The tiny reads input from a 2ch rc tx/rx system using pluseIn() on 2 digital pins, which means it works with any rc esc style project including rc cars/trucks/robots/etc anything with pwm and custom electric skateboards.

Ch1 - Steering wheel is used for turn signal control

Ch2 - Throttle is split and sampled for brake lights while still allow an esc to read the same signal.

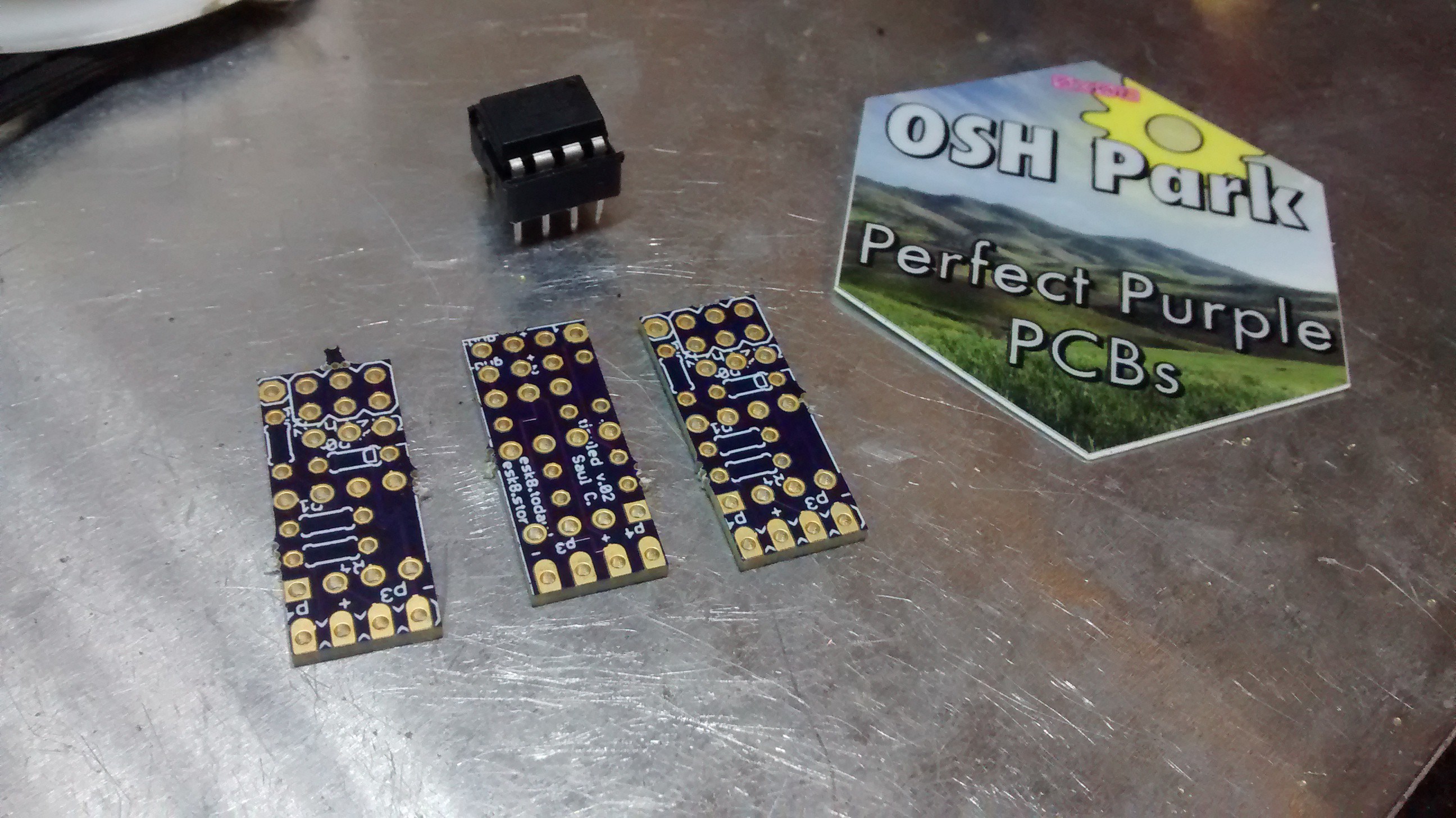

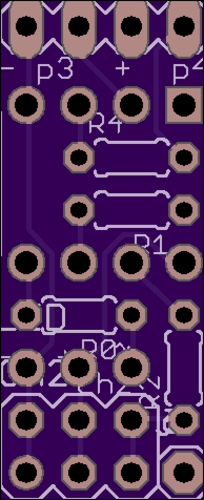

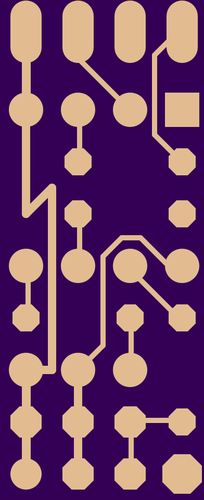

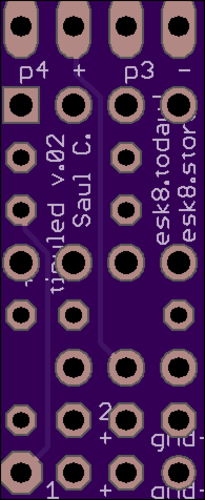

The hardware is designed to be as compact as possible, soldering through hole components with this schematic is quick, easy and elegant. So instead of creating a custom pcb, using perf board makes this a simple soldering project that doubles as a prototyping experience. It also means the design can be quickly adapted, customized and hacked with no cost and minimal time!

Turn signals are not required on an esk8 but this feature was inspired by the led display is (see video2 @ 1:30) the control feature can also be adapted to control a led headlight or aux/under glow lighting (testing but really another project).

The micro switch is not current used in the code:

Option 1: use it for configuration with the rx, for now configuration can be done by changing variable/constant values then reprogramming. (only 1 time for setup)

Plan B: change modes, brightness, colors, on/off (sleep mode).

or just ditch it in favor of a even more micro size.

Saul

Saul

Jithin Sanal

Jithin Sanal

DIY GUY Chris

DIY GUY Chris