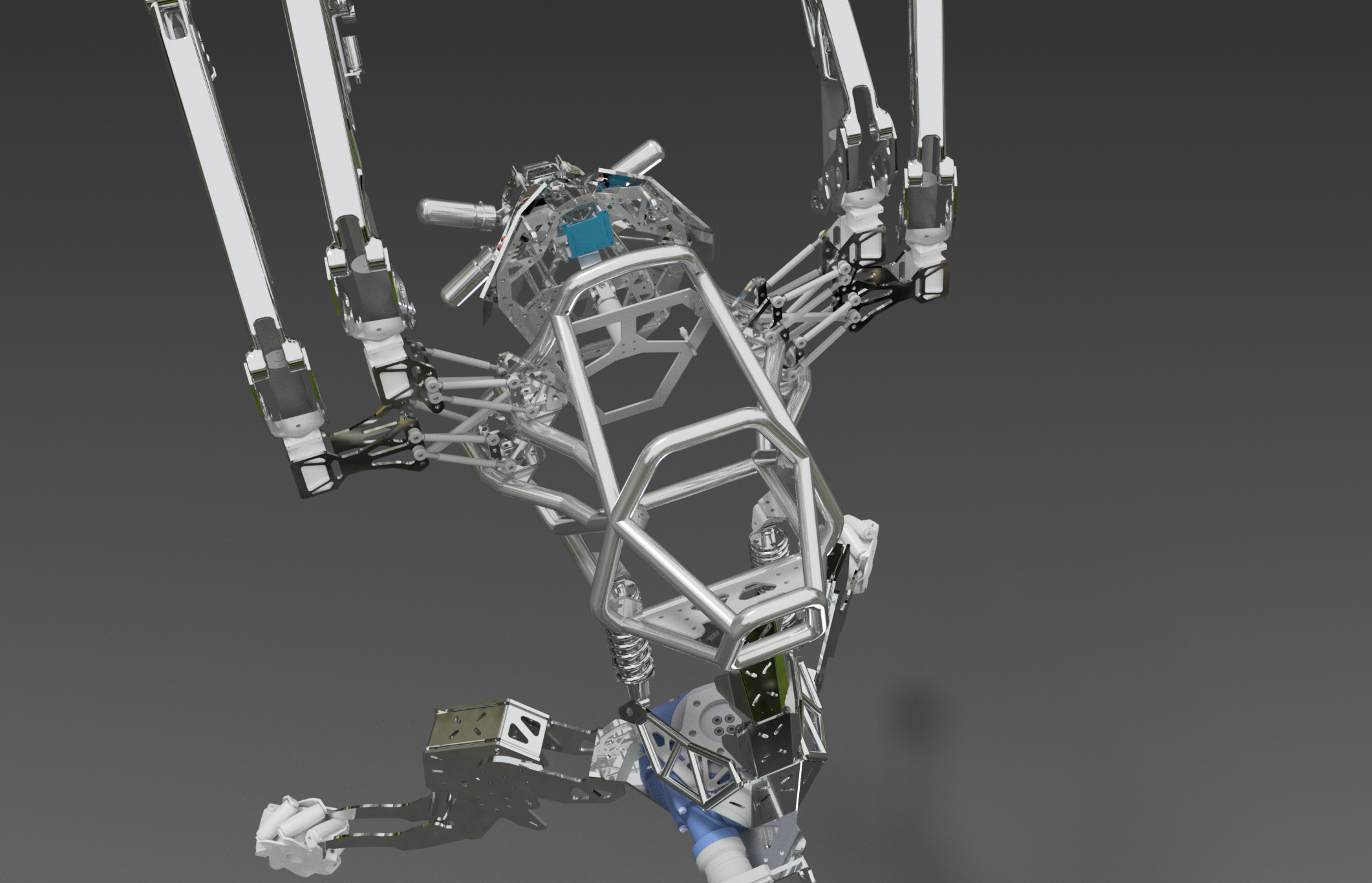

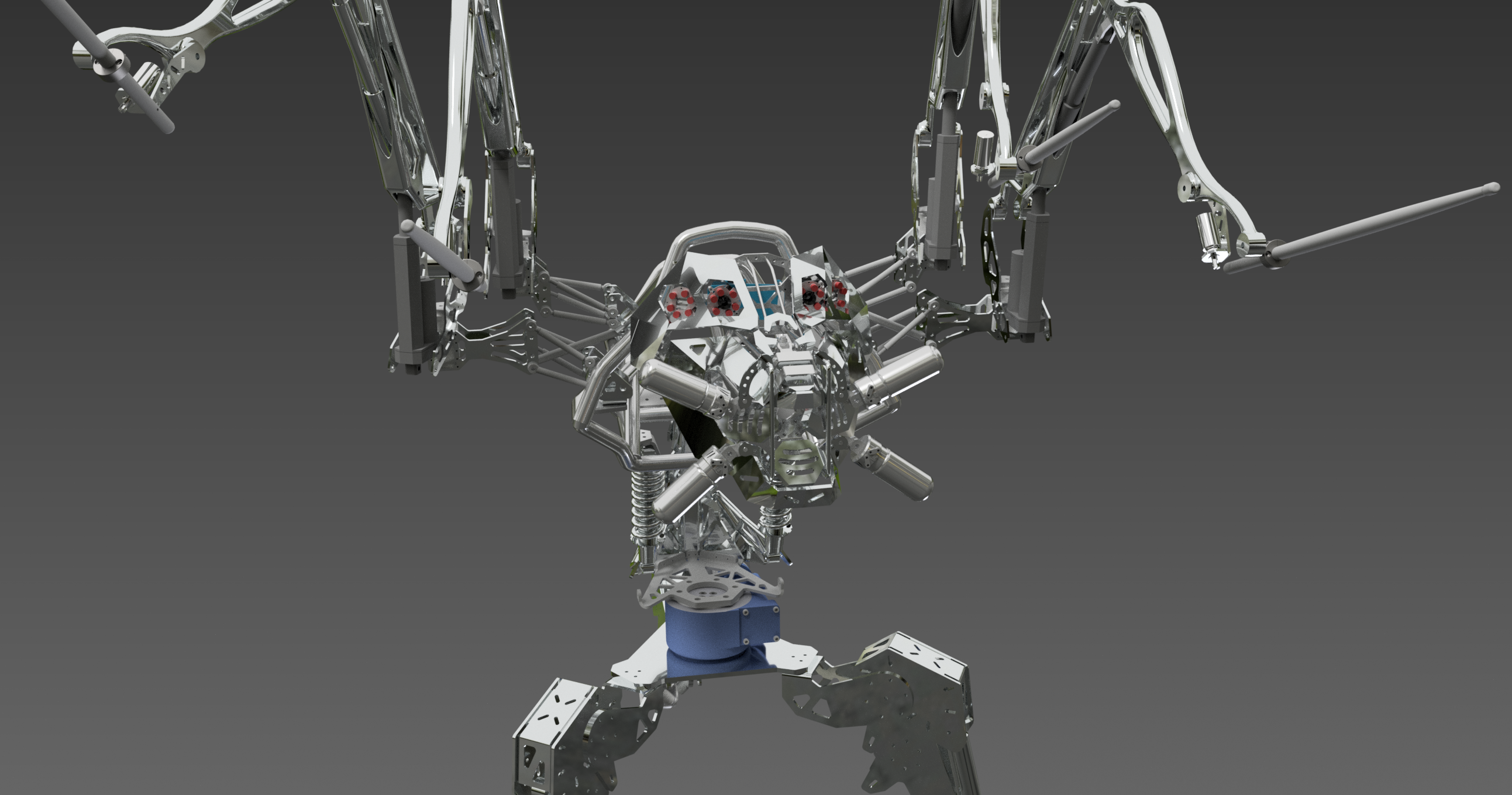

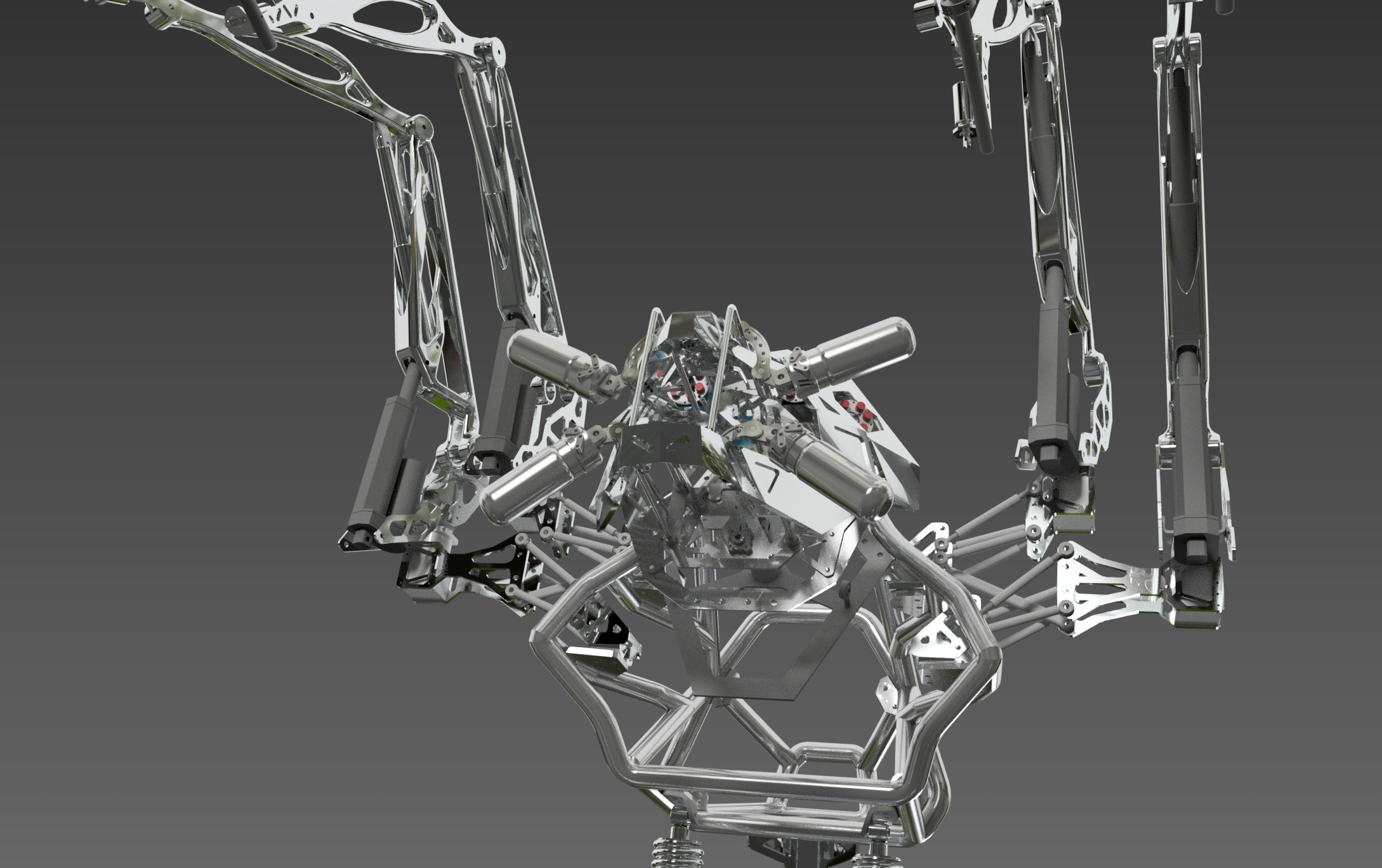

