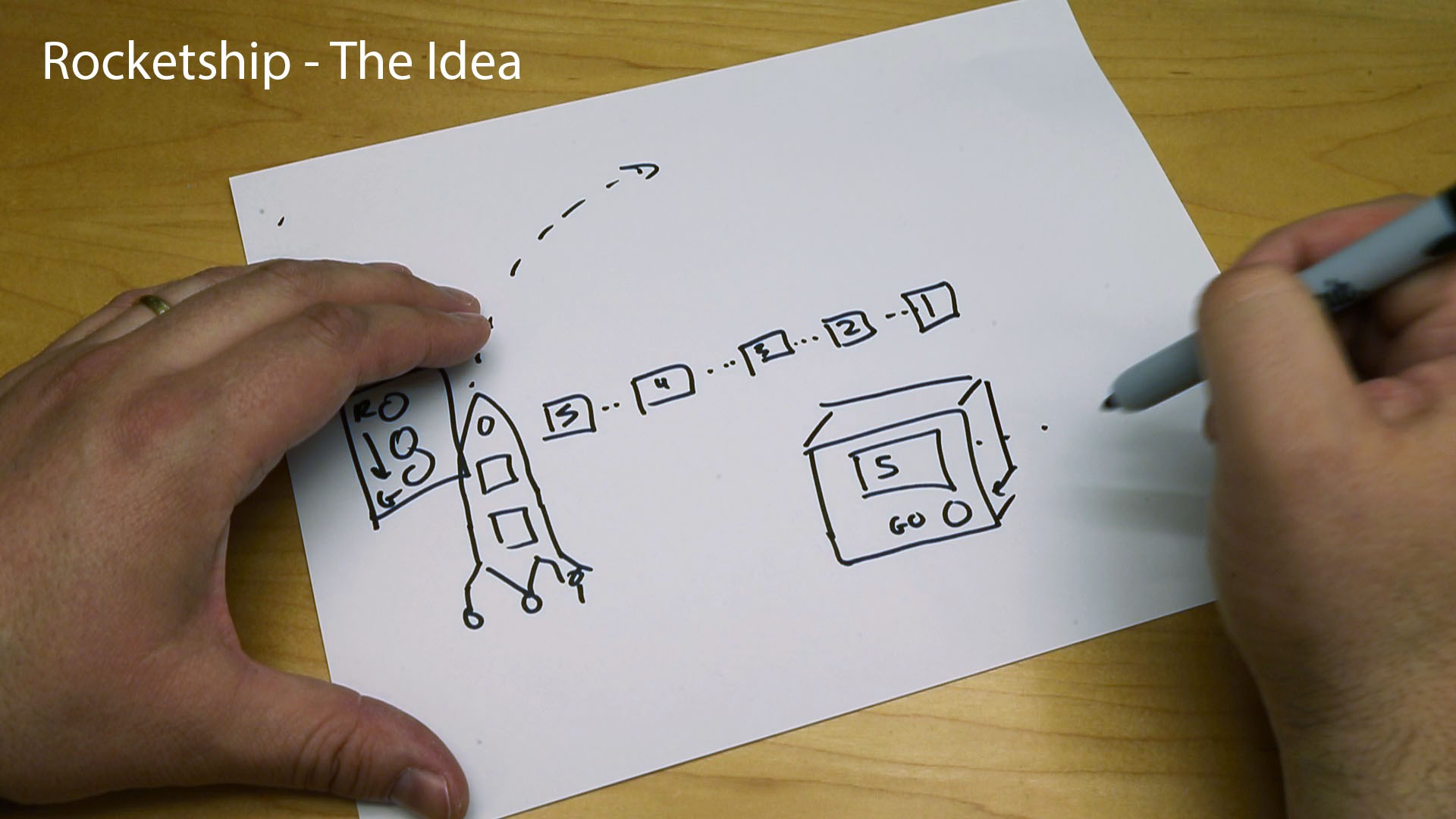

Makernet simplifies electronics projects and makes low-level hardware act more modular and abstracted like software. I want to enable makers -- especially young makers -- to build cool projects with minimal effort.

See the concept video below:

