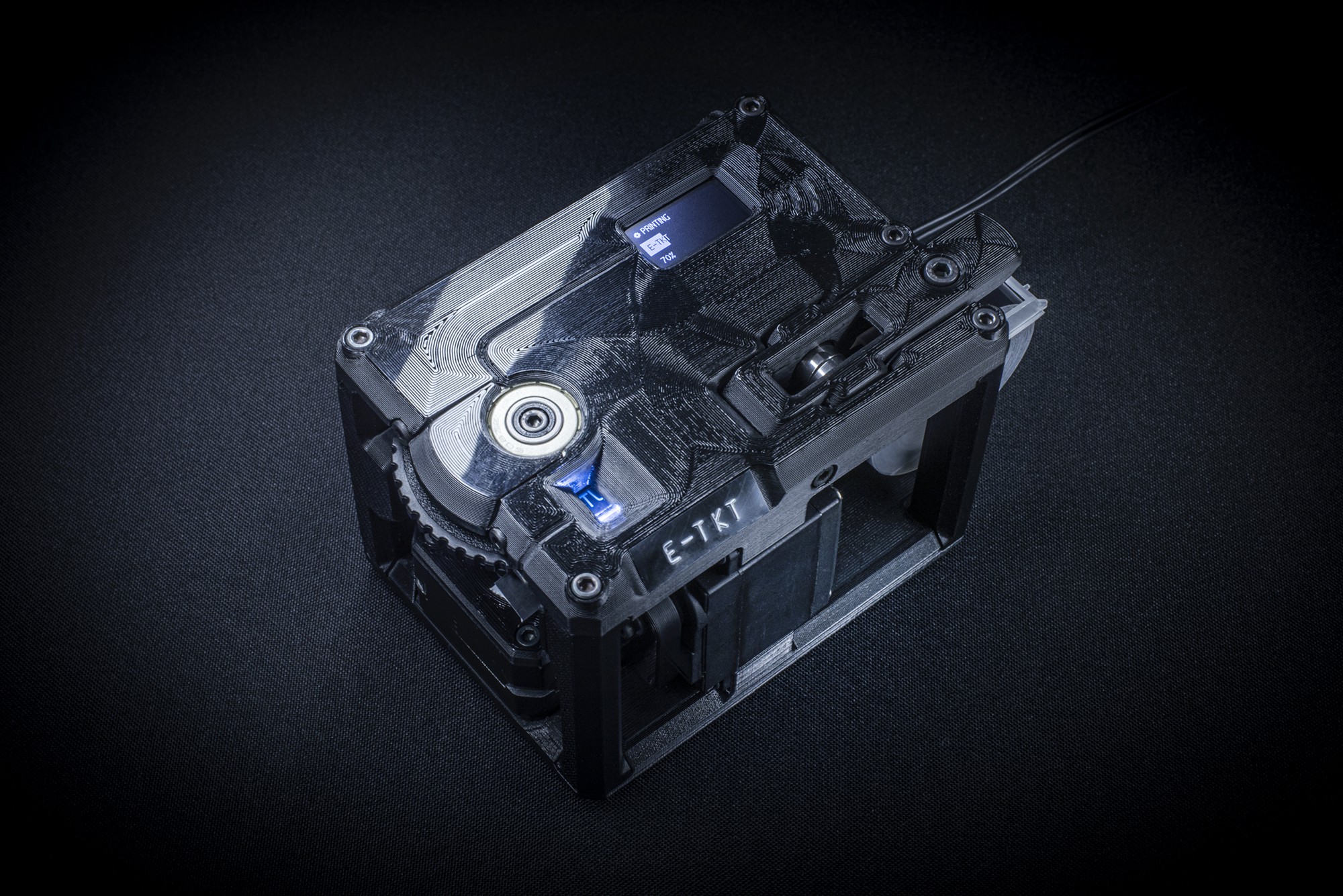

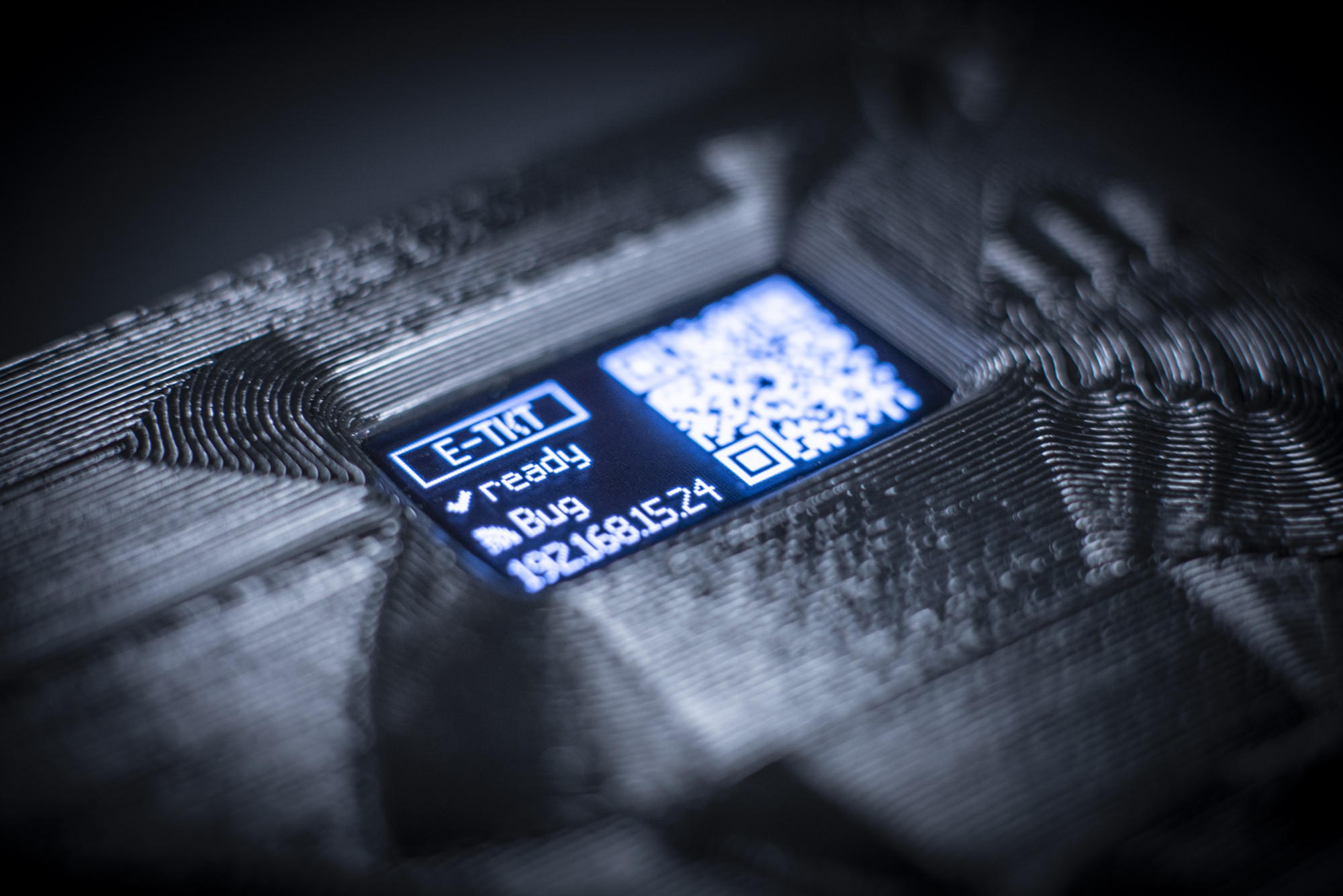

E-TKT: anachronic label maker

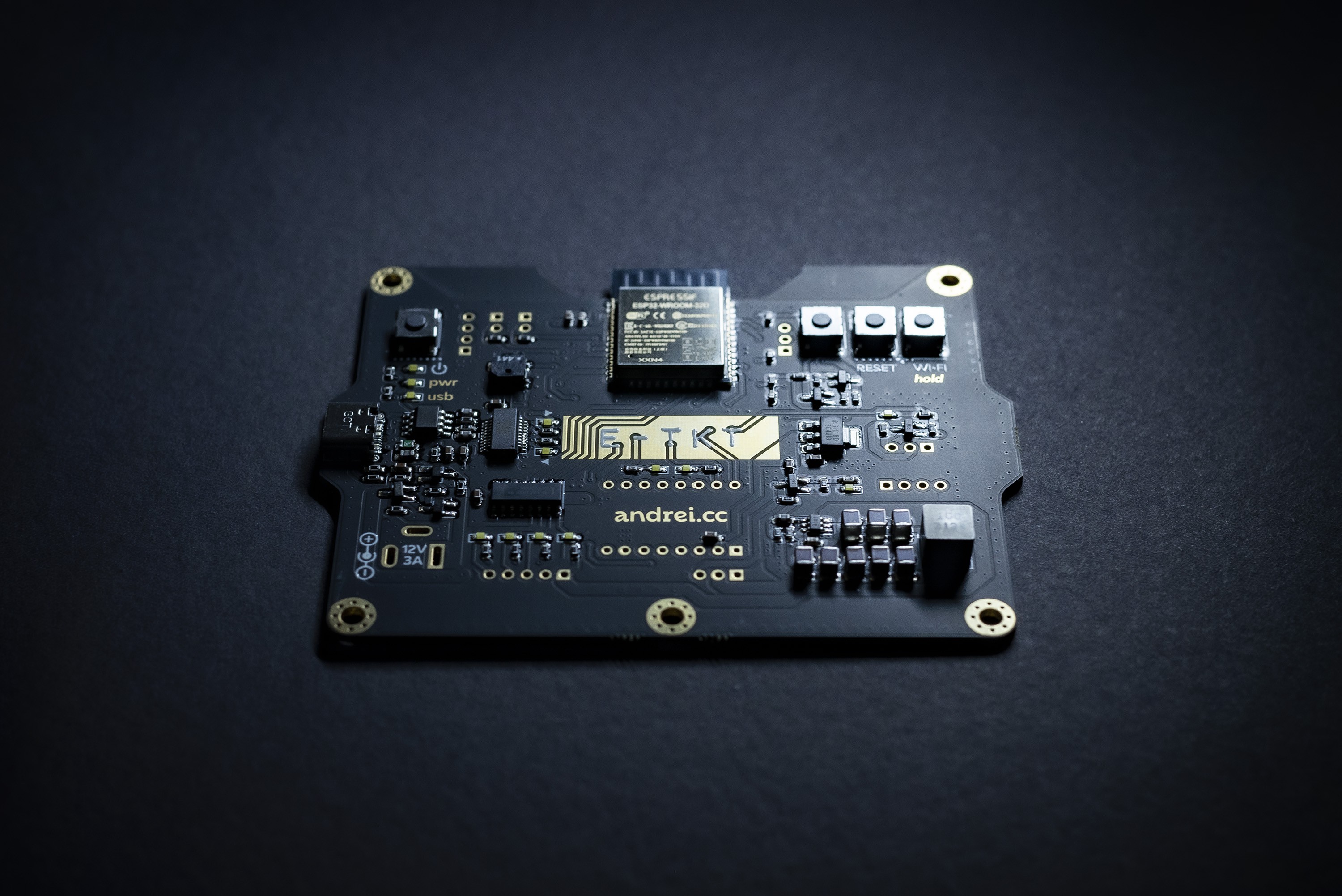

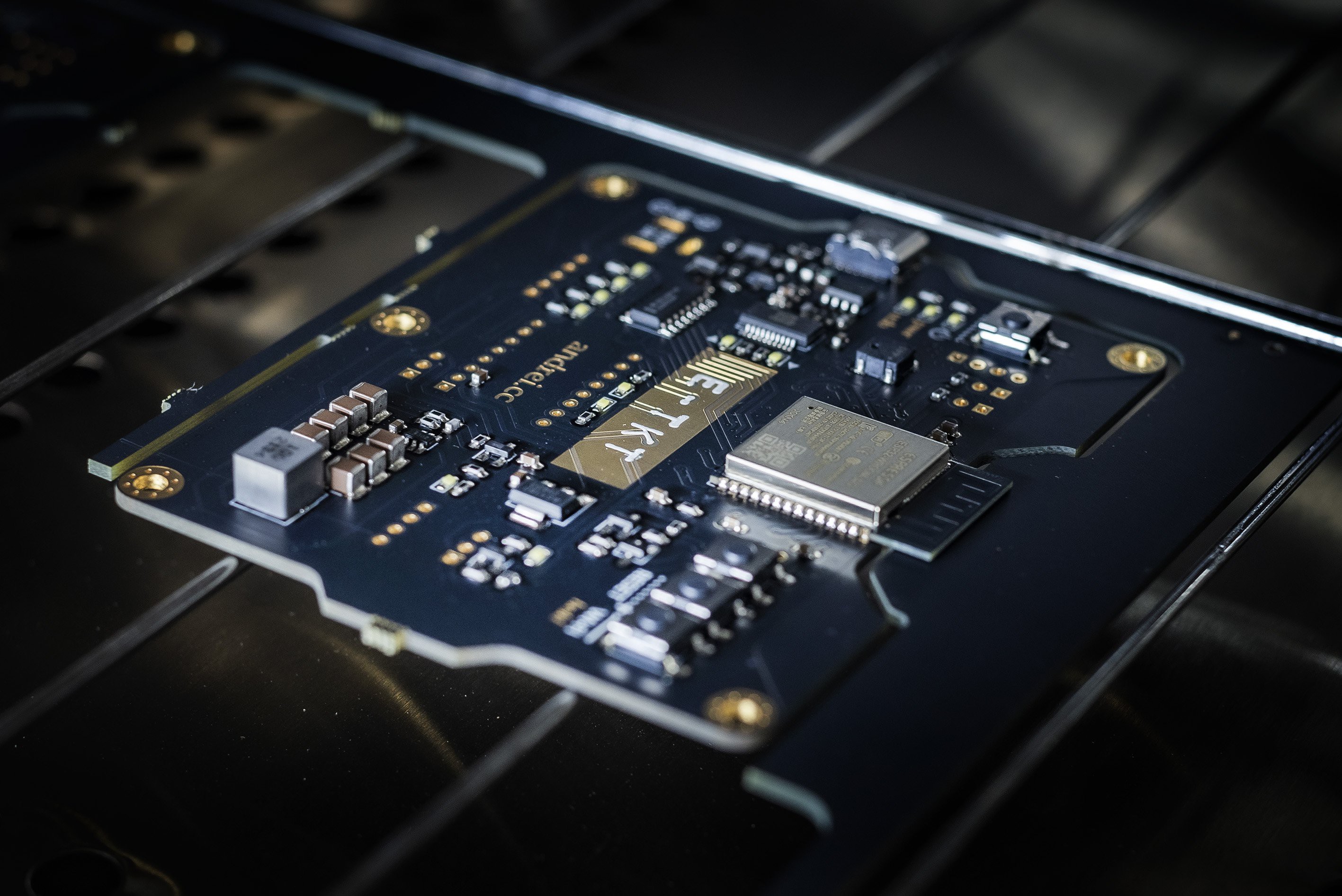

Andrei Speridião 2022 - http://andrei.cc

📺 media

E-TKT has already been featured in several places:

- Digi-Key Maker Update (project of the week) — “Ep.289 - Stamp of approval”

by Donald Bell — June 30, 2022

- Make: “Old School Label Making, New School Interface”

by Caleb Kraft — June 22, 2022

- Hacksterio “E-TKT Prints Embossed Labels with the Power of IoT”

by Arduino “having11” Guy — June 17, 2022

- HACKADAY “DIY AUTOMATED PRINTER KERCHUNKS OUT CLASSIC EMBOSSED LABELS”

