Project Progress

- Brainstorm functional requirements - Done

- Brainstorm: mechanical solutions - Done

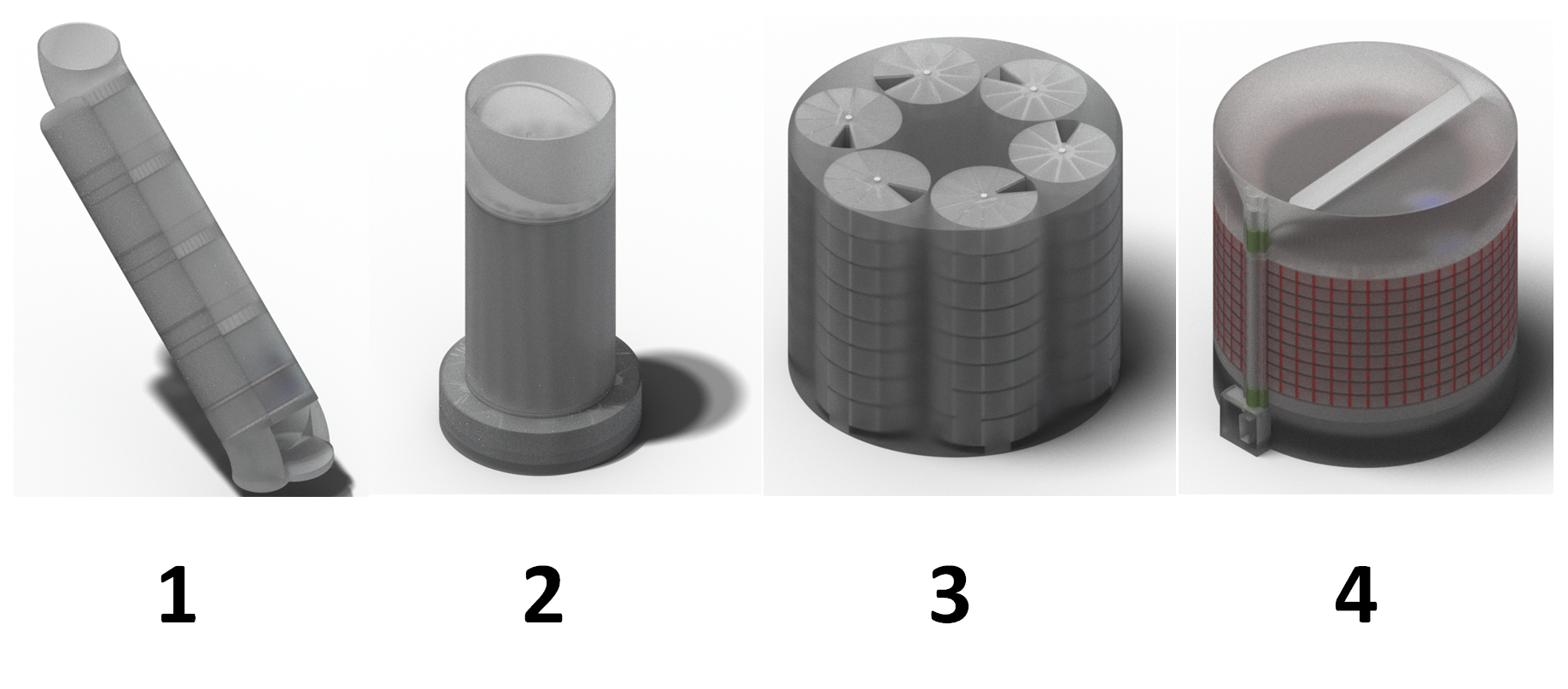

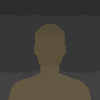

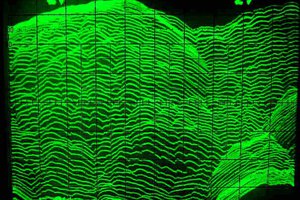

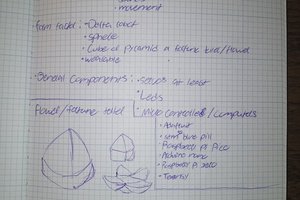

- Digital prototypes

- Rotating Plate - Done

- Tube - Done

- Cascading Container - Done

- Stacked Container - Done

- Determine "Project Direction" - Done (Cartridge Type)

- Physical prototype

- Cartridge Mounting - In progress

- Cartridge Dispensing - In progress

- Appliance

- Human interactions

- Define electrical scope - In progress

- Define program scope - In progress

- Prototype electrical system

- Prototype GUI

- Working Prototype

- Complete prototype

- Failure analysis

- Determine improvements

- Revision 1

dthunes

dthunes

Alessio Fabrizio

Alessio Fabrizio

Carl Strathearn

Carl Strathearn

Laurence

Laurence

I might be outdated but load-cells in the past have been used more for heavy work, not these little ones... I personally installed them for truck and railroad scales... YEARS ago :o)