The FireVolt Project

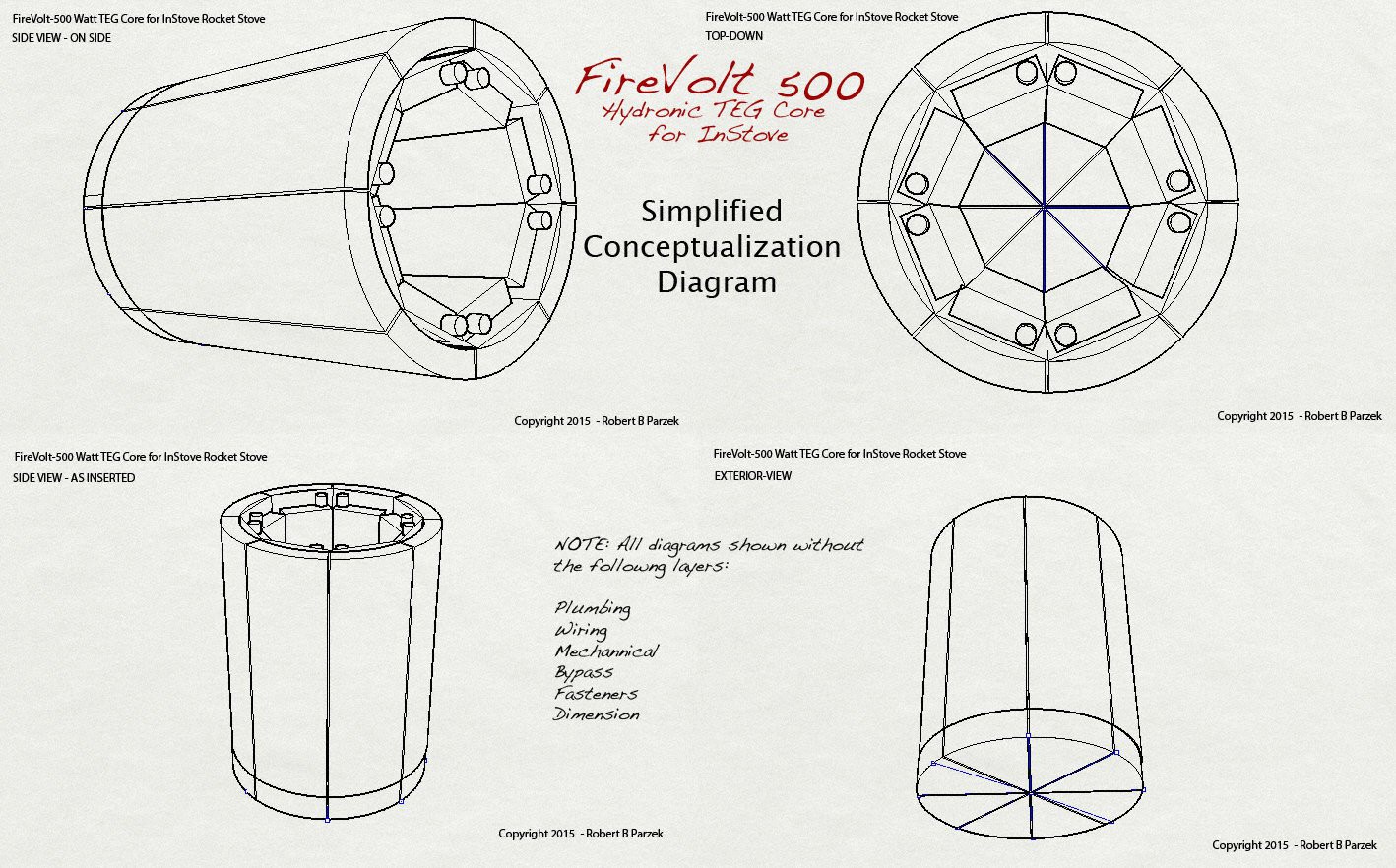

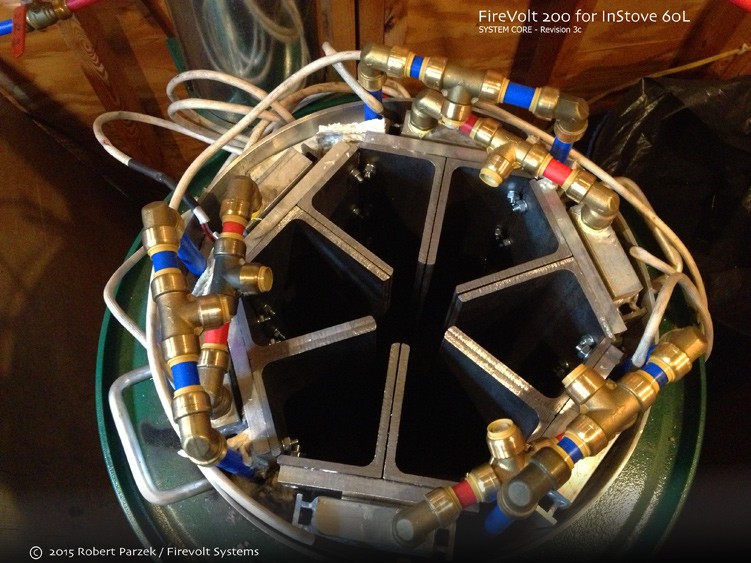

A 200w Wood & Pellet fired Thermoelectric Generator for the InStove 60L Rocket Stove; "Help People, Be Sustainable, Electrify the World."

A 200w Wood & Pellet fired Thermoelectric Generator for the InStove 60L Rocket Stove; "Help People, Be Sustainable, Electrify the World."

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

with a shoutout to #Hacker Channel for the support!

Before we get to that live demo video (the worldwide debut?) of the FireVolt. I'd like to present the "Opposing T" core bypass system. This focuses, not on the plumbing or pumps up at the top, (nor the core array below), but the space in the middle. As you may notice, the silver "mini T" connects to the large black T (originally where the straight smokestack was). This is a keystone design element which allows the system to harness the true power of the InStove's awesome combustion characteristics. The pathways that the combustion gasses flow through are each controllable (adjustable) by dampers, allowing a fine-tuning of the burn and power generation profile.These are off-the-shelf DuraVent chimney flue components. As a side note - The very top of the silver T features a "clean-out cap"which currently has a Rutland Burn indicator (temperature gauge) sitting on it to provide a rough core temperature reference. Ready to fire it up?