by Dan Maloney — June 15, 2022

🤓 about E-TKT

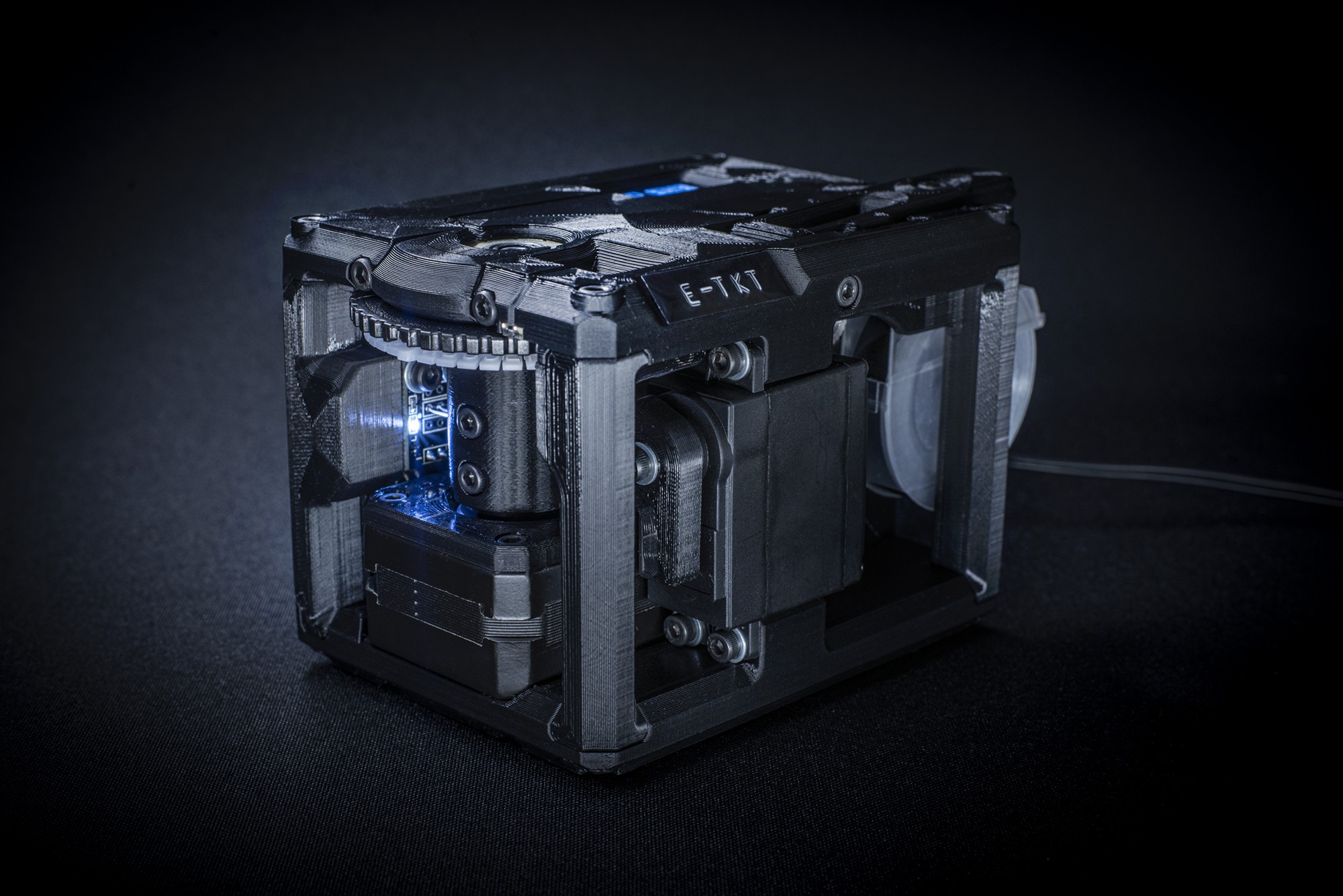

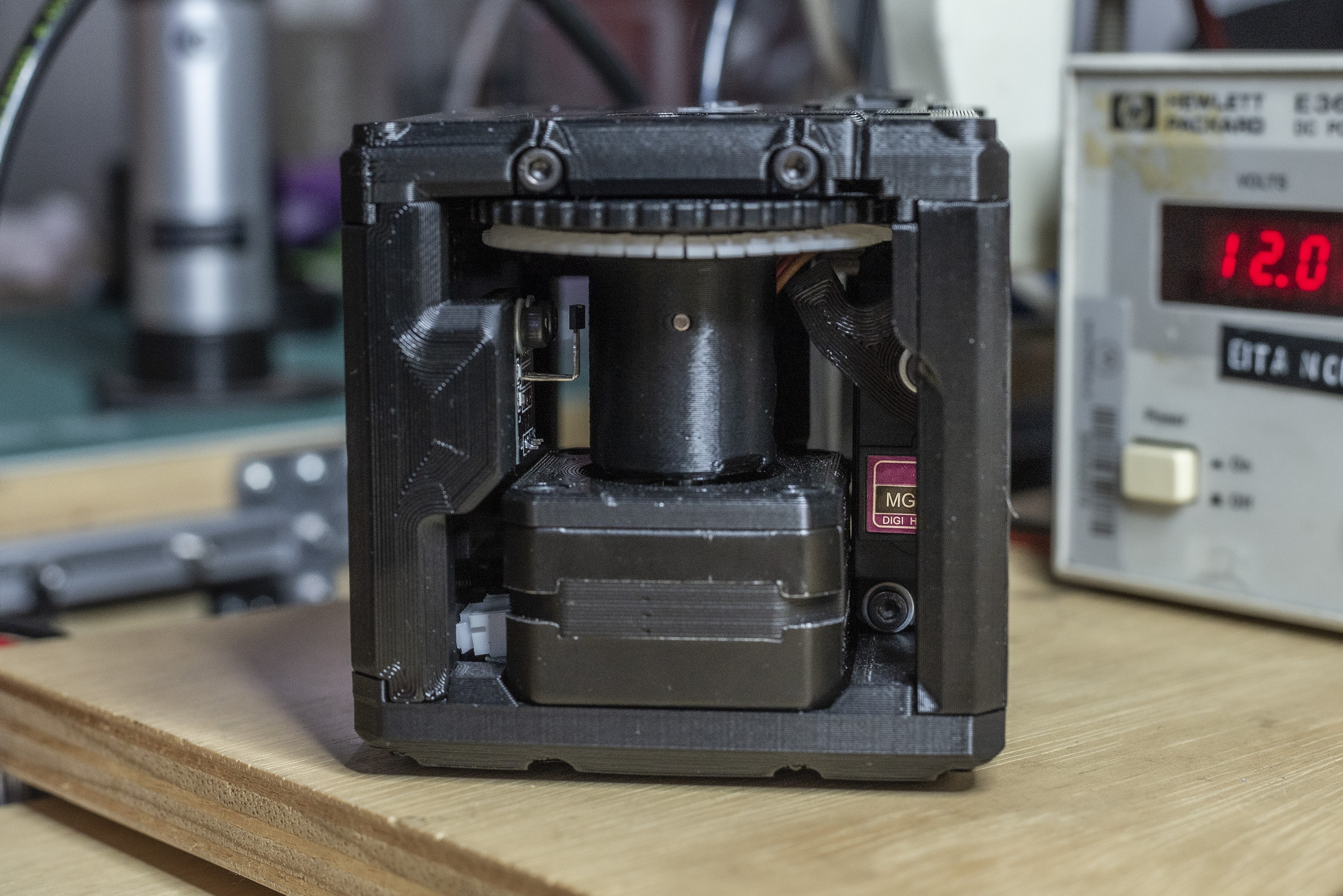

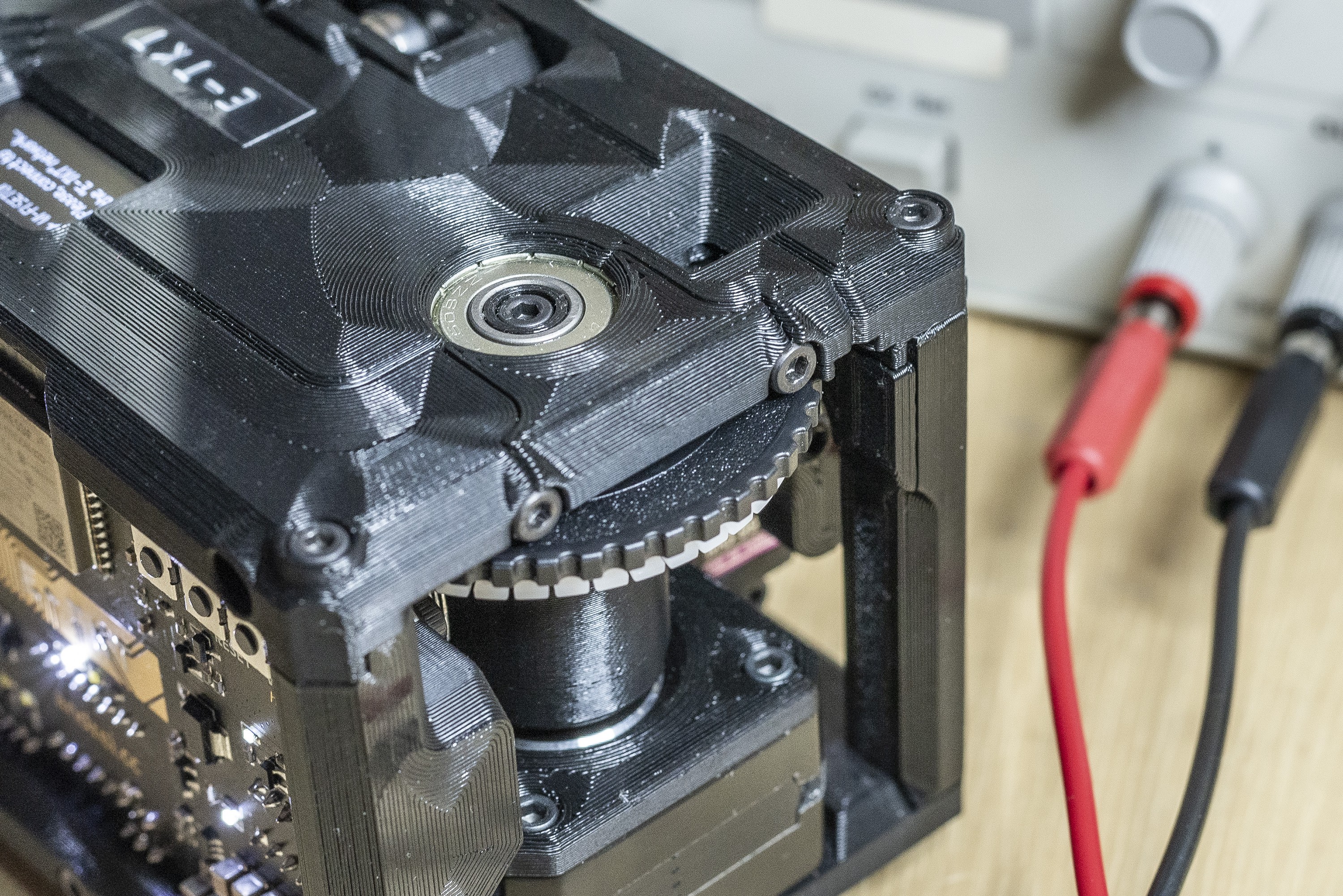

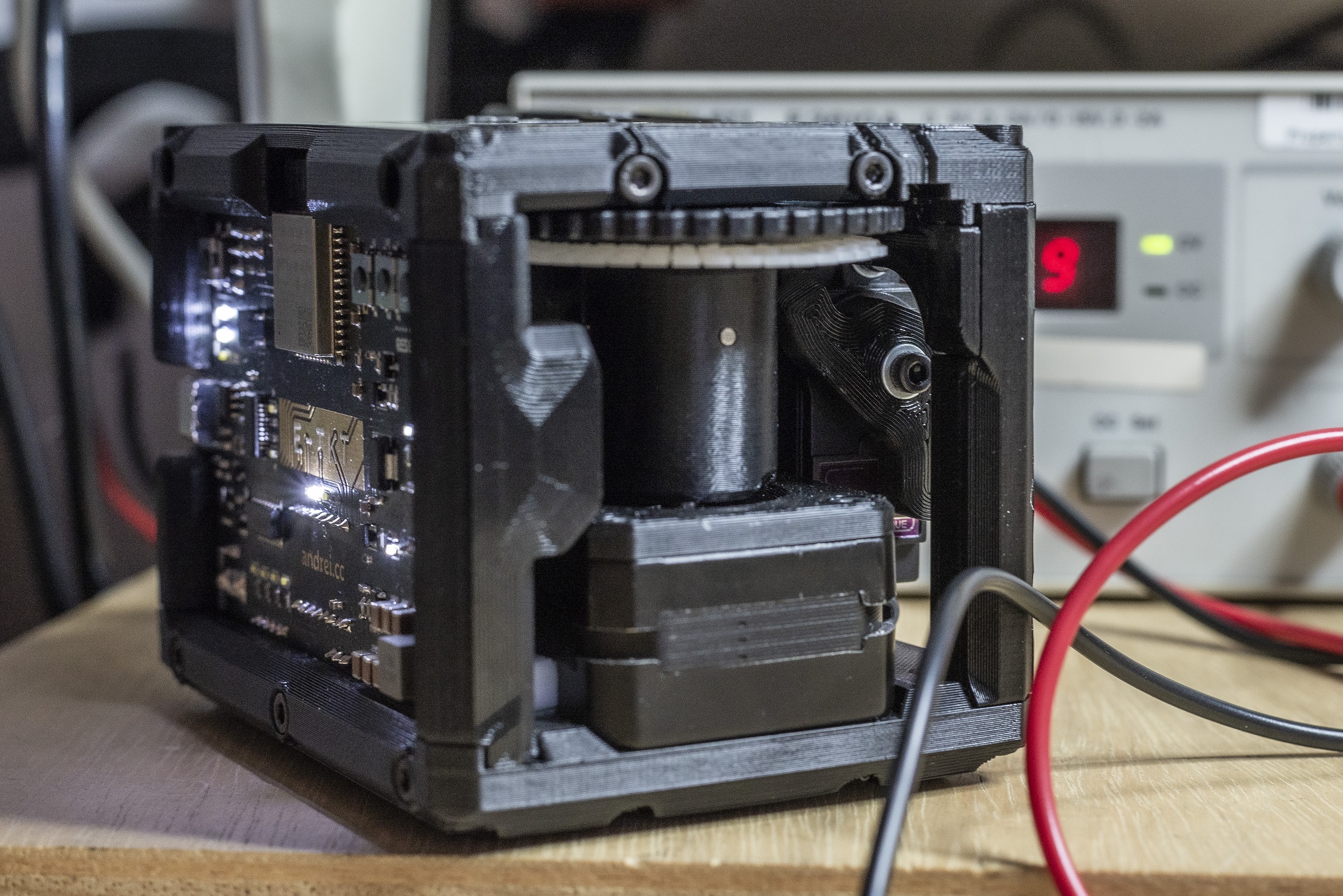

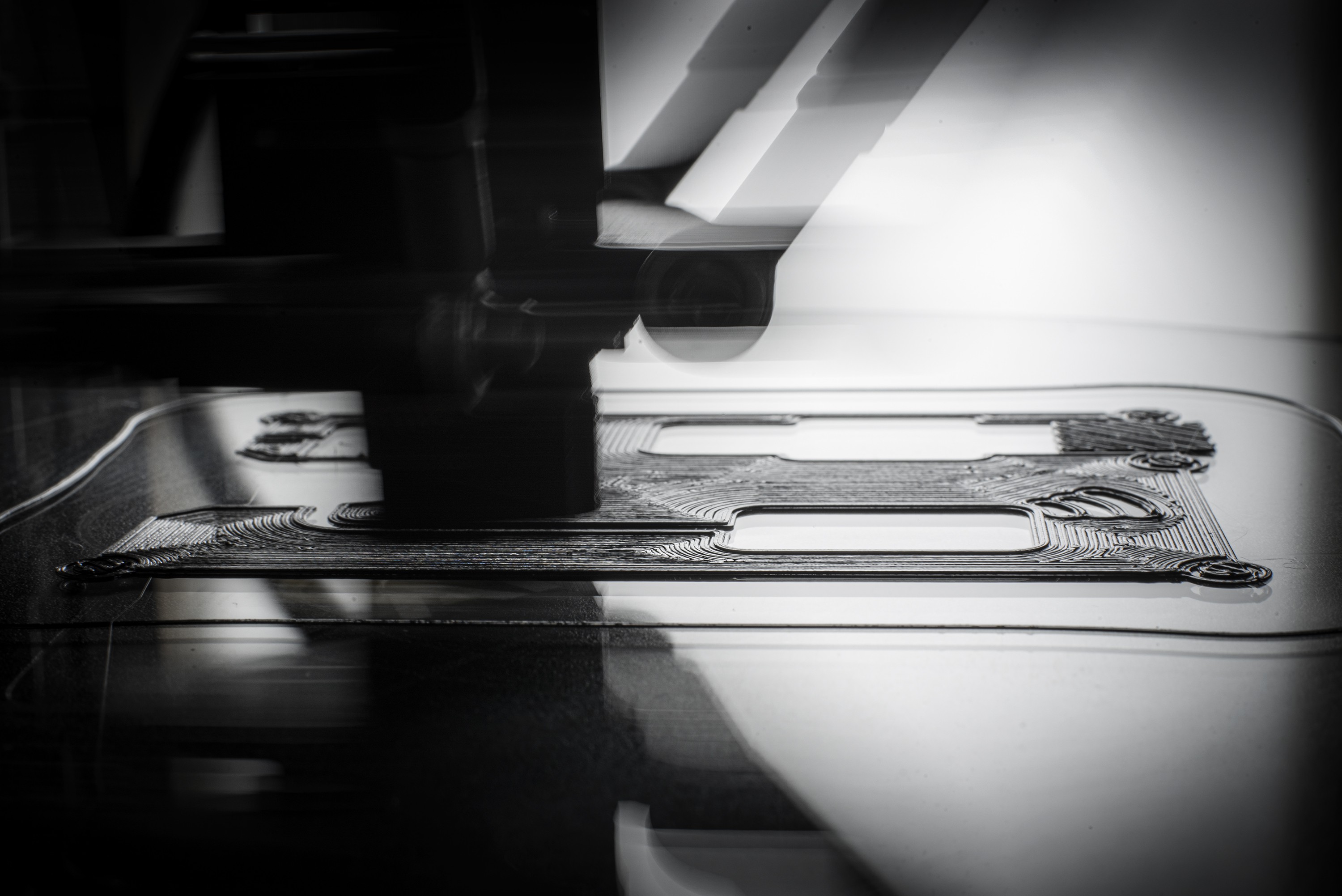

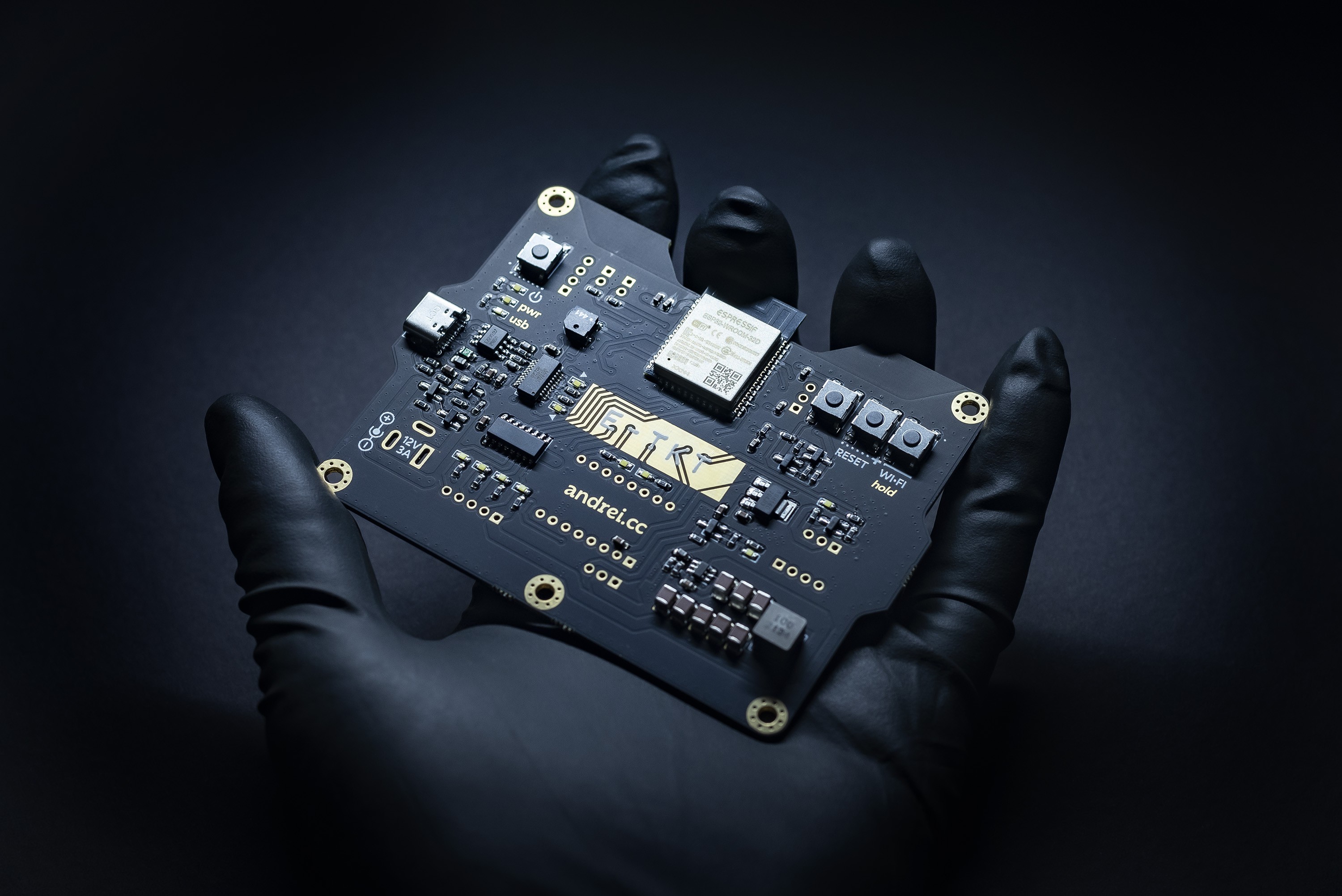

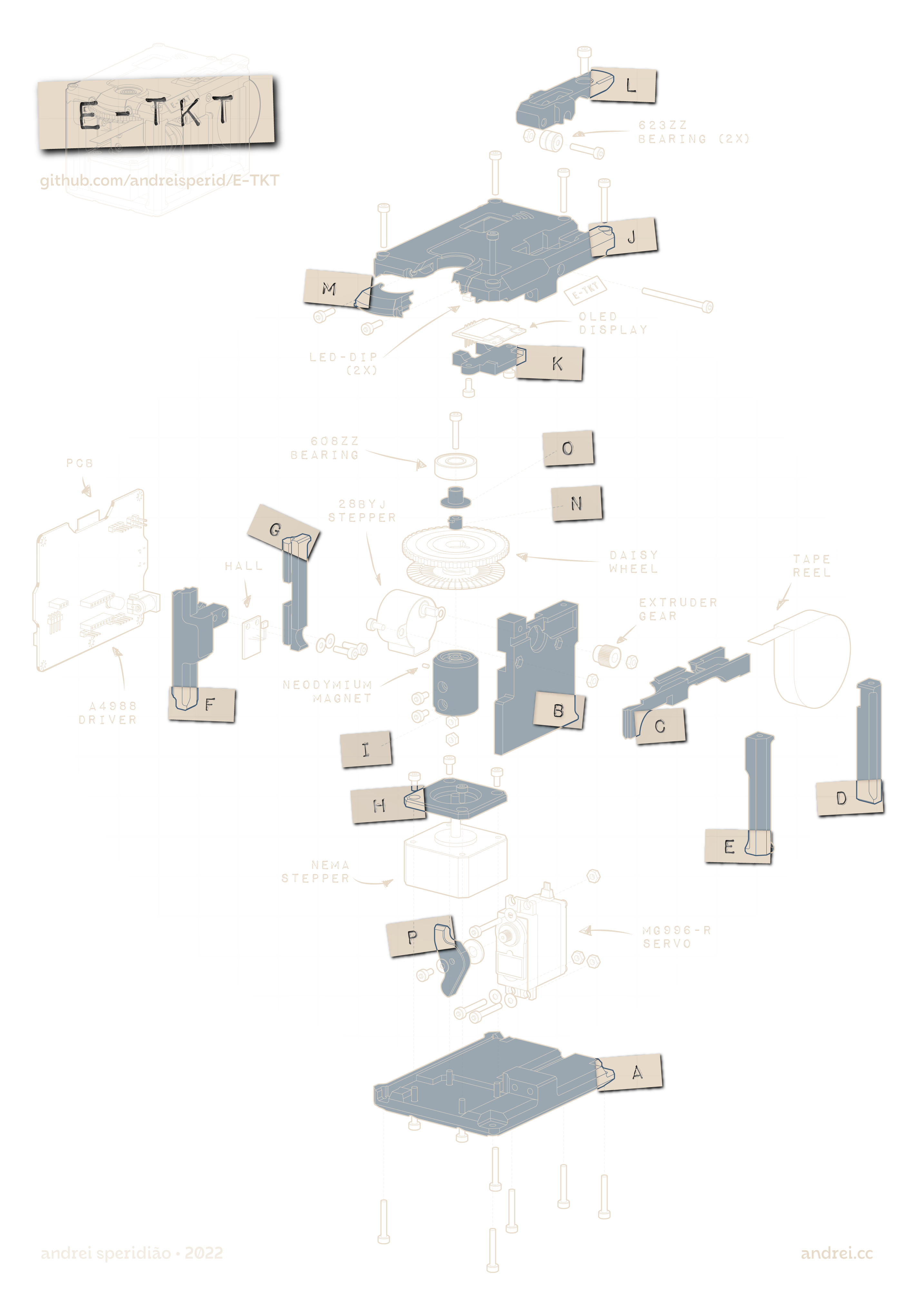

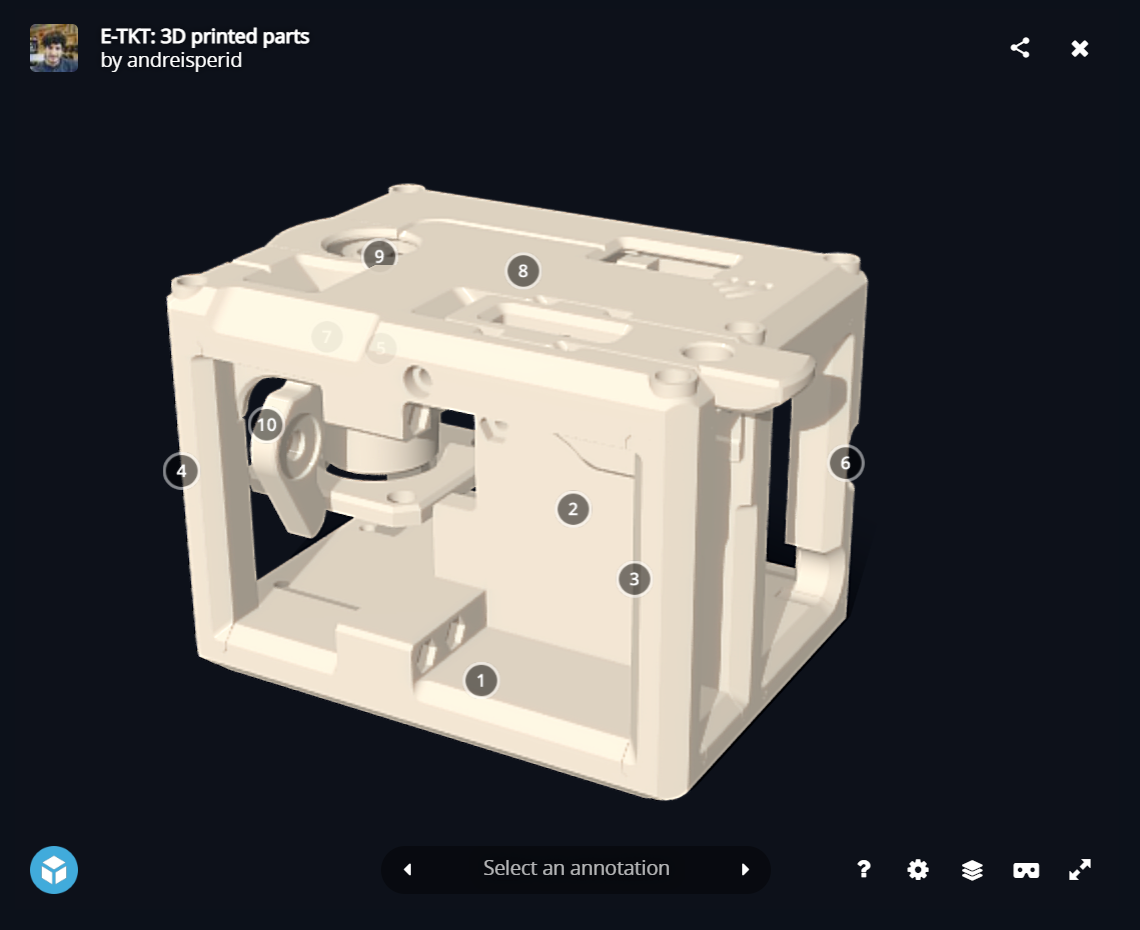

By combining simple and widely-available embossing tapes in a reliable mechanism with modern connectivity, E-TKT rescues a would-be future that did not happen, and at the same time gets rid of the dependence on proprietary cartridges, which are environmentally impacting & expensive.

🧐 what?

étiquette f (plural étiquettes)

“ticket, memorandum, attach, stick, pierce, sting, to be sharp, goad, puncture, attach, nail”

- tag, label

- prescribed behavior

It’s curious how both meanings are a consequence of each other: we name things around to state and reinforce what they are or should be, and at the same time, we end up influencing our own behaviors mediated by these labels.

🤔 why?

TLDR: curiosity, technical challenge and of course organizing stuff.

The initial spark for this project came from an ordinary manual labeling device that I bought to organize my workshop. I was VERY UPSET when I noticed that it was basically rubbish, getting broken and unusable after just a few operations. Just to imagine something made in another part of the world, travelling to me and breaking this way is unbelieavable.

