Background:

I've built one pad before ~ 10 years ago. http://www.angelfire.com/d20/ddrhomepad/ The mechanical design is flimsy, the support structure is corner brackets and peg board. Most home built DDR pads utilize mechanical switches varying lengths of weatherstripping for adjustable sensitivity. This method is tedious and cumbersome. While a digital switch functional its not the most accurate solution.

The Goal:

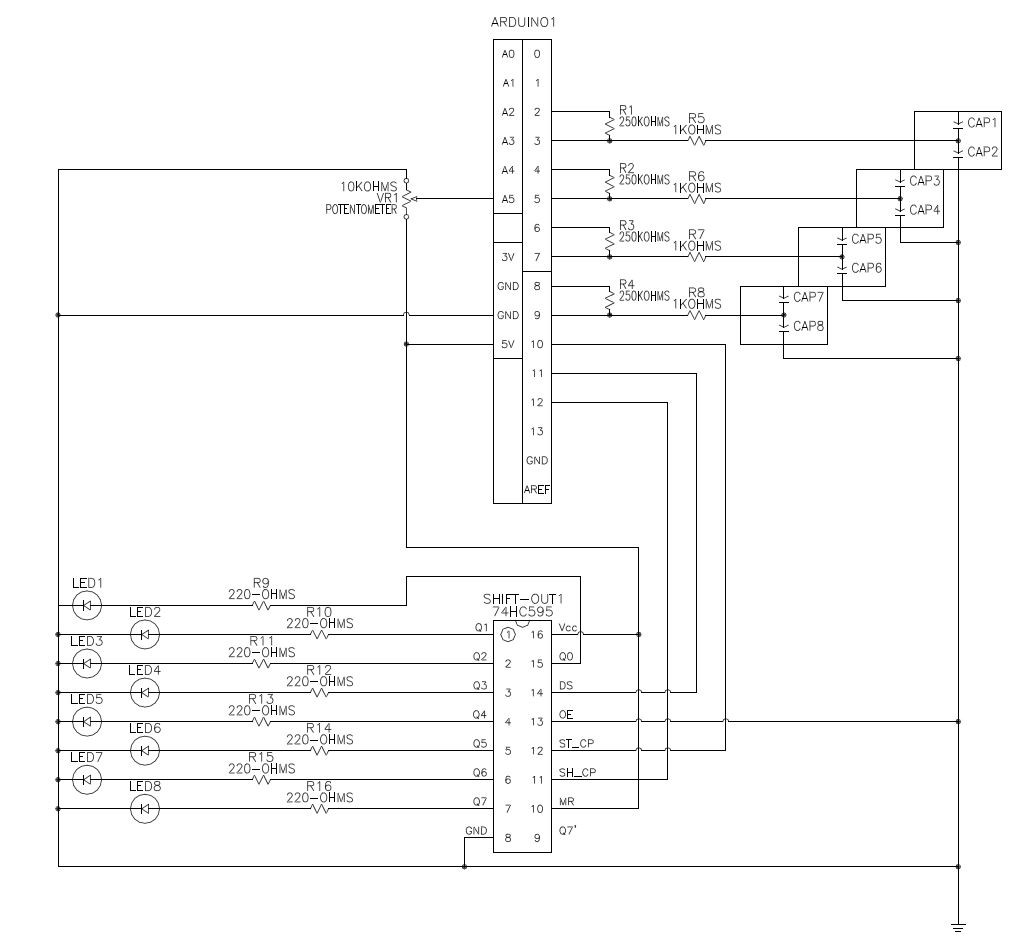

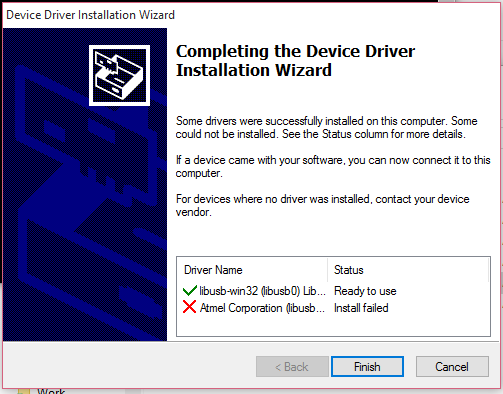

Utilize low cost analog sensors using an Arduino micro controller as a USB game controller.