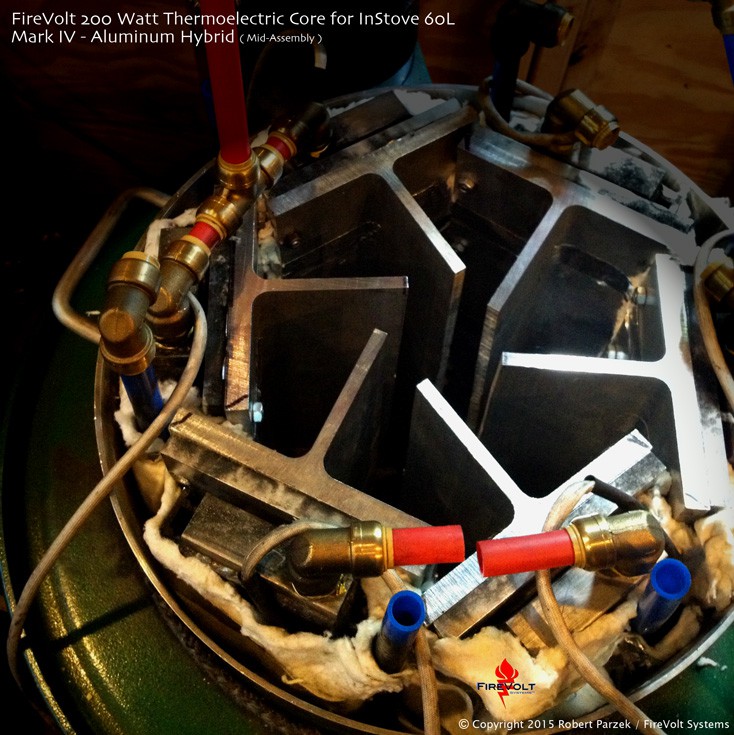

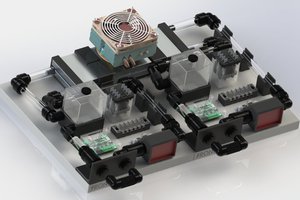

Modular design principles throughout, this picture shows the water block cooling side of a 70 Watt pair

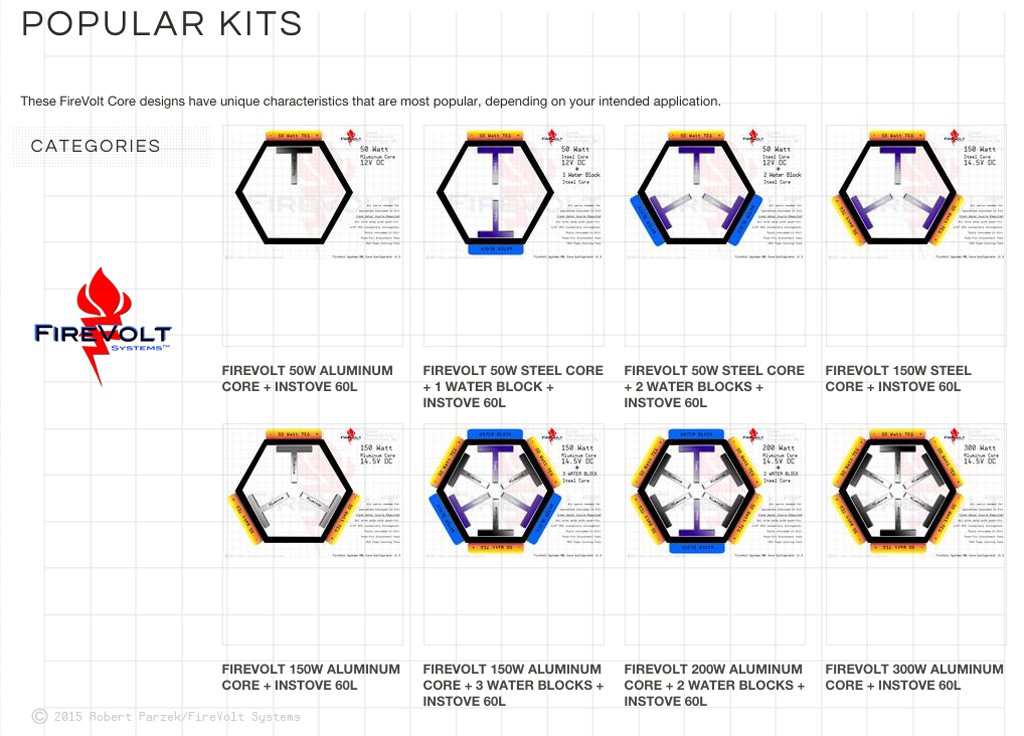

Scalability and Modularity are a big part of the design goals. Here are some variations on the theme.

