Crowdfunding campaign has started! There are kits and aluminum/walnut Nixie Taps.

More info: Nixie Tap Crowdsupply page.

Latest PCBs can be ordered directly. To order, visit PCBWay project page.

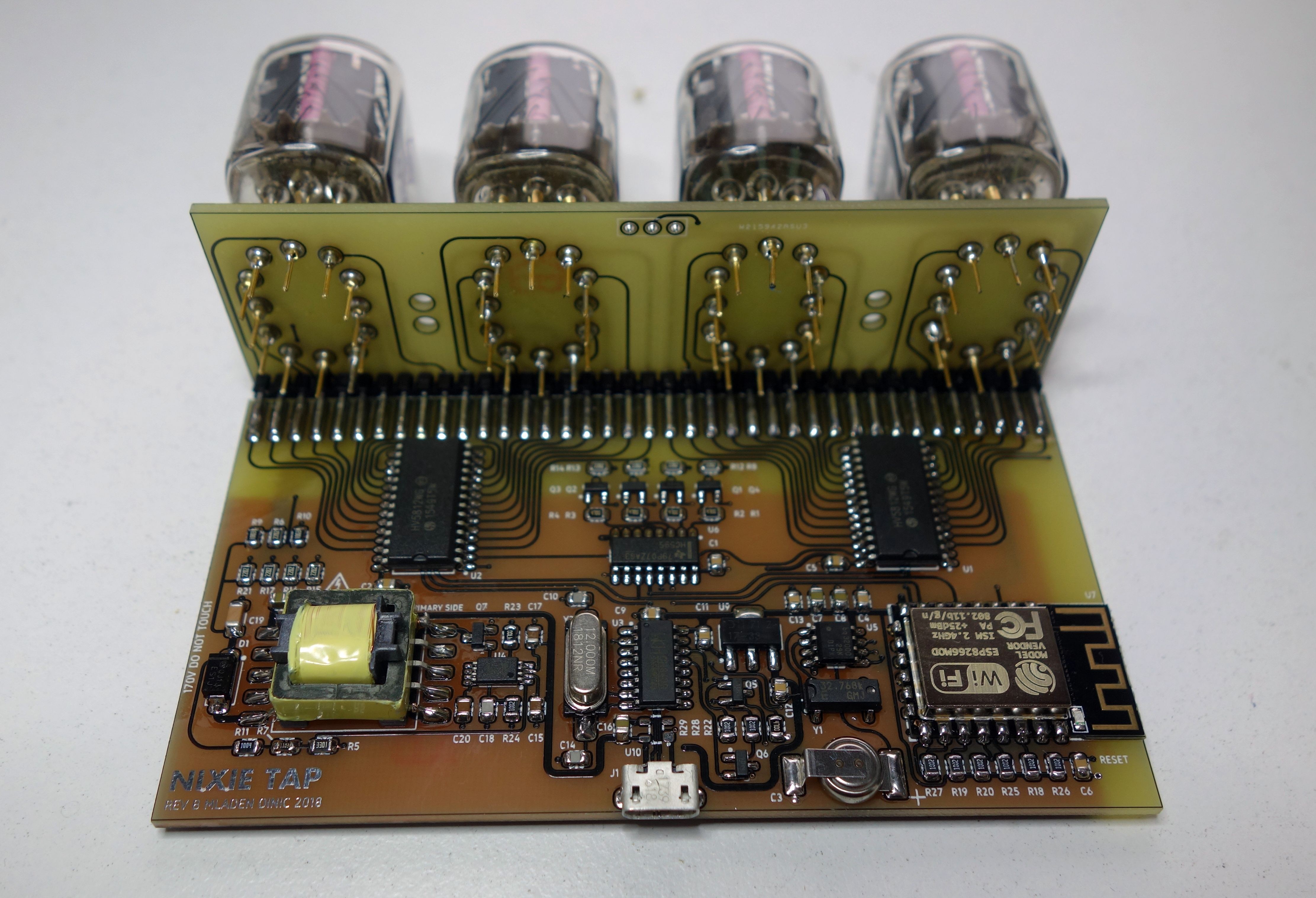

Device displays time, date, as well as arbitrary information from Internet (temperature, cryptocurrency price, IFTTT...). It also has an IoT button functionality, via a capacitive touch sensor.

