ddprint: a fdm 3d printer firmware and printing system

The aim is to print functional and strong parts with high flowrate and with reasonable quality at the same time.

Key features:

- Uses a incremental sensor to measure extruder flowrate at realtime to "close the loop for E". This limits the speed of the printer if feeder tends to slip.

- Automatic measurement of feeder system caracteristics for calibration.

- Automatic measurement of filament caracteristics to create filament profiles .

- "Auto temperature algorithm": hotend temperature depends on the gcode-requested flowrate.

- "Temperature-flowrate limiter": speed of printer is limited if hotend has not (yet) the right temperature for the requested flowrate.

github.com/ErwinRieger/ddprint

ibrieger.de/close_the_loop_for_e.html

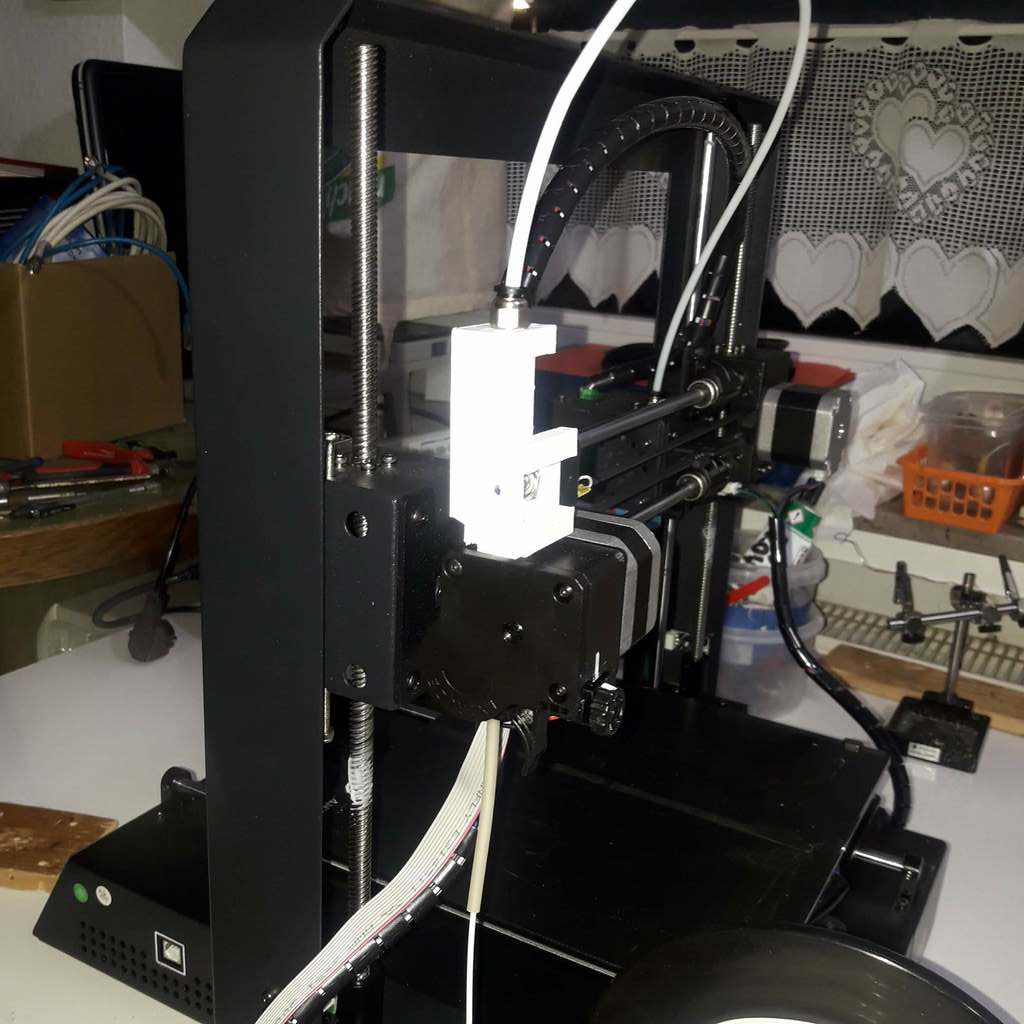

ddprint converted Ultimaker UM2: http://www.ibrieger.de/pimped-ultimaker-2.html

With ddprint, many of the *advanced features* of the slicers (i call it *slicer hacks*) are not needed. This makes it easier to choose the right slicer settings, see http://www.ibrieger.de/close_the_loop_for_e.html#simpler-gcode.

