To do optics experiments you need a way to hold the components (lenses, lasers, gratings, and whatnot) at a particular height and particular orientation. For example, a laser holder will need a way to adjust the "aim" of the laser up/down and left/right so that the beam lines up with the optical axis of the other components.

Commercial holders are usually complex and expensive.

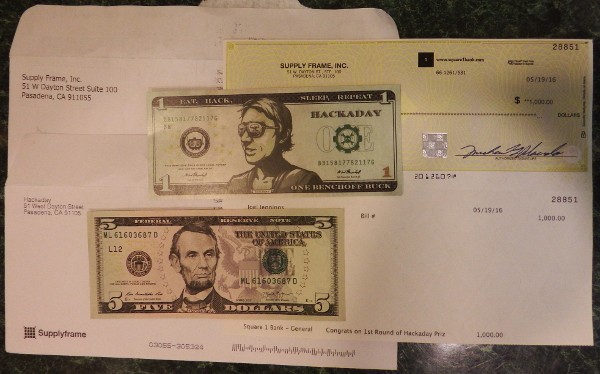

| If you have access to a laser cutter, you can make a pretty decent optics kit for around $50 which lets you make a wide variety of optical experiments, from basic principles all the way through college-level experiments. (Click any image for more detail.) |

|

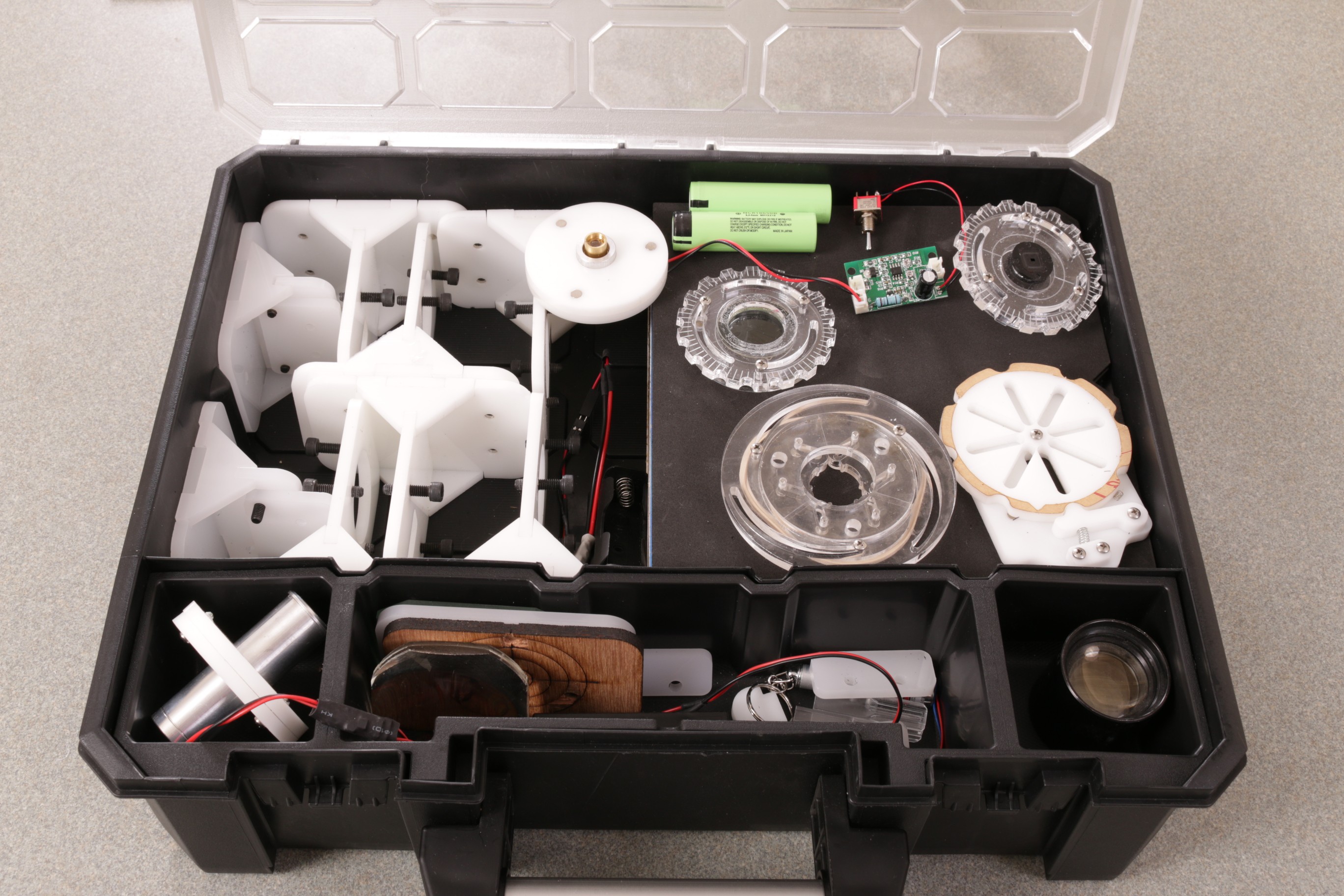

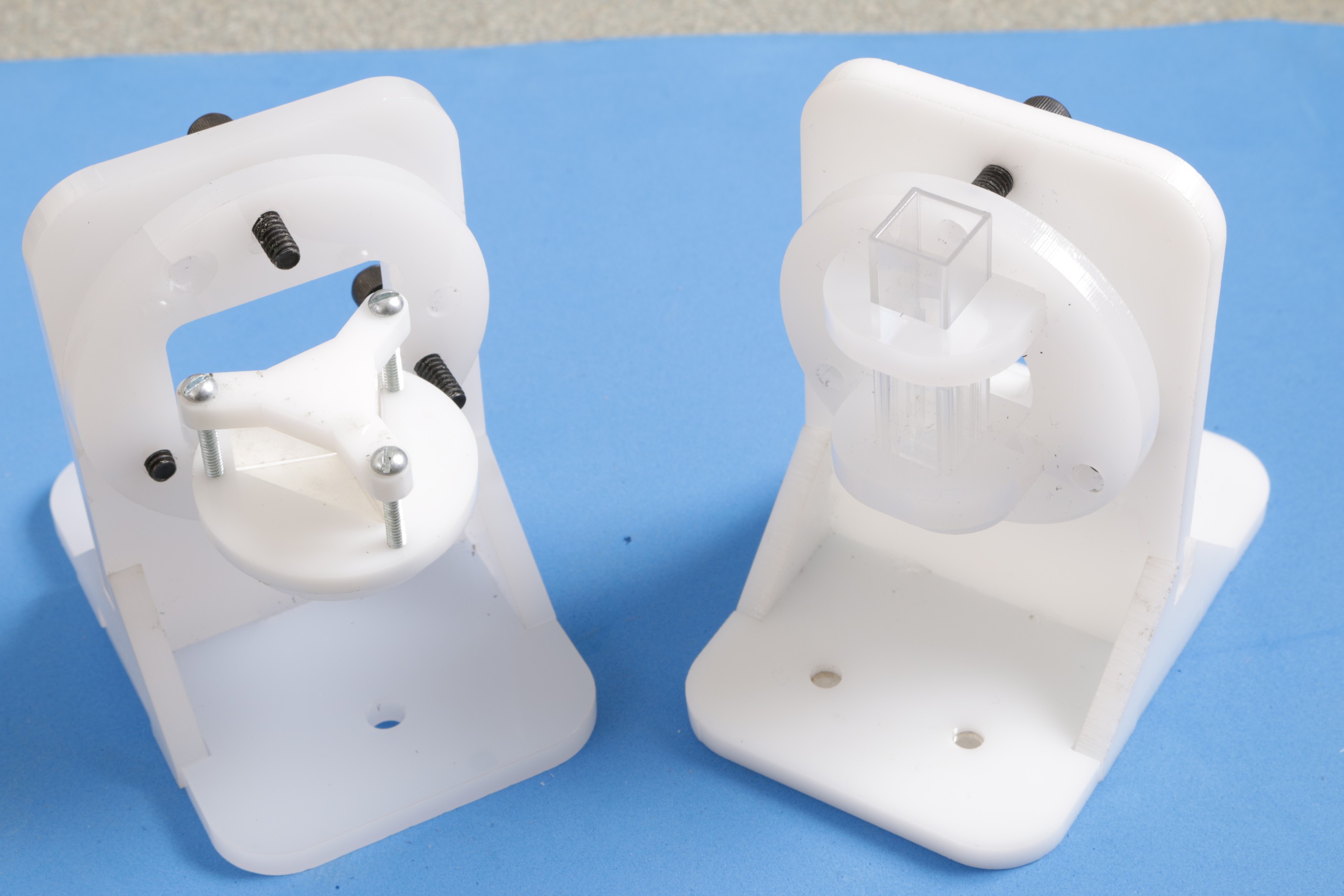

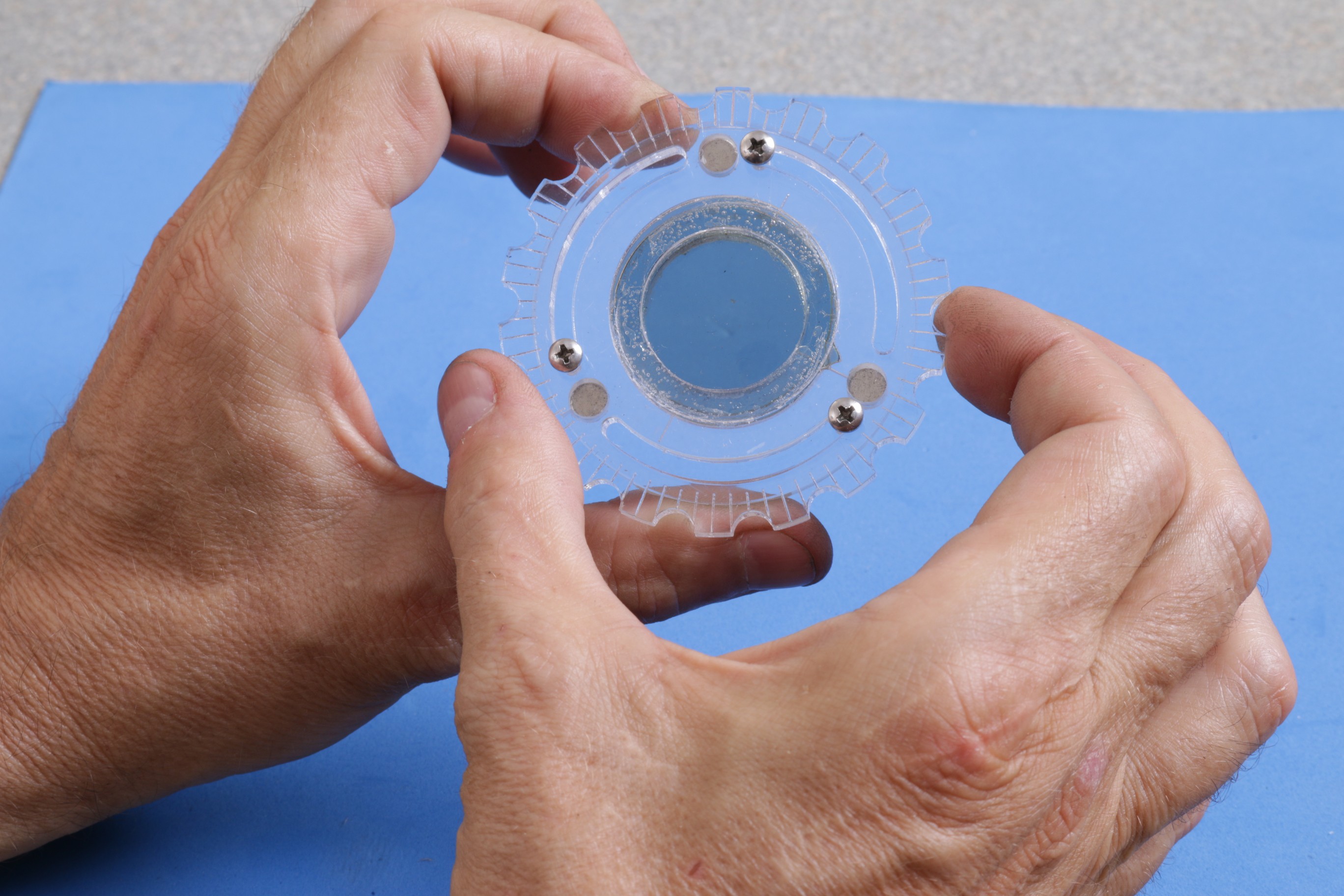

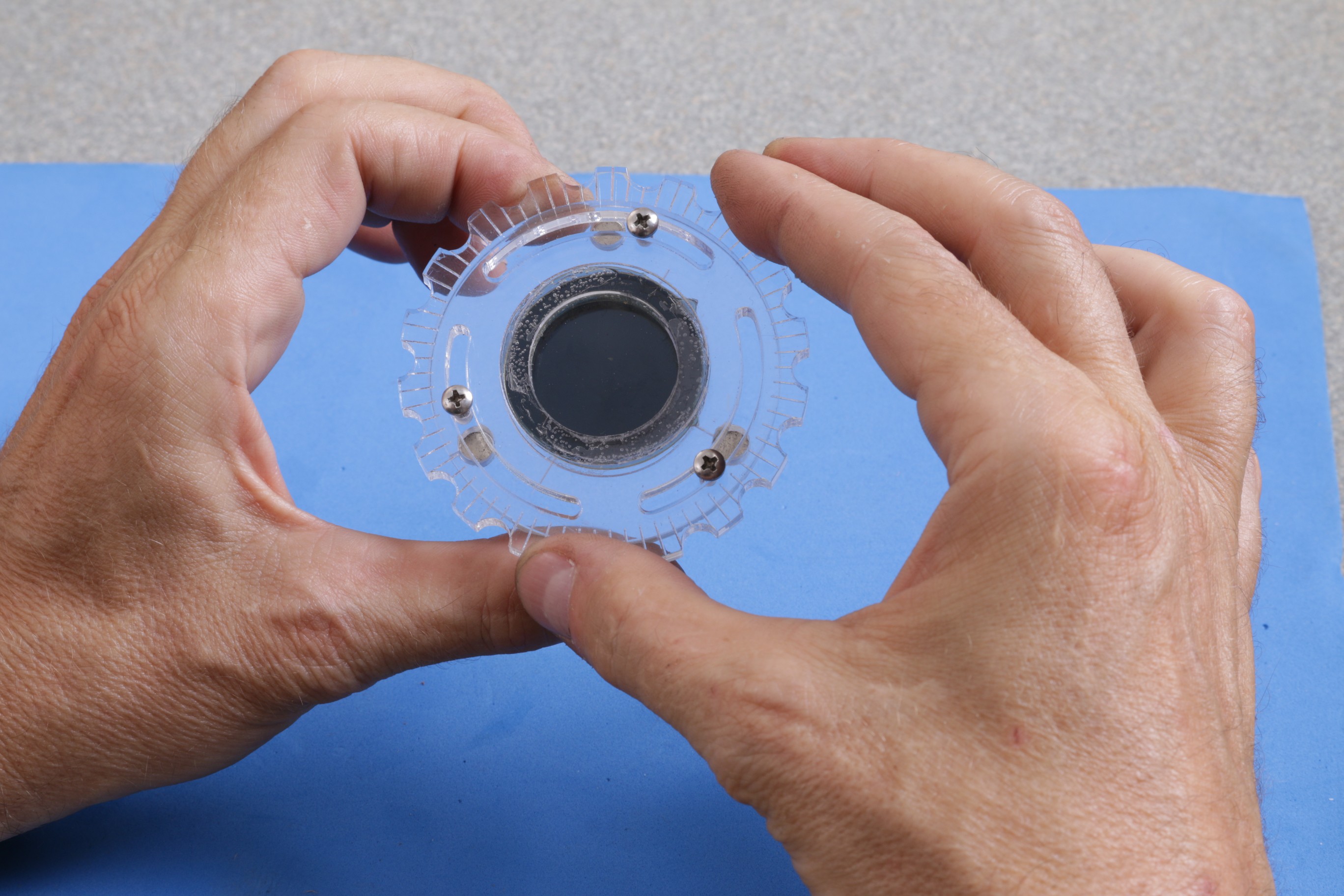

| The kit uses holders with steel screws that mate to rings with embedded magnets. When you need a specific component, just grab a ring and a holder and *snap* - you've have a ready made optical holder. The rings can be "aimed" up/down