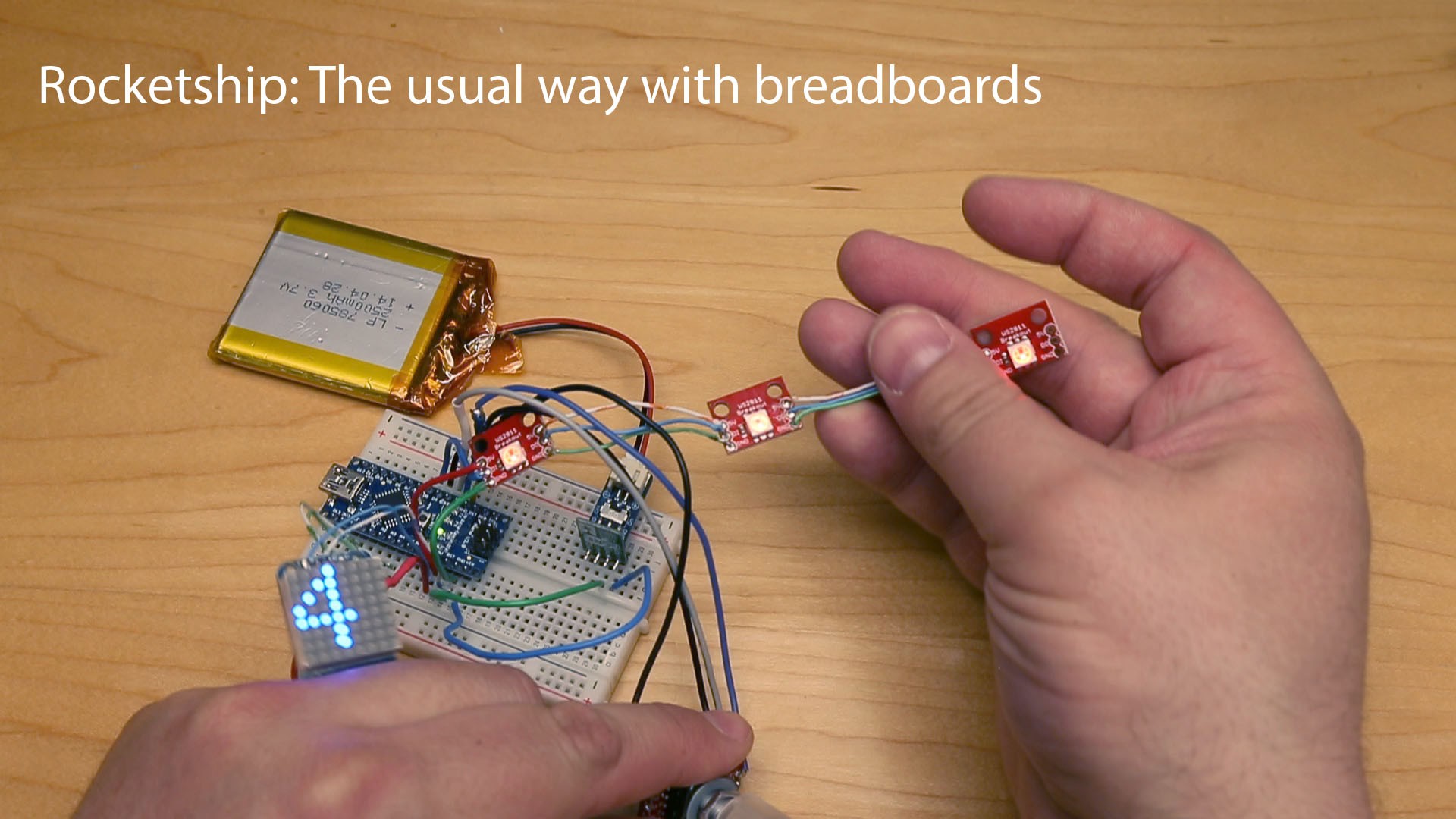

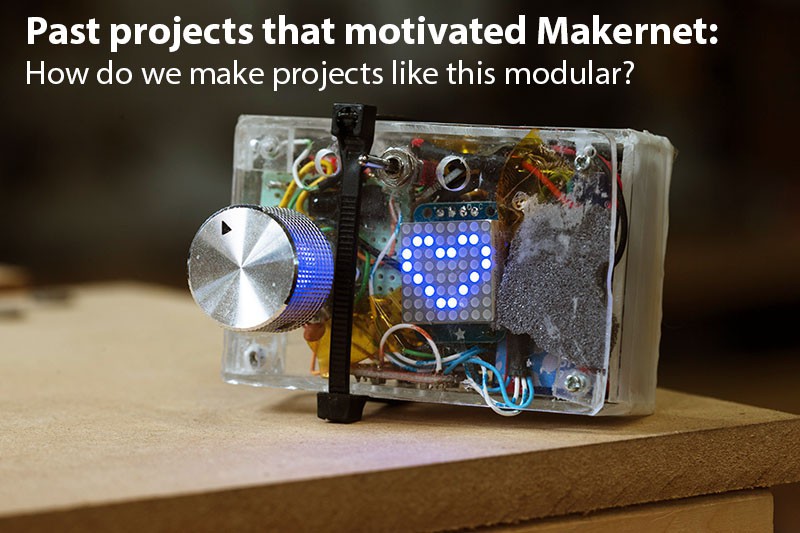

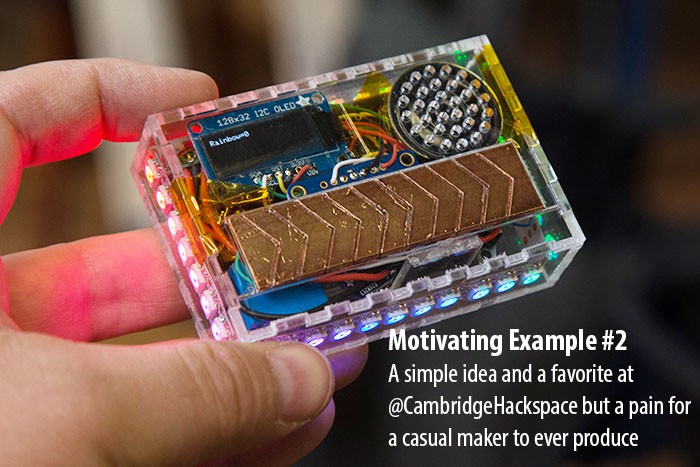

Everyone loves the thrill of building cool one-of-a-kind hardware. But lets be honest: hardware is pretty esoteric, much more so than software. Imagine someone raised on Minecraft and smartphones. How do we get new makers excited about building things? And how can experienced makers make projects more repeatable and less one-off and hard-coded?

