Specifications

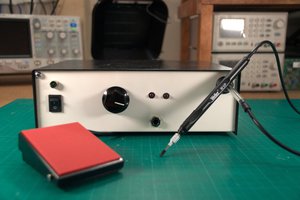

- No Compressor needed. Works with Co2 cartridges.

- Adjustable pressure 0-60 psi

- Adjustable timing from 50 millisecond up to trigger release.

- Ergonomic Injector hand tool

- Dimensions : 155 x 120 x 75 mm

- Weight : 770 gr (without packaging)

- Works with 12V DC adapter

Nuri Erginer

Nuri Erginer

David McEwan

David McEwan

Lithium ION

Lithium ION

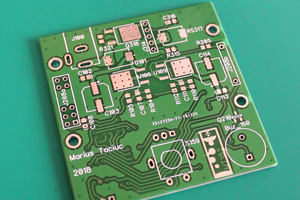

Marius Taciuc

Marius Taciuc

leumasyerrp

leumasyerrp

Hi Makers.

I have always loved and supported open source projects. But developing new devices as open source is getting harder and harder. I need your help to continue building tools for makers so I have to ask to pay a small amount for source files.

I hope you do not misunderstand my behavior. Be sure that, this money will be spent on funding new projects. Thank you in advance for your support.

Nuri

MakerStorage.