Voron V0.1 Stock

Building a stock v0.1 to learn and make judgements on the methodology to influence my custom printer.

Building a stock v0.1 to learn and make judgements on the methodology to influence my custom printer.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

I finally have all the hard required parts. I am missing some feet, one ABS part broke, I don't have side panels on. But all of that should be printable at a slow speed, the first thing I'll do is print the part that broke, and that'll be that.

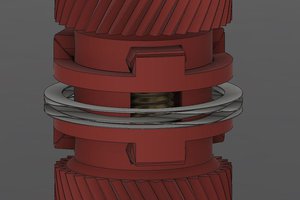

The mini afterburner is an exercise in BS. You take apart one perfectly good extruder to reconstruct it in a smaller place, and if anything binds you tell by trying to rotate a gear. Great, but if it doesn't rotate, you can't actually see any of the insides, so you can't really troubleshoot. You just take it apart, rebuild it, and hope it somehow got better. I did eventually get it working though.

The missing part now is electronics and software, the parts I'm 100% confident on as they are my jam. Mechanics has always been the hard part for me. I will probably only have one or two more entries in this project. One final one when it's actually done done, and then probably one reflectory one on what I would improve and whatnot. But as a summary, the mini afterburner probably has to be this way for size, but it's by far the most obnoxious part of the build.

I finally learned how to properly drill aluminum extrusion. There are so many things that aren't adequately explained online. I had borrowed a drill from my father in law and dulled a few bits before I figured out that when people said "go slow" with aluminum, they mean literally slower than his fancy drill can go. I had to go buy a $40 drill that went as slow as possible, and even then only barely squeeze the trigger.

But! That was the final blocker for a lot of progress on building the machine. Finally all the extrusions are prepared, and I managed to slam together about half of the build instructions. Then I hit some parts I haven't bought yet, so I'm blocked again. But I did find two complains.

First, the misumi rails potentially have an incompatible cross-section. The M3x6 blind screws bottom out before they get tight enough to bind. I used some shims to fix it, and I'm hoping that that doesn't bite me later.

The much bigger issue is that the 3007 fan is extremely fragile and it goes into the mini afterburner with a press fit. I demolished the face plate of the fan. And taking the fans out once they are in is even harder than putting them in. I get that the mini afterburner is designed to be ... mini, but this is the first part I consider bad rather than a minor inconvenience. I will be getting a new fan and more of the parts I hadn't obtained yet.

On some good news, wanting to print the skirts in a similar quality to the PIF parts made me finally dig in and tune the hell out of my Ender 3V2. It can now print in 0.2mm layer height at a really good quality! I only trust it to do PLA, but that shouldn't matter for the skirts, and there are some other designs I have that can benefit from the higher level of detail as well.

Without going into TOO much detail, I have approximately $10,000 of medical bills coming up. I am blessed to know this in advance, and to be able to navigate that (carefully). That's been a big part of my silence recently. I have started to (carefully) spend high-impact dollars recently, most notably spending $20-ish to replace the tap that I mangled. Turns out, proper(ish) technique and thread cutting oil work wonders.

I have been cutting threads on my aluminum extrusions during times when I don't need my hands (see: work meetings) and things are going much more smoothly.

The next thing I probably need are motors and fans. Those are both relatively expensive, so I am not sure when that purchase will be, but that should provide a much better update than this one. We're in a holding pattern to see how effective my cost-cutting methods have been and if I feel comfortable even with the upcoming bills.

PIF

My PIF parts arrived, and I am now proud to say that it was Defib who printed mine. Proud to say it because they are basically flawless. If I look REAL close I can nitpick some things, but they are some of the best prints I've seen and a new quality I aspire to match. I didn't want to name them in case I had to bad mouth the quality, but nope. Unfortunately I am still waiting on some of the parts, so I have been able to do things like pre-emptively install the heat set inserts, but my progress is still very limited.

Feedback

Not related to PIF specifically, but I do have some more feedback for the process in general: The heat set inserts are slightly problematic.

If you don't have a specific heat set insert tip on your soldering iron, just about everywhere online suggests that you use the side of your soldering iron tip, not the tip of it. Nobody really says why, but that is drilled into your mind. The Voron build guide says "heat inserts with a soldering tip," not calling out any hard requirement on a specific heat set insert tip.

