Spaceship Menorah

A large blinky sculpture with 2142 RGB LEDs

A large blinky sculpture with 2142 RGB LEDs

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

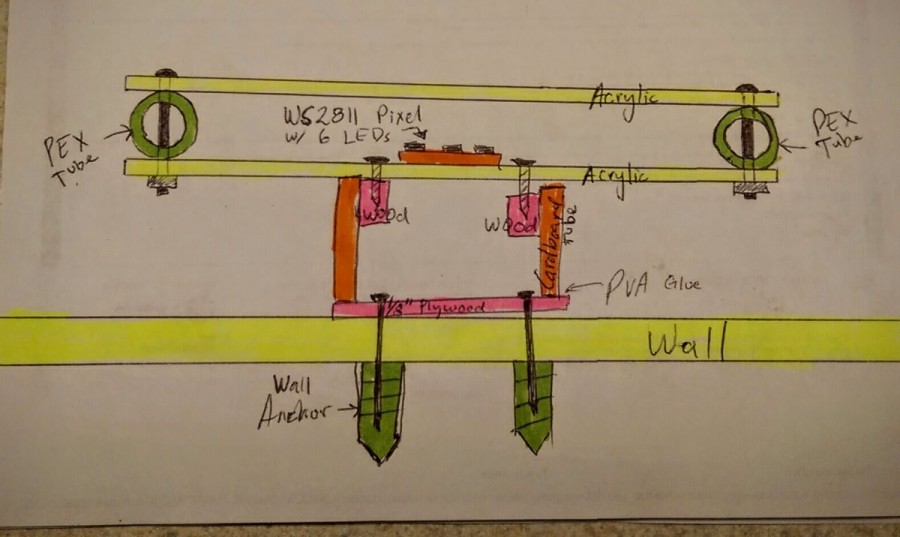

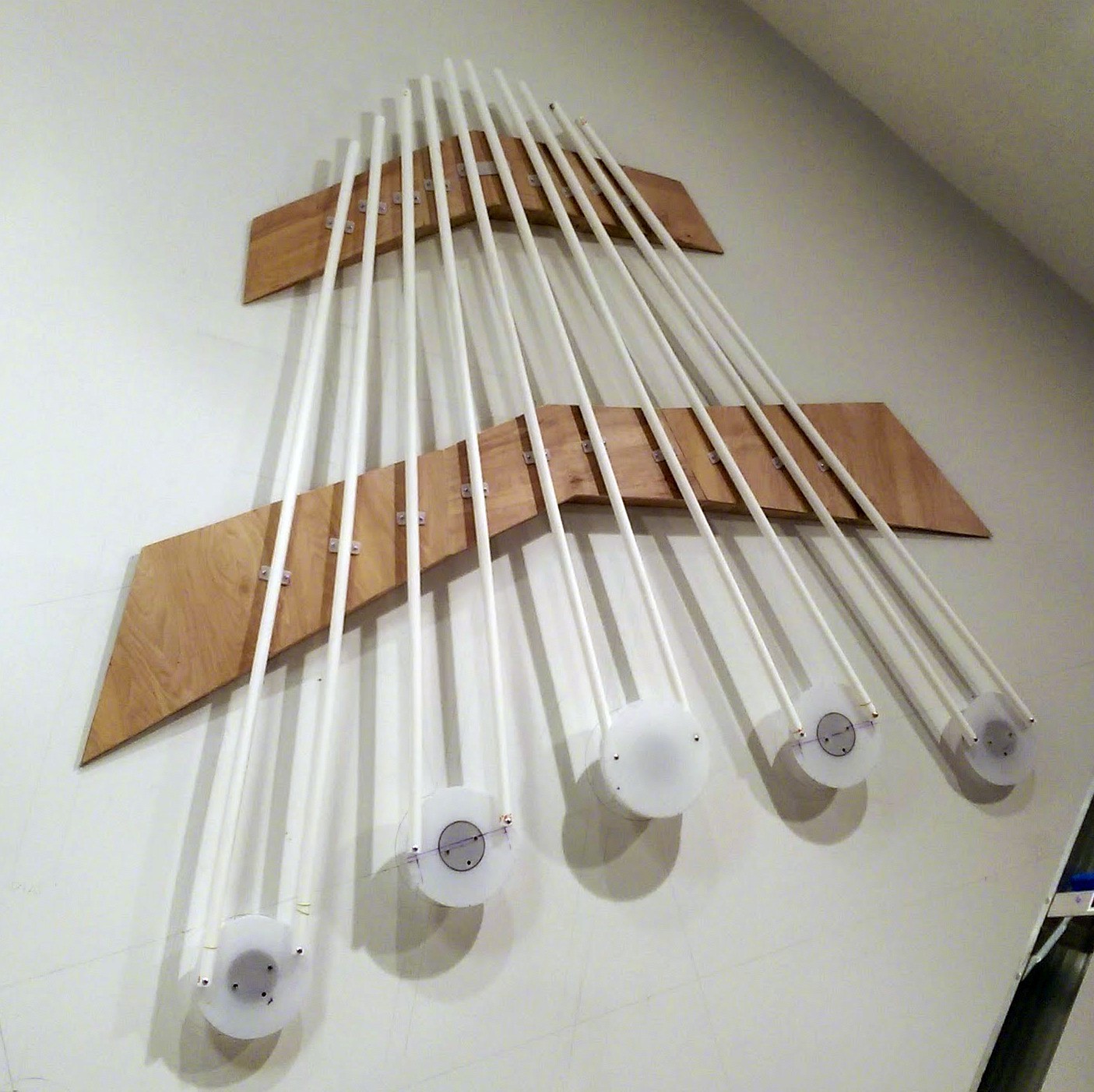

The PEX tubes are all mounted! I still have to install the WS2801 boards with the 6 LEDs, then put on the front acrylic discs. To do this, the hinge screws will need to come out sometime in the future, but right now I really want to see this thing light up. I also sketched a behind the scenes look at how the center discs are supported with sections of 3" cardboard shipping tubes.

I've made seven 4-conductor wires 52" to 60" in length, depending on their position. At one end of these wires is the waterproof connector for attaching to the control box. I've soldered the other end temporarily to 3-LED sections of RGB strips so I can test some code before the main event. Next: attach the ESP8266 in the control box and upload some test code!

I knew that the weak adhesive backing would not hold my strips in place for very long, so I peeled off some adhesive backing, stuck the strip in, and put some hot glue over the edge of the strip near the last LED. This worked well, but I did not take the time to scratch up the inside surface of the PEX tube to strengthen this glue joint. We'll see how long it lasts. For now, the LEDs seem to stay in the tubes just fine.

I had an incident when installing one of the shorter tubes: my machine screw caught on the (completely cool) hot glue insulating the wire ends of a strip. Because I was using a powered screwdriver, it tore the other end of the strip free from the hot glue and started wrapping around the glue-contaminated screw. Luckily i don't think it ruined the strip (I will test it to make sure). So I learned something about threads touching cooled hot glue: My glue has a tendency to catch and become one with a turning screw if allowed to press against it.

I decided on colors for the wall: Semi-gloss "Campfire Ash" paint for the background. It was supposed to be a light gray color. I think the mixing machine at Home Depot was a little out of tolerance, because I can sense a hint of sage green color, but it's mostly gray. For the tube supports, I went with a color I had on hand: MEGA BLUE! It's almost the same color as blue painter's tape. Hopefully the semi-gloss paint background will reflect some of the light coming from the PEX tubes when this thing is operational.