left/right by adjusting the screws, so if the ring has a laser or mirror, it's easy to align it to the optical axis. |

|

| You can design your own rings to mount the optics you have, and the project has designs that handle common components: lasers, lenses, mirrors, and so on. |

|

| For example, the clamp holder will hold flat optics such as filters, polarizers, film, or glass plates. You can adjust the height as needed to put the plate in the optical axis. |

|

Having made the kit, collecting lenses and other components is easy.

Glass lenses are pretty-much everywhere, and are easy to come by. You can often find great deals on Craigslist, yard sales, eBay, and surplus houses - often for free.

My friends and family know that I'm collecting lenses, so everyone keeps giving me their old camcorders, slide projectors, telescopes, and binoculars. I saw the barrels apart on the bandsaw and use the lenses in my kit.

I'm now drowning in lenses.

| So in an attempt to tame the chaos, I got foam sheets from the art store, lasercut an array of lens "wells", and glued them to a thin piece of posterboard. I added hardboard sheets top and bottom in the manner of book covers. A rubber band keeps everything together. |

|

| The result is a "lens portfolio", a sort of shelf system for storage. Each shelf has posterboard (thin cardboard) backing for support, a thin foam floor, a thick sheet with lasercut holes, and a thin canopy sheet. You can store a surprising number of lenses this way. Also, when the shelves are laid out it's very easy to browse and select the right lens. Much easier than rooting around in a box of lenses! |

