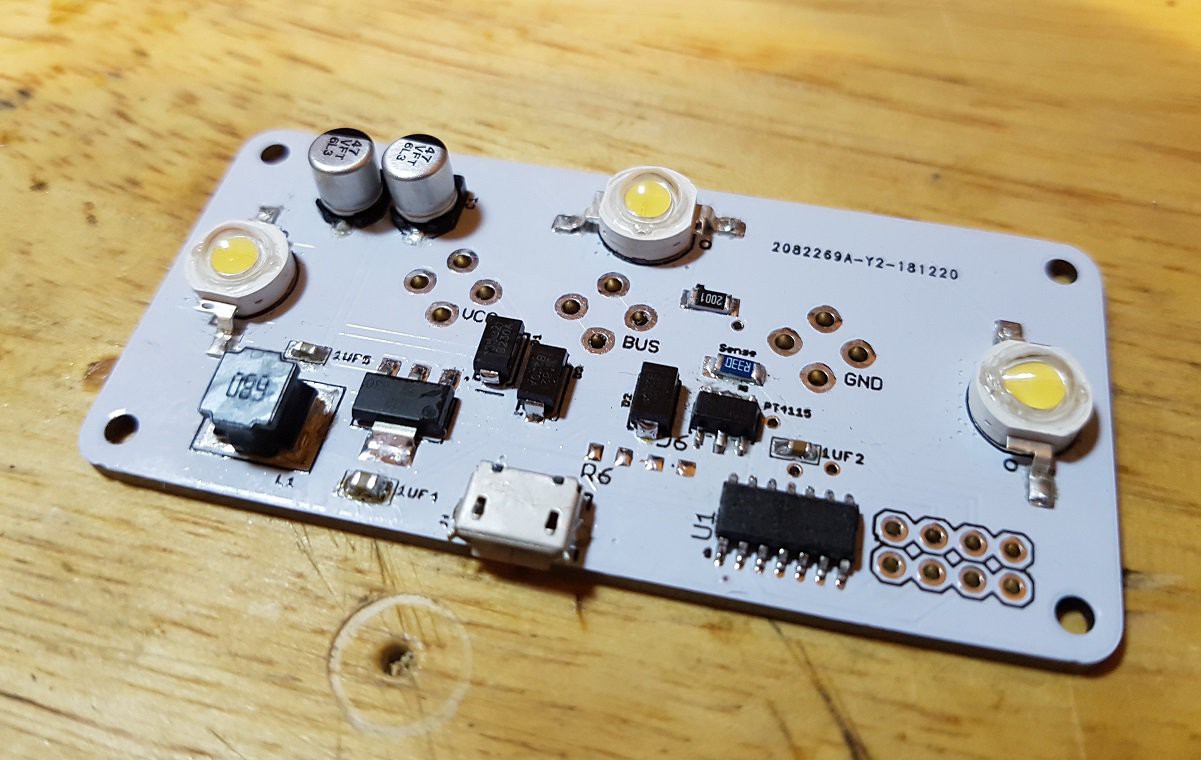

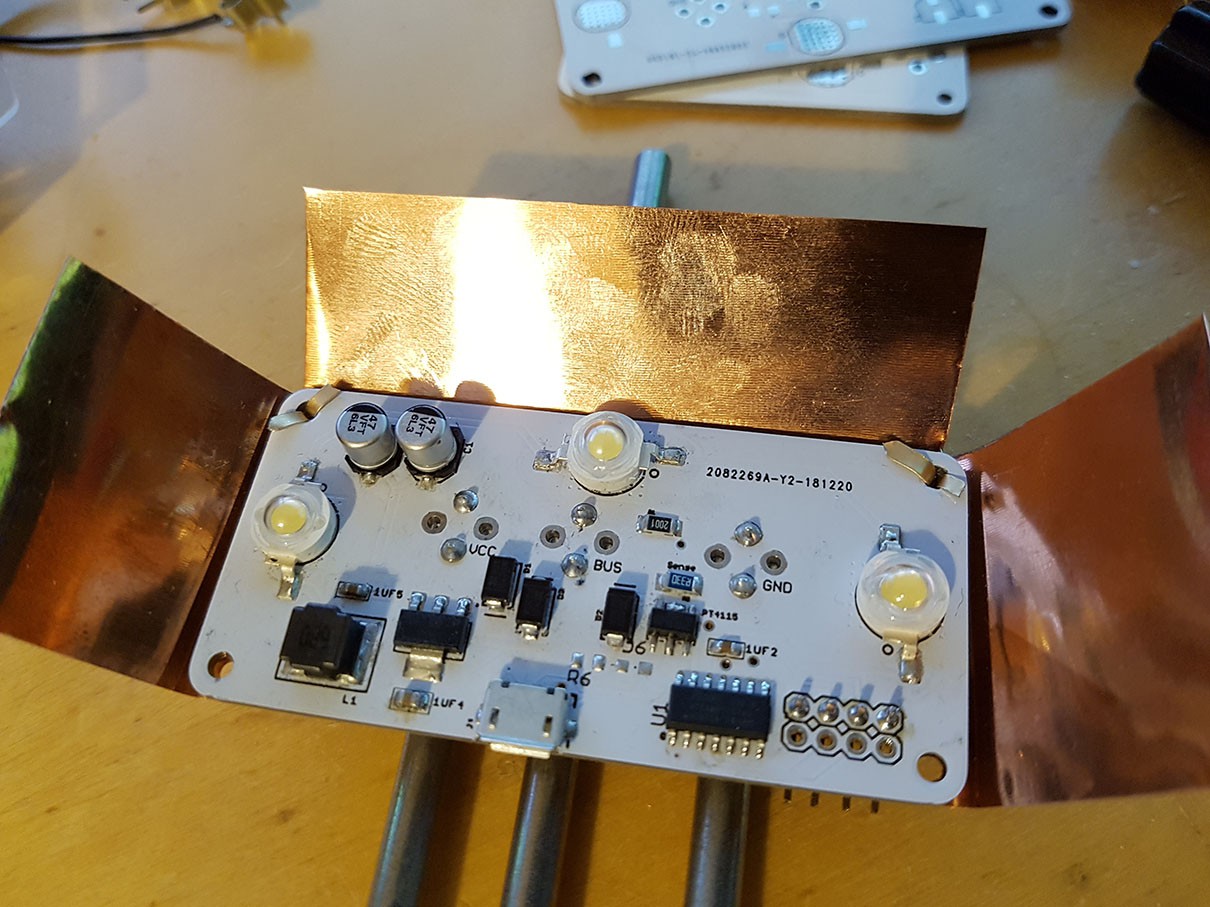

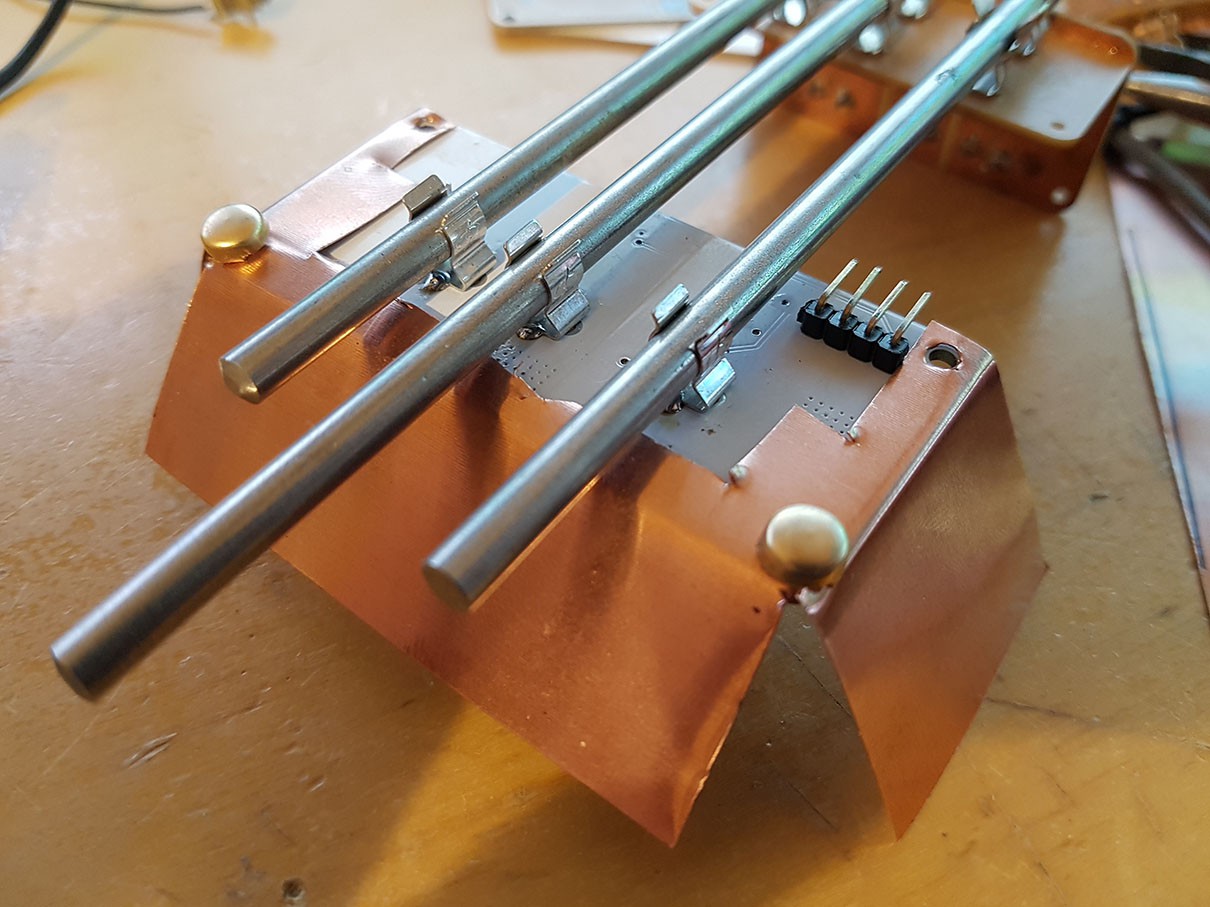

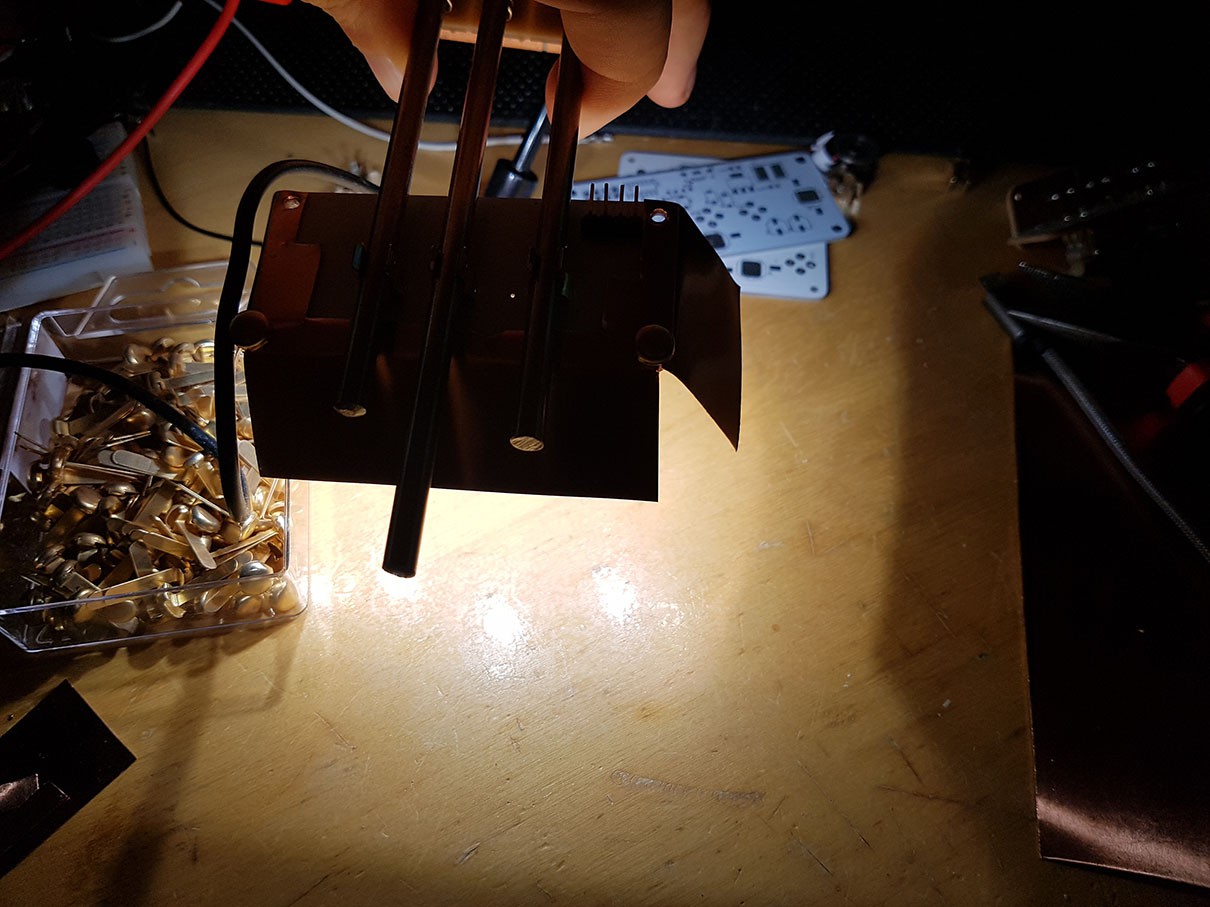