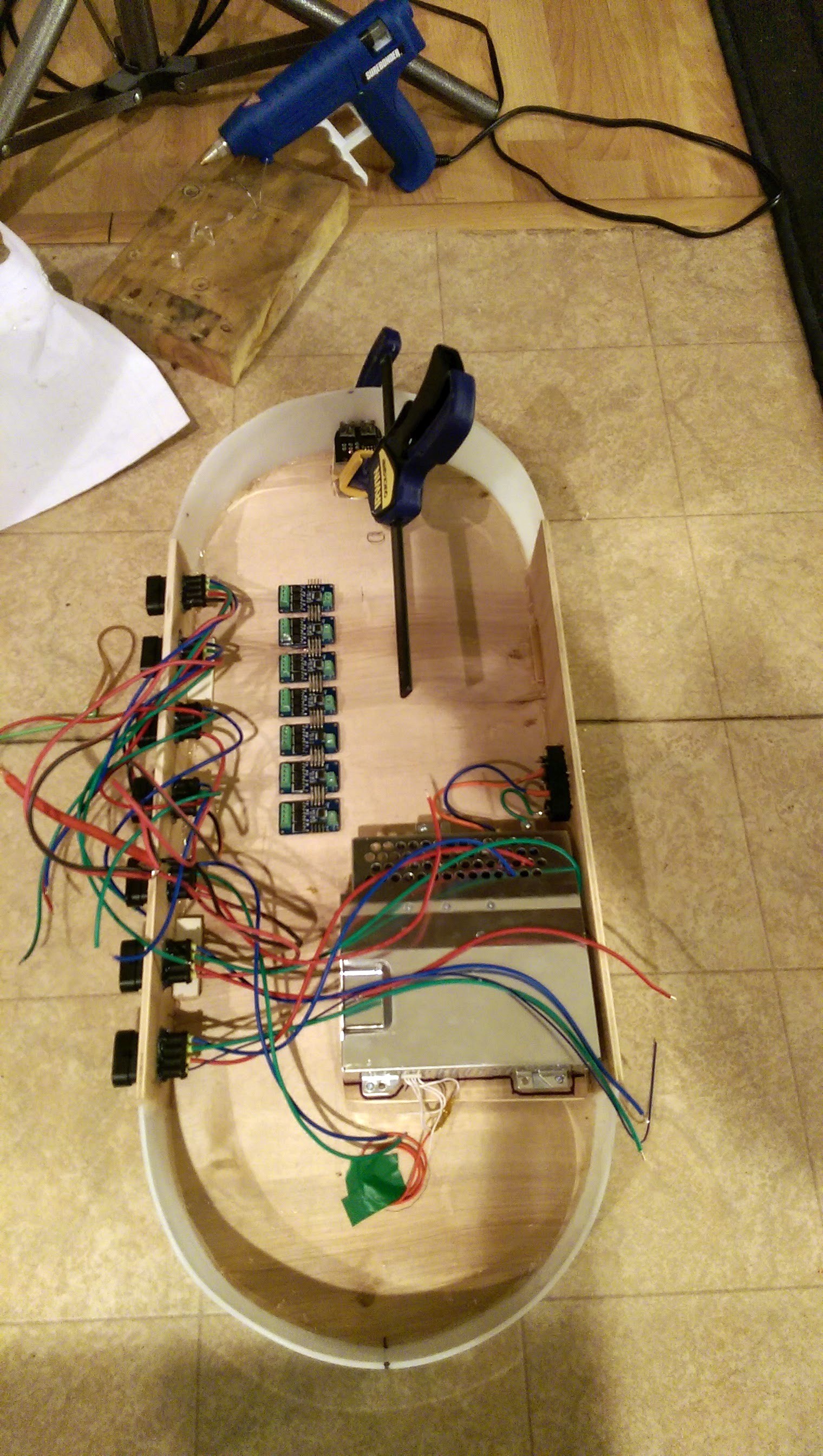

Great Scott made a great video about repurposing an old PS3 power supply. In addition to being a convenient form factor for my project, it provides two voltages- 5V at 3A and 12V at 32A. I've abandoned my idea of using 3 power supplies in favor of using one SUPER power supply that I believe will be more robust and reliable. I will be connecting the 5V to a AMS1117 3.3V linear regulator to power the ESP8266. I'll connect some right angle banana plugs to the 12V terminals and use all 32A of the output to drive the LEDs. I decided to use the thin 1/4" underlayment plywood + two bent pieces of acrylic + a bunch of hot glue + some wood glue to build the LED driver enclosure.

After this photo was taken, I've added the front panel which connects via two 7/16" wood dowels. I've also added two small 12v fans right next to the PS3 power supply.

This week, I noticed a new kickstarter project called LongPixel. Basically it's the same driver as what I have in this project, except it uses a WS2801 instead of the P9813 chip. It's good to know that if my cheaper boards don't work for some reason, the guys at Maniacal Labs have my back.

Designing the supports for the round acrylic tube mounts was a challenge. My first thought was to use a ~2.5 X 12" piece of of acrylic and bend it four times, making it a square tube. This would have worked, but I have not built an acrylic bender yet. Instead I cut up and reused some 3" heavy cardboard tubes that were used in rolls of large format printer paper. This way I could use wood glue to attach plywood to the bottom and glue pieces of wood to the sides for holding screws. This worked well, and now I have 3 large supports and 2 small supports. The remaining two acrylic discs do not get supports, they will be mounted on a thin 1/4" disc of plywood, close to the wall.

I picked up 28 1-1/4" machine screws and began attaching my PEX tubes to the discs. They are only on there temporarily in the photo because I still need to take them off to paint the supports and paint over the lines on the wall. To attach the tubes to the wood, I cut a bunch of small 3/4" X 2" rectangles of acrylic and roughed up the front surface on the belt sander. When it was time to attach the PEX tubes, I already had one end screwed to the support, placed my acrylic rectangle, and marked spots to drill the holes. After drilling and screwing with some 1/2" sheet metal screws, I used a dremel cutoff wheel to score some lines in the back side of the PEX tubing so hot glue could grip it. This worked well because the hot glue cooled quickly, minimizing the time I had to stand on the ladder holding each tube in place. The next step is to build one more support for the bottom third of the sculpture. When this is in place, I will take the tubes off and paint the wall and supports.