|

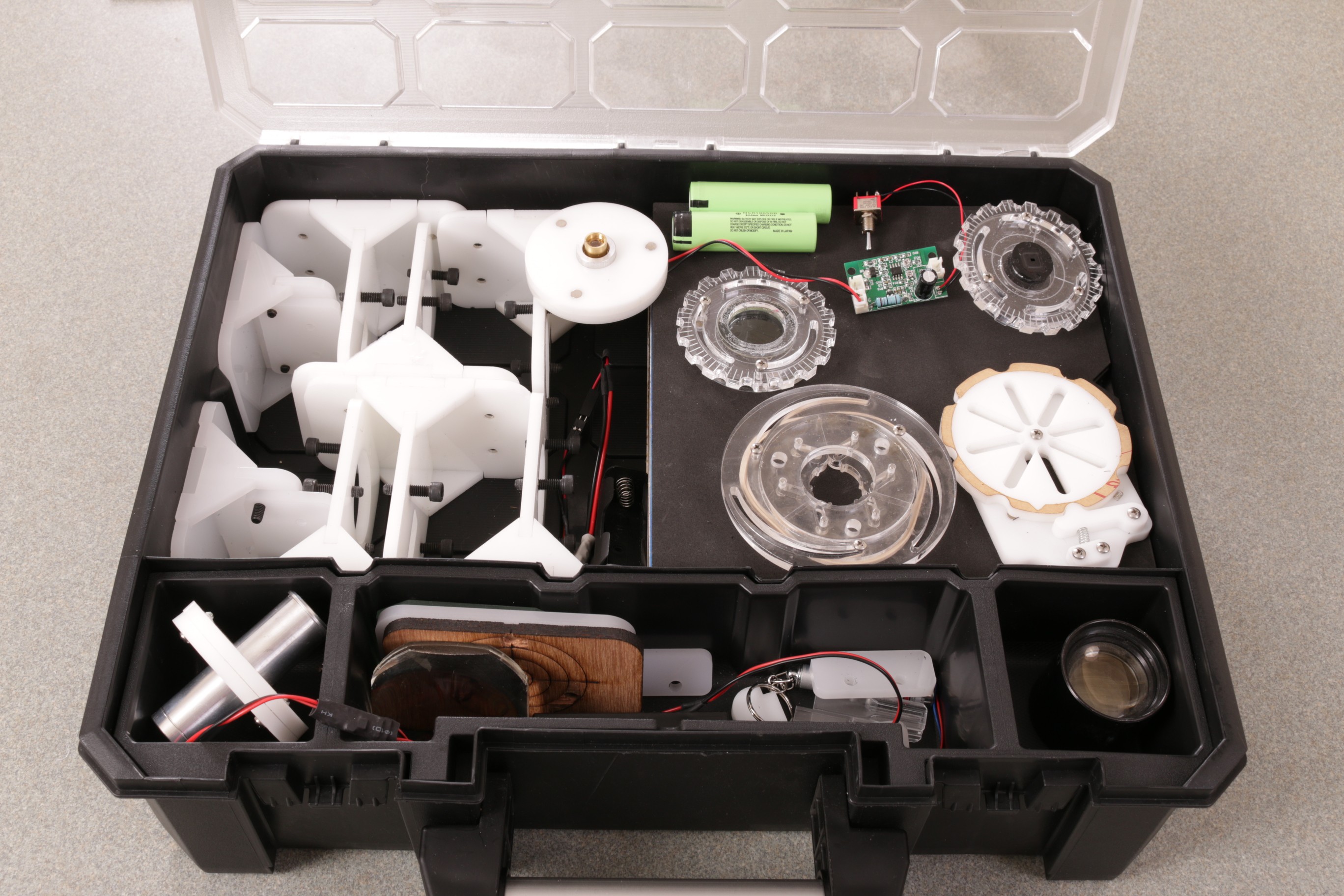

| For about $15 you can get a Husky branded parts organizer and make a lens portfolio that fits snugly inside the case. (Husky 16-1/2 in. 8-Bin Deep Pro Organizer, Black, Model # 211102. Available at Home Depot.) |

|

| Ring holders and clamp holders nest together alongside the folio. Extra storage bays in the front (near the handle) can hold non-flat items and extra hardware as needed. |

|

| And the entire kit can be carried around or packed for storage. The holders won't get mixed or bounce around within the case, and the optics are protected in foam wells. |

|

Although inexpensive, the system can be used for a variety of interesting and subtle optical setups, such as:

