The Quick Story:

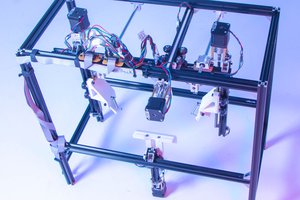

Back a few years ago, I built a 3d scanning rig for my 3D printing store in Pasadena (Seen here with Metalnat). The purpose was to offer 3d selfies and then 3d print them (as we did at Hack-A-Day's 10th Anniversary party, room with green windows on right in the timelapse http://hackaday.com/2014/10/11/hackaday-10th-anniversary-wrap-up/). Eventually people kept asking me if they can buy it, and so last year I started working on a more portable (the current one was 2 meters tall, not easy to travel with) and sturdy one to offer on Kickstarter.

In the process of designing it, I came to a part where I wanted a nice looking, smooth and precise actuator to move an arm. After shopping around a lot, I realize that adding an actuator like what I needed was actually going to cost more than the whole rig it self...and I still wouldn't have the specifics I needed.

This gave me the idea to explore what it would take to create an amazing actuator while having it be much cheaper than getting some custom ones made (that were literally quoted above $1200 each!)

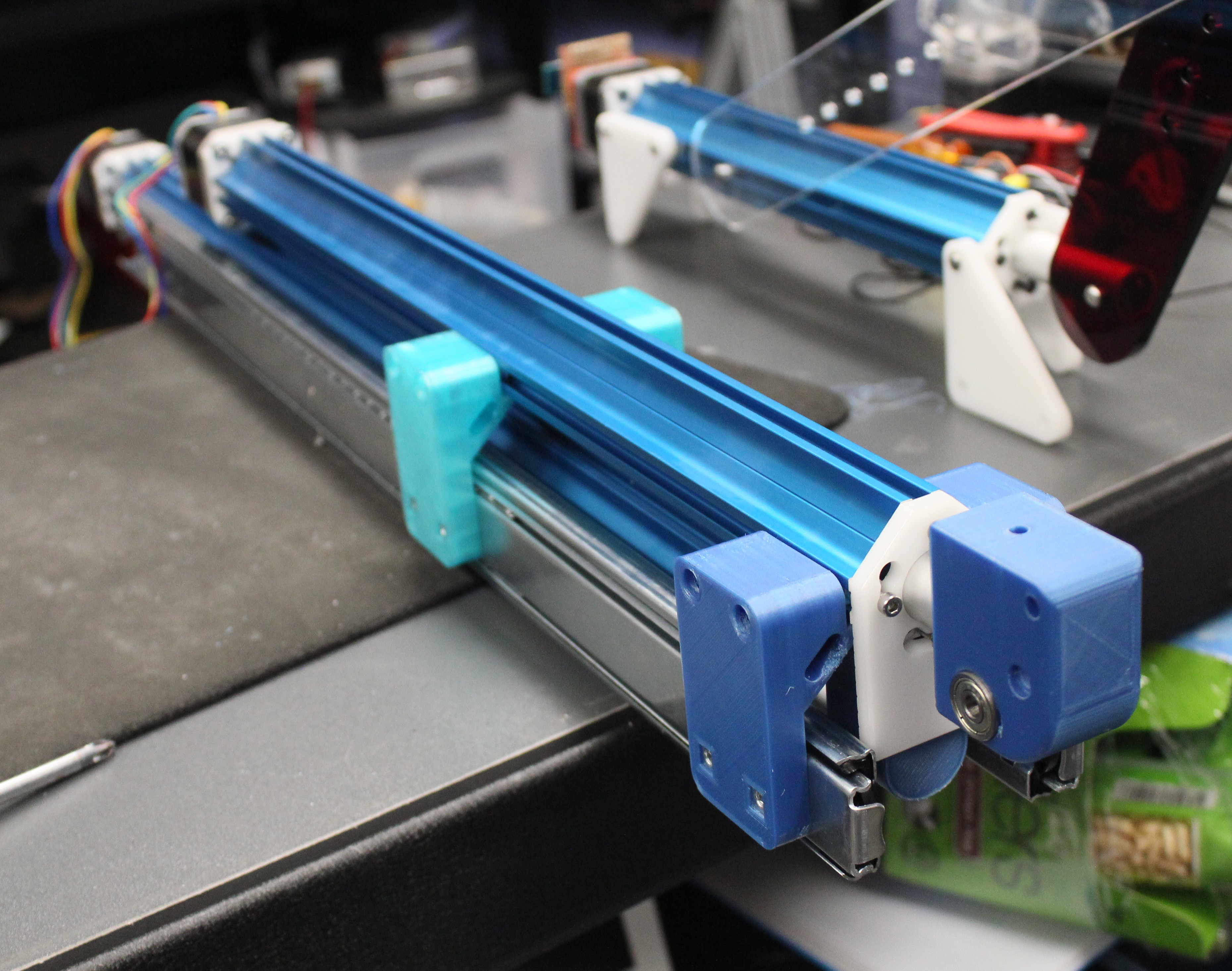

When I started, I made a list for myself of the features I wanted in the actuator and integrated them into the design. After some research, 3d printing some body housings shapes, and testing, I came up with the Maker Muscle concept.

I then went to a few friends that are actively working with robotics and got some amazing feedback. The great thing was that they asked me when they can get some Maker Muscles for their own projects... I said "soon my friends..."

....and that's how I got this started.

Details about target feature.

