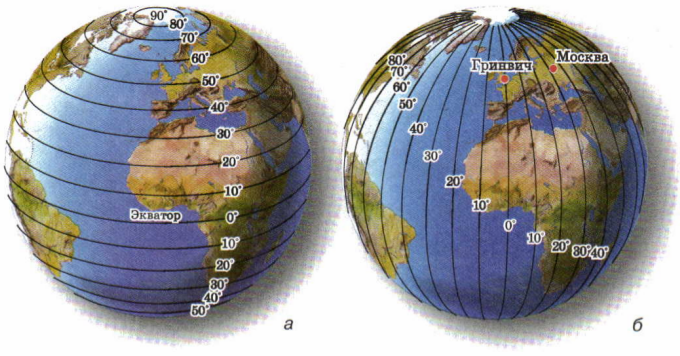

Cavers are one of the few under-funded groups of people who still do mapping and surveying using old civil engineering tools. In 2016 the most common tools for cave mapping are the notebook, tape measure, and Suunto tandem (compass and clino). Some groups have upgraded to using a DistoX which is a modified laser distance meter with compass and clino readings. And a few of those have upgraded to using a PDA (yes...they still sell these on eBay) or tablet for sketching the map.

A few groups of cavers have begun using LIDAR to map caves. But this costs around $1k per weekend to rent the equipment or $40k+ to purchase the equipment. This price range is far outside of the realm of local citizen scientists.

