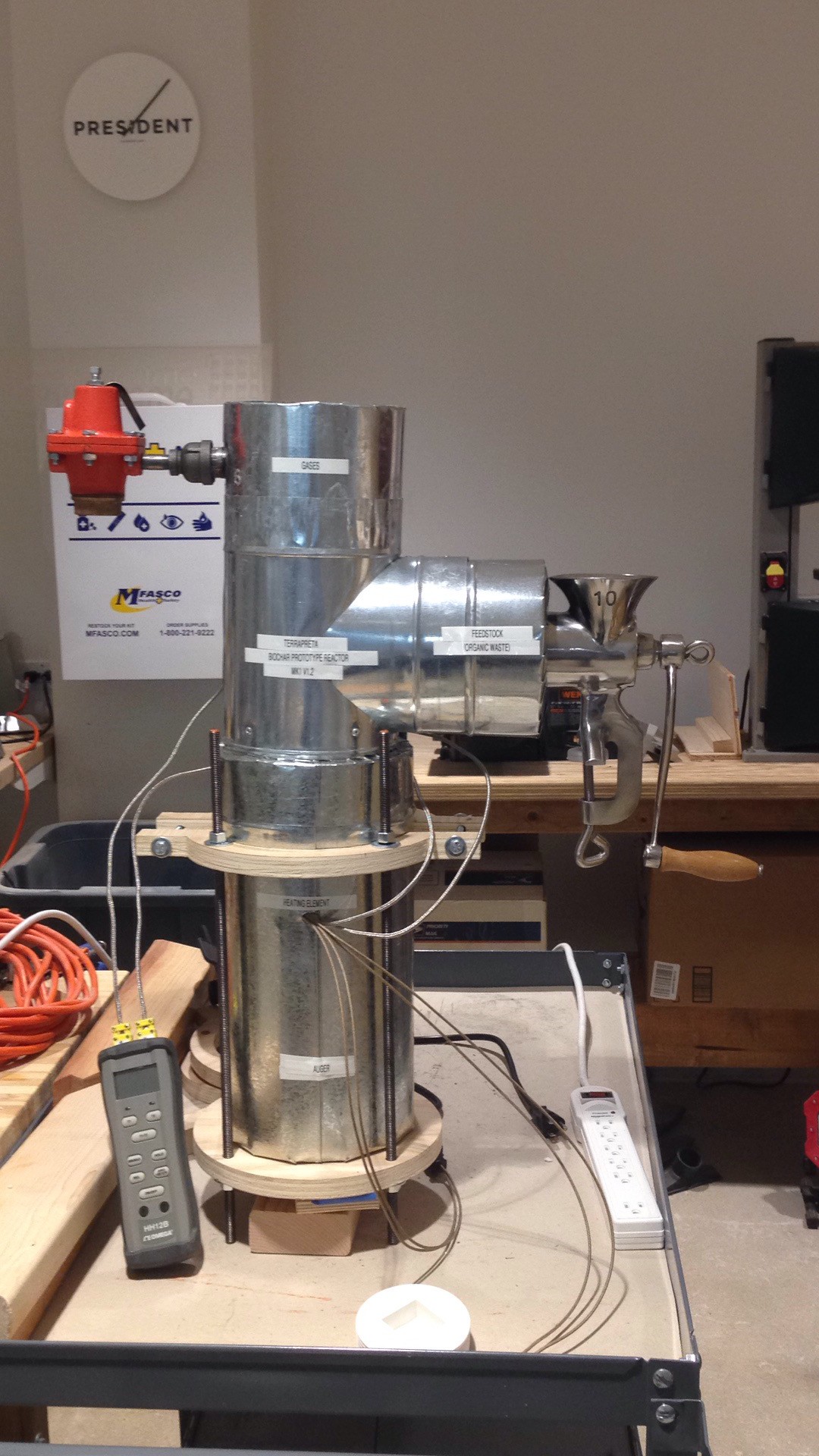

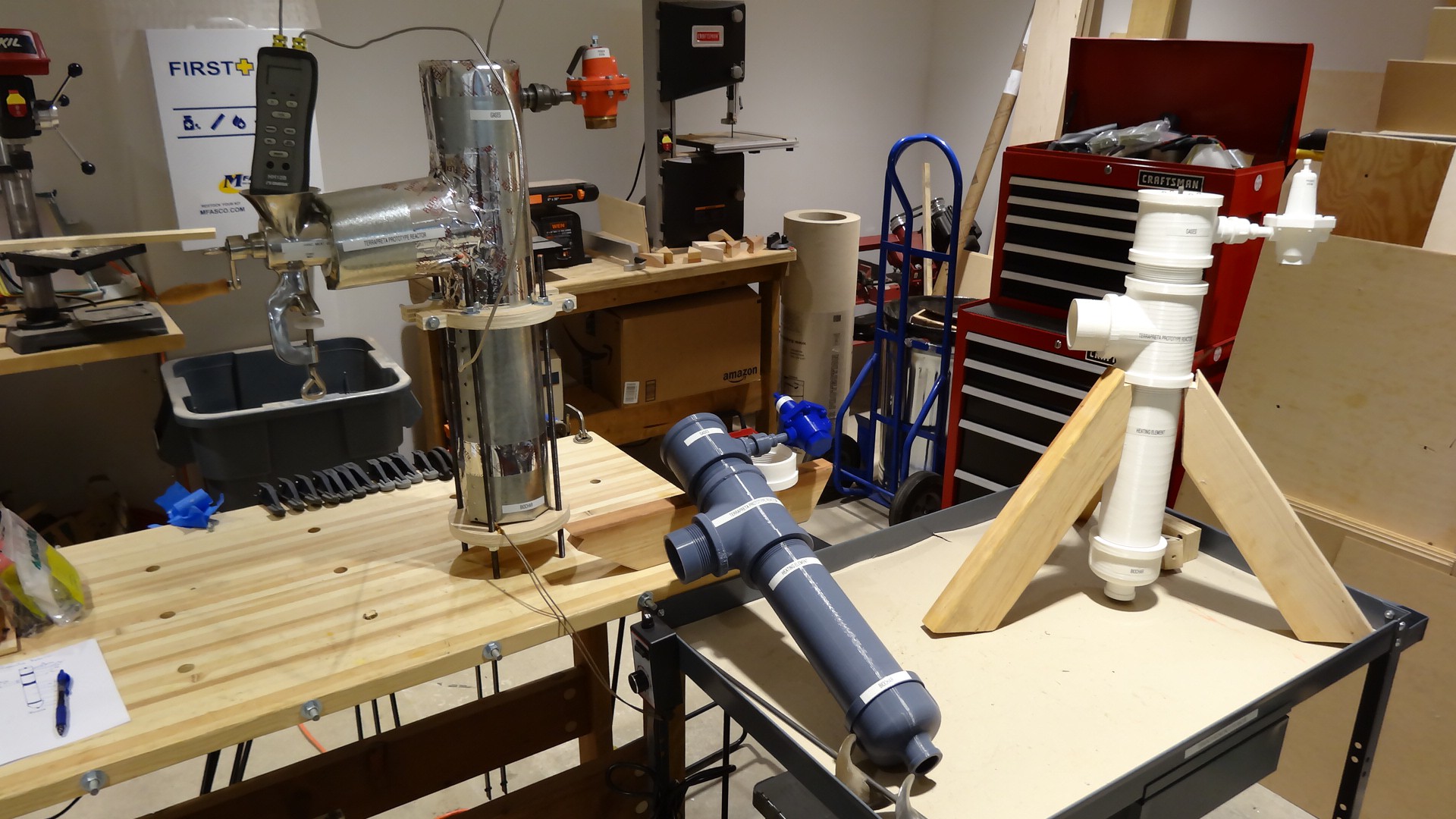

Since the raw material to be used in this project is organic waste, and it varies depending on the source, there are a vast number of conditions that we need to evaluate (feed source, temperature, pressure, among others), in order to be able to conclude what is the best performance to be used in the system. At the same time, the main objective is to produce Terra Preta to add it to Usual Soil to increase is yield of fertility, allowing us to mitigate carbon sequestering carbon, producing heat to reduce the energy requirements of the process being more efficient, and the last but not least, contributing to a better green environment.

Leonardo Zuniga

Leonardo Zuniga

Supplyframe DesignLab

Supplyframe DesignLab

David

David

Bill Smith

Bill Smith