Makernet addresses this challenge by creating a common robust bus network for all of the peripherals of a project. Everything is wrapped in a clean OO like paradigm. All you have to do is literally plug and play and forget about addresses, level shifting, battery charging, etc. Now electronics can be more like legos!

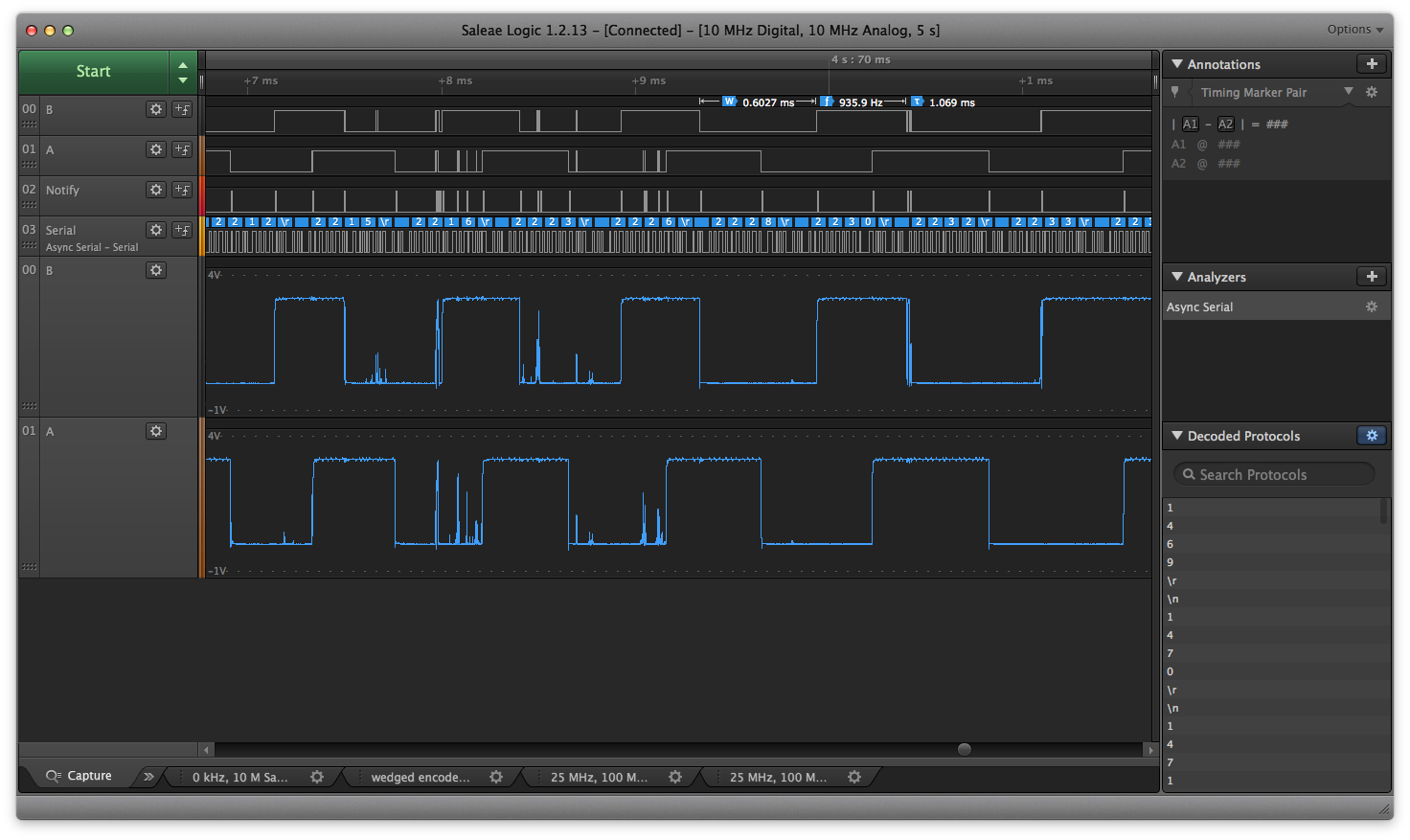

All of this is empowered by some clever hacking of the I2C bus and the availability of $1.00 SAMD11 ARM processors. A common event-based architecture sits on the inside passing messages back and forth.

