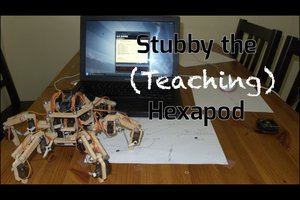

So here we have the first set of parts for the ServoStock, a derivative of the Rostock using Closed-Loop control, a whole new com architecture, Servos for drive and NO STEPPERS. Pictured is the first attempt of the single axis using the Vitamins from a Printrbot.

Software/Communications:

The system we developed over 4 years and have now applied to a 3d printer is an extensible, namespaced communication protocol. Think of it like a domain specific language over a generic serialized communication link. The protocol allows devices to report to the computer their capabilities, then the computer can generate packets based on that report. We have complete implementations in Java and C99. Clojure, Jython, Jruby and Matlab have been tested working with this library. There is a partial implementation in pure Ruby as well.

Electronics:

We have redesigned the entire control system from the ground up. From the get-go we started using magnet orientation encoders plus low cost continuous servos. The motherboard is a Pic32mx440f128h with each axis receiving a servo pulse and an SPI channel for the encoder. The motherboard uses a 7x2 ribbon cable to connect to each axis. Each axis has a small board with the encoder chip and the connector for the servo.

Firmware:

The control loop runs at 20 ms for the servo pulse calculation, interpolation and forward/inverse kinematics. The device identifies itself as having the PID control namespace, the kinematics namespace, and the 3d printer configuration namespace. Through the communication layer you can change kinematics models, change PID constants and store all the Slic3r/Cura configurations. The configurations are stored non-volatile in Flash and travel with the printer to be read at runtime. NO MORE CONFIG FILES!!

The firmware also has auto-config system. The servo dead band is measured at boot time. The end stops are measured using the encoder with no limit switches. I am thinking about doing a bed calibration as well, but that is future work.

Bootloader:

a (new to you guys) bootloader that i developed for the DyIO controller. It is a serial bootloader that uses the same communication protocol as the printer or any other device for that matter. The bootloading interface is just another namespace that any device can implement. The toolchain for generating bootloader file is all written in Java and attaches to any Makefile build chain.

Hardware:

We have taken the idea of the Rostock and started from scratch using a full set of parametrics. A single file with measurements from the vitamins you are using is all that is needed to generate a whole new printer.

Servo-Stock

A Kossel derivative to show off a new PID control framework and command system called the Bowler Communication System.

Kevin Harrington

Kevin Harrington

The Big One

The Big One

ArsenioDev

ArsenioDev

sporkius

sporkius

Haddington Dynamics

Haddington Dynamics

really exciting idea ...

you can also unleash your framework with 2.1W and 3.5W diode lasers (EnduranceRobots.com)