- Laser Interferometry

- Design and development of different lens systems

- Measure the speed of light

- Faraday effect

- Measurements of lens type and focal point

- Measuring specific rotation of organic substances

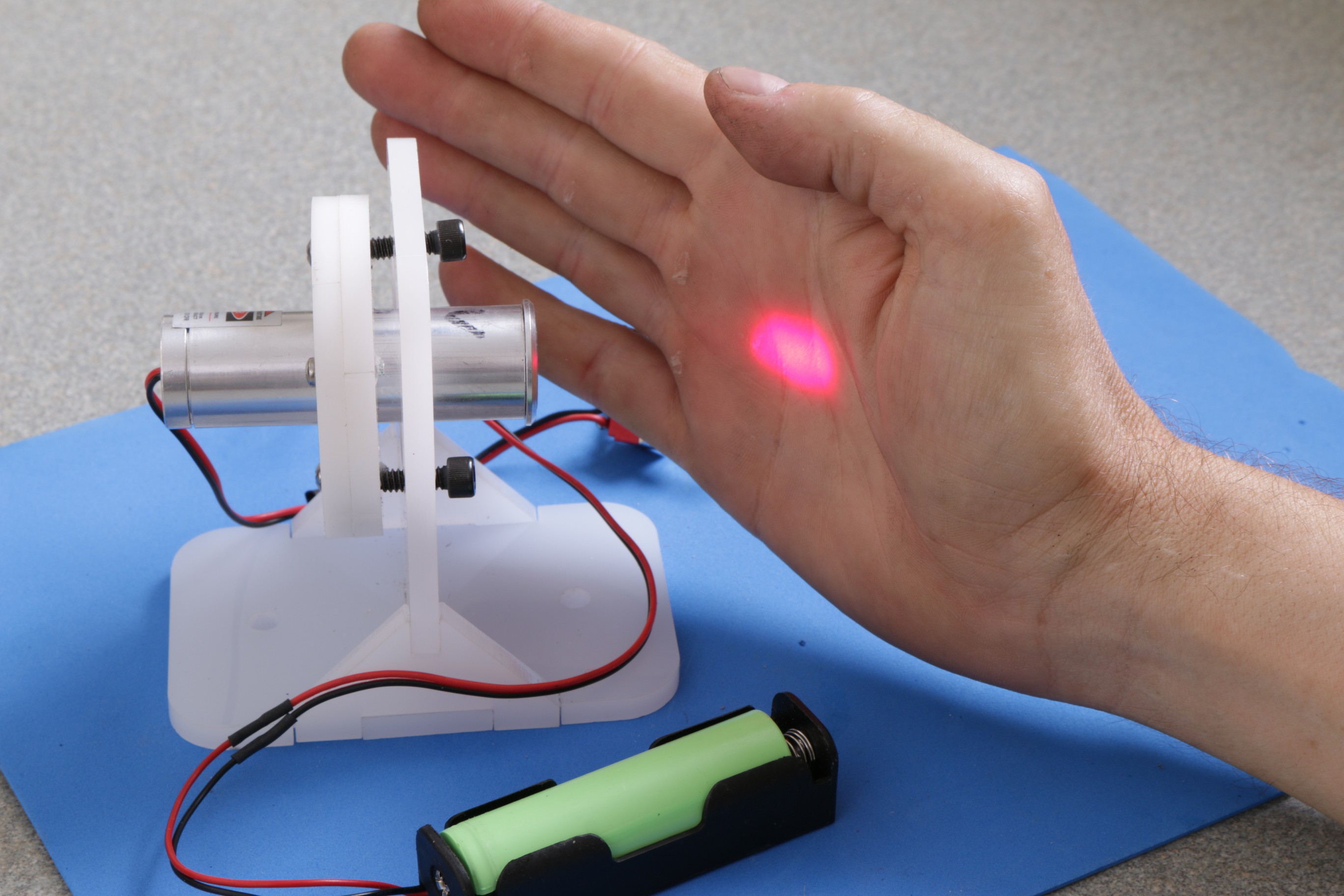

| For example, here's the system set up as an interferometer. This works well enough even on a wooden table in a noisy room - it's easy to get interference fringes, and takes about 5 minutes to set up and get everything aligned. |