Well, some of the heat set inserts are supposed to be lower than flush. You have to either use a specific tip, or go against advice and use the tip of your soldering iron tip. I did the second, but I was kinda surprised that I had to. More clarity here wouldn't be a bad idea.

Overall, not a huge deal, I'm still finding the process fairly pleasant. But as I said early on, this log is useless (in my eyes) if I don't offer feedback as I go.

M3

Frustrated at having snapped my M3 tap, I got into a chat for my local maker space, and they confirmed the multitude of things I was doing wrong. Not wanting to wait on shipping, I bought the ONE kit (that came with way more than I need) that included any metric screw taps. It was garbage quality. I'm going to have to return them and order another M3 tap from the Internet. The quality of the first one was good, I was just bad at using it. Sigh. A LOT of the Voron build is locked behind having properly tapped extrusions.

I don't regret DIYing the tapping, because I DO need to learn to do this properly for my own projects. But this has been painful learning.

Finances

I got hit with some unexpected financial bills. That's made a lot of my projects a bit slower. This is probably the most-hit because I'm following existing plans and am missing pieces I cannot realistically make myself. My other projects will probably shift more to theorycrafting rather than building for a bit as well.

This log is likely to appear nit picky. There's a reason for that. I really don't want to just write a project log for a project that's been done to death. A Voron 0.1 is the subject of many videos and project logs all over the place. Doing just another one adds nothing. So to make this project worth documenting I have to do something more. That means being nitpicky and pointing out where things can improve. Overall, none of the things in this log are things I would consider "bad," so don't take it that way. They just aren't perfect.

First up is my own mistake: I ordered a DragonFLY when the PIF system only allows me to select a Dragon by default. Thankfully, when I got to the top of the PIF queue, it begins with a conversation, and I was able to explain that and it was no problem. I probably COULD have asked for a Slice hotend with this process, but I intended to go through the most common defaults/recommendations, and that meant Dragon.

My PIF person (who I won't name yet, because I can't realistically UNname them once I do, but so far they've been nothing but awesome) not only handled the mixup easily, they also pre-preemptively asked me about the nut guide. Turns out, the printed version of the nut guide exists, and works, but it's "a nightmare" to work with. They recommended a metal one, sent me to a place to buy it.

Since I am not that price constrained, and the nut guides shouldn't impact the end result in a way I care about for a testing platform, I decided to go that route. So that's one more part I need to buy eventually, but it'll save some headache.

I ordered a Dragonfly, heat sock, and heat set inserts from Deep Fried Hero. I won't really know much until I use it, but I have no problems with the sock at a glance. The heat set inserts come in a pack of 100, and I originally thought there was no way that I got 100. It looked like maybe 50. So I decided to count... it was 105. These things are small enough to throw off my gut feelings about count. 5 is such a nice number that I am willing to bet that DFH aims for 105 in every package, so that it's still at least 100 if they/the machines mess up. Good plan, and I got more than I thought I paid for, so I'm happy.

Now, that Dragonfly. My mistake that I got the wrong hot end, but I won't hold that against Phaetus or DFH. First, I ordered the sock, because I wasn't sure if the Dragonfly came with one or not. The description on the site is non-existant. That could be improved. Overall I'm happy I did get the second sock though for two reasons: one, it's always nice to have a spare, secondly the one that came with the Dragonfly isn't my preferred color.

The Dragonfly itself came in a sealed box, so I assume that all of my constructive criticism about it is on Phaetus, not DFH. The instructions tell me how to assemble it... but it comes assembled. Bit odd.

Except it's not assembled exactly like in the instructions. There are some screws that aren't installed by default. Now, those screws are interesting. Community opinion is split on whether they SHOULD be installed or not... but the instructions say to do it, and it's not done for you (even though everything else is).

EDIT: I got this wrong. I misinterpreted the (badly translated English) instructions and thought there was supposed to be screws connecting the hot end and the heat sink. Those exist in some other hot ends, and that's what I'm referring to above when I say community opinion is split. The Dragonfly does NOT have that option, what I saw was grub screws.

The tin coating around the copper is flaking off in a few minor places. I don't think that will really impact anything, and it'll be under a sock anyway, but like I said, I'm being nitpicky.

It came with a set of wrenches, but NOT the right size to put on (or take off, since it was pre-installed) the adapter. I want to take mine off, so I will need to use pliers and put more pressure...

