Backyard Woody Climbing Wall

What do you do when a pandemic hits, and your climbing gym closes? Why, make your own, of course.

What do you do when a pandemic hits, and your climbing gym closes? Why, make your own, of course.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

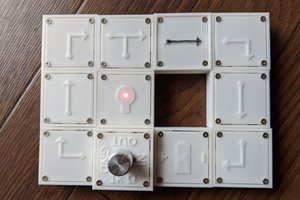

Imperial Specs for MoonBoard Panels.pdfMoonboard hole layout. We followed this pattern for our holes.Adobe Portable Document Format - 248.14 kB - 03/25/2020 at 11:34 |

|

|

SOLD -

1 - #1 climber moved out of the house.

2 - Our great climbing gym, Scrapyard Climbing Collective, in Holland, Michigan, is open again. We want to support them, and their walls are fantastic!

How do you move your backyard woodie?

1 - Post it on FB Marketplace or Craigslist

2 - Strip it down and pack up those sweet holds. They are at least half the value of your investment

3 - Get a boatload of friends over to help you lay it down and throw it in your buyer's U-Haul. Better be a big U-Haul for this bad boy.

We'll miss our backyard wall, but glad to have it go to a new home and get great use.!

Our wall was "featured" on climbing.com. Check out their article on 16 Scrappy Home Climbing Walls

My mother in law is an upholsterer, and helped us with some large crash pads. There is a 6x8 area that should be covered, and extra care should be given to the bottom lean-to boards. We used high-density 6" foam cut into manageable sections and upholstered in vinyl. I think there's a lot of options for crash pads, but you need to remember that you will need to slog them in and out of the dry storage area. Mattresses would work, but are pretty cumbersome. Anyone have a line on cheap futons?

We purchased a two Metolius hold packs from Amazon and have been very happy with them. But, as you can see, this "Splat Wall" has plenty more room for more. Element Climbing makes some great holds, and has a bulk loose holds discount that can save you some bucks. You get what you get, but, for a splat wall, well, that's pretty good. We just added a few, and waiting on more bolts to add more. I think we were lucky with Element - Our "grab bag" was all matchy-matchy. We feel very fortunate as color-matched holds allows us to build a route without other route markers. Very cool. Remember not to expect too much when ordering bulk. You don't get to pick your holds and you get what you get. But, if you are just looking for quantity, buying bulk holds is a great way to fill your wall.

Element Climbing was great to order from. They were very responsive, and we were very impressed with their build quality. From captured washers to nice variety and texture - We highly recommend Element holds.

Don't forget the bolts and/or screws you will need to mount your holds. It sucks, especially in a pandemic, having to wait for bolts!

The weather has not been cooperating with us here in Michigan. Snow today, and a freeze advisory tonight. Guess we'll wait a few more days to climb on.

Ok, so we were not happy with the straps. A more solid frame would make us feel better about all this lumber up in the air. Swapping out the straps for 2x6x7 boards worked well. Things are tight!

One final thing - Crash Pads. Grandma runs an upholstery business and has a bunch of foam. We might be able to make our own. No climbing until the pads are in place!

We will need about a 6 x 8 landing zone. Hopefully 2 3x4 pads maybe 2 deep?

The sun came out, so we went to town today.

The treated wood is pretty wet and does not drill cleanly. We used a counter-sink to try to clean the holes up, but didn't help much. Still, it came out alright. Alex used "Pluto", a large size ball peen hammer that belonged to my grandfather. I think it was a little too heavy, as some of our nuts didn't drive in straight.

No biggie. We can come back and fix them later.

Now is a very good time to be sure that your frame is straight. Measure cross corner to corner in both directions to be sure that you are square before screwing down your boards. Remember that you identified which alignment was which, so you don't end up with some wonky hole pattern. Your work to be sure that your joists don't interfere with your t-nuts can be seen when you flip the wall over.

Now the moment of truth. We have to move this beast. We've been worried about exactly how heavy it will be once we get things together. Sure enough - IT'S HEAVY. Alex and I managed to slide it into position and prop it up to attach the wall to the kicker with 5 hinges.