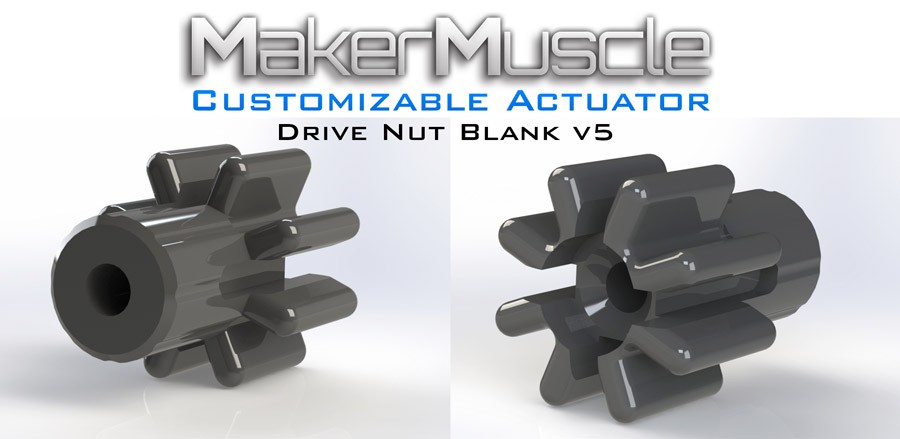

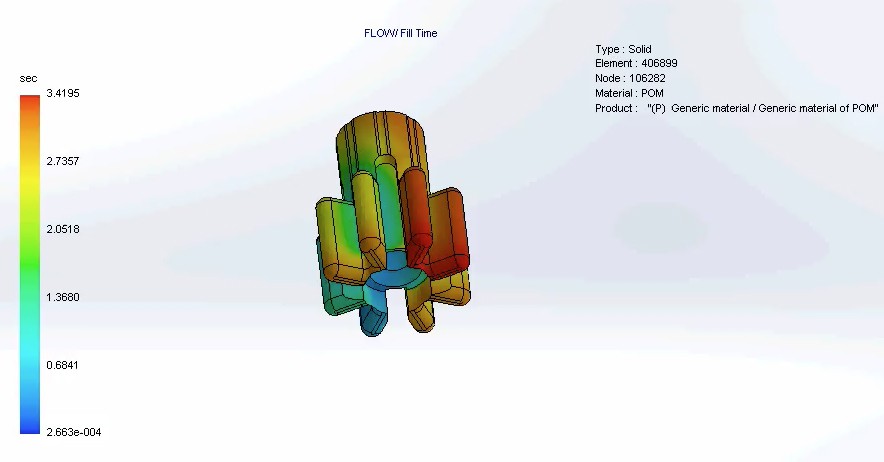

1. Has to be Customizable.

This is my most important goal for this project. Looking around the actuator market, I found that most actuators that can be customized in some way were super expensive (Check pricing at Misumi: https://us.misumi-ec.com/vona2/detail/110302584160/?Inch=0).

a. Custom Lengths

b. Custom Motor

c. Custom Screw Pitch

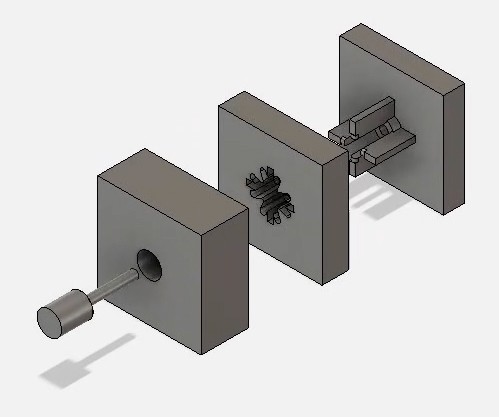

2. Modular

Being able to upgrade or change parts on an actuator, without buying a whole new one, I think is a critical feature to have. Modularity would save both time and money in a situation where you have an actuator already installed on something specific, but you just want to swap out the motor or a mounting bracket.

This is where the motor mount plates and attachments will come into play. As of now, you can install everything from steppers motors like NEMA 14, NEMA 17, NEAM 23 to almost any DC motor, with or without gearboxes.

I understand some Makers have a variety of motors they love to work with or maybe some robot contest have rules on the motor types, so with the Maker Muscle, you can turn your favorite motor into an actuator.

3. Must be lower cost.

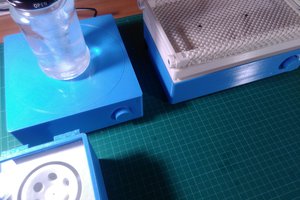

Creating a standard for mounting and fittings allows for more universal options that would be cheaper to produce. Starting with the main core aluminum extrusion, the features i design into it will allow a huge of cheap options to mount things on to it.

4. Must allow many mounting option with T-Slots.

I love T-Slots. The Bukito 3D printer we designed in 2013 was a great example of how T-slots can be used to reduce parts and also give you the option to tweak or add more things with little effort.

So on the Maker Muscle, I thought that having T-slots on the outside would open up a world of creative mounting options that I think Makers and take advantage of in new ways never done before.

Write up in progress....more to come....

Deezmaker

Deezmaker

barb

barb

Antonio Regueira

Antonio Regueira

ProgressTH

ProgressTH

Since there seems to be NO SOURCE FILES provided, no update in quite some time, and what seems to be yet another failed kickstarter campaign, i have started to reverse engineer this design concept and have published my initial drafts up on github. https://github.com/keen101/Maker-Muscle-Reverse-Engineered