Overview:

The idea of this project is to capture kinetic energy from a moving vehicle during coasting operations and convert it into electrical energy using the vehicle's existing alternator. This energy is to be stored in a user-removable 'battery' that can be used for secondary purposes (not re-applied on-vehicle).

How:

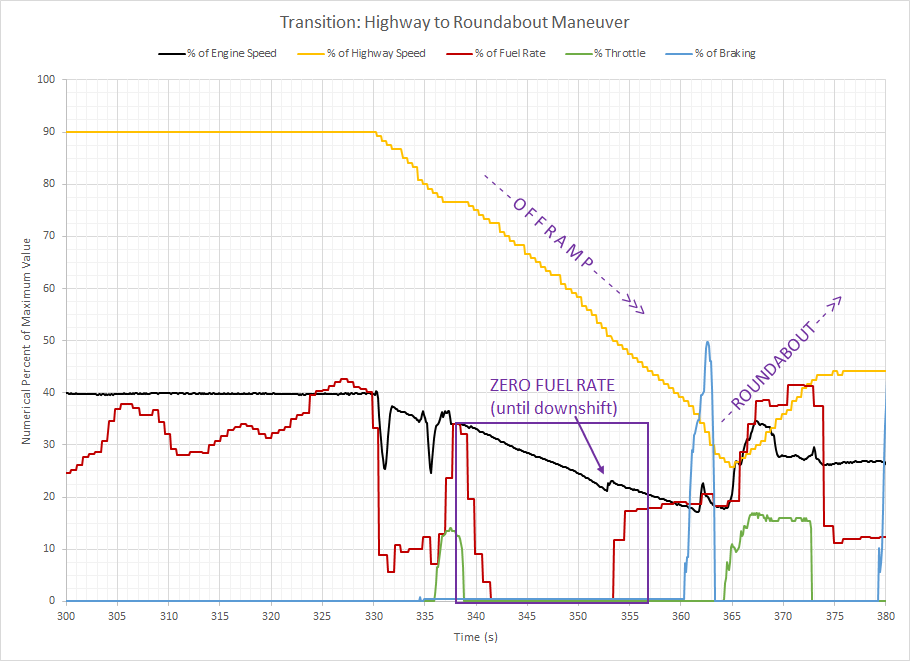

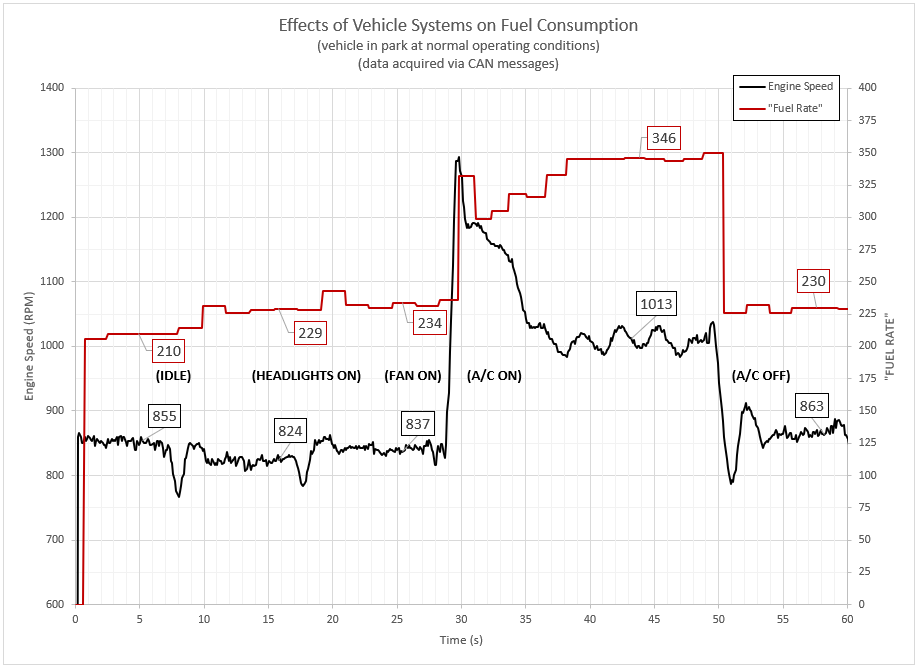

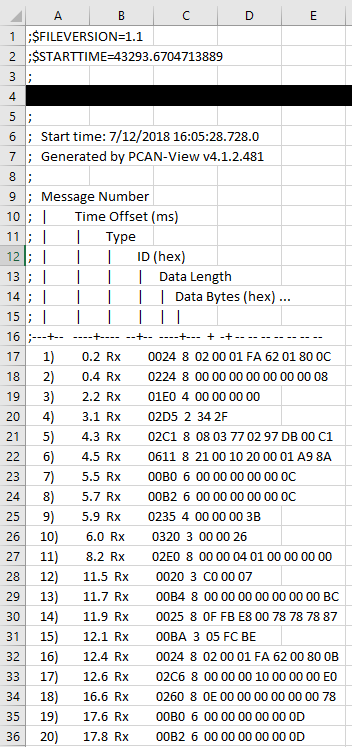

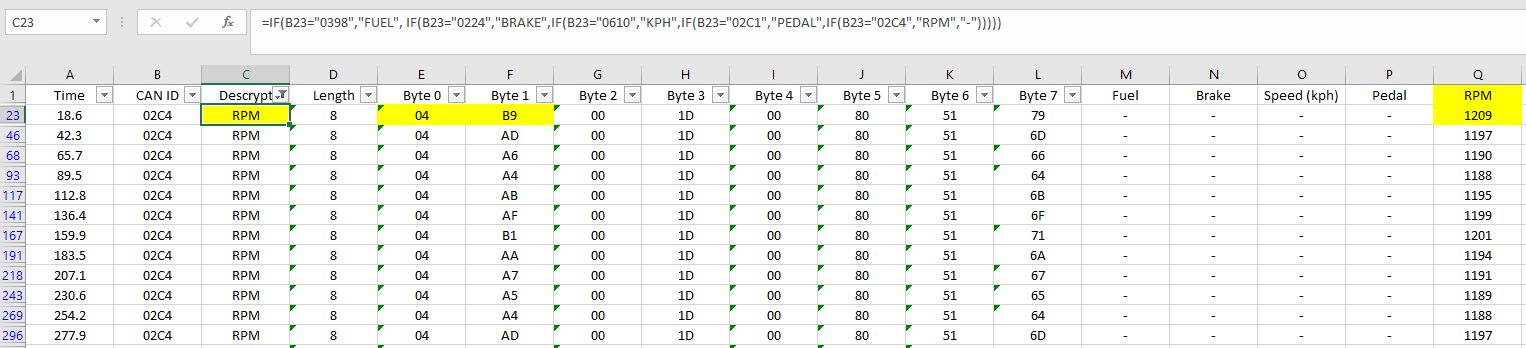

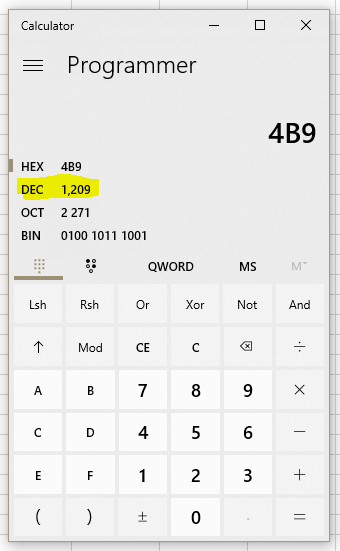

In example, your vehicle is cruising at highways speeds. At some point, you need to exit the highway (using a typical offramp). Instead of mechanical braking (converting your vehicle's kinetic energy into thermal energy), an onvehicle DC-DC converter is activated which captures electrical energy from the vehicle's alternator to the 'battery'. The logic is composed of an onboard CANbus monitor which is continuously monitoring the vehicle's fuel consumption rate, throttle input, brake input, and speed. The simplified algorithm considers these 4 inputs and decides if there is a 'near-zero' fuel consumption condition in which activating the DC-DC converter will affect the fuel consumption rate.

