System Design Document

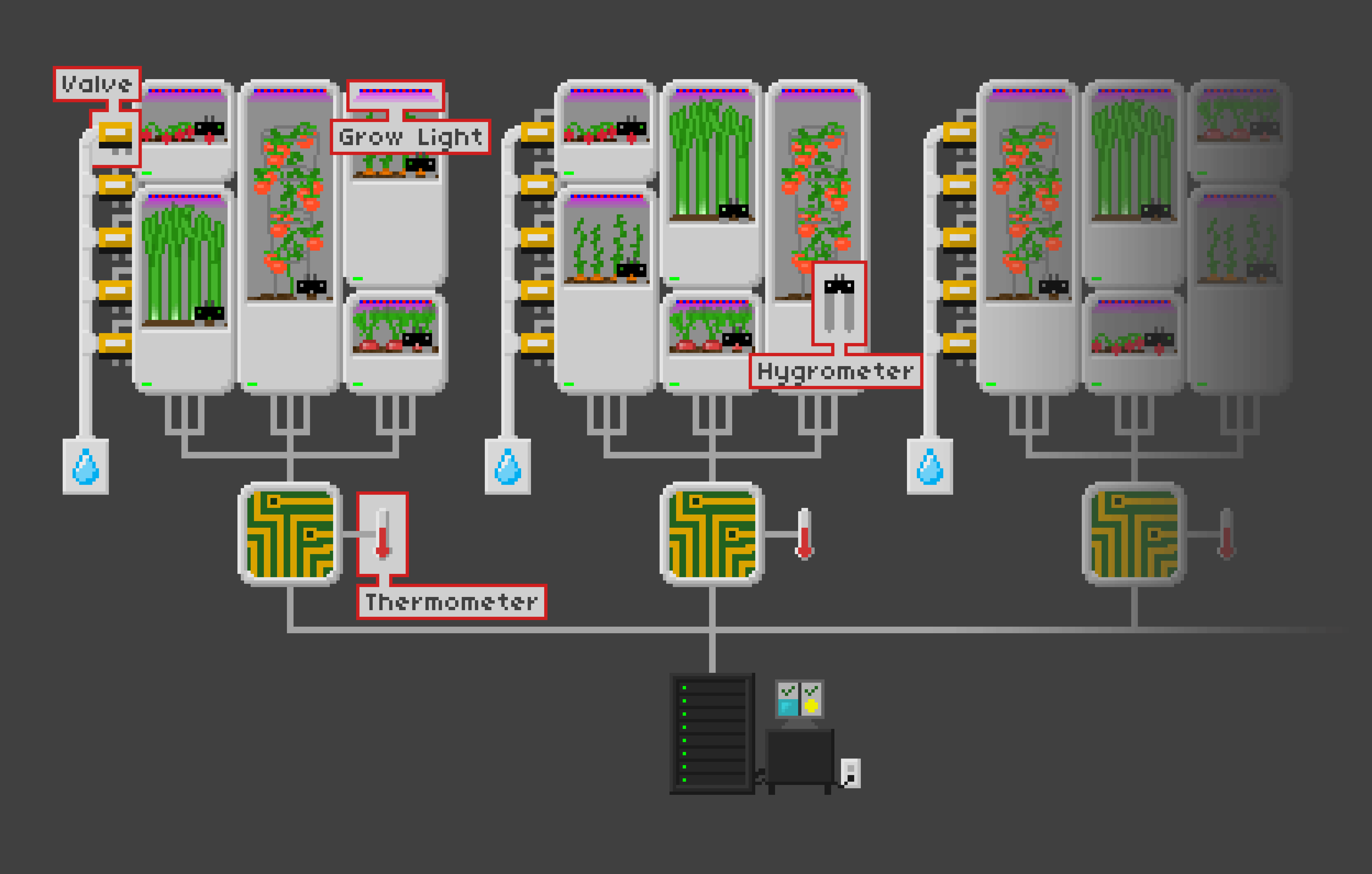

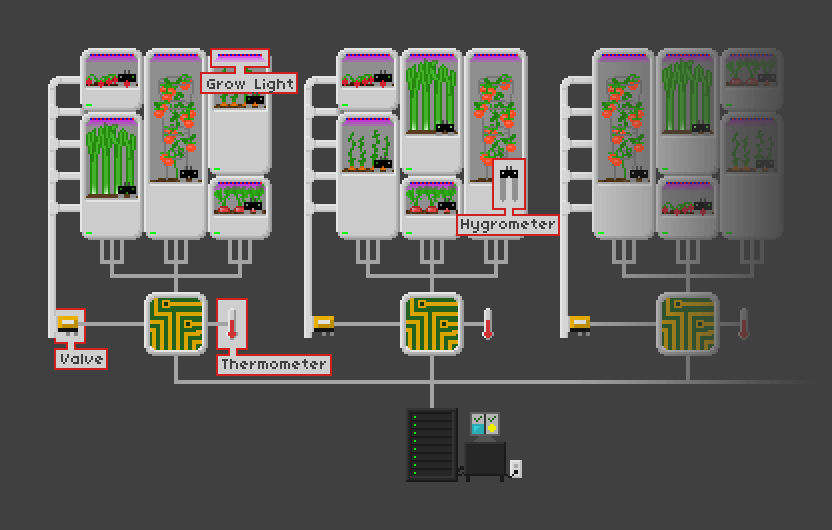

I'm building toward the following:

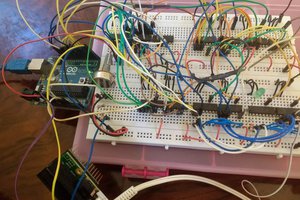

- Modules with grow light strips, solenoid valves, docks.

Design finished, construction will start soon. - Communication between Modules, Controllers, and Servers.

- Communication between Modules and Controllers done, Controller-Server communication is currently in progress.

- A graphical interface that shows the status of the system.

- Mockup has been made, coding is in progress.

- Temperature sensors in controllers

- Work hasn't started on this.

Please see the components section for a preliminary list of components.

![]() Information:

Information:

This is a project aiming to:

- Enable growing food at sale locations (→ supermarkets, etc)

- Aims:

Reduce pollution caused by transportation

- Aims:

- Enable automation of growing food

- Aims:

Permit use of analytics to maximize growing efficiency

- Aims:

- Facilitate use of robots in plant growing process

- Aims:

Reduce needed space

Achieve consistent quality

- Aims:

- Reduce wasted water by eliminating runoff problems and reducing evapotranspiration losses by means of catching runoff and dehumidifying, then filtering water and reusing it.

- Aims:

Use & waste less water.

- Aims:

- Accommodate plants of different sizes.

- Aims:

Allow use of a single frame to grow different plants (especially useful in smaller commercial contexts)

- Aims:

In conclusion, these are the major goals I am trying to achieve.

- Grow food where it's needed (at local supermarkets, etc...)

- Give customers access to fresher food

- Improve health by reducing the cost of vegetables & fruit in general and making them a more attractive option

- Simplify growing of food in remote regions, especially those that have arid climates

- Give customers access to fresher food

- Reduce the environmental impact of growing plants, especially in large scale

- Use less water

- Stop releasing pesticides / herbicides into groundwater & nature

- Use less water

Licenses

Wire library (c) 2006 Nicholas Zambetti, GNU LGPL 2.1+. Not modified by me.

Other Arduino.cc Software used (GPL and/or LGPL), but also not modified by me.

alpha_ninja

alpha_ninja Information:

Information:

I've thought a bit about the organizational structure of the project. I've come to the following conclusions:

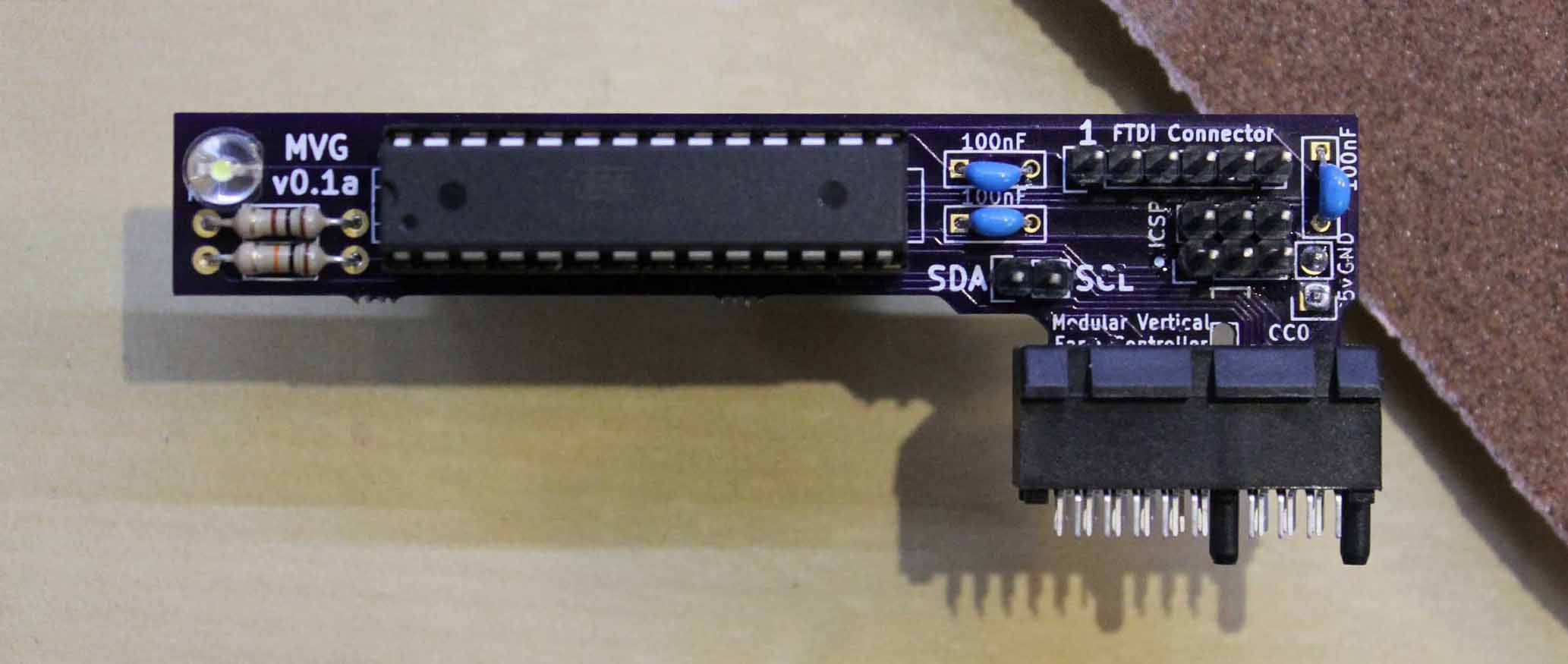

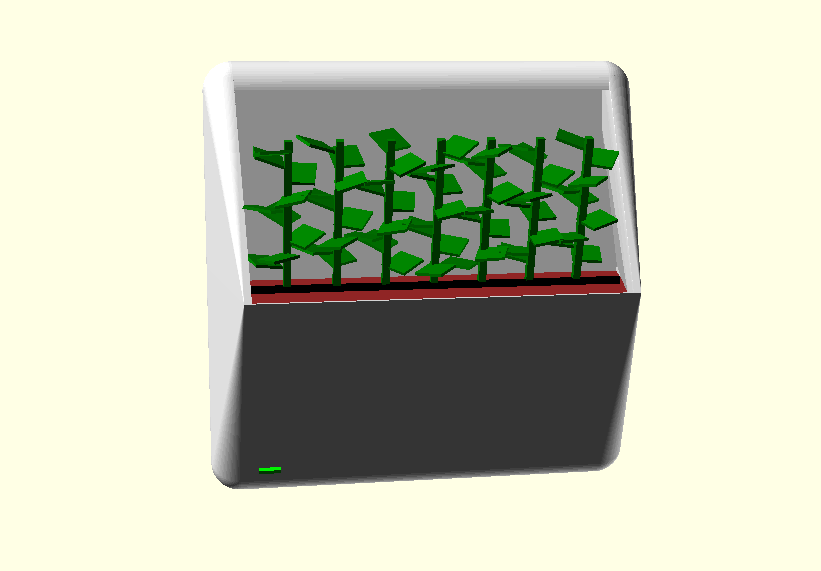

I've thought a bit about the organizational structure of the project. I've come to the following conclusions: The plants, soil, and watering tube are in the image to clarify usage.

The plants, soil, and watering tube are in the image to clarify usage.

strange.rand

strange.rand

novirium

novirium

timonsku

timonsku

Matt Bradshaw

Matt Bradshaw

Whoa, so many followers all of a sudden! what happened?

Edit: Looks like the project is/was featured.