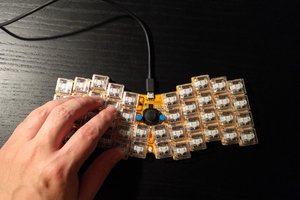

Mechanical split keyboard with OLED displays in the key caps

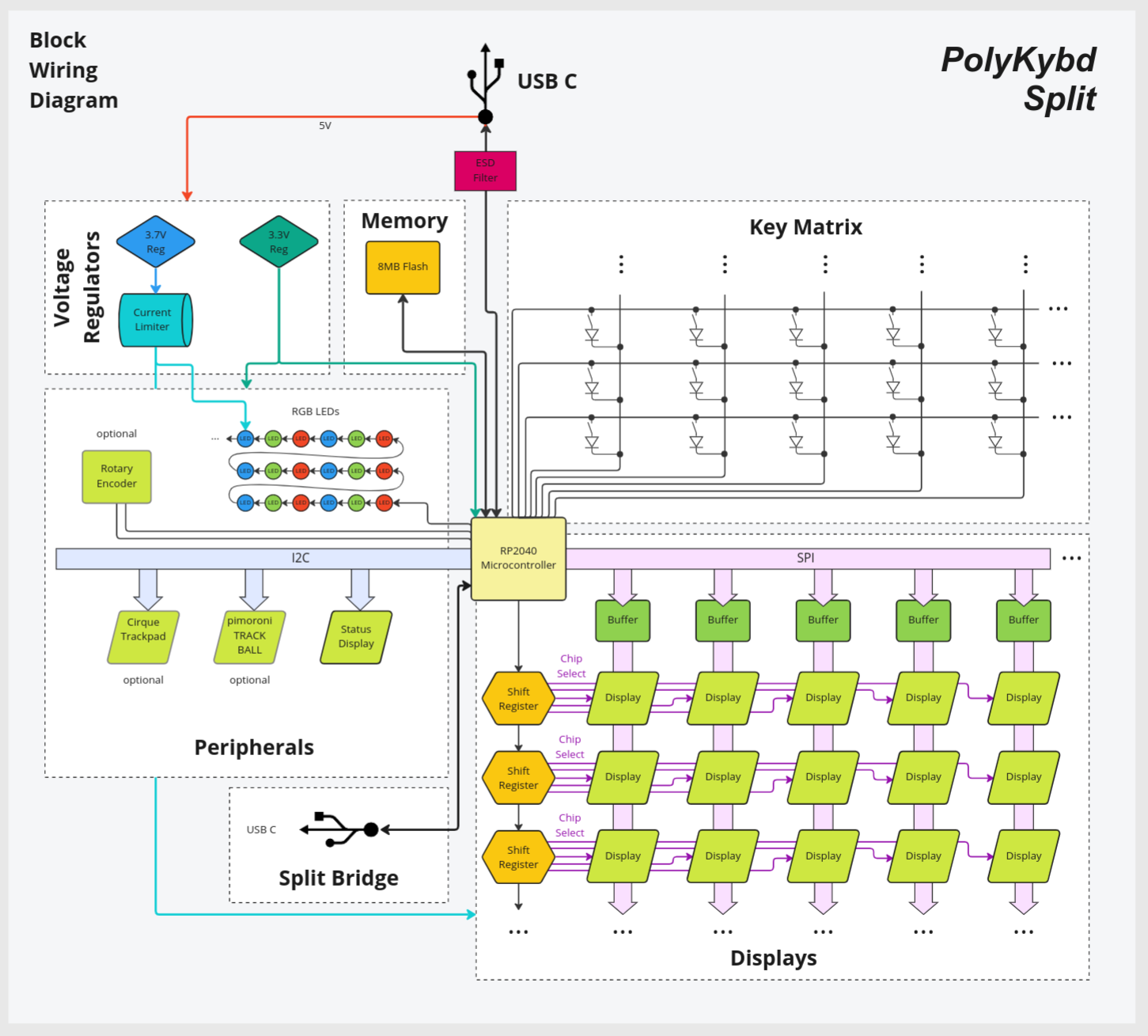

It uses QMK as firmware for the keyboard and controls the displays via SPI and chained shift registers to address all displays separately or even all at once.

Other keyboard sizes might follow later (maybe a 75% version and a macro pad?).

There was a Hackaday post earlier about this project: https://hackaday.com/2022/10/17/poly-keyboard-has-screens-in-every-key/

Current Status

The HW development is almost finished. The firmware still needs further improvements as it is currently really just a work in progress to show what is possible.

However, the build guide is ready at https://github.com/thpoll83/PolyKybd#readme and I am happy to share that there is a pre-launch page on CrowdSupply in case you are interested in getting a kit: https://www.crowdsupply.com/polykybd/polykybd

Overview

More details will follow, please feel free to dig around in the git repos and ask questions.

thpoll

thpoll

RasmusB

RasmusB

Kārlis

Kārlis

deʃhipu

deʃhipu

I've been coming in from the opposite direction. I'm currently working on a Corne keyboard, which has very few keys usually (~36-40) and I was pondering screens in the keys to help me learn/remember layers. You already have the screens, and they'd make the layers a lot easier.