I am trying to convert my mill without having to purchase any parts. Many of the parts I can source from work. I service and sell x-ray imaging equipment. We end up with outdated or broken stuff from time to time. So my plan is to repurpose it as best I can.

The majority of my parts are coming from a CR Reader. CR stands for computed radiography. After the imaging plate is exposed to x-rays it is placed into a CR reader where a laser is shined onto a plate. The amount of light given off by the plate is recorded by a photo multiplier tube. Afterwards the plate is erased by shining lights at it, usually florescent. There are numerous sensors, belts, motors, laser optics, power supply, rollers, shafts, gears, etc in each machine. They are really a treasure trove worth of parts. Think of 'em as an 80s photocopier with at least 3x the parts.

I will have to machine some custom parts to mount the motors and also to attach the toothed pulleys onto the lead screws. The metal for this will also be sourced from work. I've saved some steel weight blocks from x-ray tube supports that we have decommissioned. They are a nice size for making custom parts out of. I also have some pieces of rails that will work well for mounting the motor onto.

I am going to do my best to avoid making any permanent changes that I can not revert to the mill. This way if the CNC goes down I will still be able to make things until get it going again.

System Design Documentation:

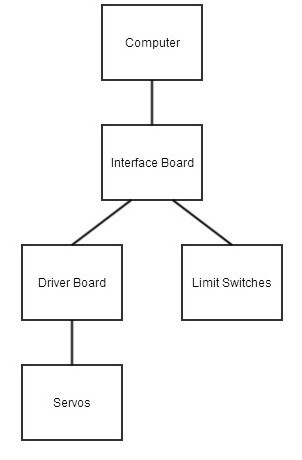

The system will be powered by a power supply salvaged from a CR reader. The drivers will be controlled by a computer's parallel port running Mach3. The drivers limit the current going into the steppers and also only require two pins for input (step and reverse). The steppers will be attached the the lead screws using toothed pulleys.

Eric

Eric

smashedagainst

smashedagainst

Sci

Sci

Did you get anywhere on this? My father just passed away and I took on the task of helping mom sell some of his stuff. He was a custom knife maker and I've already sold his belt sanders, buffers, drill press and heat treat furnace, but he has one of the same type of mill. I was thinking what you're suggesting and thus searched and your post came up. I would be curious to know if you got anywhere. I have a project currently to add a stepper-based focuser to a telescope and started accumulating parts to build a 3 axis framework (not sure yet if I'm going to rig it for lazer or cnc - I have 3x 3d printers at the moment and have worked quite a bit with arduino/espressif and other micro controllers and have a whole farm of raspberry pis, burn my own firmwares for my printers, etc. I also have a tentative project, possibly for that 3 axis, to try to rig something to make a stone memorial in a remote location (flatten the top of a rock and etch in the message w/names).