This project is based (with minor tweaks) on the work of Nick Wilson, covered in his video, "Resin Printer Mods and Continuous IPA Filtration!” The idea is to pump dirty IPA out of the wash bucket, expose it to UV LEDs, partially curing the dissolved resin (easing its filtration), pass it through two filters, then return it to the bucket. The IPA won't be adequately cleaned in a single pass through the machine, or even 30 passes, but, eventually, it will be almost like new. Because of it's similarity to the process used for purifying blood for people with kidney disease, I call it "IPA dialysis."

To get an idea of how quickly resin will cure under the light of the UV LEDs recommended by Nick, I did a couple of tests, shown in the video below. First, I just dipped a popsicle stick in some resin and hit it with the light. It probably cured faster than I waited, but I was hoping to see some change. When I didn't after a few seconds, I touched it and the resin stayed on the stick (except for a thin film of something that transferred to my finger), instead of smearing.

In the second test, I add some resin to some IPA to see how the LEDs affect the mixture. After the zoom, the filaments you see forming are the curing resin. I speed the video up 20X to jump ahead five minutes, and you can see the goopy result. All that stuff should be easily filtered long before it gets that far.

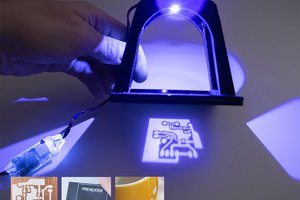

Here's is the final layout of the machine:

The dirty IPA gets pumped through a triple loop of clear vinyl tubing wrapped in the LEDs before heading to the filters (5 micron first, then .5 micron) and back to the bucket. The countdown timer lets you set a run-time and then forget about it; the system will shut down when the timer times out.

Here's a short video of the machine in operation:

Here are some samples that show how the cleaning progresses (the "Dirty" in this test wasn't nearly as dirty as in the previous test), with about 1.5 gallons of dirty IPA. The times are the run-times:

A spreadsheet bill of materials is attached to this project.

Things I have no idea about:

- How to quantify the cleanliness of the IPA?

- How long will the filters last (though they're not particularly expensive at $US 6.25 each)?

- How to tell when the filters should be replaced?

- Can the filters safely be tossed in the garbage (since the resin in them is, at least, partially cured), or do they have to be treated as hazardous? I'll do the latter, but it would be nice to know.

- How necessary are the LEDs? Would the filters alone work just as well? This should be easy to test, but I'm lazy and the LEDs are already there, so I'll leave this to someone else.

- How long will the IPA last, even with cleaning. Does it degrade?

Nevertheless, for me, this eliminates a minor headache when 3D printing. YMMV.

Involute

Involute

kelvinA

kelvinA

Kyra S

Kyra S

paul

paul

Besides the fact that many "vinyl" (polyvinyl chloride aka PVC) tubing brands are not UV-transparent hence make the UV loop reactor pointless, the material may react and crack in the long run under the influence of such high-concentrated (99%) alcohol. I suggest using clear PTFE (or its derivative FEP or PFA) tubing instead, which is high-pressure resistant (unlike some cheap soft PVC tubing!), chemically resistant to IPA, as well as UV-transparent.

½" clear PTFE/FEP tubing is maybe a bit stiff though. An alternative is silicone tubing, which is also very soft. A drawback is its lower PSI rating.