|

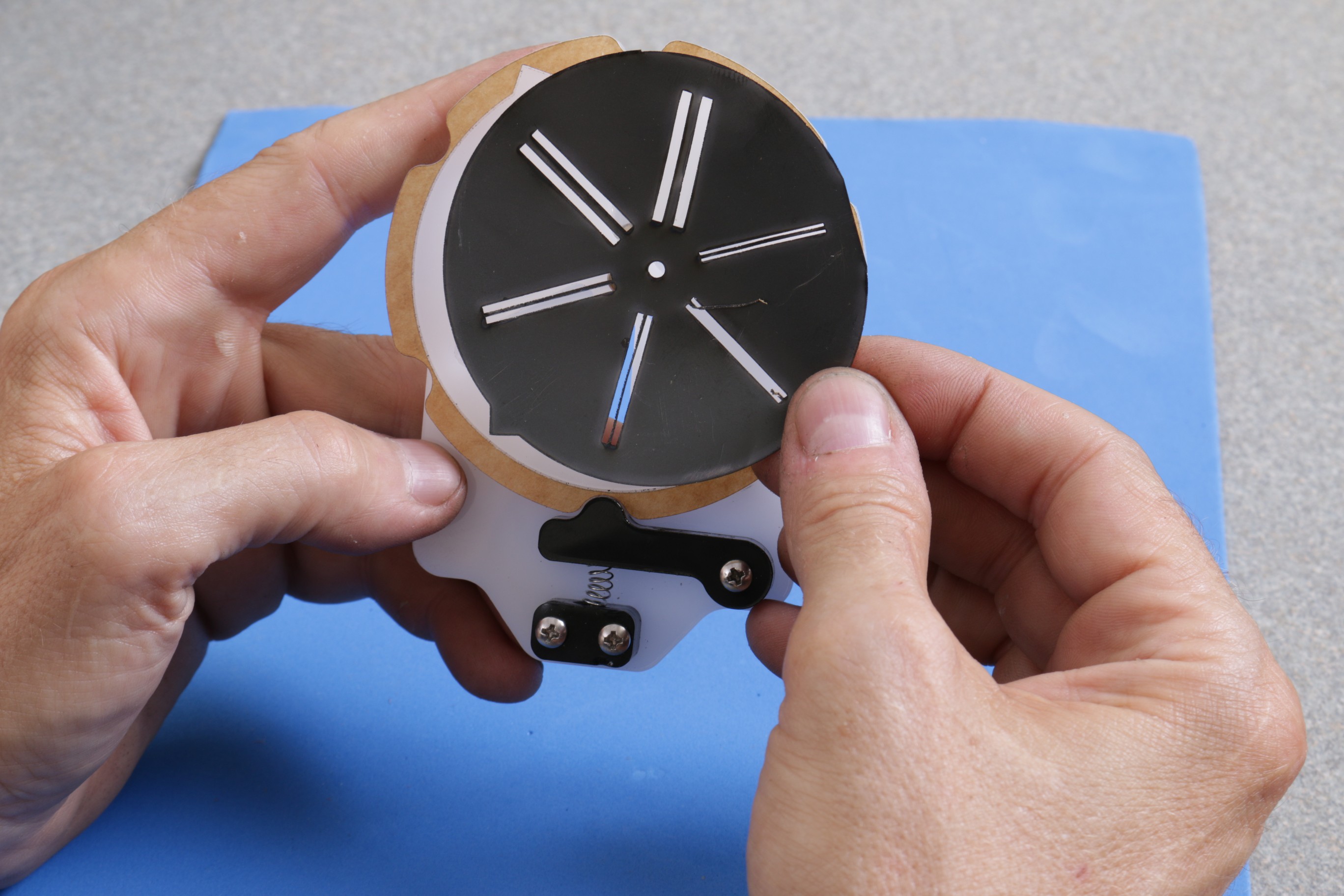

| If one of the mirrors is mounted on a piezoelectric disk, adjusting the voltage on the disk will cause the fringes to move in accordance with the distance. (This mirror has a magnet glued to it's back, and an unglued magnet on the back of the piezo keeps the mirror in place.) Our demo video shows the fringes... |

Peter Walsh

Peter Walsh

andrew.powell

andrew.powell

eBender

eBender

Lixie Labs

Lixie Labs

Dan Levine

Dan Levine

Looks a lot like ramanPi when it first started............... https://hackaday.io/project/1279-ramanpi-raman-spectrometer/log/3108-3d-printed-parts-so-far I mentioned a while back that I'd like to turn that phase of the project into an optical lego set.... You beat me to it... ;) Congrats!