Instead of embossing, it was really embarrassing labels 😅

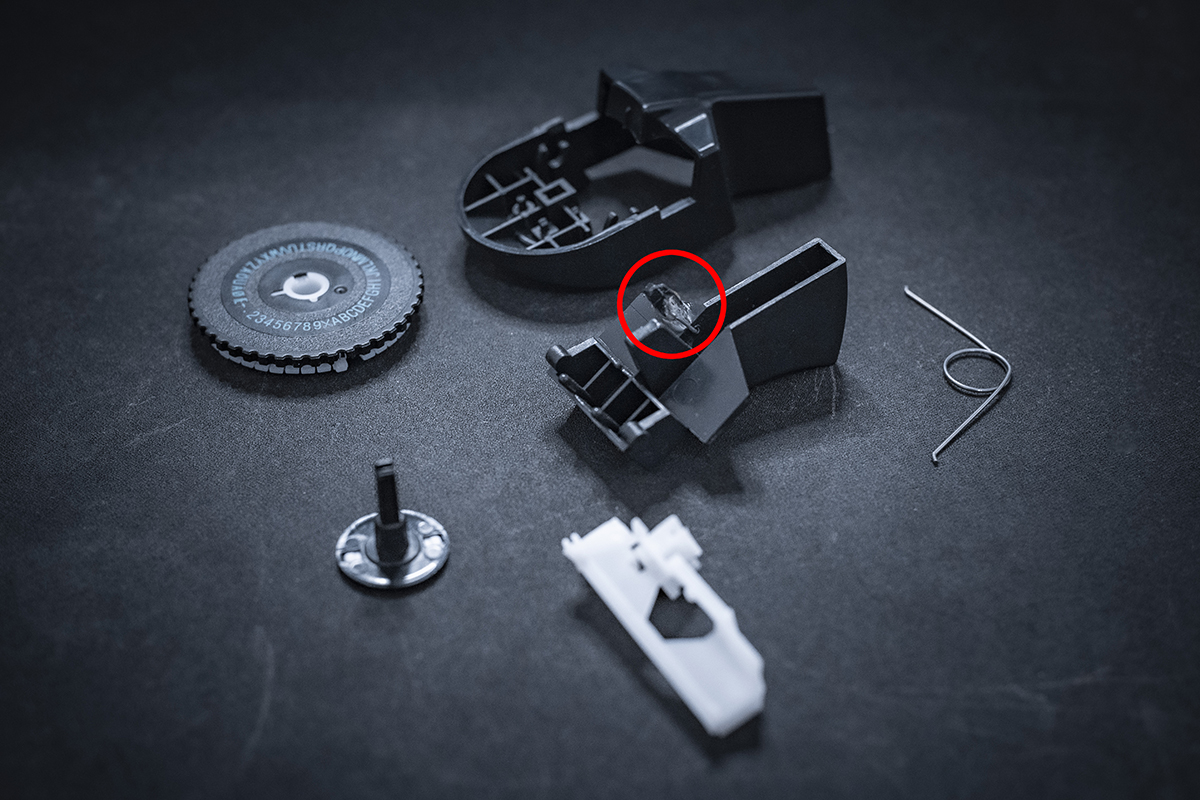

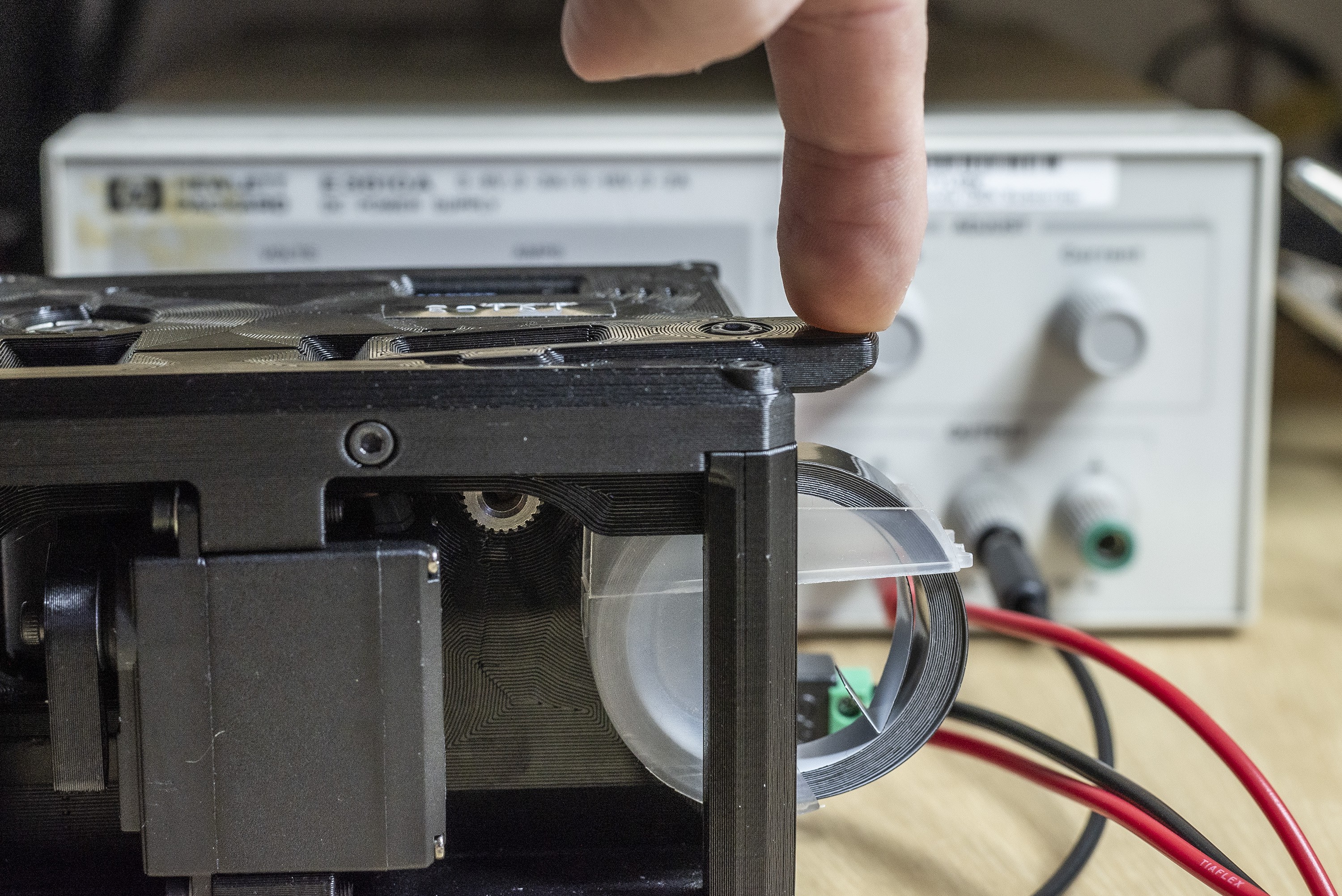

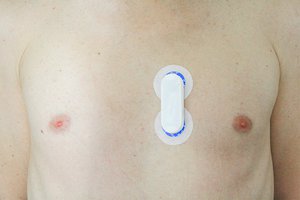

This little plastic hook (circled in red) grabs a ratchet mechanism (the white plastic part below) to feed the tape forward. I tried to fix and reinforce it, but the failure was unavoidable because there seems to be a critical flaw in the project: it is too weak for the lateral force imposed.

At that moment, I could easily buy a brand-new electronic thermal label printer (such as this Brother model), but something about the vintage embossed finish fascinated me. Also, these new models use expensive DRM proprietary cartridges that create a lot of trash after use, not to mention that some other recent models are DRM protected.

