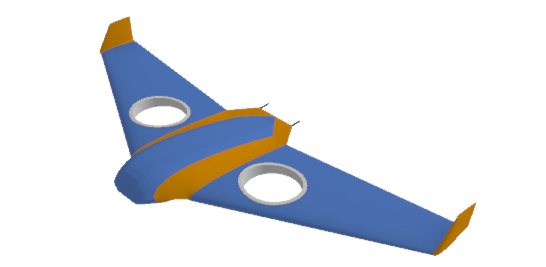

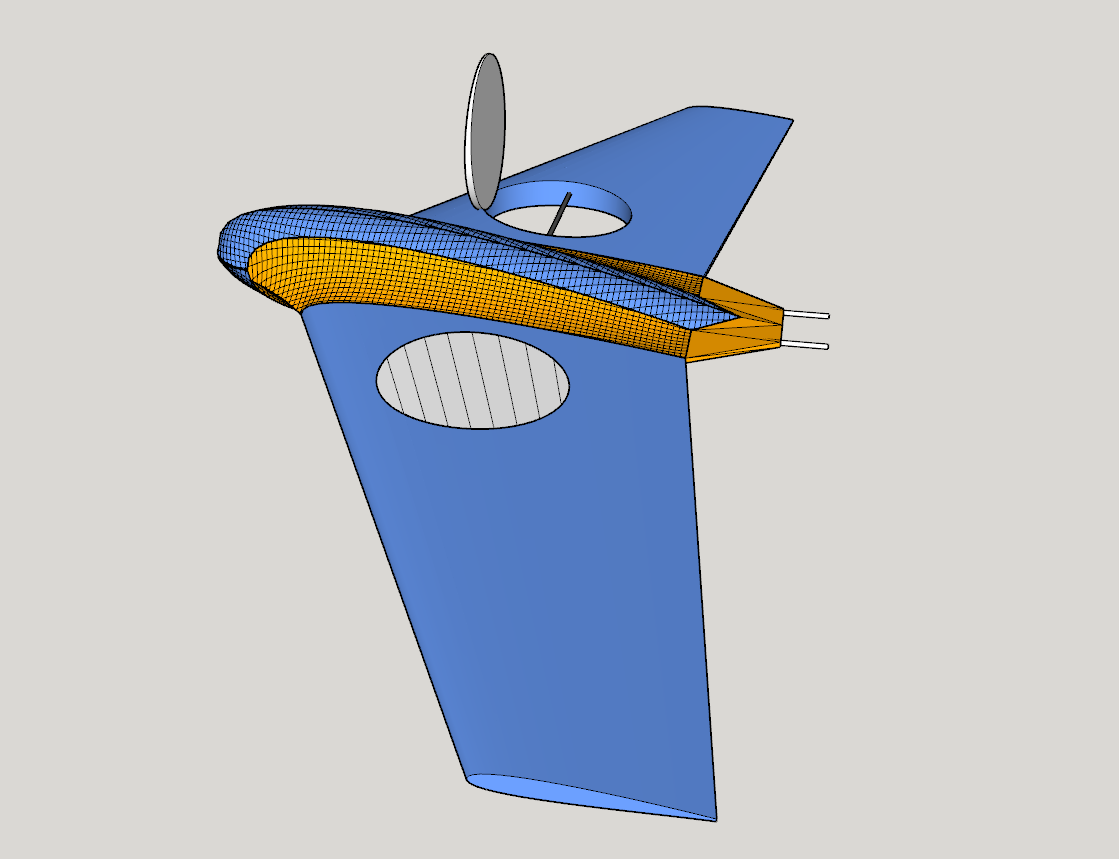

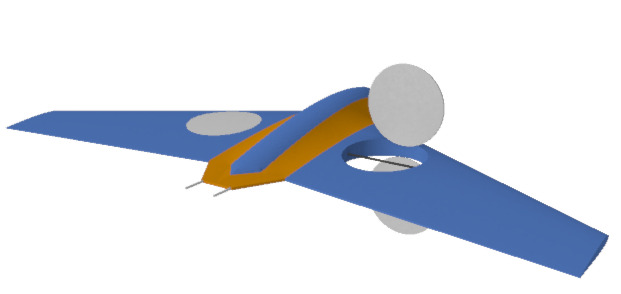

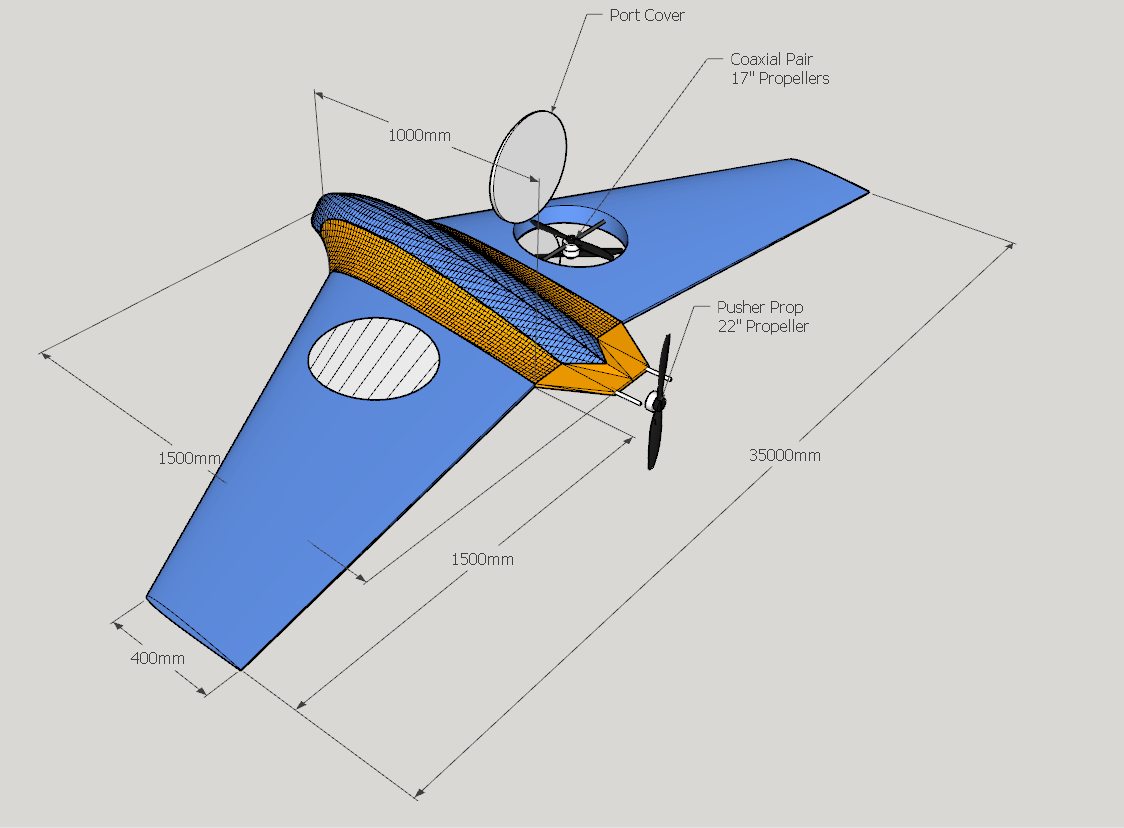

The body style is a hybrid of a traditional flying wing and delta wing. Eight BLDC motors and rotors can lift the frame clear of ground obstacles. Tilt of the forward drive units will provide thrust.

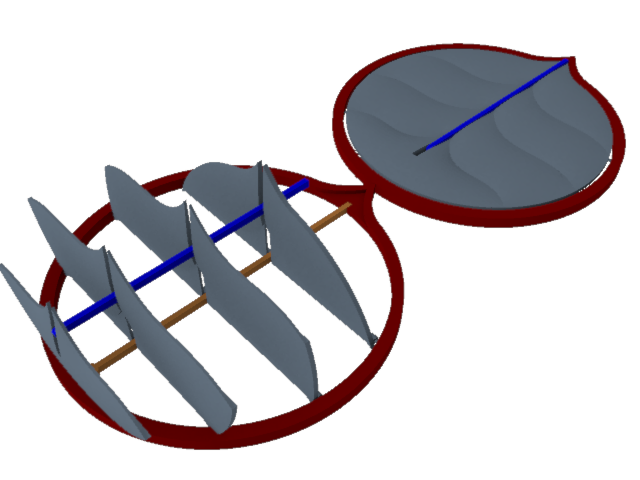

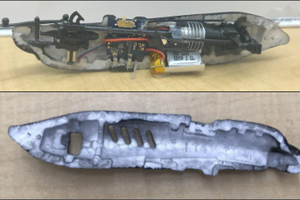

In the centerish of the main body, an auto-levelling 3-axis gimbal will carry the sensing equipment, be it visual or IR camera, thermal imaging, LIDAR or other. This gimbal will have spherical line-of-site, the body of the craft designed to maximize the extents. The gimbal will be self-contained when possible, with power for the gimbal motors and devices mounted within, giving 360 degree rotation on all axis.

Flight time is increased by the aerofoil lift the craft receives from the wing design. The large surface area will help increase lift.

Control will be achieved with a combination of thrust vectoring and thrust differentiation to minimize moving parts and the need for additional servos and the associated weight.

Several unique attributes will make this drone/UAV different from what is out there.

ken.do

ken.do

Benjamin Prescher

Benjamin Prescher

BART

BART

Thanks for the sharing informative post. Keep sharing more post like this one.

https://www.tellpopeyes.ltd/