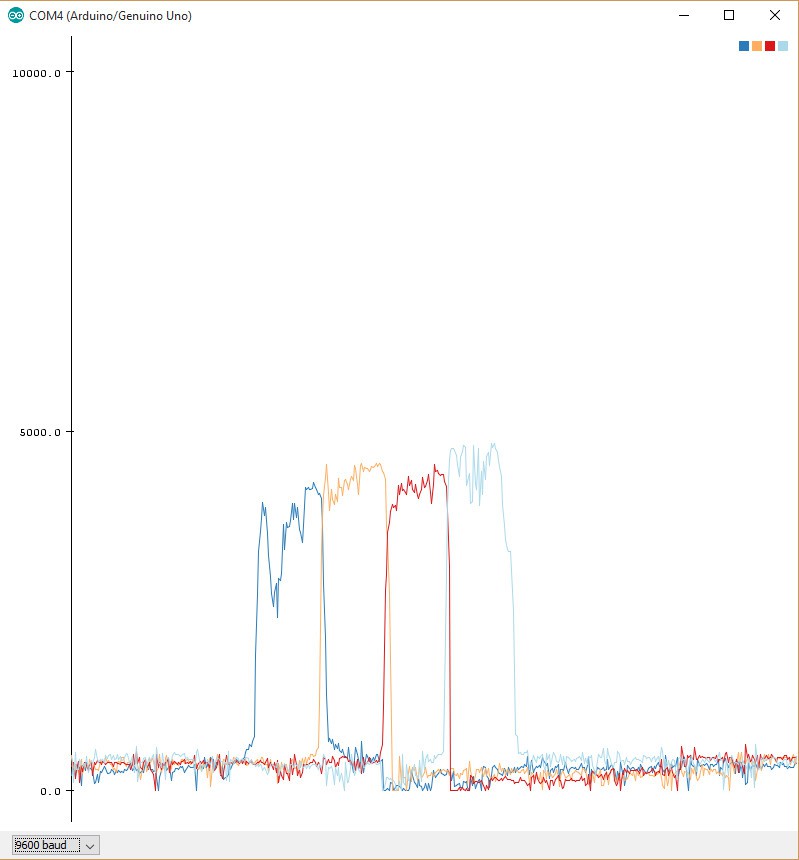

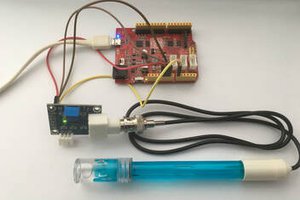

The current plan is to use Capacitance sensors. They are cost effective and in theory can be more accurate than the arcade pad as we can sense the step before it makes physical contact with the pad, assuming we can eliminate any RF interference.

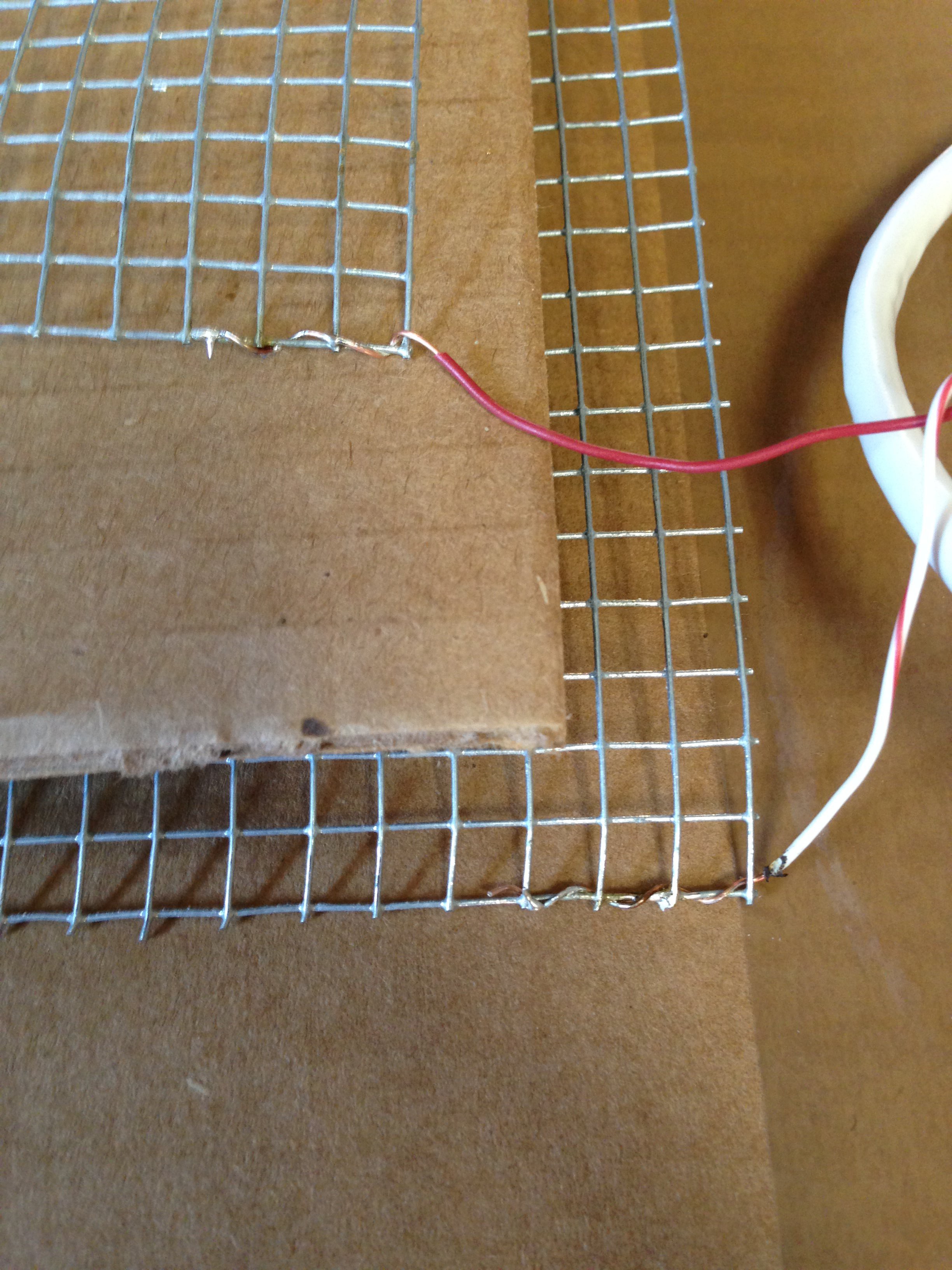

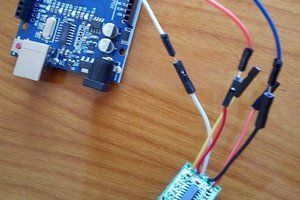

The backup plan is to use homemade analog sensors wired in parallel.

http://www.instructables.com/id/How-to-Make-a-Ridiculously-Cheap-Analog-Pressure-S/

hIOTron

hIOTron