Testing:

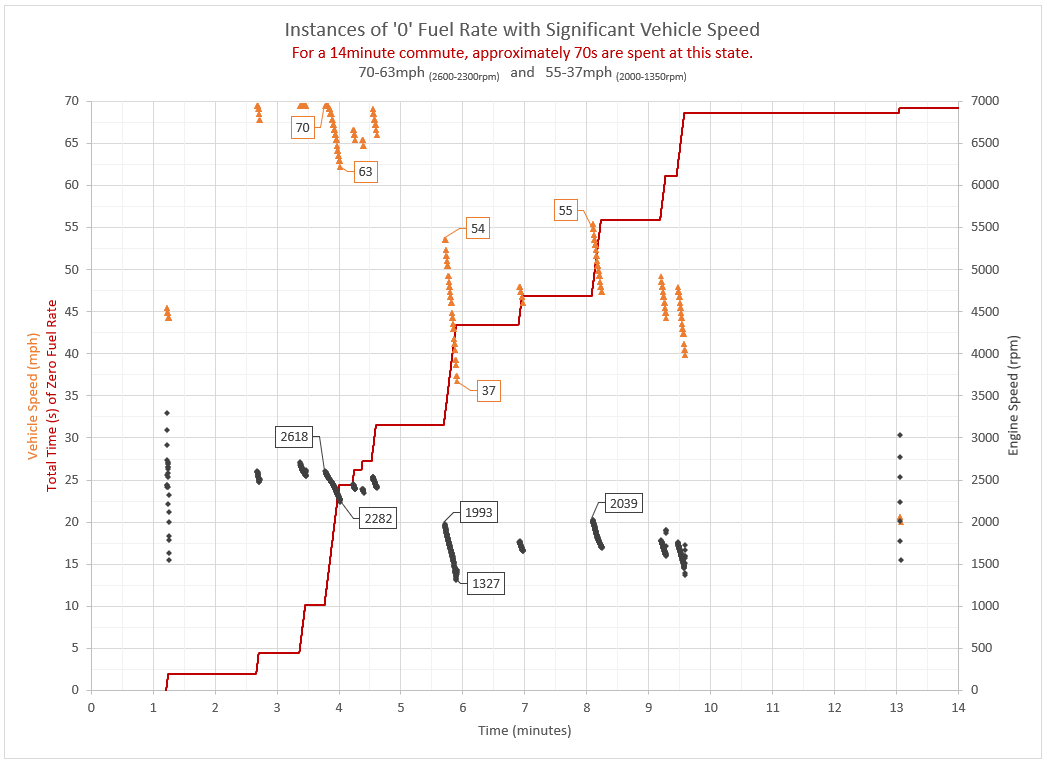

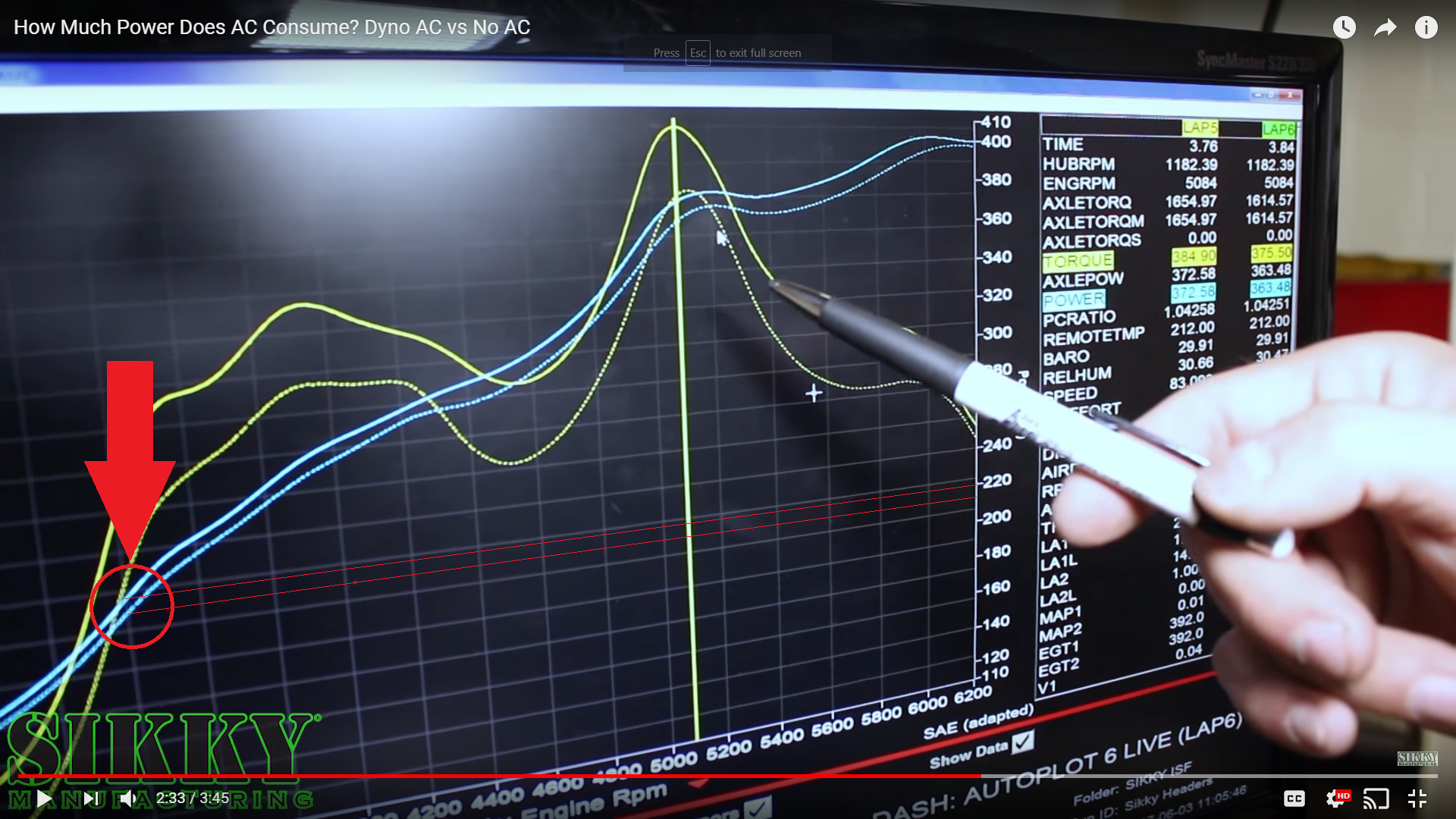

To simplify the project, I looked at the effects the Air Conditioner has on the fuel consumption rate. Since both the A/C and alternator are both belt-driven off of the auxiliary power output of the engine, the A/C appeared to be a good 'equivalent' loading method to simulate a DC-DC converter system (which I don't actually have), pulling somewhere between 5-10HP (3.7-7.5kW) at full load. After connecting to the vehicle CANbus, I took a typical commute route with the AC and HVAC fan on HIGH, recording a variety of parameters. On this typical commute, about 8% of the journey was in a reported 'zero' fuel consumption rate, always while coasting to a stop or turn. If the fuel consumption rate is real (from the CAN messages) - this means that the AC was delivering 'free' energy during these coasting situations.

Unknowns (for future investigation):

- Can the alternator actually output 'a lot' of current at low engine speeds? If so, at what rate?

- Is the 'zero' fuel consumption rate as reported by the CAN message real?