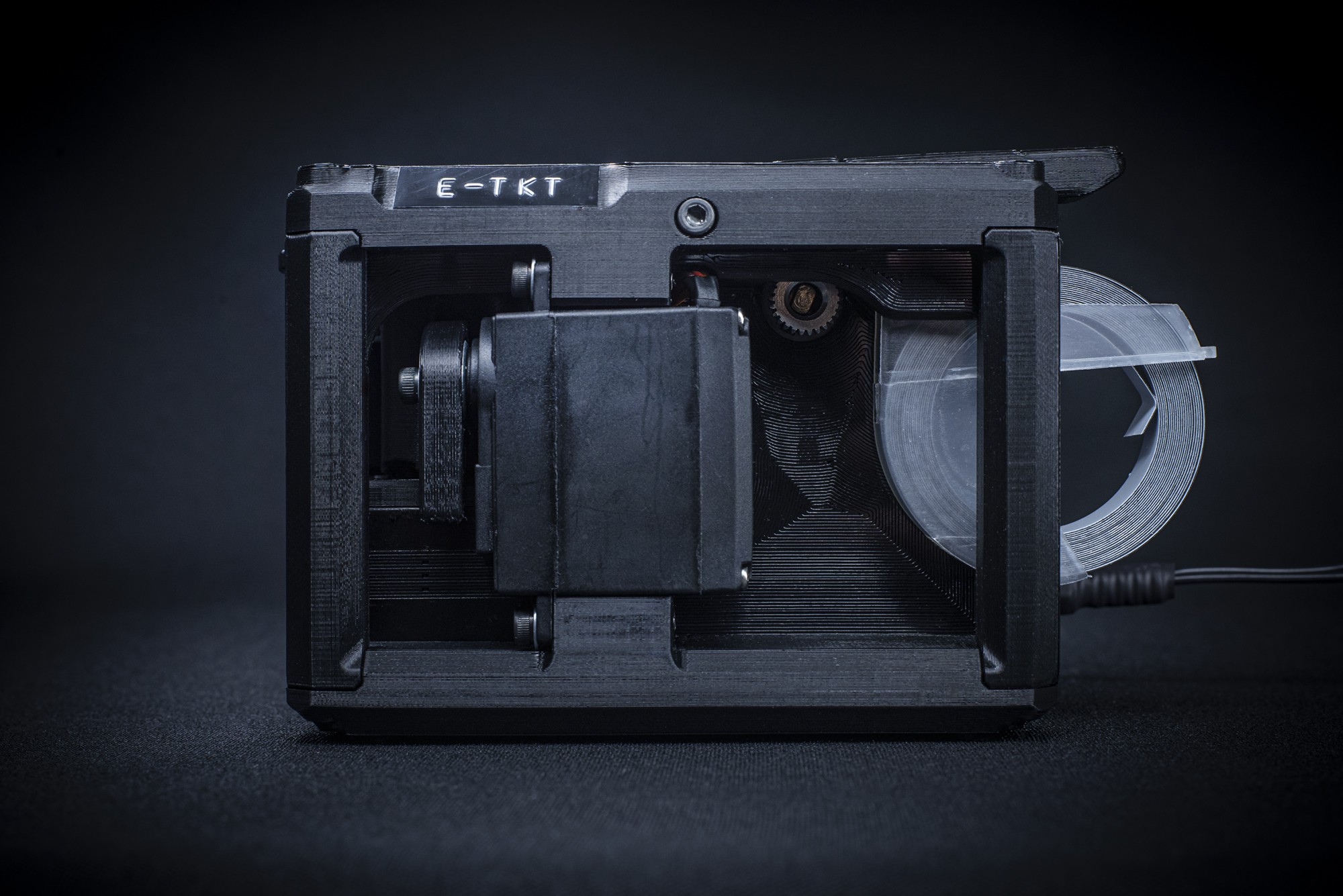

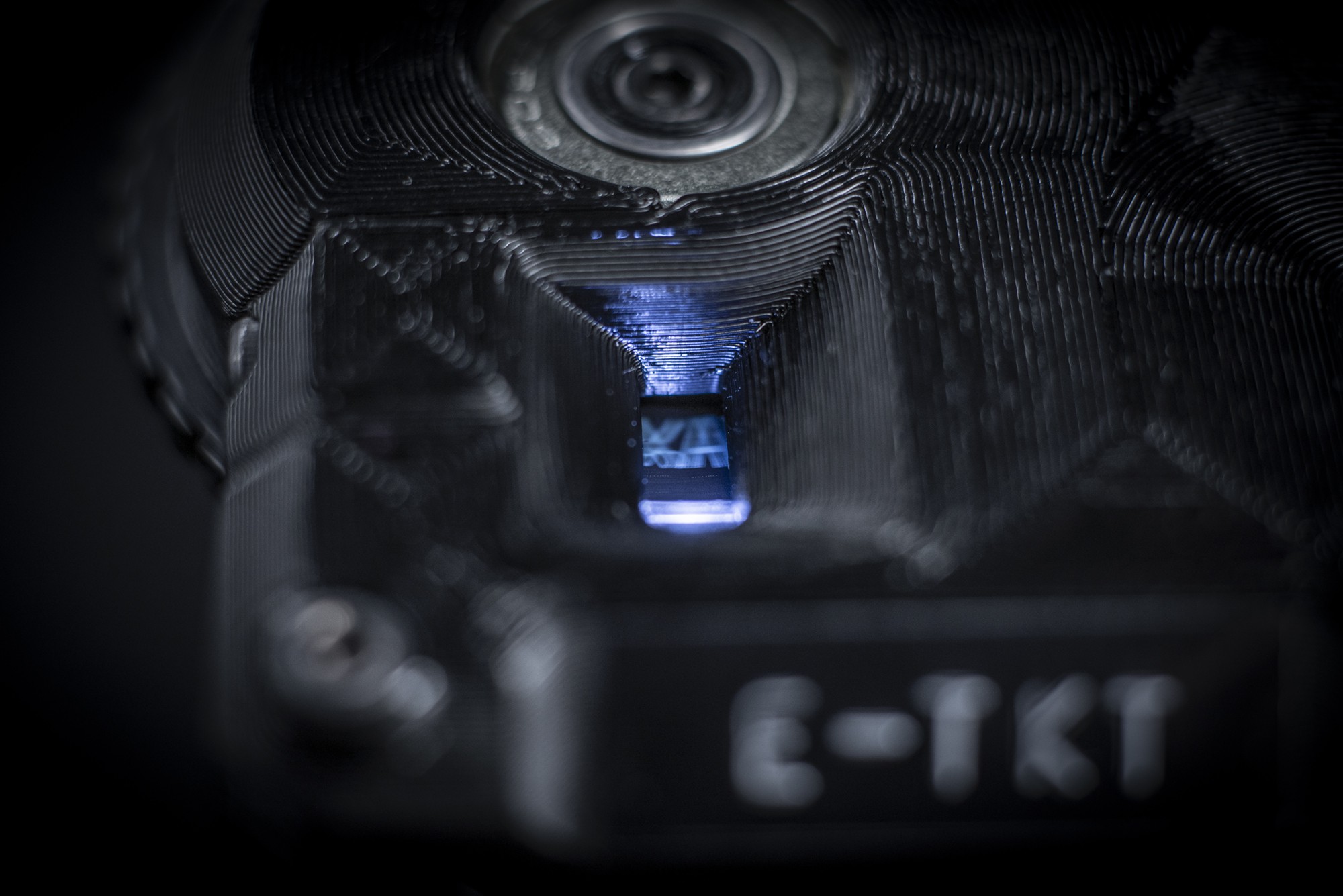

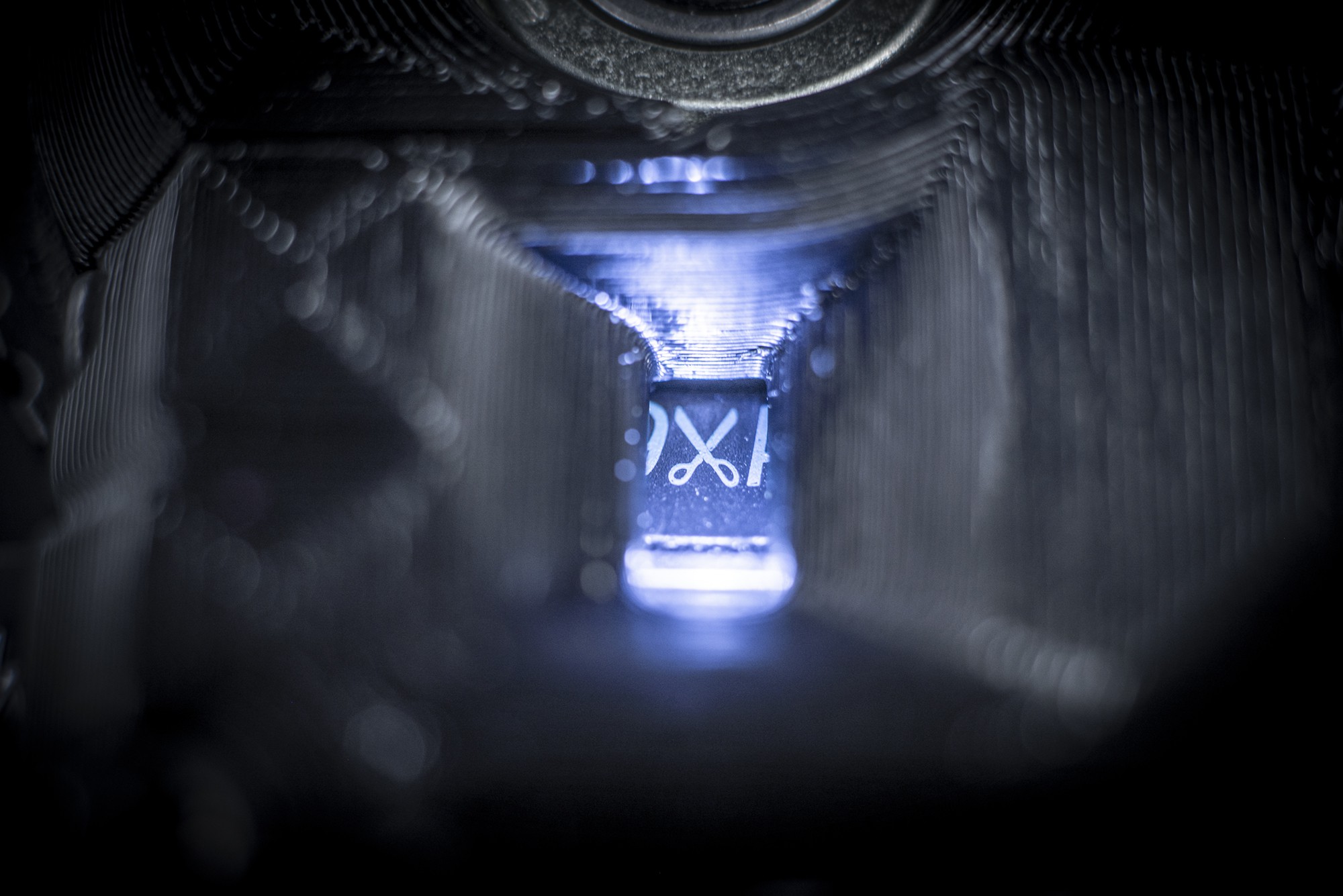

After all, even though the pressing mechanism was poorly made, the daisy wheel was pretty sturdy and sharp-printing. So I thought: can I build over its principles to create a functional device? If so, then why not make it physical-digital?

…why bother mixing an archaic printing method with current automation and connectivity features? Because why not? It was a technological blind spot ready to be explored!

🤯 reasoning: context & purpose

- ACCESSIBILITY: braille labels are only a step of distance for a possible future spin off.

- CULTURE: embossed labels are deeply ingrained in culture, as well pointed by Dan Maloney (HACKADAY), spacestationkru (reddit) and agent_kater (reddit);

- NICHE NEEDS: there are situations where a paper, flat and/or thermally printed label doesn’t fit the needs, let alone the need for the embossed relief;

- ERGONOMICS: when there is no other way than using embossed labels, making them manually is a straining process that might give the operator repetitive strain injury;

- REACH: this is a cheap mass-produced device, meaning that lots of people around the world might have one at home or work;

- ENVIRONMENT: these devices...

Andrei Speridião

Andrei Speridião

source: Ars Technica

source: Ars Technica

Kenneth Marut

Kenneth Marut

WΛLLTΞCH

WΛLLTΞCH

Lex Kravitz

Lex Kravitz

Ultimate Robotics

Ultimate Robotics

Have you see the vwestlife video on these? He has a model with a changeable both disk which could be interesting for you. https://www.youtube.com/watch?v=3w95K0FOIo4