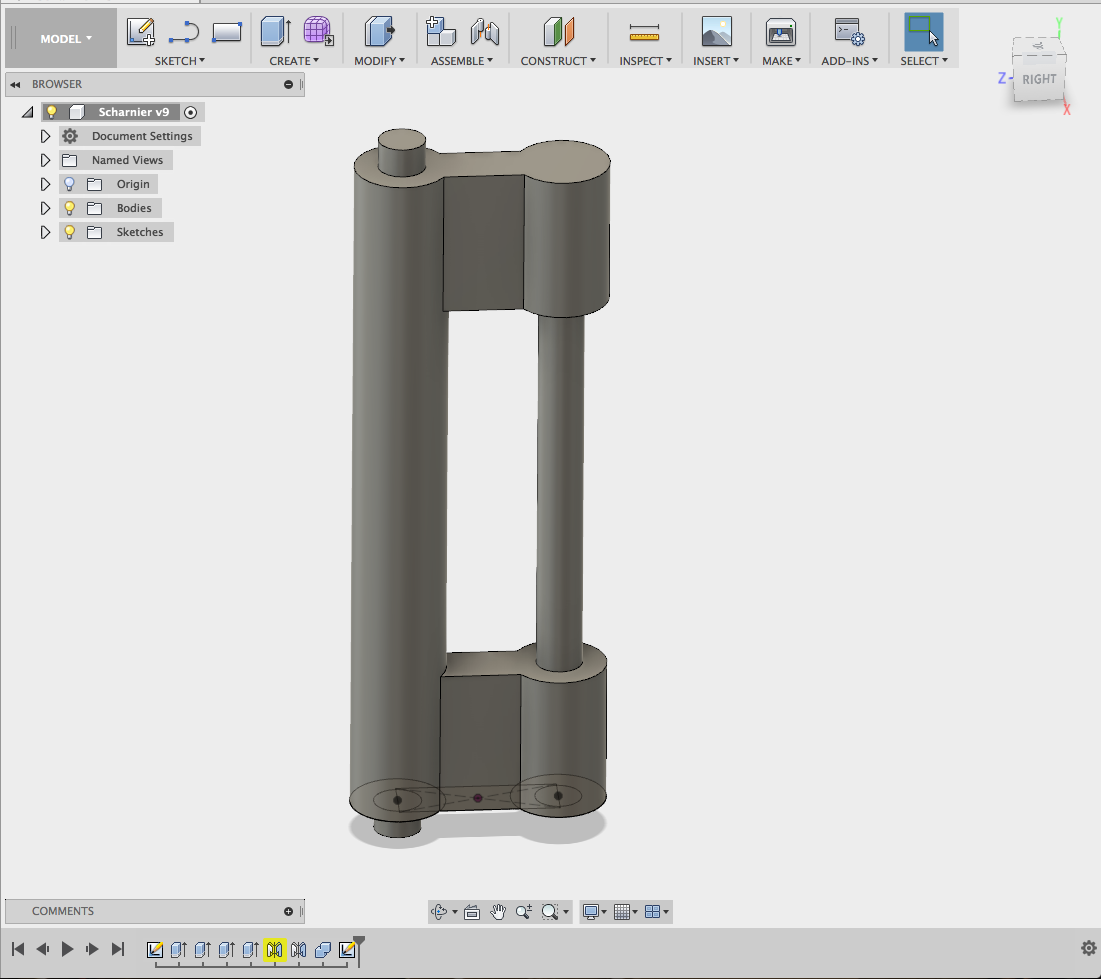

Finally, I used the mirror command to get the finished 3D model:

In case you have a similar problem to solve, the STL file and the Fusion360 model are linked below. The hinge was printed in PLA with the following parameters:

- 100% infill

- printing speed 60mm/s

- 205°C hotend and 60°C bed temperature

- 0.15mm layer height.

Matthias Kesenheimer

Matthias Kesenheimer

AVR

AVR

Greg Zumwalt

Greg Zumwalt

I have not encountered any problems yet and the part itself feels very stiff and durable. How long the part will last in the end remains to be seen. But I have no doubts that it stands a worse treatment than the part before.