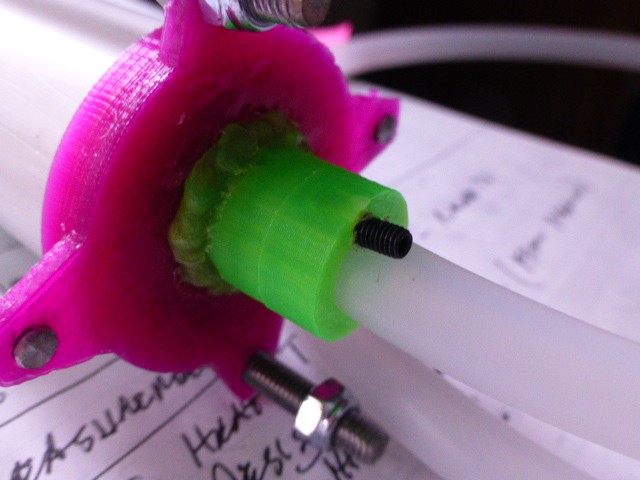

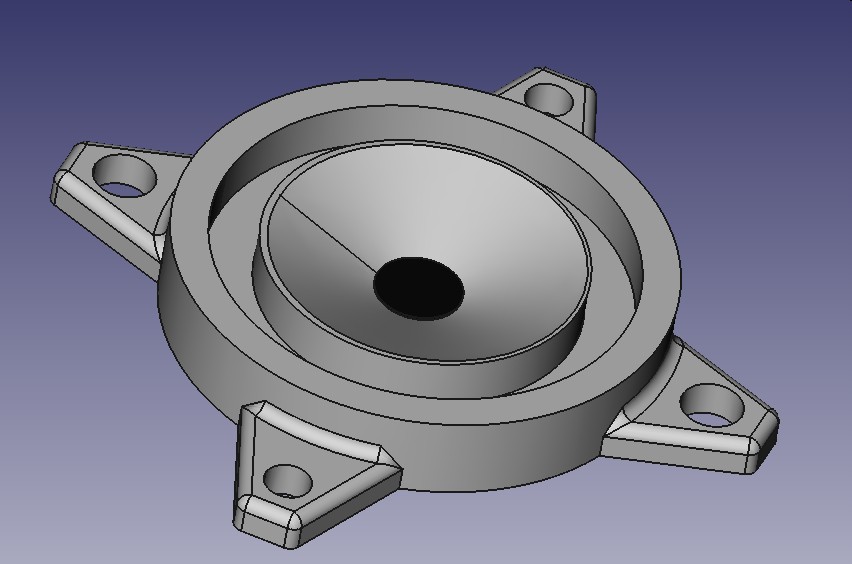

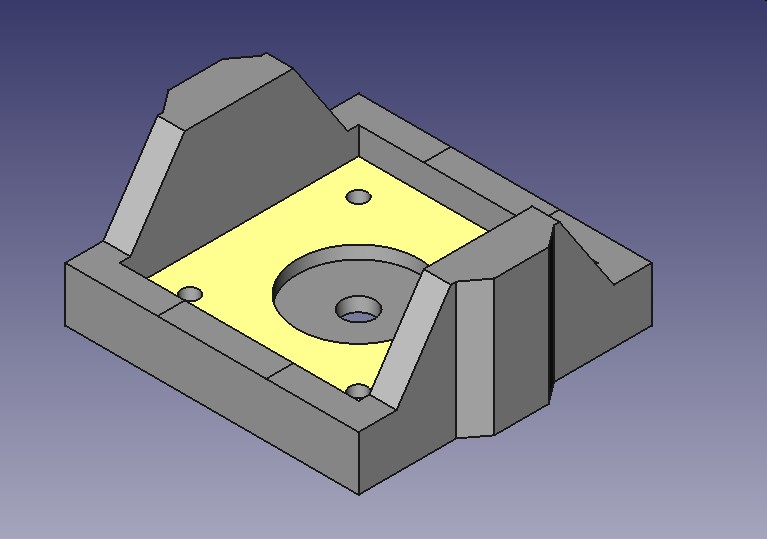

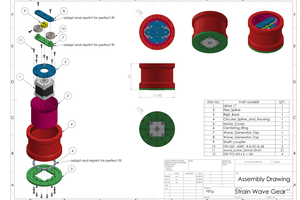

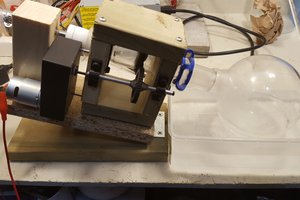

While there are many syringe pump designs, the ones I have seen all use a standard medical syringe. This design will be for a syringe that has a body made from PVC piping with ends and plunger made of PLA plastic and built with a 3D printer. The design will be done using FreeCAD and all files will be available on Thingiverse, with the latest versions always on github.

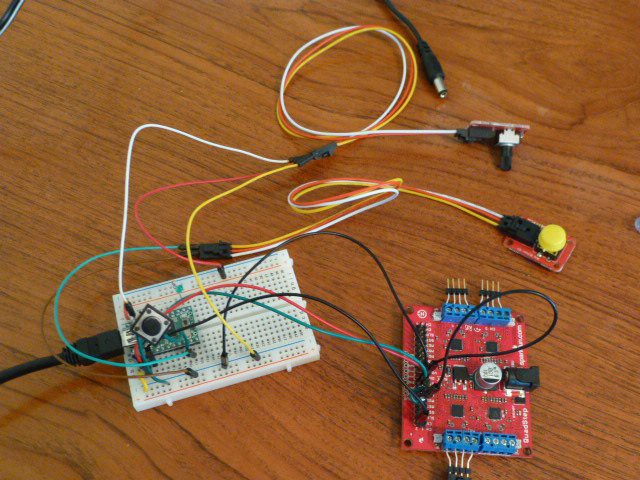

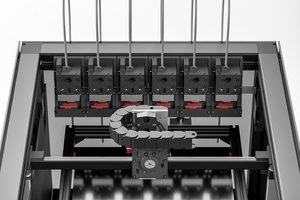

The syringe pump will be driven by a NEMA 17 stepper which will turn an 8mm threaded rod to move the plunger. The idea is that this pump will not be mounted on the 3D printer carriage, but will feed material through a tube to the extruder.

Such a supply system is needed by the two extruders I am developing.

doctek

doctek

Sam Baker

Sam Baker

Marc Schömann

Marc Schömann

Johannes Hassler

Johannes Hassler

Personally I would have built it like a stick of deodorant, leaving the motor in a fixed position and having the screw inside the syringe moving a plunger as the screw moves. To make a pump from there you'd just have to add 2 valves to the front and rear of the PVC openings. one side having the hole for the screw. As the plunger moves back and forth the respective chambers fill while the other empties