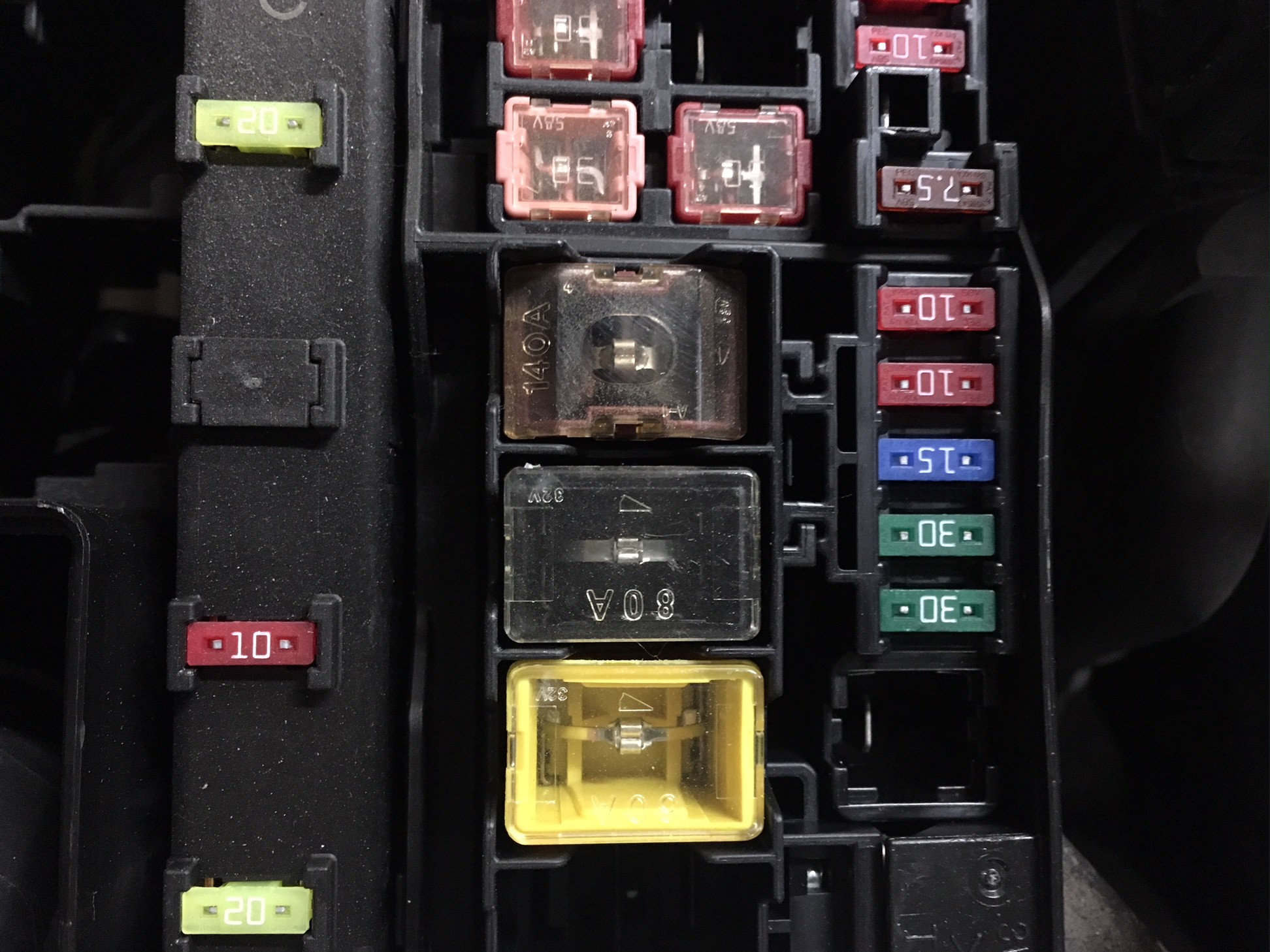

- Is there a 'battery' that can take the full charge rate of 140A from the alternator?

- Does this method work in warm as well as cold climates?

- What sort of cumulative damage does this loading cause to the alternator?

- At what load does the alternator 'not keep up' and instead, energy is drawn from the main battery?

Project Result:

- Yes - it is totally feasible and does offer significant energy reclamation opportunities (≃280Wh)

- No - it does not appear to be cost effective, as the electronics and battery would never pay for itself.

Michael

Michael

[skaarj]

[skaarj]

Olivier

Olivier

PJK

PJK

Alfonso Delgado Ollero

Alfonso Delgado Ollero