Makernet is at the light concept stage. I have prototypes and I'm submitting this to the concept contest. I'd like to see if this idea resonates with other people.

Some of the intended features:

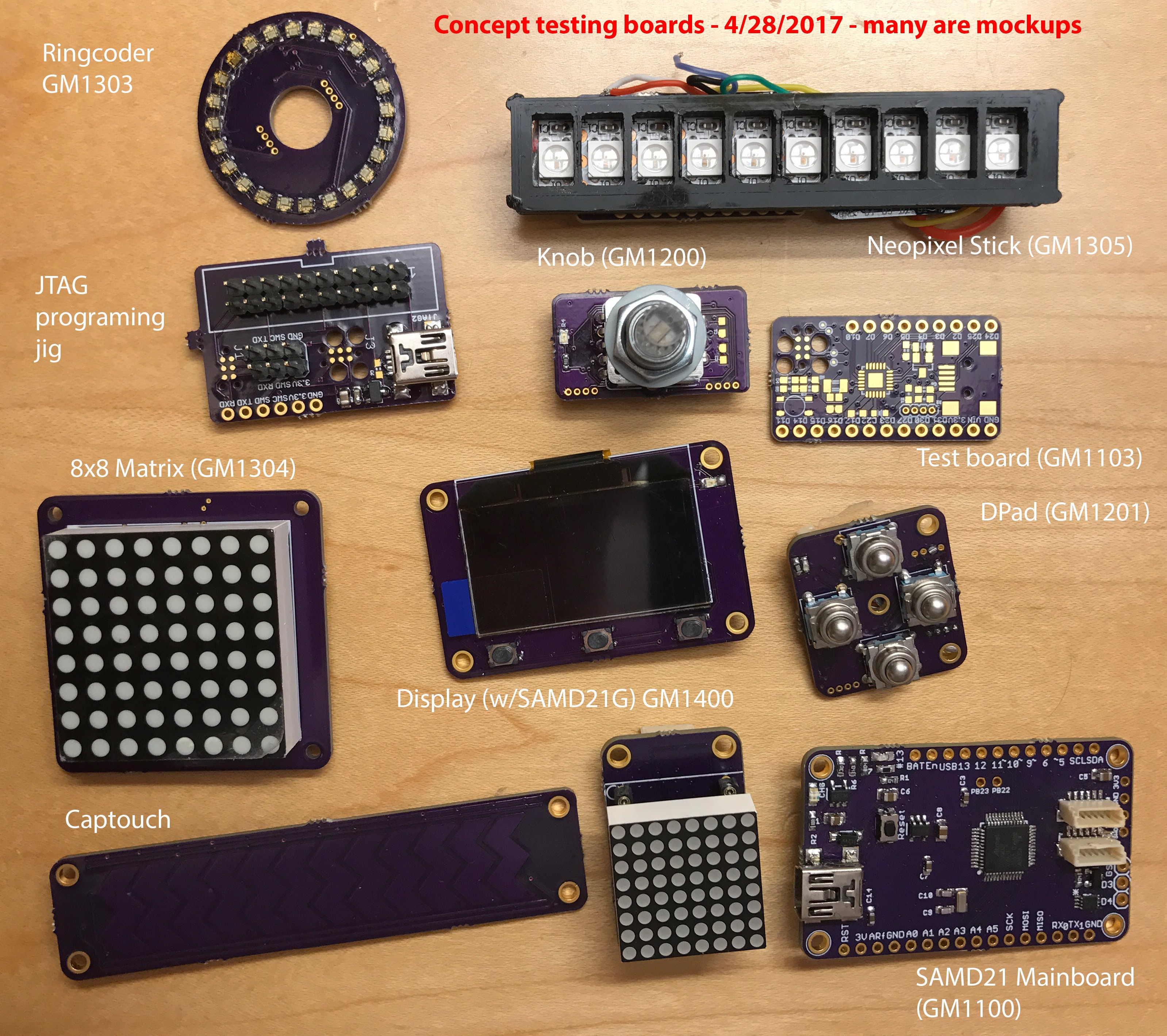

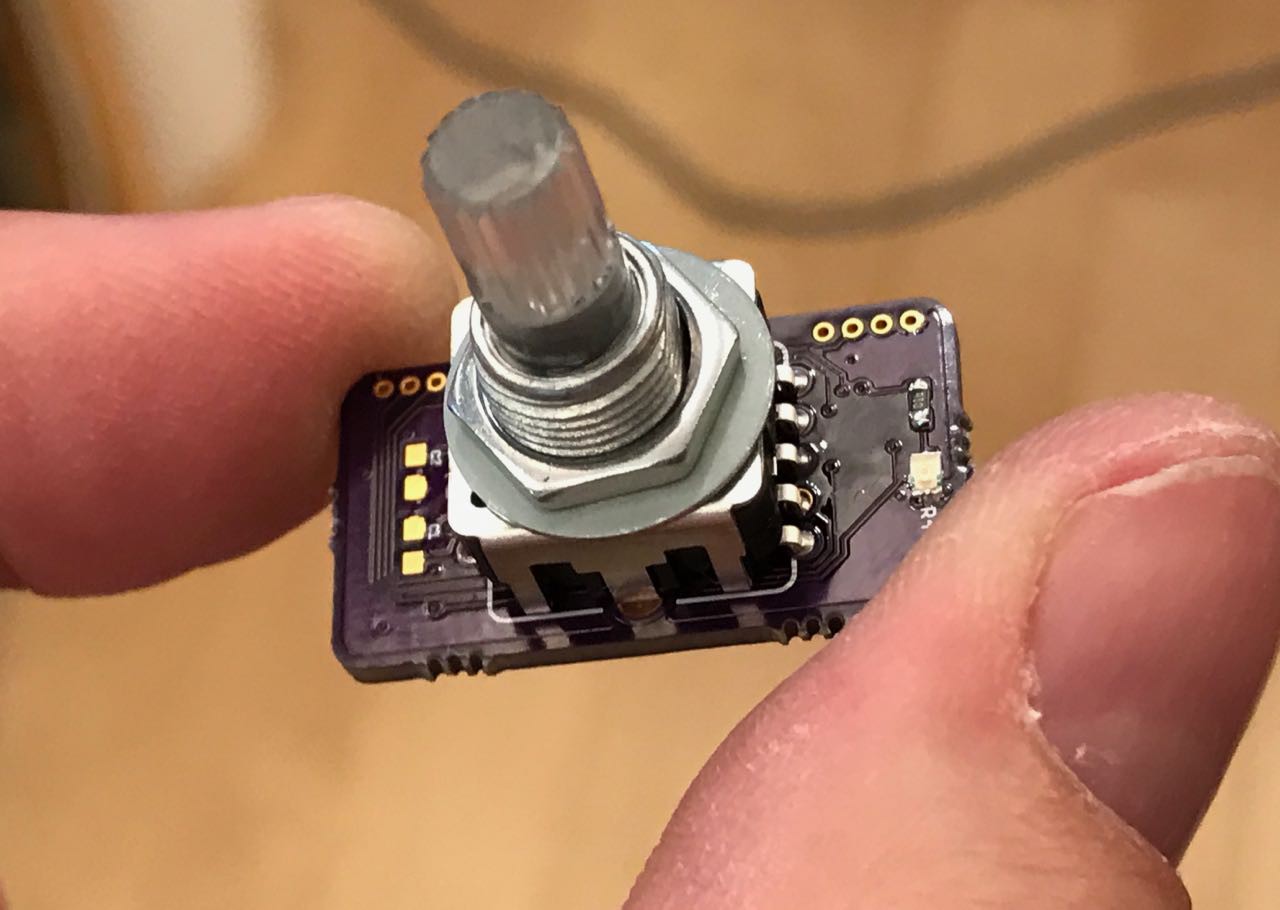

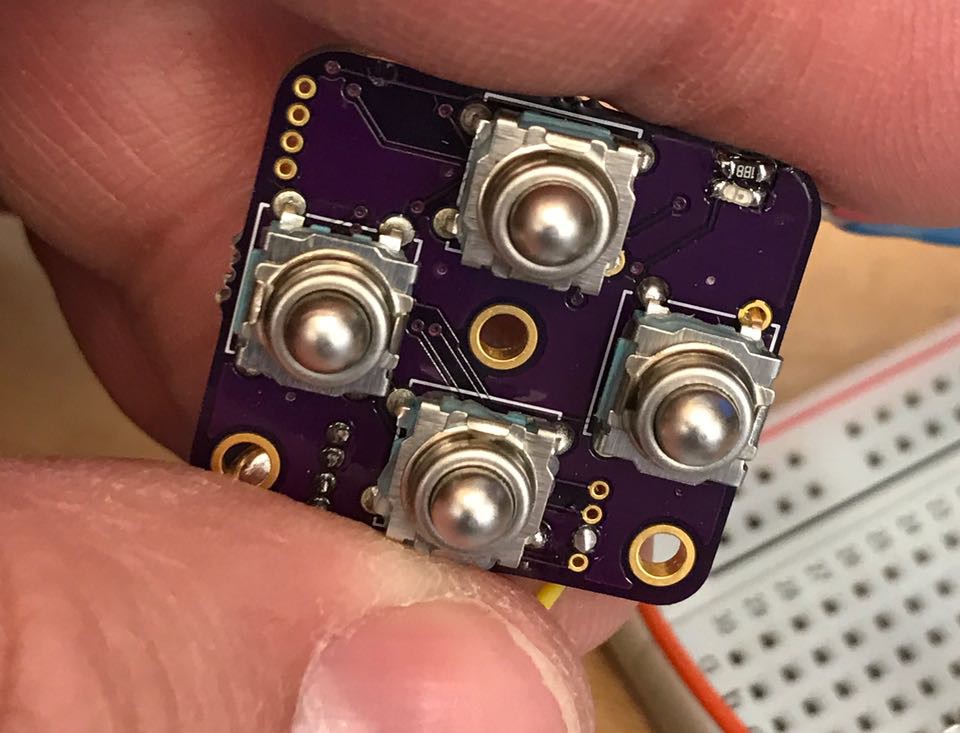

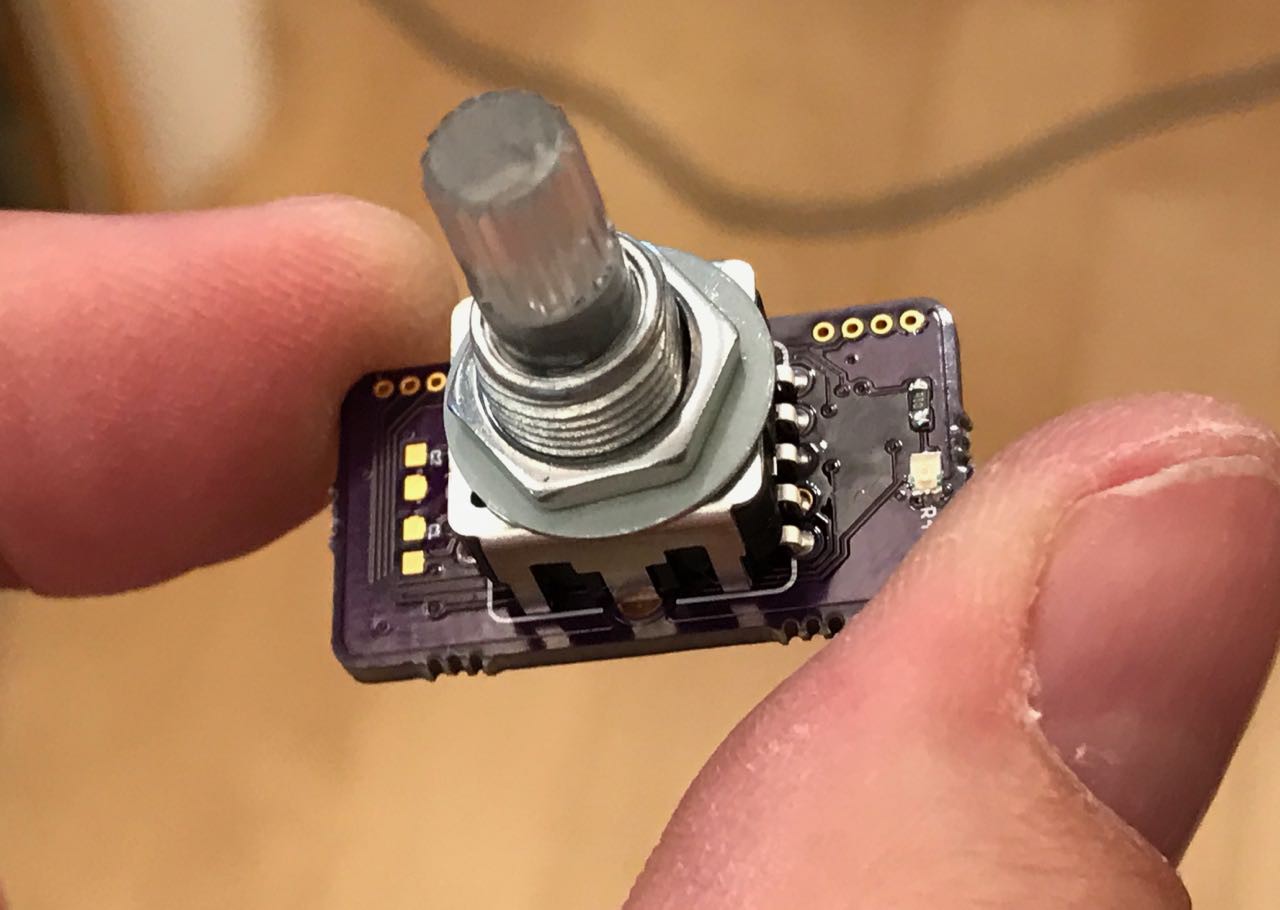

Pre-made modules: A small library of cool modules such as a rotary encoder, 8x8 matrix, capacitive slider, MCU board, neopixel driver, LCD/OLED screen, 4-way control pad, sensors, etc. All of them will be compatible and interoperable

Bus Architecture: MakerNet will be built on a bus architecture (initially I2C, later RS485) that allows true "plug and play" for most projects

No Soldering: Everything is connected with JST-SH 6 pins and can be daisy chained

Case plans: Every component has a clear mounting strategy, eliminating guesswork on how to put it into a case. Mix and match modules to create the control panels of your dreams! Everything flush mounts with countersunk M2 hex flat-head screws.