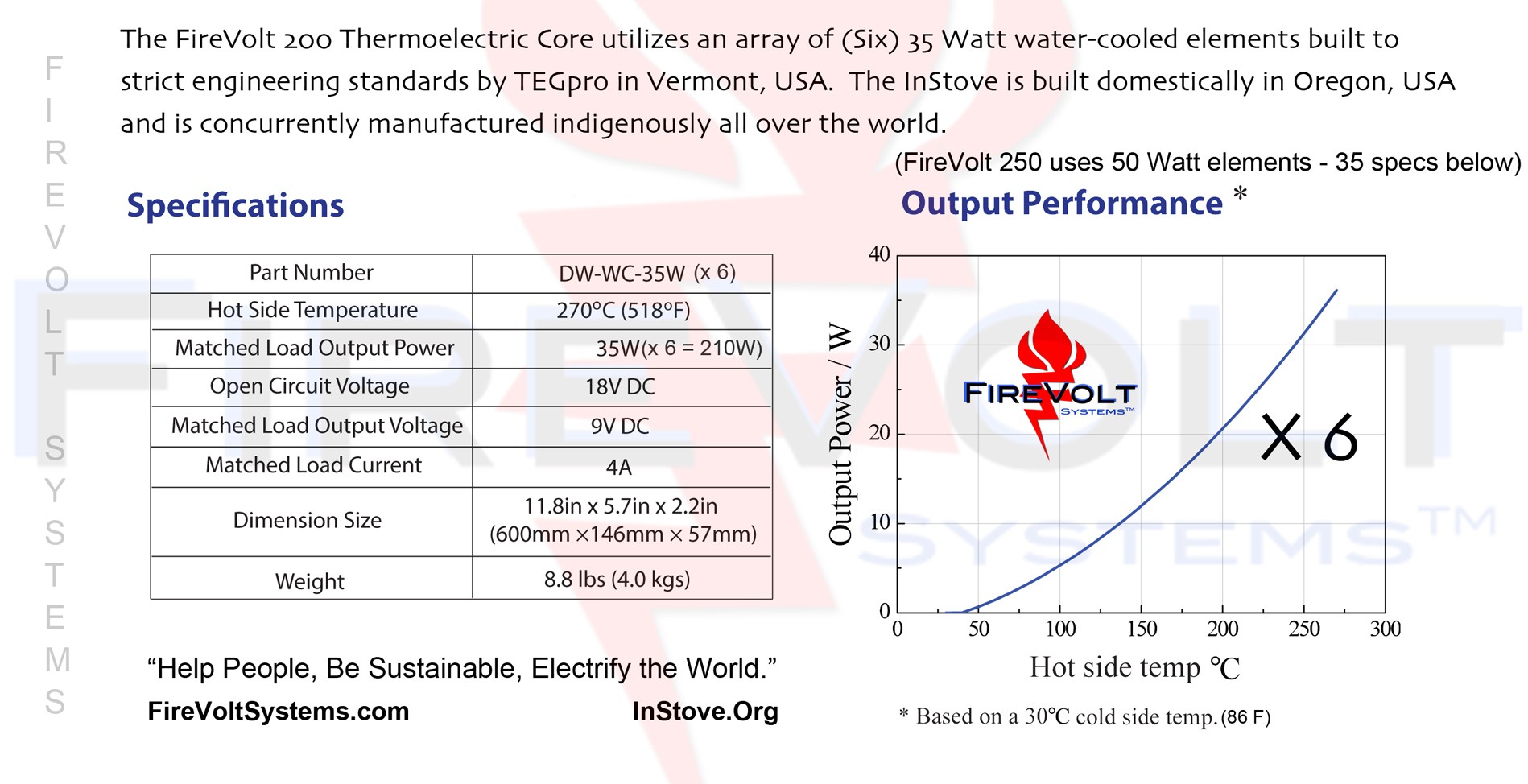

For those of you interested in the Electrical Engineering specs on the FireVolt 200 Watt Thermoelectric Generator for InStove 60L.

Exciting news for the FireVolt output specs! TEGpro has just released their next generation TEG elements. Output ratings of 7 volts and 22 watts (per TEG tile) will allow the InStove 60L Core to reach 300 watts max, 250 watts nominal. The same form factors allow a whopping 500 - 600 watts possible on the InStove 100L (though build cost is also proportional) it is exciting to consider a solid state, non-radiant, wood-fired rig with those numbers.

Want to help the FireVolt project and get your hands on some of the very best TEG components?

I'm offering TEGpro hardware for sale and will price match or better, depending on your needs and quantity. Message me directly, or browse the online shop. More to come.