Some videos (more ddprint related videos in this playlist: https://www.youtube.com/playlist?list=PLzn7lnnZpS7XP-JhLw_o7p27ayv5bJ29o):

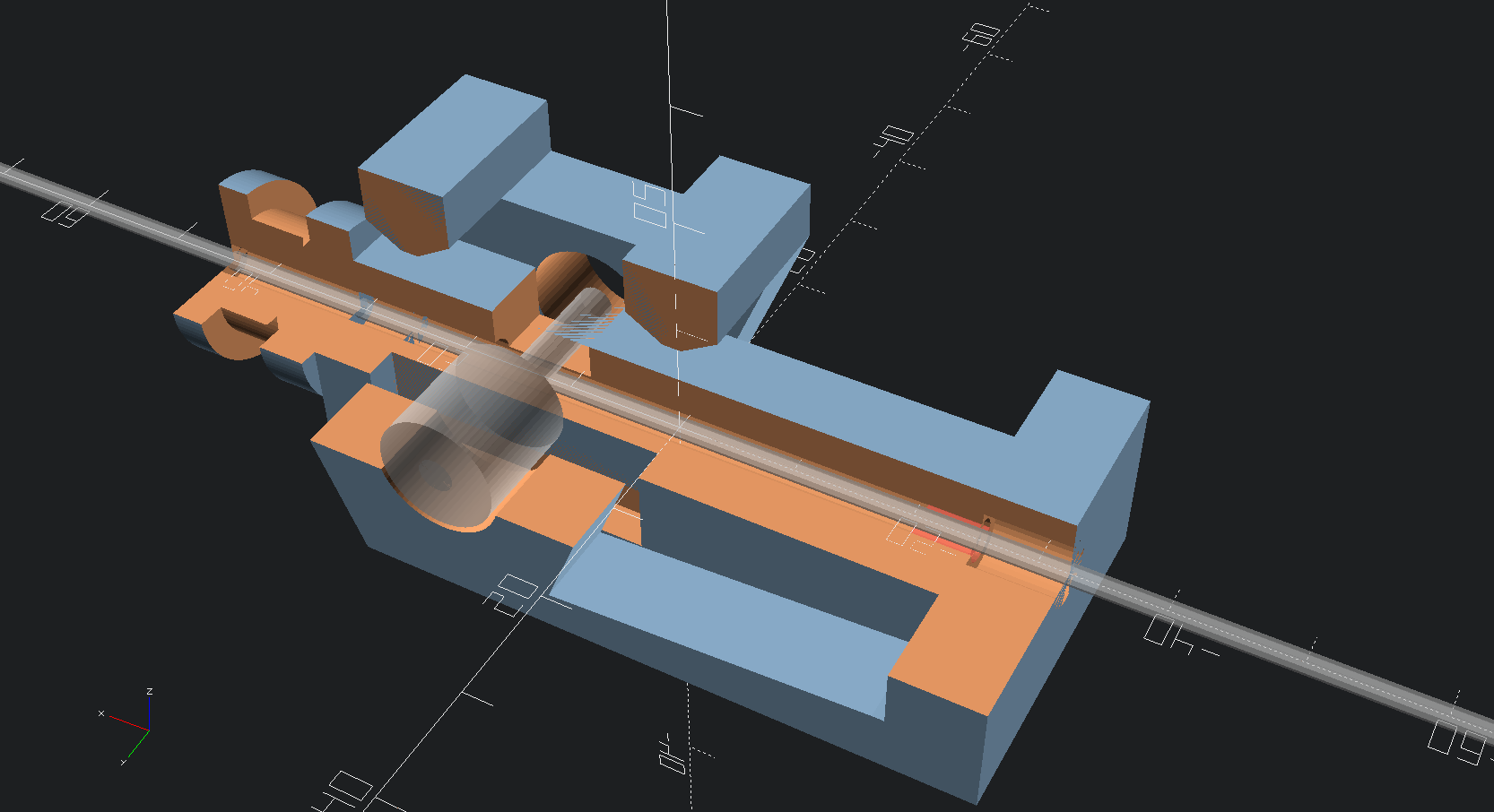

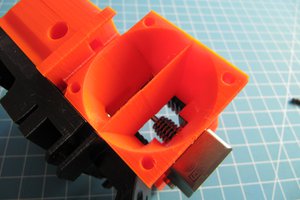

Video of the flowrate sensor while printing. You can see the rotationg axis shaft of the bourns incremental sensor. The shaft touches the moving filament directly. It is pressed slightly against the filament through the force of a spring built into the flowrate sensor case.

More information and pictures about the FRS are available here: http://www.ibrieger.de/pimped-ultimaker-2.html#feeder-flowratesensor.

Video showing the result of the ddprint intro video shown above, a benchy printed with *real* 15mm³/s flowrate (sliced with s3d, 0.25mm layer, 0.8mm nozzle and 75mm/s). NO postprocessing was done, this is how it comes from the buildplate.

The next video is showing an example of the *automatic filament property measurement*. The result is a material profile that is used by ddprint when printing with this filament. Material this time is a cheap 'kaisertech pla white'.

Supercell

Supercell

mark

mark

Cadmium

Cadmium

Daren Schwenke

Daren Schwenke