Low Power: All modules can be shut down into a low-power state consuming only a few microamps, meaning your projects won't need on/off switches

Battery management: The base MCU board will support LiPo charging and charge monitoring

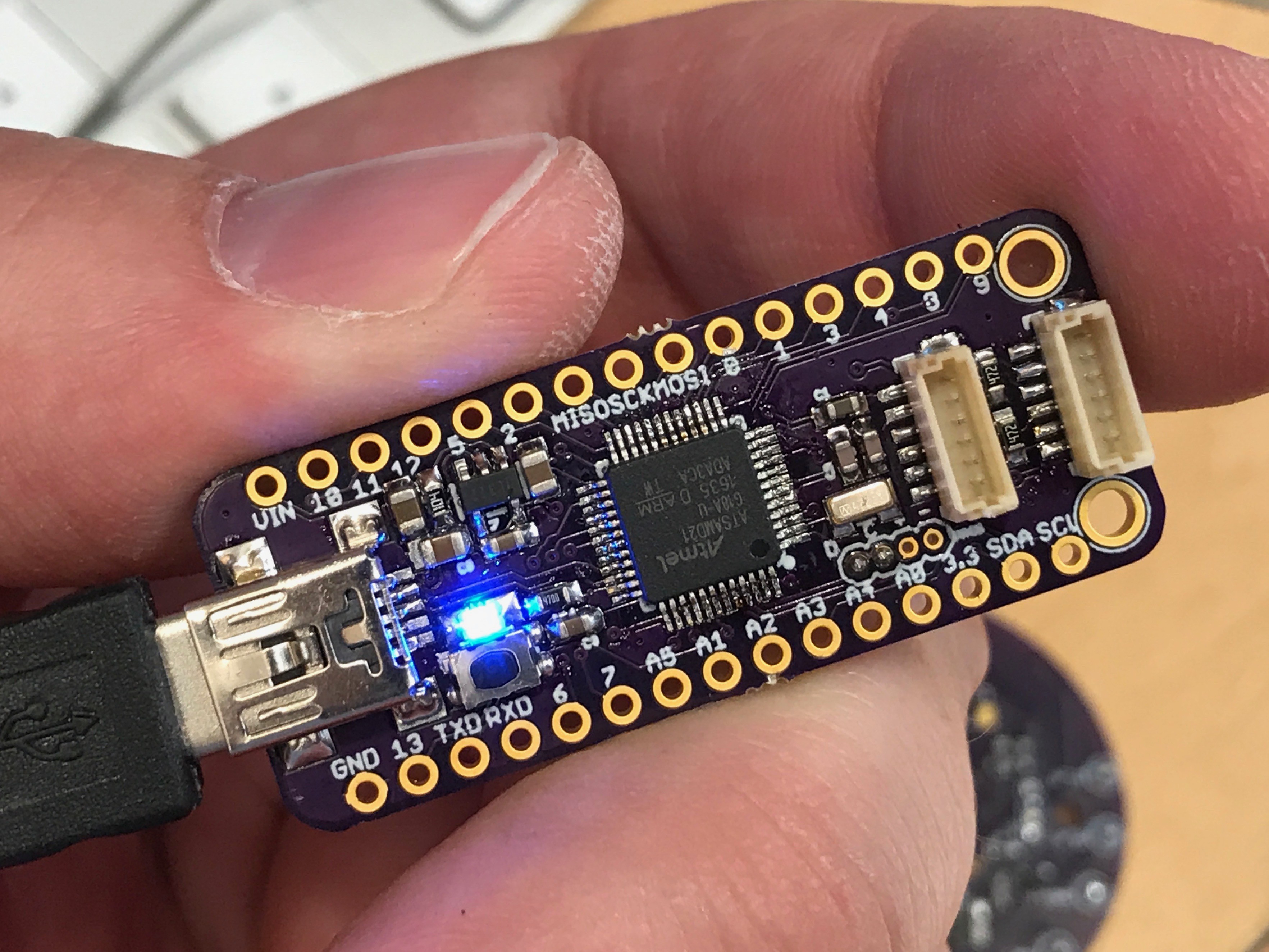

USB programable with Arduino: The core MCU will be either the SAMD21 or possibly the Teensy 3.2. The core module will expose a USB port to the outside of your case.

