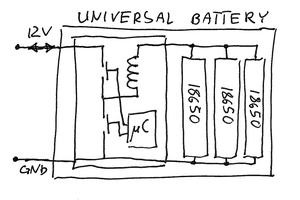

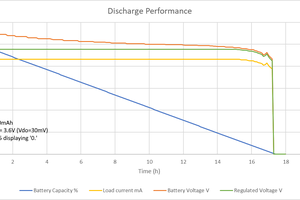

The topology of the pack is a stack of 3 series of 2 paralleled 14500 (AA) 550mAh 3.2V LiFePO4 cells. This results in a nominal voltage of 9.6V. During charge, the voltage will go up to 10.8V. An undervoltage protection feature will switch off the load when a single cell reaches 2.7V. In practice, that means the battery will turn off when the output voltage gets down to 8-9V. Due to the extremely flat discharge curve of LiFePO4 cells, the voltage will only drop to that level at the very end of discharge, so most of the 1100mAh capacity should be available.

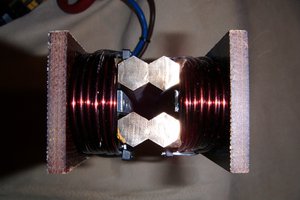

The charger uses a booster current source, with shunt regulators set to 3.6V to limit the end of charge voltage on each cell. An MSP430 ultra low power microcontroller monitors the voltages of each cell to manage charge voltage and provide undervoltage protection.

Patrick Van Oosterwijck

Patrick Van Oosterwijck

George

George

Christoph Tack

Christoph Tack

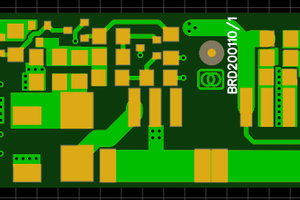

hey, could you please also add a picture of the schematics? Nice project!