A brief rant on the properties of base metals and heat transfer. From a practical angle, the FireVolt prototype design revision 3c incorporates a great deal of thermal isolation and a range of ferrous and non ferrous metals, jacketed by the InStove's insulation and a steel shell. To say it another way; "This thing doesn't radiate heat very much" and you can run it, indoors, full-tilt on a hot day, with nothing but a vent fan on in the room to maintain ambient temp. The rest of the buildings temps are virtually unaffected because the InStove itself is highly concentric and insulated, as is the FireVolt Core. (You can also choose to run it outside, but a small weather shelter is highly suggested for outdoor installations).

(the above cross-section is of an un-modified InStove)

(the above cross-section is of an un-modified InStove)

Where you actually put the harvested heat (harvested via water riding the 1/2" PEX plumbing) is up to you. For these warmer months I'm operating a water holding tank, a mini cooling tower in essence, outdoors as a thermal diverter. Once the buildings' domestic hot water tank is brought up to 110 Fahrenheit, and the building itself has no further heating requirements (signaled via thermostats) - the excess heated water is cycled into a large open-top tank which radiates to the open air outside. There are better (more conservative) ways to do this, but it works for now as a robust thermal dumping ground while I've been pushing into high temperature test cycles.

In the warmer sunny months the system gets run at night usually, as it delivers a steady charge to the buildings' 12v LiFePo4 battery array at a time when Solar is useless.

But - back to the Thermal Mass vs. Thermal Conductivity topic;

The current core material, Carbon Steel "Angle Iron" - has a rather nice thermal mass but a poor thermal conductivity compared to, say, Aluminum. However, core firebox temperatures can hit 1000c and the slow but steady creep of that heat - through the steel, eventually hits the TEGs hot side Aluminum plate, and things really start to get interesting about 45 min after startup, full power is usually hit around 1.5 hours.

Another interesting thing related to the Steel core. After the firebox flame goes out (due to fuel starvation) the system continues to produce highly useable power for 2 hours on cool-down., again because steel conducts heat poorly, but there is so much of it, you get this nice long discharge profile on cool down. Now, when the next re-pack of the core takes place I may swap the Carbon Steel for Aluminum and all of you Thermodynamics gurus can imagine what that'll yield for a temperature Delta between my hot and cold sides : D - thats why theres a cooling tub outside! eventually I think it may end up as a pool. Year round. We'll see.

Greetings and thanks for checking out my project. The FireVolt 200 Prototype has been in operation for about 5 months as of this entry. The consistency of the system performance has yielded a breadth of data about further system optimization, which is the framework for the next steps of the project. There is much more to follow relating to micro-controller based system / load management, automated pellet feed and unattended long-runtime configuration. Ultimately the system will self-feed, self regulate and provide remote monitoring and control.

Step one is to get yourself an InStove 60L and get familiar with it. Boil some water, try different fuels, play around. Everything related to the build is downstream from this. At worst, if this is as far as you get, you'll be able to cook huge amounts of food and heat 15 gallons of water on a very small carbon-neutral fuel budget. But of course, that's not the only end goal. We're here to generate Electricity. So... step 2

Figure out your TEG budget. The FireVolt System is scalable. You can invest as little as $350 in the TEG side of a viable build with room to grow as your budget allows. In such a configuration your max output would be around 35 Watts, matched load at 9v DC, with a TEG block occupying only 1/6th of the core. The remainder of the Core walls could be water block / heat harvesters only, or simply insulated dummy panels made of 1/4" steel.

p.s. this is a no-weld build! (believe it or not) - more on that later - but going forward the instructions assume you are building a full 6-sided TEG core.

Cut 1/4" Aluminum T-beam to 10" lengths, de-burr any sharp edges. With 300 grit paper, sand the face you're mounting your TEG block to so that it is well-polished.

Create an account to leave a comment. Already have an account? Log In.