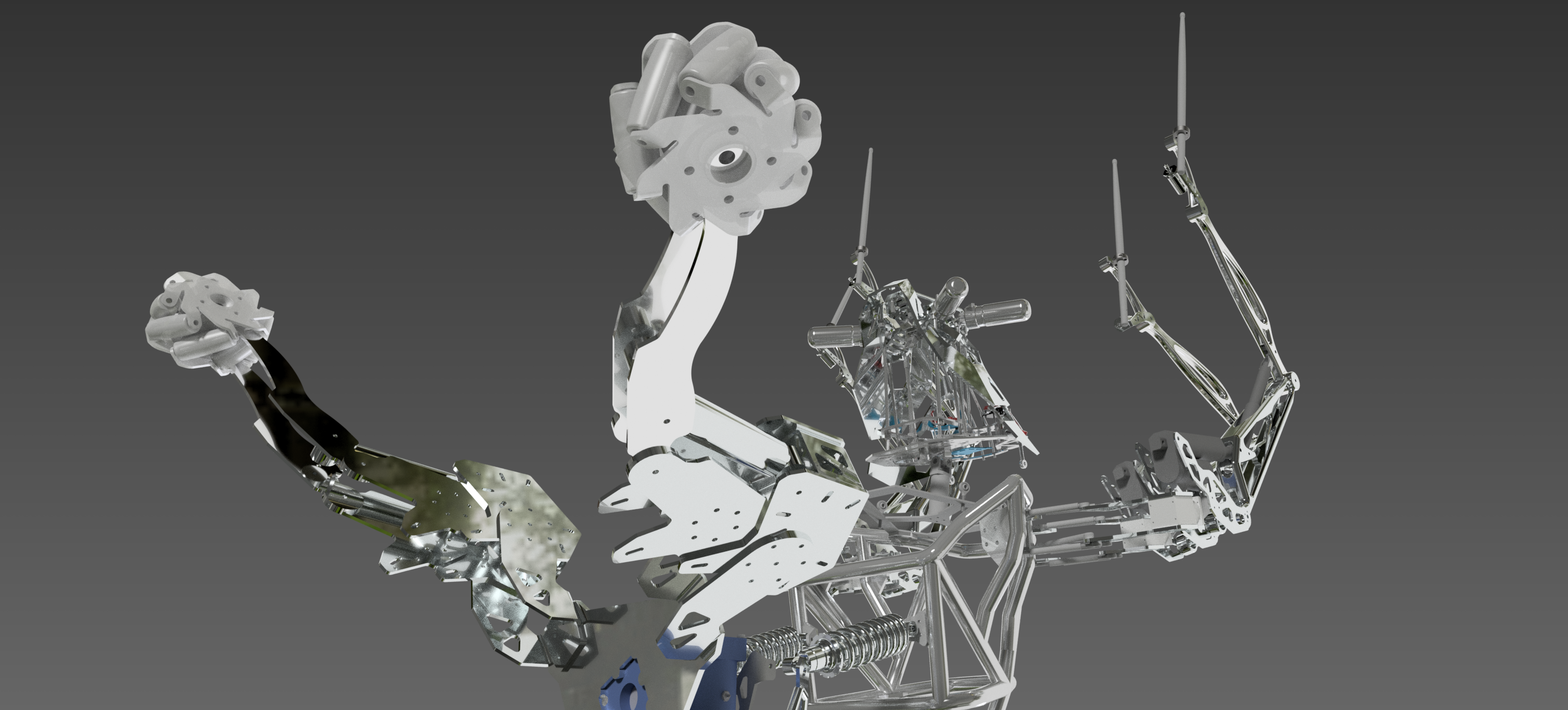

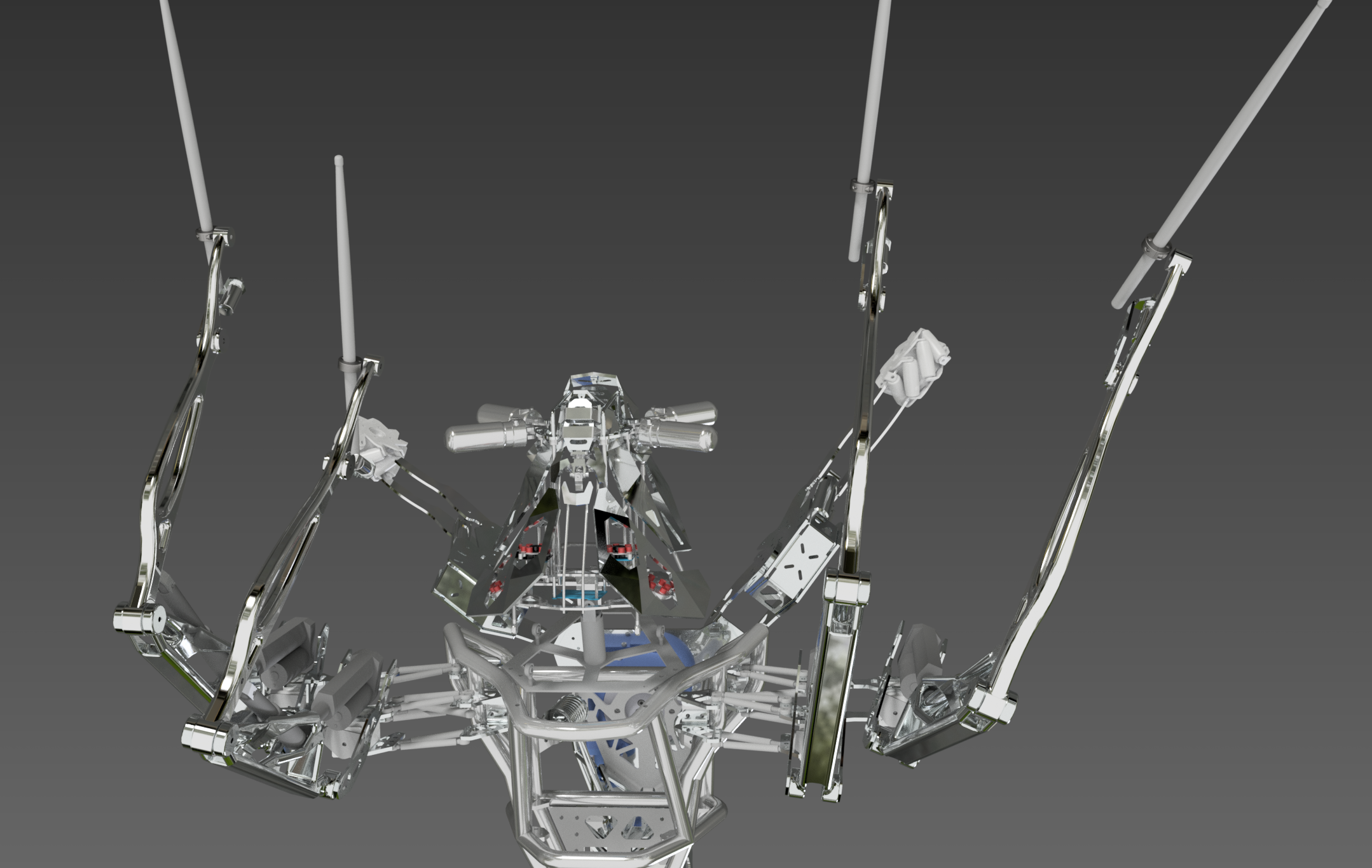

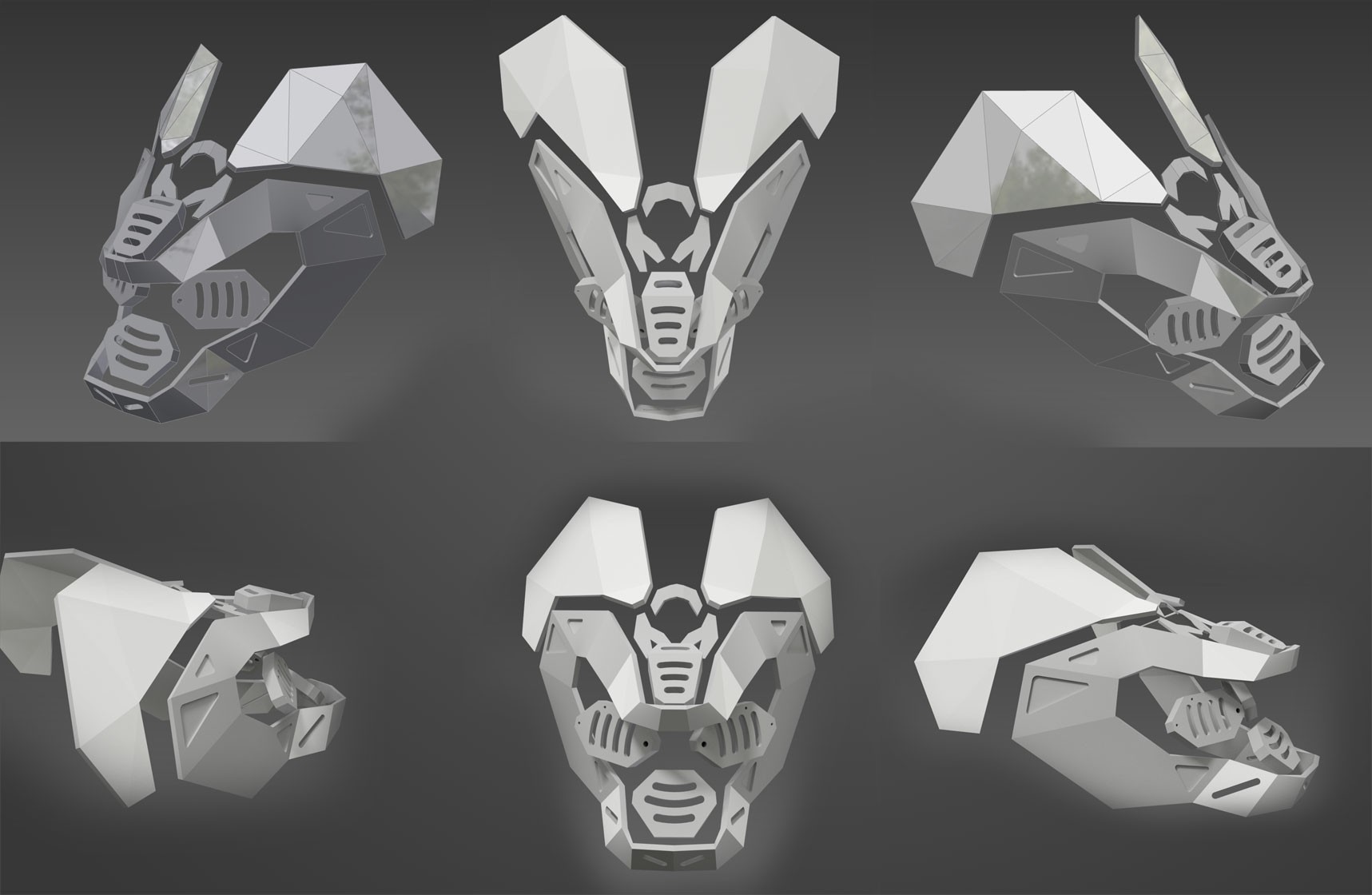

For this project my goal is to learn ::ROS, create parts that look organic by using Generative Design functionality in Autodesk Inventor, get experience with modern servos and linear actuators, and finally build a robotic drummer for my neurometal band. Also see my exoskeleton and cyber guitar.

The files are available on GitHub.

