The Squeezebox Keyboard is a custom-designed ergonomic computer keyboard I have been working on for nearly a year now. The primary design driving factors include:

- Wanting the keys really close together both within a column and across columns

- If there was a nice switch smaller than the Kailh chocs, I'd be interested

- "Home corner" concept for the home row and bottom row taking curvature to an extreme and making a straight-up corner (100 degree angle)

- Each finger can rest on 2 keys and hit either without "moving" by using the fingertip and pad, respectively

- Mechanical tailor fit without many rounds of long and perilous 3D prints

Earlier Prototypes

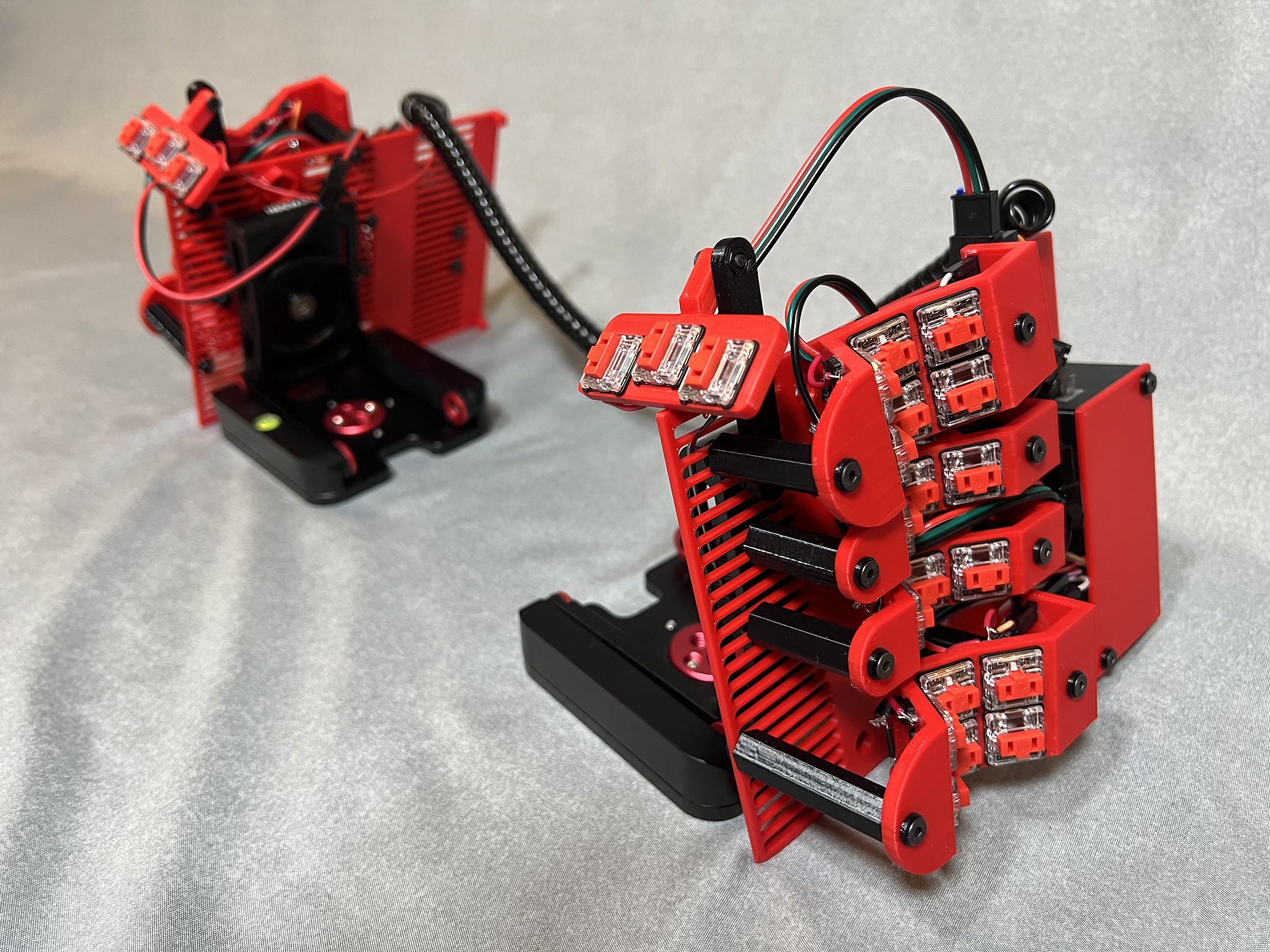

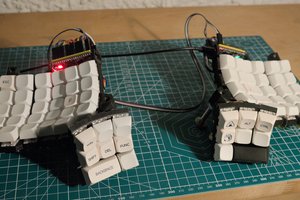

This post describes my latest fully functional build/prototype. Earlier builds include the original non-tented version from April 2021 and the steeply tented version with magnetic posts on a steel base plate from June 2021.

Review of existing aspects

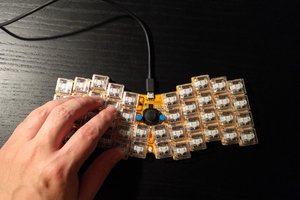

If you are just seeing this project for the first time, here's a recap of some other things to note about the design.

- No keycaps! Naked switch stems. Kailh choc switches don't need no stinking caps.

- Super tight spacing. Even the pinky can reach all 3 rows without stretching/straining and without having to move the whole arm. I have to move my arm to type the top pinky row on most keyboards I've tried, and for years I pressed that key with my ring finger without consciously realizing it.

- Allow chording the middle and bottom row with a single finger from the home position

- Whether this is really practical with QMK, whose chording support is not that great, is still kind of TBD. A custom firmware with carefully implemented first class support for this might make this a central feature, but as of now I can't yet do it consistently/accurately enough to use it for important stuff.

- Switches can be hot swapped out

- Each finger can be independently finely adjusted in column stagger, splay angle, and height

- Modular design facilitates things like swapping in a different thumb cluster, for example

- Designed around steep tenting split usage

What's new in this version

Slots on the base plate

The primary mechanism of adjustment near/far has been changed to moving the finger columns along a grid of slots in the base plate, which has been custom designed and 3D printed to support this. The previous build used a steel base plate and magnets. That was kind of neat in the arbitrary precision of it and using the same mechanism for both columnar offset (near/far) and splay angle (finger columns like rays emanating from a center point vs 4 parallel lines). However, it was a bit too difficult to get everything in an optimal position and then lock it in and know it wouldn't accidentally get moved around or knocked loose.

Now the slots on the base plate afford columnar offset by sliding posts along the slots, and splay by putting the front and rear post for a column in different lane of slots. You can think of this like the front of the finger column can be swimming in a different lane than the back of the finger column. I generally put the middle finger straight ahead, splay the index finger by 2 rows, and splay the ring and pinky by 1 row. The degree of precision for this adjustment is not very granular, but it's adequate for sure.

New standoff columns

The standoffs/posts that afford the height variance across fingers are now hexagonal posts, so they don't roll around when loose and have heat-set threaded inserts in both the top and the bottom. They get bolted to the base plate and to the key column. I'm very happy with this mechanism. I have some tiny washers I 3D printed and when tightened down just a little snug on the bolts everything feels very mechanically stable and secure.

New thumb cluster post

Same basic mechanism of slots and bolts is used to attach the thumb cluster, but as it is oriented 90 degrees off...

Read more » Peter Lyons

Peter Lyons

Simon Merrett

Simon Merrett

David H. Bronke

David H. Bronke

deʃhipu

deʃhipu