Thank you for the excellent feedback and good words! I agree that Sharkbite (any push-fit hardware) is expensive, but there is a subtle and extremely useful benefit to them in this build, and that is the ability to swivel after connecting without compromising the seal. Toward the end of the assembly process this becomes imperative. Also the ability to casually disassemble the rig for field service, TEG replacement or cleaning is a keystone function. I'll have to ponder the cost/benefit but, I like your way of thinking.

That's a great point. The crimp tool does come with a go-nogo gauge, and if you don't do the crimp right (and the gauge doesn't fit) the joint is liable to leak/pop off. Not something you want to have to deal with, so SB might be the way to go.

I really have abused the heck out of the Sharkbites. Huge daily temp gradients and cycles, exposure to soot, smoke, ceramics and hundreds of disconnect/reconnects as I have built-revised-rebuilt the system. Not to say they cannot fail, but when the rig is actually up to temperature and producing max power, the very very last thing you want is any kind of cold water eruption in the firebox. I'd just slap some postage on my back and kiss it goodbye if thats the case! No contest necessary! ; D

It would be interesting to see more of your circuit design ... raw voltage ...serial/parallel ..buck converter mppt ......

Hot cold... a more detailed view would be nice...since it is not obvious from current drawings how the teg-elements is actually connected and cooled ( water block )

It basically looks like a few of these blocks + rocket-stove..

http://www.tegpower.com/pro7.htm

Personally I'm very interested in a small portable an reliable system

Thank you for the skull and feedback mr.jb.swe! I will take note and include more of that information and diagrams in the next main update before deadline. The best website to find the TEG elements and DIY hardware is http://tegmart.com - lots of datasheets there too. (I have met with the guys that design and build those units, Shane and Dan and crew and I have toured their technical facilities in Randolph Vermont). And you are correct! it basically *is* a few of those blocks and a rocket stove! : D with a Parallax Digital I/O as a load manager/diverter. Feed the Voltage out to whatever you like (raw, MPPT, bucked, boosted). I too love the idea of small and portable, but since that space was well-occupied I figured I would "Go Big or Go Home". Besides, worse case scenario I end up warm, with the lights on. : )

>space was well-occupied

Don't be so sure...

In my opinion the space of a truly durable ( like mil spec ) and lightweight is still vacant ...

Be careful what you wish for... deforestation in Haiti (as a result of widespread use of wood as "free" fuel by impoverished population) has stripped the landscape of windbreaks and removed roots that used to hold the soil in place. As a result the danger from hurricanes, mudslides, earthquakes etc is amplified dramatically.

Indeed. Thank you for bringing this up! Sustainability is a specific goal of the project. The fuel usage you describe is the result of highly inefficient and often dangerous cooking methods; open fires, three stone cooking, etc. which is what the InStove was designed to replace; http://instove.org/60-100-liter-cookstove The stove yields a massive reduction in fuel consumption, and provides a pathway to other technologies via the modular design. Also, the stove is capable of leveraging alternate fuel strategies in the hardest hit locations. http://instove.org/alternate-fuel-method Hopefully these aspects help mitigate your concern, though it is quite valid.

wow that is really awesome, I was looking into this tech last year, and basically failed with a stove made from a concrete mould..

http://projects.hascomp.net/Rocket_Stove/

this is kinda inspiring as how to extract usable energy from a rocket stove!

Thank you for the good words! Kudos to you diving into a project like that. The concrete form concept that you have there is really interesting - you certainly didn't fail - the insight gained is worth the effort. "Fail often and early" is actually a desirable path, though admittedly not for everyone. I am standing on the backs of giants by using the InStove as a starting point. I spent two years off and on prior to discovering this marvel, tinkering with home builds and melting holes in my build material.

Become a member to follow this project and never miss any updates

David Scholten

David Scholten

Robert Hart

Robert Hart

extremerockets

extremerockets

isaacporras

isaacporras

Cool project! One comment on the BOM--I redid my house's supply piping in PEX and found the investment in a crimper to be worthwhile (roughly $100). SharkBite fittings work well for quick prototyping but they're expensive; copper rings and brass PEX barbs would save you a bundle of cash.