Val

Val

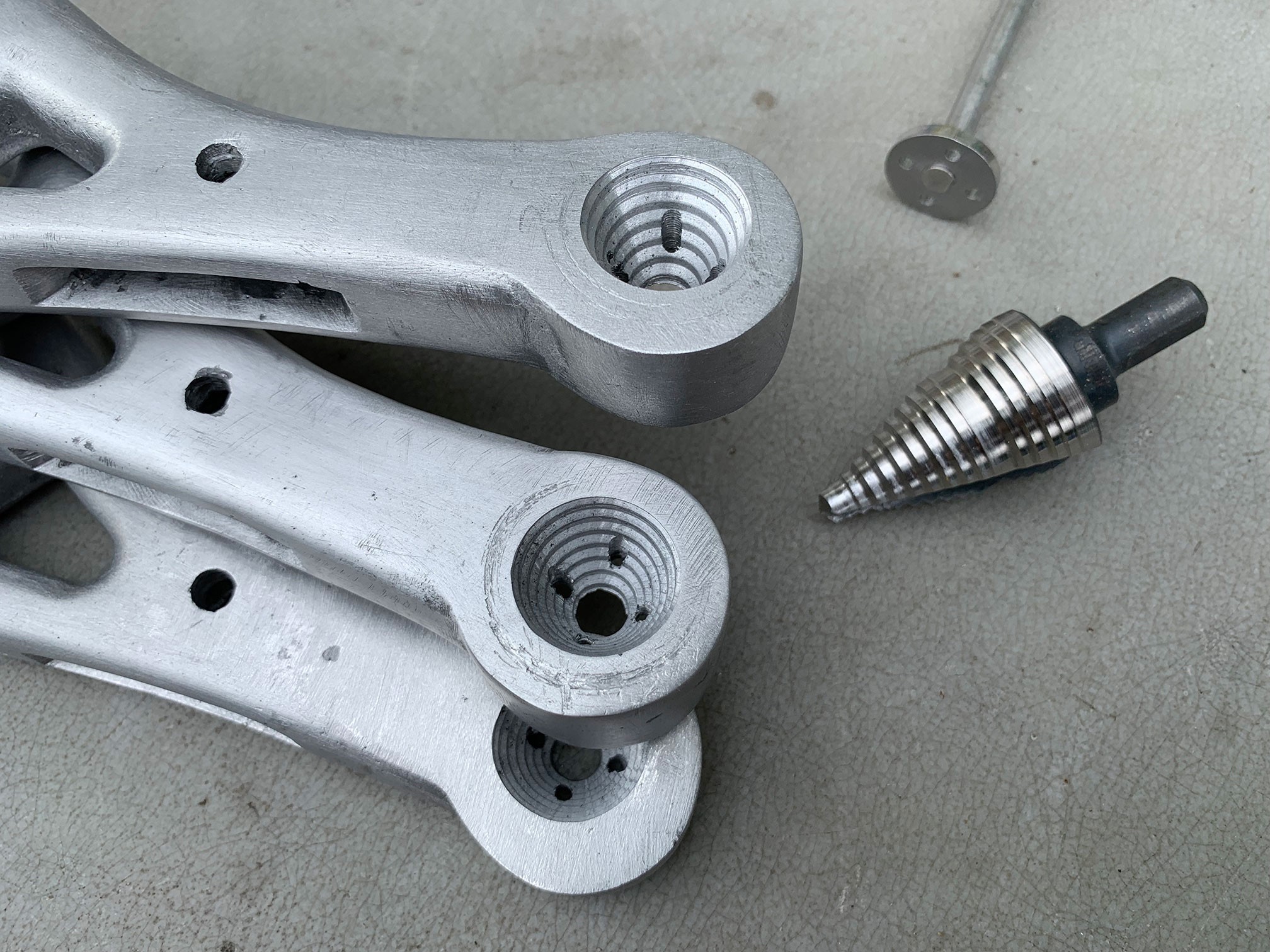

The easiest way to do this would have been to design these parts with counter-sinks baked into the 3D model, as drilling them with this monster bit was really nerve-racking (is there a word for a phobia of drilling counter-sinks?)