Common libraries: Programming is largely event-driven

Jeremy Gilbert

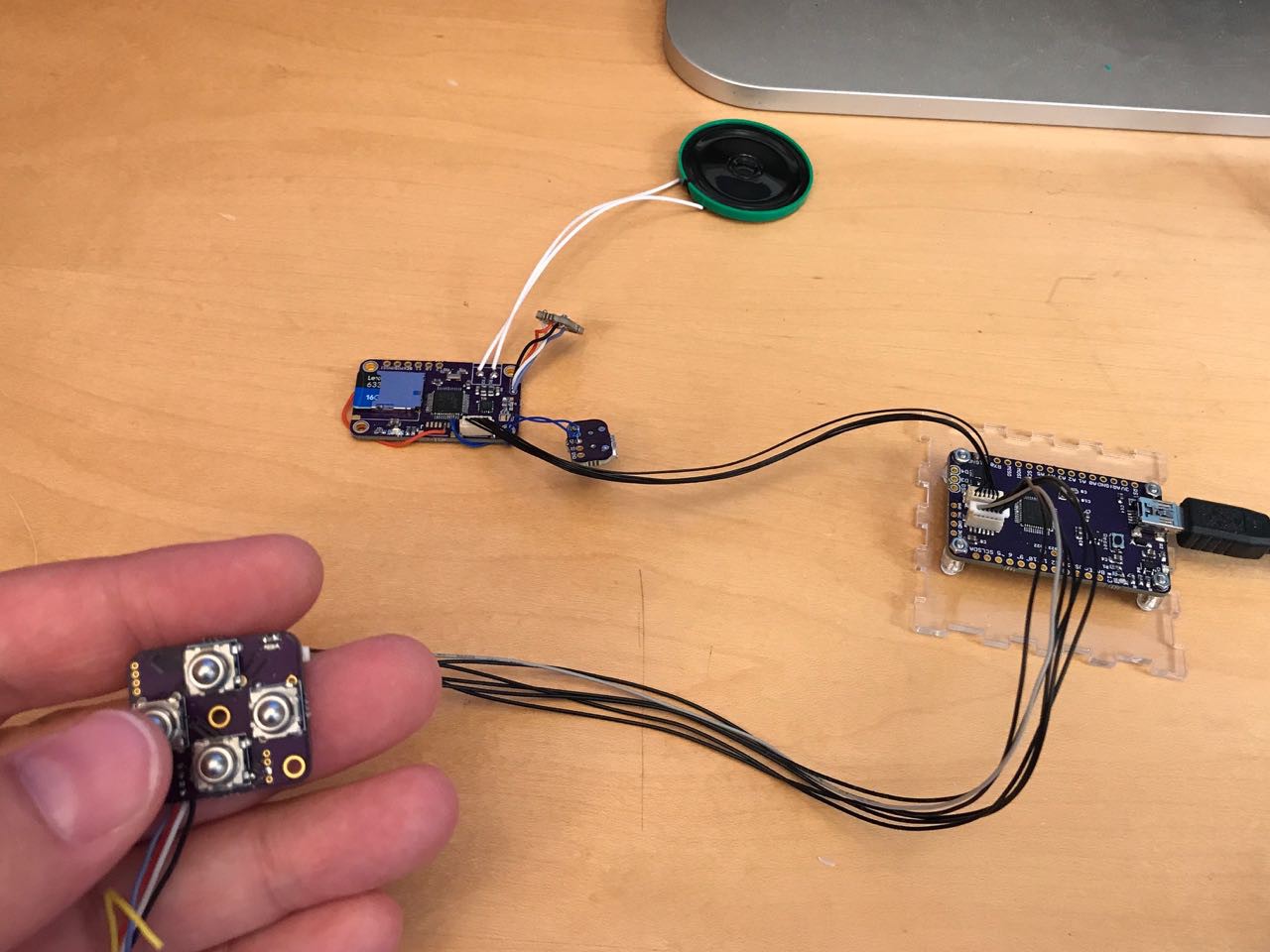

Jeremy Gilbert As you can see, this little baby is still being prototyped (note the dangling USB cable and programing jig). It has a MicroSD card reader, a SAMD21G18 MCU and plays sound out of a MAX98357A I2S audio chip. Of course it also has the regular 6 pin makernet header that provides it with network, 3.3V and VIN (usually 5V).

As you can see, this little baby is still being prototyped (note the dangling USB cable and programing jig). It has a MicroSD card reader, a SAMD21G18 MCU and plays sound out of a MAX98357A I2S audio chip. Of course it also has the regular 6 pin makernet header that provides it with network, 3.3V and VIN (usually 5V).

Chris

Chris

Alex Brown

Alex Brown

Pavel Zhovner

Pavel Zhovner

ziggurat29

ziggurat29

1. Please add Lora network similar gotenna.com or sonnet

look at cc1101 procesor

2. change connection. in my opinion rj45 is better than normal wired. why not using normal rj45 or smalest for old phones to connect power and i2c ?