Two sets of PEX supports complete, with banana for scale.

I've already put the top support on the wall. For the center section, I found a stud to put some screws into. The left and right pieces were more tricky. I needed to make a wedge shaped piece of wood that could be screwed to the wall at just the right position to match the sloped plywood. To accomplish this, I put a ball of plumbers putty close to where I thought the support would be, then smooshed it against the wall to make the wedge shape that the wood needed to be.

I purchased and started building with a 4' x 8' x 1/8" 3-ply piece of plywood normally used for floor underlayment. At ~$11 it was affordable, but I have gotten several small splinters in my fingers while working with it. I am cutting it with a hand saw, then sanding it with a belt sander. So far I have cut and glued together 14 pieces for the two supports that will be above the circular joints. I will be cutting at least seven more pieces for the support below the joints.

I have cut 14 acrylic circles: qty= 8 at 7.5", 4 at 8" and 2 at 8.5". These will hide the PEX joints and diffuse light from the WS2811 6-LED modules. I shopped on eBay and purchased qty=15 200mm pieces of 6mm brass tubing for cutting standoffs at different lengths. I plan on putting long wood screws through these to provide support for the acrylic discs.

Since this is a large thing to hang on a wall, I am considering breaking it up into smaller components that can be hung separately. To enhance the 3D look of the sculpture, I am considering mounting it to pieces of thin plywood that can pop out from the wall a few inches. Idea: drill two concentric holes through the back of the PEX tube, perpendicular to its axis. Place a small 1-2" piece of wood beneath the tube, drill a parallel hole though the wood, and attach the two with some steel wire. The wire will be behind the LEDs, so it will not block the light. The block of wood can be glued to either plywood or a supporting piece of wood that runs perpendicular to the 14 PEX tubes.

The white paper under the power supplies is the approximate shape in which I would like to build the power / controller box.

The white paper under the power supplies is the approximate shape in which I would like to build the power / controller box.

Two weeks ago I drew my empty wall in SketchUp. I decided to keep going and model the entire room to give a feeling of how the sculpture would look in the space. Lots of work with a tape measure getting dimensions of doors, windows, stairs, etc.

Last week I drew the Spaceship Menorah in Tinkercad. I found it difficult to change the length of the PEX tubes once I had rotated them in the model. SketchUp has a better way to do this with the push/pull tool.

Yesterday I exported the tinkercad model to an .STL file. Then I imported it into SketchUp using a trial version of a SketchUp plugin. It lets you do 30 imports before you need to pay for it. It appeared in my SketchUp model but it was about 140 feet tall! After scaling it down, I slapped it on my virtual wall. It looked good!

Then I used SketchUp's dimension tool to measure the lengths of the PEX pieces that I modeled. Not all of them added up to 98 inches (~2.5m), so I made some corrections. Then I took some bamboo skewers (for grilling kebabs) and cut them to a ~10 inch scale version of the sculpture. I mounted it on a piece of scrap foamboard. I used coins in place of the acrylic discs.

Create an account to leave a comment. Already have an account? Log In.

The P9813 drivers are talking to the WeMos D1 Mini just fine without level conversion.

Did you ever get this working? I'm working on LED project using the same driver and Wemos D1 mini but overlooked the fact that the Wemos is 3V3 logic while the P9813 driver I believe requires 5V logic.

Just wondering if you got around this somehow. I have order some logic level shifters but it sets back my project.

While waiting I'm going to try some of the diode and resistor level shifters.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

Steve Pomeroy

Steve Pomeroy

TwystNeko

TwystNeko

Colin Russell-Conway

Colin Russell-Conway

Quinn

Quinn

Certainly! Crafting an effective CV is crucial for career success. Assignment Helper offers top-notch <a href="https://cvwritinginc.com/">professional cv writing services</a>, ensuring your resume stands out in a competitive job market. Our expert writers understand the nuances of various industries and tailor your CV to highlight your strengths, skills, and achievements. We emphasize a professional and polished presentation, optimizing your chances of landing interviews. With a commitment to quality and a deep understanding of the American job market, Assignment Helper is your trusted partner in building a compelling CV that showcases your unique value. Secure your professional future with our specialized CV writing services in the USA.