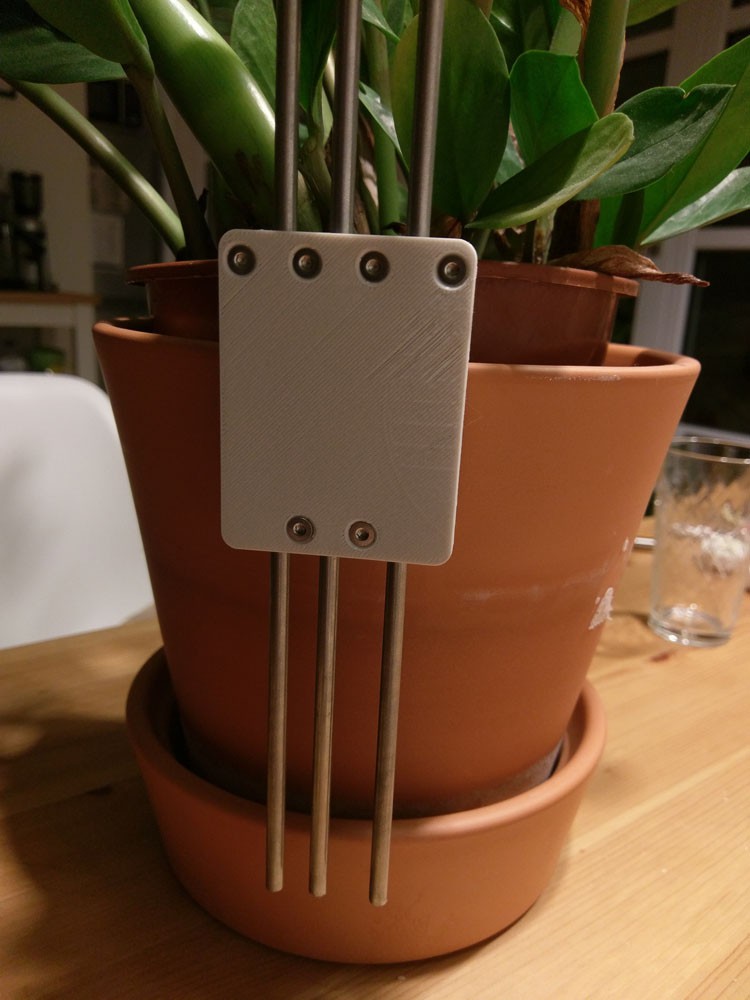

This project is based on previous years entry: #MoRaLiS: Modular Rail Lighting System . This project advances on some of the basic concepts of MoRaliS and turns it into everything that is needed besides lighting. See my project logs further down for my progress. Unlike last year I try to document my process a little more and will try to write an entry for every step I take to realise this project.