Ok, we've added the eyebolts for the bottom straps, and the side lean-to boards. Ready for the big lift! Liz and Maggie joined us for the final lift. OOF! Yes, we have a wall. We discovered a couple problems here. Our original calculation on the side supports was wrong, and we had to move them on the fly. Second, we're not so sure about the straps. Between the weight and the fact that they will be outdoors in the elements, we're not totally comfortable with them. We'll think about that.

An adjustment to the sidewalls, and things are better.

Nice day here today. With good weather and the fact that our first shipment of holds came in a bit early, time to get back at it!

Alex built out the kicker board today, seeing as the shipment had enough t-nuts. We used a countersink to clean up the burrs on the holes, and hammered in the t-nuts. Then just build the kicker board! The kicker board sits at the bottom of the wall. it's made with half a sheet of plywood, giving a 24x8 kicker board. The hole layout is the same as the rest - 7 7/8" (20cm) hole spacing.

We're waiting on the rest of the T-nuts to come in before we can proceed with the main wall build.

We're somewhat concerned about the quality of the plywood. It is a little splintery. We're contemplating some type of sealing paint to protect against splinters and weather.

With wood, saws, chalklines and screws, it's time to get to work. Here's today's activity.

To drill the holes, we first lined up the 2 and 1/2 sheets stacked perfectly, and screwed them together. We used a chalk line to lay out the hole grid as per the Moonboard plan with imperial panel template. Take your time here, as it can be a bit fiddly - remember to mark the lower-left corner of each panel so you can maintain the orientation as per the design. The Moonboard has a quirky feature that between sheet 1 and 2 the hole spacing is 22cm instead of 20. They call it a feature. Ha.

We used a cheap drill guide from Harbor Freight that seemed to make holes go better, but not sure it was worth the $19 we paid for it.. It's sort of a piece of junk, but may have been better than nothing. Be sure to use a 7/16" drill to drill the holes.

As it turns out, we decided to use the same hole pattern for our kickerboard, so we should have drilled first and then cut the sheet in half.

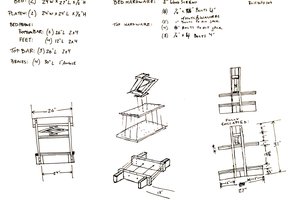

While framing, we could lay out our sheets to be sure that the joists were not going to interfere with holes. For our build, we needed to shift one or two joists slightly to clear the 20cm hole grid. This is an important step. You won't be happy if your holes are covered up!

Be sure your frame is square by measuring opposite corners to match length, or use the 3-4-5 method. See Climber Dad's video as to how he used a board to lock the square into place.

This thing is going to be HEAVY. With 2x10 treated and 10 feet, it's going to be a beast. Hopefully the lean-to method will still work on such a large wall. We'll see.

Went to the local hardware store to buy lumber and hardware. Very busy today, as Michigan just went into pandemic lockdown. I think all the folks that were just "furloughed" decided that if they were stuck at home, they might as well do a home project.

Picked up the lumber and hardware in our minivan. Minivans are designed to be able to hold a 4x8 sheet of plywood if the seats are out, so no worries. The big-box hardware store has everything you need for this project except holds. Alex ordered a hold kit online as well as T-nuts, as they are cheaper in bulk that way.

Our plan is to build a lean-to style systems wall in the back yard. We would like it to be free standing, allowing us to adjust the angle as well as move it around as needed.

Similar to this wall, but self supported and 8 feet wide.

Our design is based on Climber Dad's wall and the Moonboard, but extended to a height of 10 feet on the main wall. By using 3 sheets of plywood, we plan on a 24" kickboard then adding the rest of the third sheet to the main wall.

Worked on details and materials list. Since the main wall is 10 feet, we went with 2x8x10 pressure treated joists for the main stringers. Detailed parts in the hardware section.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

David Tucker

David Tucker

techav

techav

Geoff Nicholson

Geoff Nicholson

Looks awesome! You've inspired me to do the same thing. I've got the lumber and hardware, and now that I'm about to start putting the frame together I have a question: Given that you cut the 4x8 in half, you then have 10' for the height of the plywood, did you trim your 2"x8"x10' pieces by 3" each? If so, did that feel optimal, or could you have preferred a 3" shorter kickerboard? Obviously this will have an impact on the T-nut holes I'm about to drill. Really appreciate any insights! Cheerio Rufus