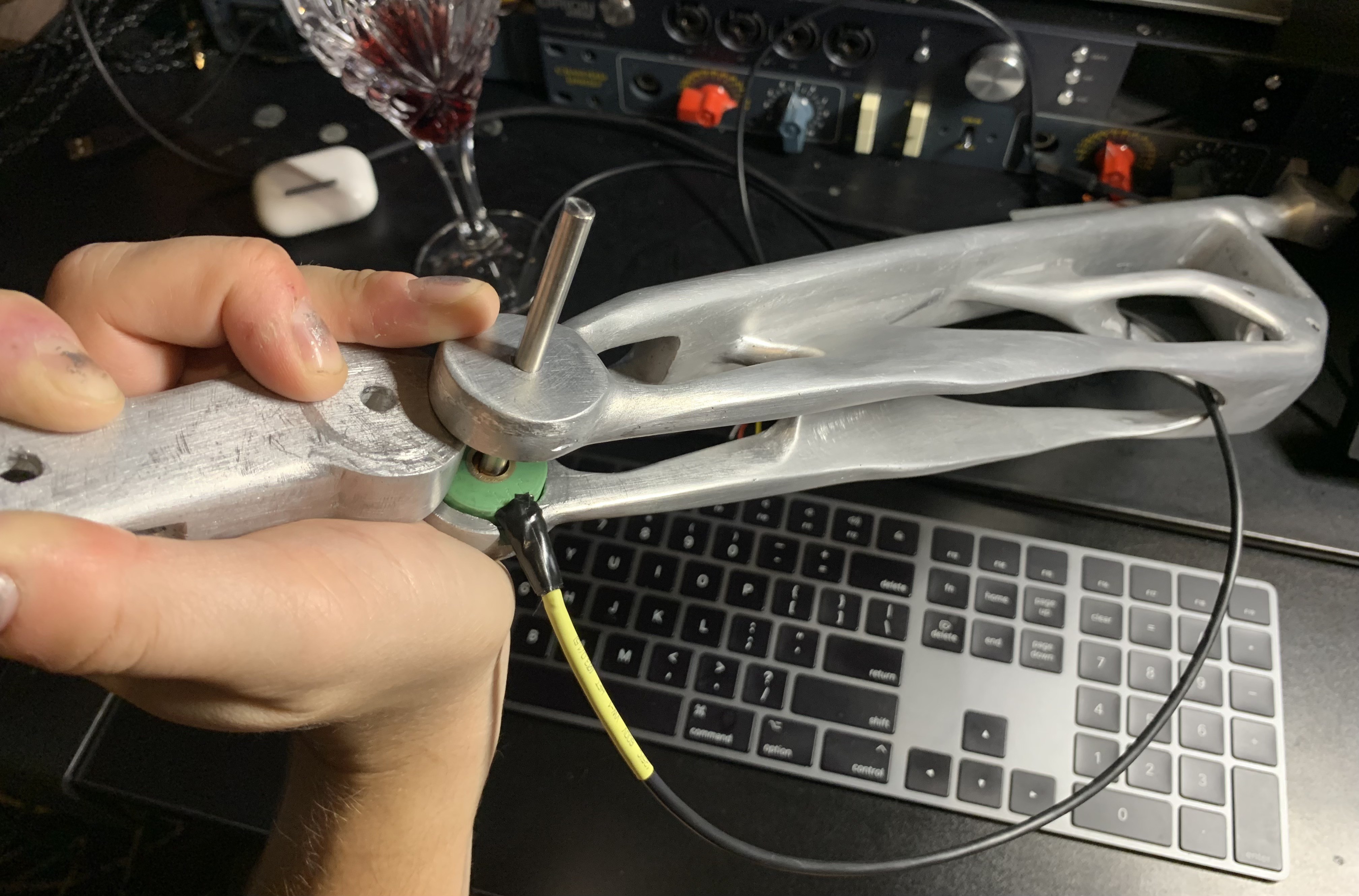

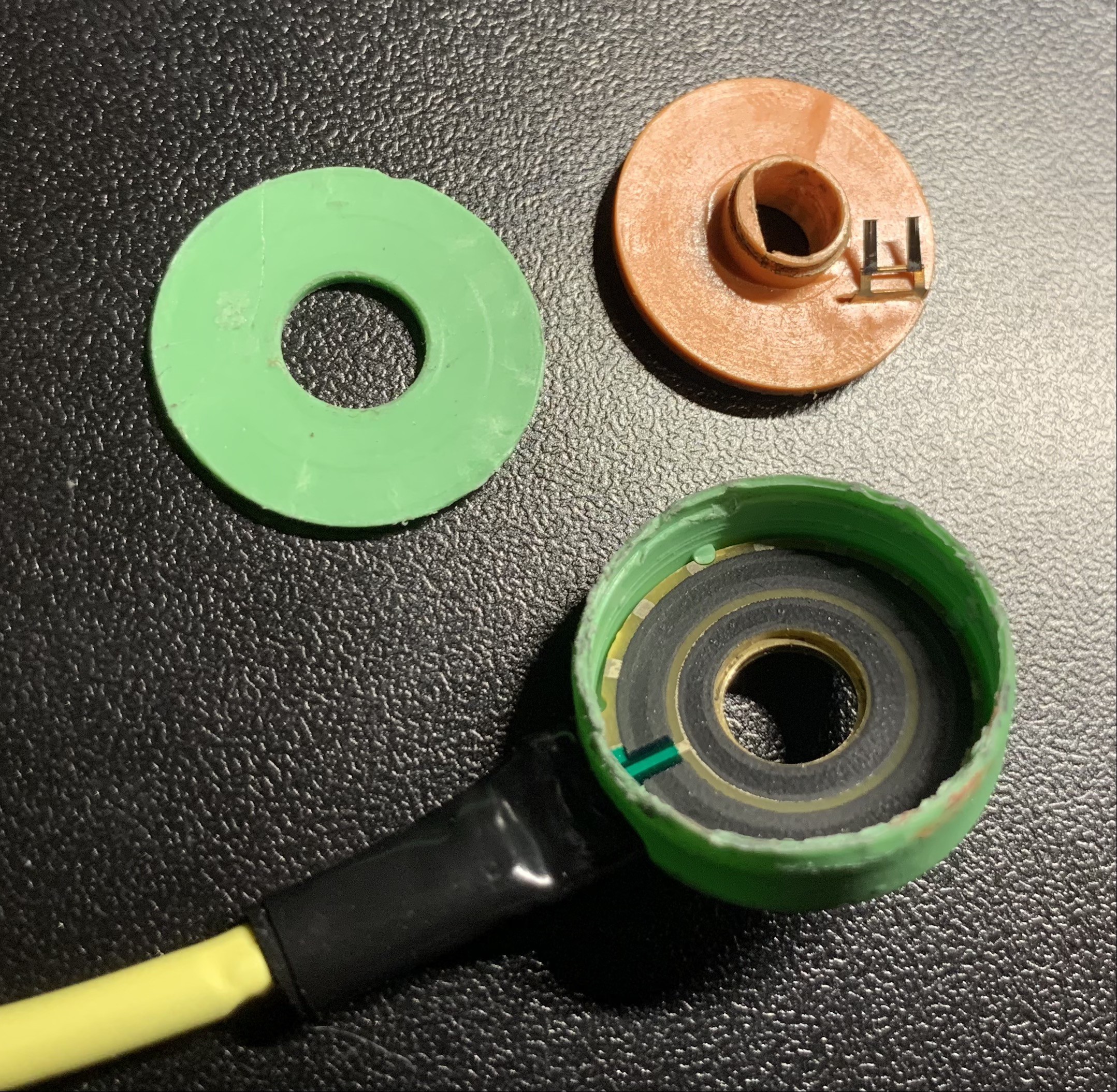

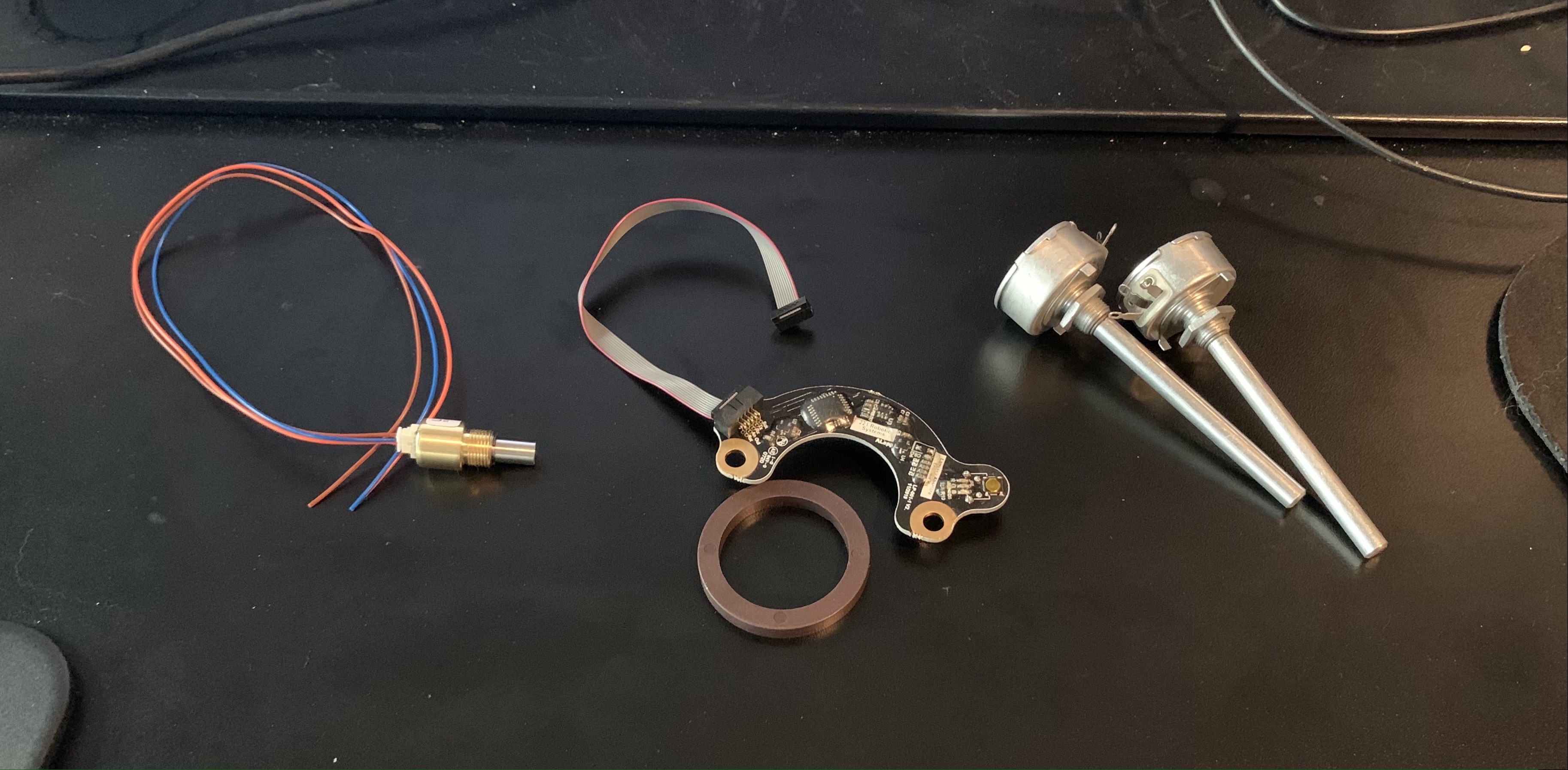

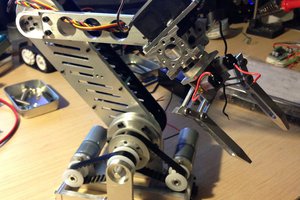

The easiest way to do this would have been to design these parts with counter-sinks baked into the 3D model, as drilling them with this monster bit was really nerve-racking (is there a word for a phobia of drilling counter-sinks?) First I tried these miniature robotics hubs, but even these were too big, more fit for projects where you have a lot of extra space:

First I tried these miniature robotics hubs, but even these were too big, more fit for projects where you have a lot of extra space:

Sarah Petkus

Sarah Petkus

CLo

CLo

Irene Sanz

Irene Sanz

Hello! This is such a cool project, thank you for sharing your updates. The organic structured prototype parts look sooo amazing. Can't wait to see it all come together.