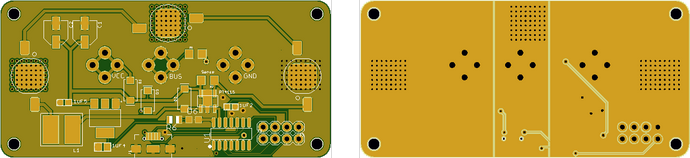

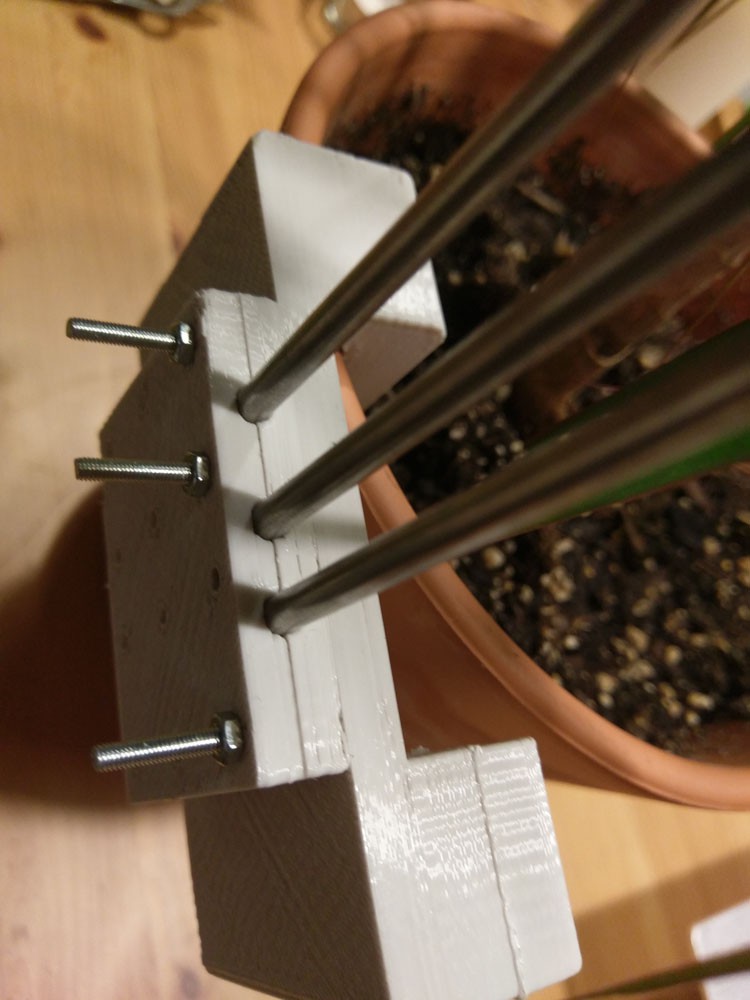

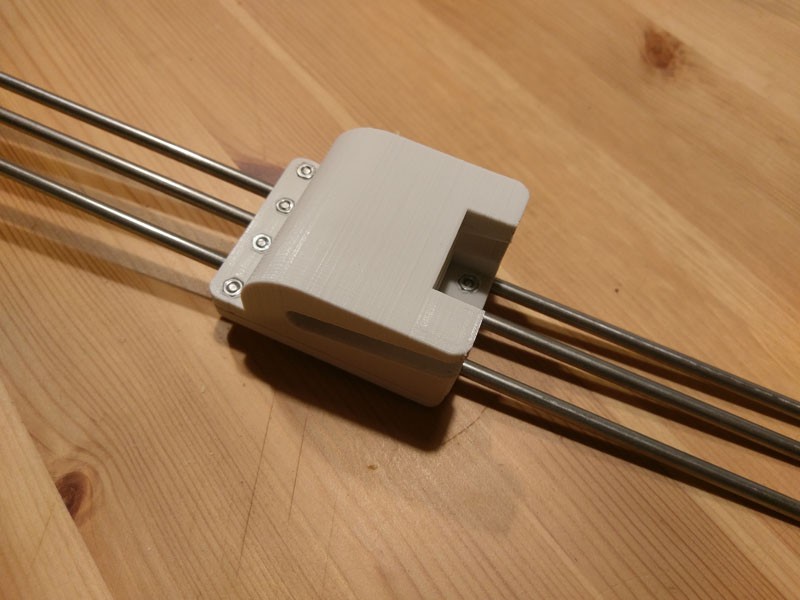

At the moment I try out the concepts I have in my head, so you will see a lot of CNC milled boards at first, trying out different things. When I got an idea how everything looks I will proceed in ordering some PCBs to test out looks and get better data on mechanical stability. As it is starting to get warm in Europe I will also start a controlled test by growing a tomato plant of the same strain indoors with MoAgriS and outdoors on my balcony using the traditional methods, e.g. the Sun, windy weather and a watering can.

So if I caught your interest, subscribe to the project and follow me along :)

timonsku

timonsku

brandon

brandon

GearheadRed

GearheadRed

alpha_ninja

alpha_ninja

Grate project. Inspired me a lot on the way to build a Greenhouse application using our m10cube https://wizcube.eu award winning platform. I like to join the team and see if wizcube concept can contribute to help this grate project.