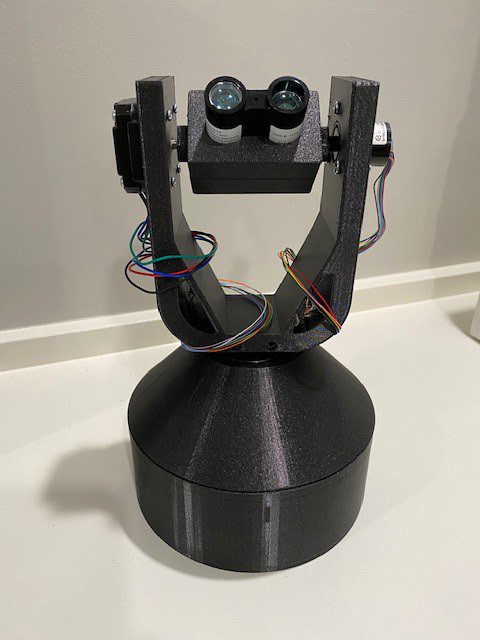

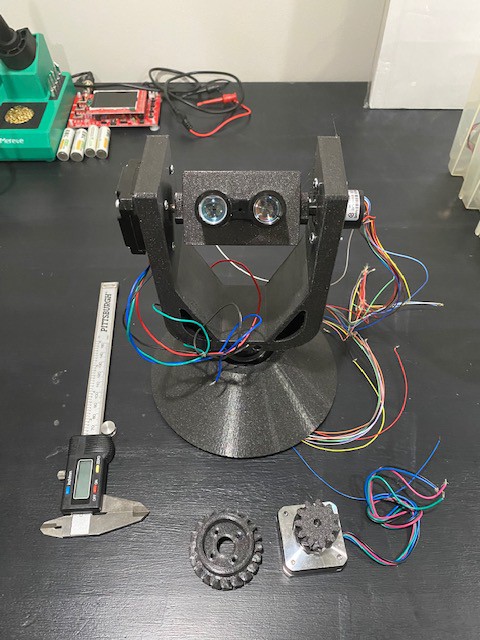

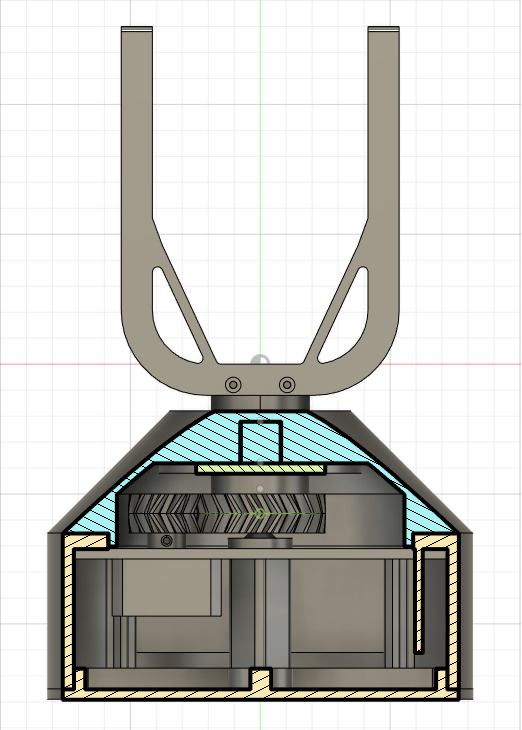

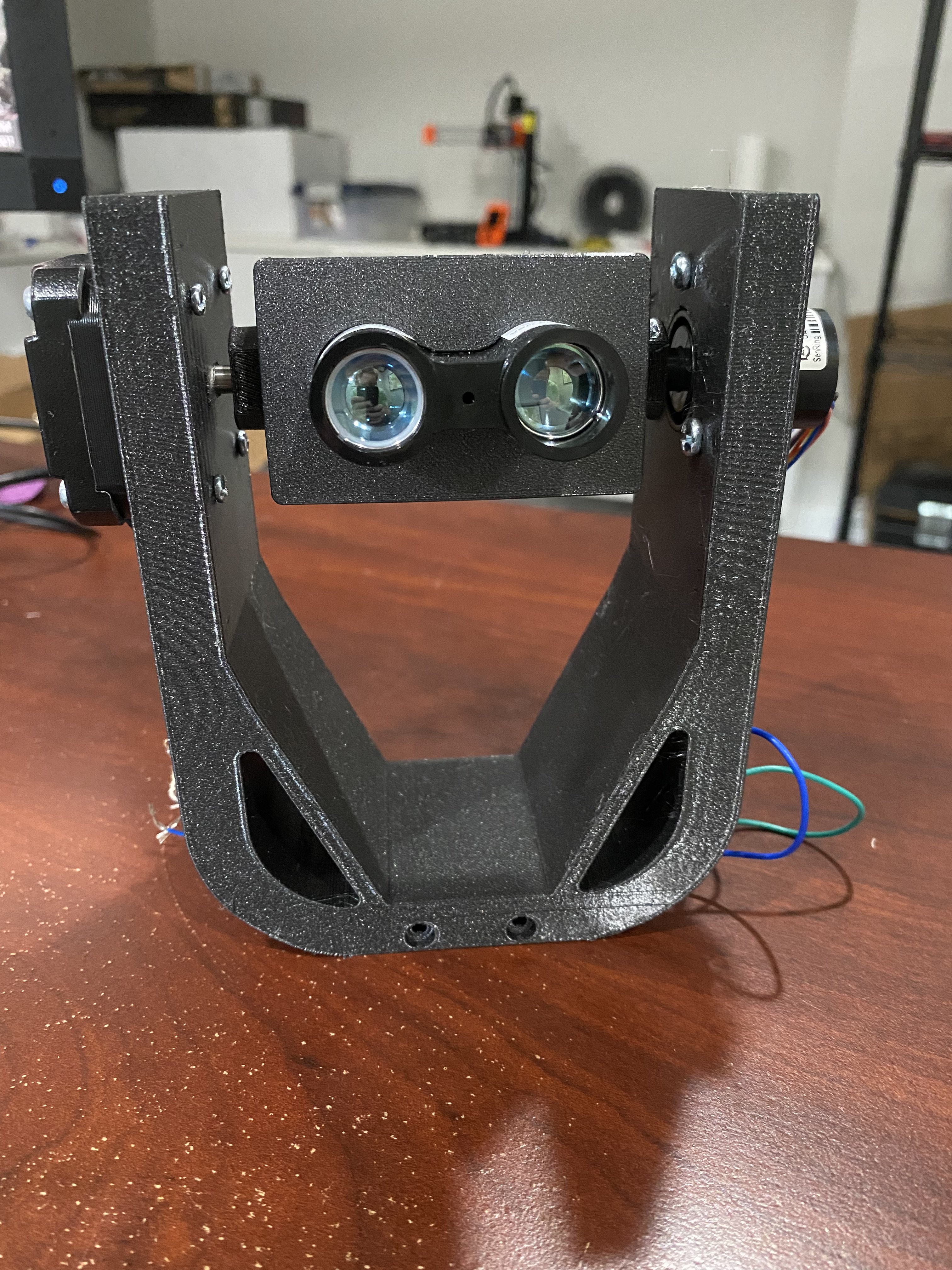

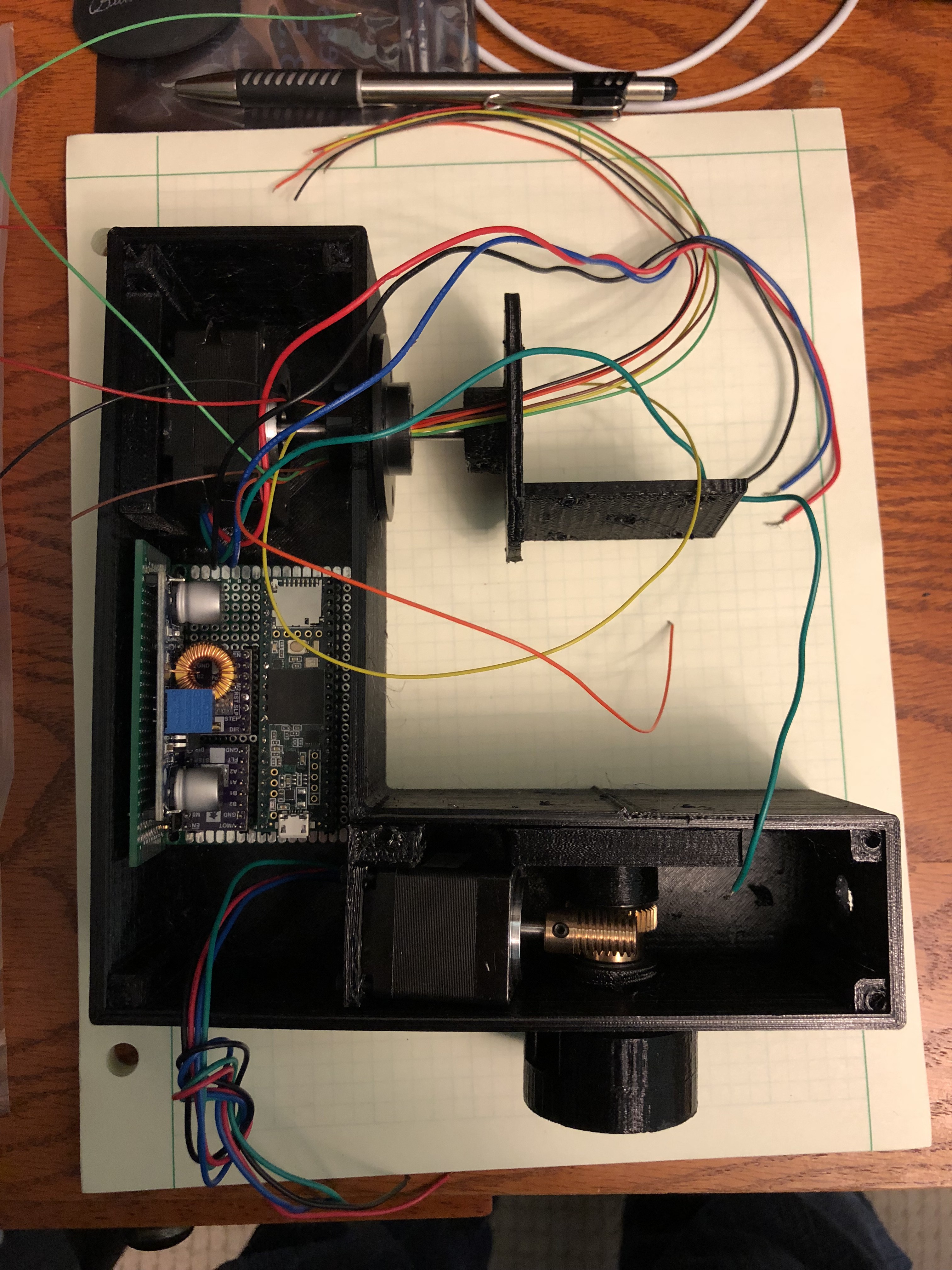

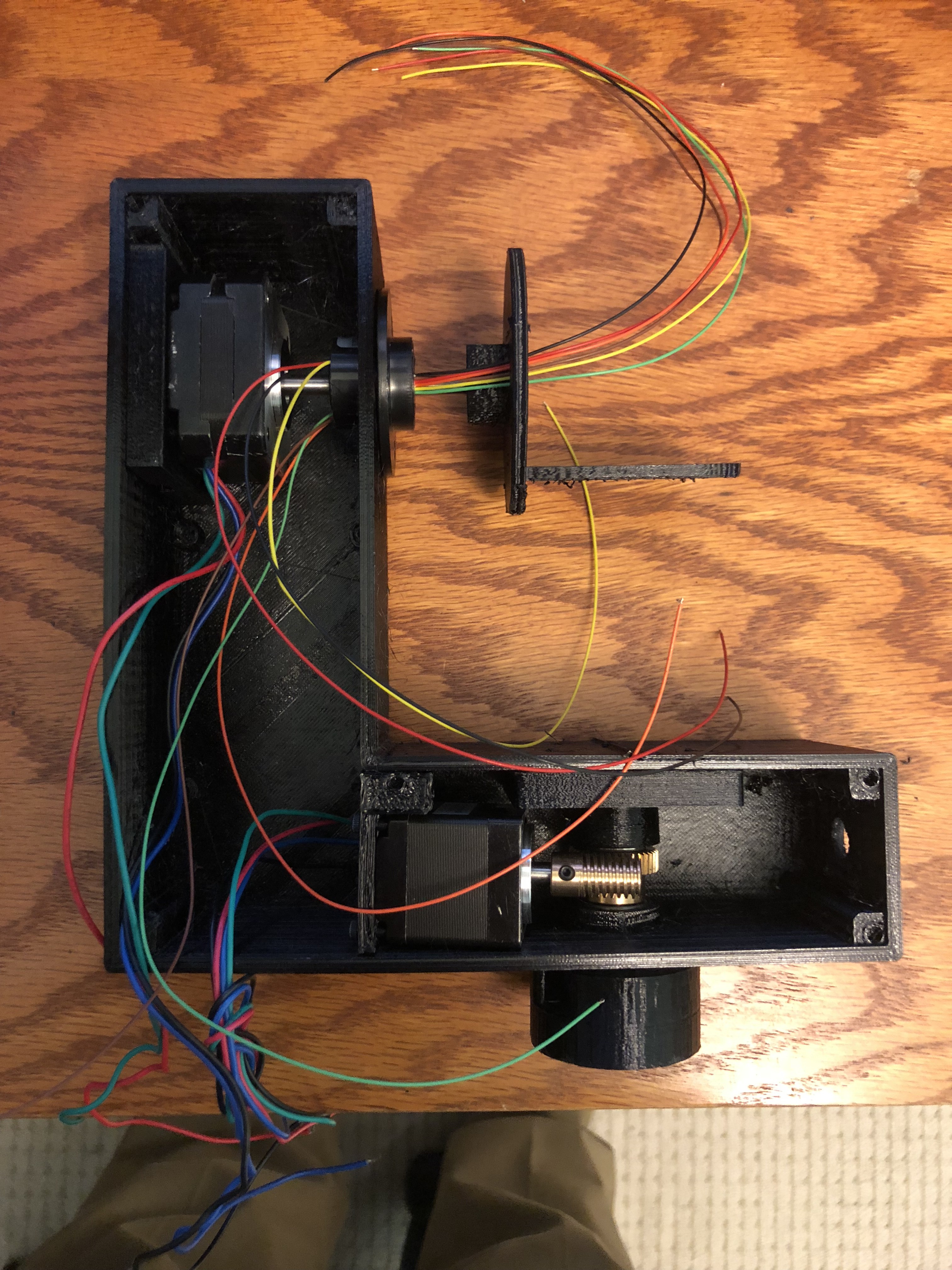

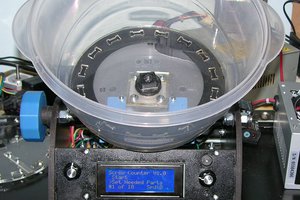

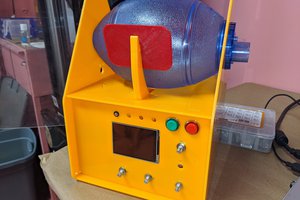

The idea for the low cost LIDAR Gimbal originated with the Lidar Lite v2. This module costs $115 and is capable of 500 readings/second. For a LIDAR which has a physical range of (270° / 2) x 360° (thanks to Alexander for the correction). It takes 48600 samples to capture a 1° scene. For 1° resolution it should take 1 minutes 37 seconds to make a capture. For a 0.5° resolution it should take 6 minutes and 30 seconds. (The SF-30B has been scrapped because the 10cm readings were not as accurate as I wanted, the sensor was damaged, and the lidarlite3 is much cheaper),

Options for Sensor Include:

| LIDAR-Lite 3 | |

| Price | $149 |

| Field of View | 0.2 deg? |

| Rate | 500hz |

| Accuracy | +/- 2.5cm |

| Resolution | |

| Range | 0 - 40m |

caver.adam

caver.adam

Douglas Miller

Douglas Miller

Will F.

Will F.

Quinn

Quinn

Daren Schwenke

Daren Schwenke

hello are you still working on the project? I am following your tutorial and i can't find the PCB file in your zip.file