Read more »I got one of my deliveries today. Screw taps for M2, M3, M4, and M5, and a few screws that weren't available via my primary screw source. I then tapped 4.5 bars and broke my M3 tap. The tap is embedded in the hole of the fifth bar. I MIGHT be able to make the tap flush and still use the bar, but I can't tap any more M3 holes.

I am super frustrated that this happened literally the day I got it. And that buying another is going to take another specialty order because America is still using the dumb Imperial system and I can't find metric stuff locally. Imperial stuff is available all over the place.

I assume that I was doing something wrong while tapping since this was literally my first time. And/or I bought low-quality taps. I did use the cheapest material they had available, maybe it's worth spending the extra for better material. My M2, M4 and M5 are all the same material, too. M4 and M5 have more girth to hopefully add more strength, but I really worry about that M2.

I should have a lot of deliveries on Monday, but the lack of screw taps actually puts a pretty big hamper on progress in the short term.

I am #16 in the PIF queue. It hasn't moved in longer than normal, and it's very tension-building. PIF is a skinner box.

Summary / What Is It?

There are two projects that make the Voron line interesting to me.

Firstly, I'm making my own printer that I designed every piece of (https://hackaday.io/project/184212-alice-3d-printer). I have a lot of respect for the Voron Design group, and I assume that they made all of their decisions sensibly. While I still want to make my own for experience, and because my goals might not line up with theirs in 100% of cases, it still seems smart to see what choices they did make and to try and understand why.

Secondly, I am making a custom circuit board for a carriage-mounted controller (https://hackaday.io/project/184838-hot-end-board), and if I ever complete that/sell it, the Voron crowd is likely the single largest market. Creality owners would likely dwarf them, but most Creality owners likely stick with stock things. The Voron group have proven that they are at least open to tinkering.

This end result of this project should be a stock Voron v0.1. If you're after the end result, you can get the equivalent of this by watching a YouTube video or reading the directions yourself.

Where I can potentially add value, and the reason I decided to pull the trigger on writing this, is in my commentary. There are likely going to be things that I disagree with. There are going to be times that I discover non-obvious bits that aren't in the manual and I will endeavor to comment on them here. I will likely opine about things that might be able to be improved upon (side note: I probably won't improve on them, at least initially -- I need a mostly-stock v0.1 for testing with my hot end board. I don't want to sully that.).

Initial Update

There's going to be a lot for a first post, because I didn't originally plan on even making this a project.

Firstly, I am buying the pieces in ... pieces. This is both for money reasons (I'm spending a LOT on other projects, have kids, etc.), but also to "savor" the choices as it were.

The first thing I bought was the aluminum extrusions. I went with Misumi as I find their prices extremely fair, and I don't want to deal with Chinese QC issues and/or shipping delays any more than strictly necessary. I could write a huge post about the complexities of Chinese manufacturing, but that doesn't belong here. Suffice it to say that most of the time I will be choosing a source that's not AliBaba or Amazon. Yes, that's going to be difficult sometimes.

The extrusions arrived quickly, packaged well, and with nothing obviously wrong with them. I do need to thread the holes (I did not choose to have Misumi do that for me as the price for that add-on isn't great, and I need to get the tooling to do that eventually anyway) and drill the access holes for blind joints. That isn't a huge priority for me yet because that is not what's blocking me yet.

I have also gotten on the PIF waiting list. At the rate it has been going, it should be a week or maybe two until I'm at the top of the list. I have asked for black and yellow. The PIF process is interesting. Knowing that it's just a bunch of volunteers and those volunteers basically break even on filament costs, I'm surprised at how polished it is. But if I were to compare it to what I'd want out of a commercial offering, it's pretty lacking. I'm not about to complain too loudly though, given I do know that it's volunteers who aren't even properly compensated.

(Side note: I am strongly considering joining PIF once I get things further along to give back, solidify myself in the community, and also stress test the boards I'm designing.)

I found the estimate surprisingly accurate. We were at about 80 requests/month when I joined, I was around #80 at first, and we're on track for being about a month after I signed up.

Just the other day I did another big batch of purchases. In preparation for getting to the front of the PIF line, I decided to really lock in my hot end choice. I originally wanted the Mosquito, then I see...

Read more »

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Daniel Grace

Daniel Grace

ReidDye

ReidDye

RX HMP

RX HMP

Douglas Miller

Douglas Miller