Interaction:

- capacitive touch sensor

- WiFi

- serial port

Display:

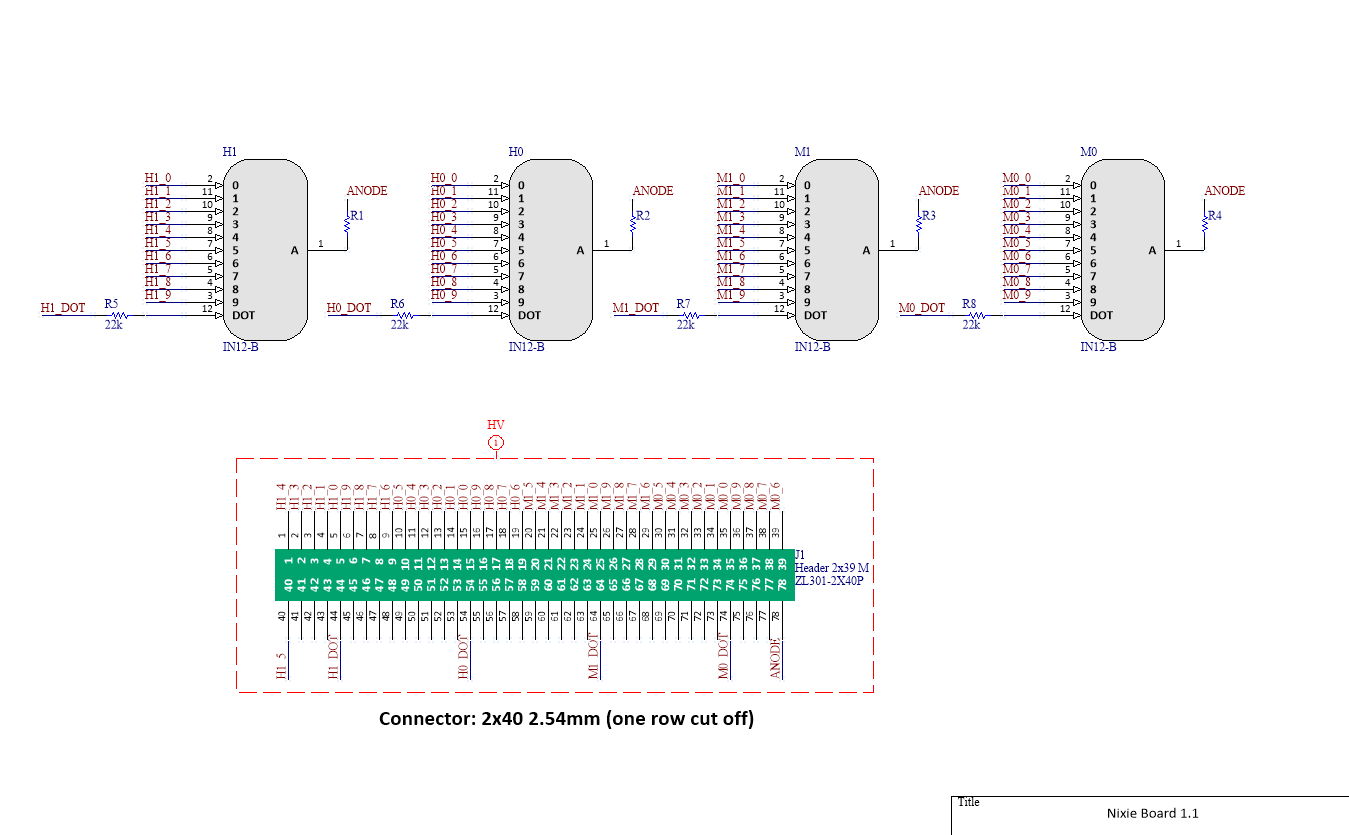

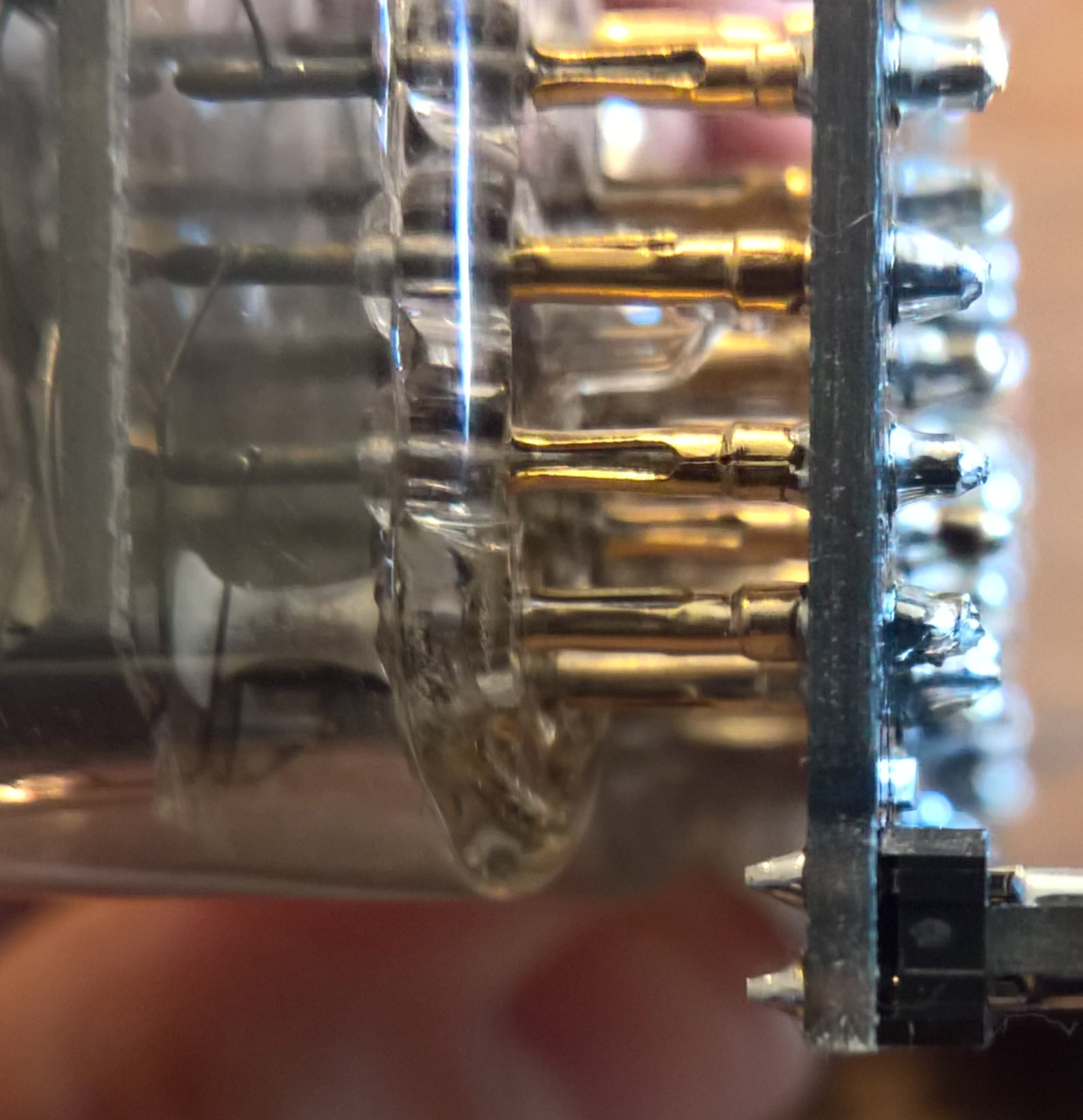

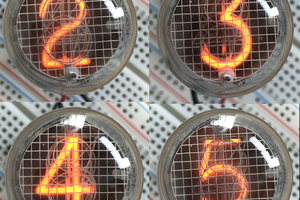

- 4 digit IN-12B, with dot

- direct drive

Enclosure

- CNC machined wood / aluminium

Design logs:

- Lessons learned, PCB 1.2

- Enclosure design and prototype 1.1

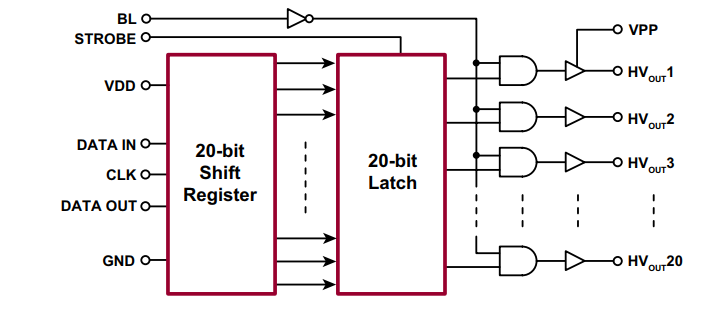

- HV driver considerations

- Nixie considerations

- Firmware considerations

- Piezo sensor considerations

Most recent PCB:

| current version | status | |

|---|---|---|

| PCB | B | tested |

| enclosure | 1.2 | tested |

| code | 0.9 | in progress |

| documentation | 0.9 | in progress |

License:

- hardware: CERN Open Hardware Licence 1.2

- software: GNU General Public License v3

mladen

mladen

As it can be observed from the video, this interface should be further optimized (skipped detection at 0 and 8). Maybe I need a transistor preamp, since handling this in code is tricky.

As it can be observed from the video, this interface should be further optimized (skipped detection at 0 and 8). Maybe I need a transistor preamp, since handling this in code is tricky. Basically, it should

be an interrupt driven program. So, let's dive in:

Basically, it should

be an interrupt driven program. So, let's dive in:

Natural materials are present, but enclosure is not smooth, and manufacturing is complicated, due to two materials. At the same time, top aluminium plate looks like it's missing something, a CNC marking, which further complicates the manufacturing.

Natural materials are present, but enclosure is not smooth, and manufacturing is complicated, due to two materials. At the same time, top aluminium plate looks like it's missing something, a CNC marking, which further complicates the manufacturing.  Now everything is smooth, manufacturing is simpler. Enclosure can be painted glossy black, or manufactured in a nice wood, such as mahagony, which would give it that nice "Rolls-Royce dashboard" look.

Now everything is smooth, manufacturing is simpler. Enclosure can be painted glossy black, or manufactured in a nice wood, such as mahagony, which would give it that nice "Rolls-Royce dashboard" look. This prototype illustrated why you should always prototype before production.

This prototype illustrated why you should always prototype before production.

Arthur Admiraal

Arthur Admiraal

timonsku

timonsku

Frederic L

Frederic L

Enrico Gueli

Enrico Gueli

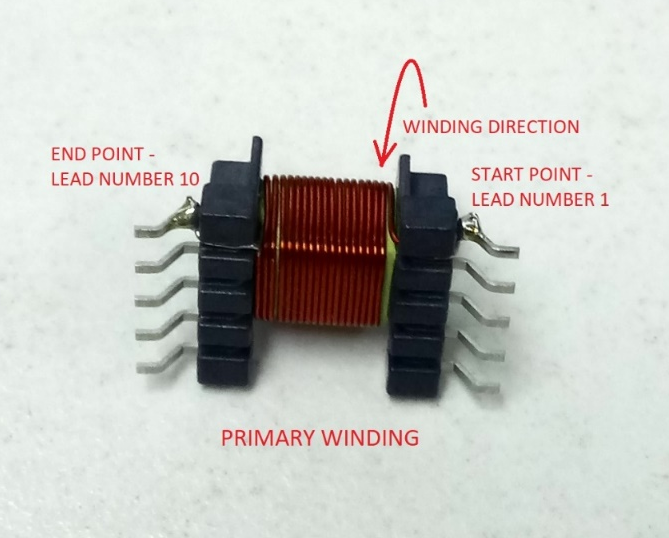

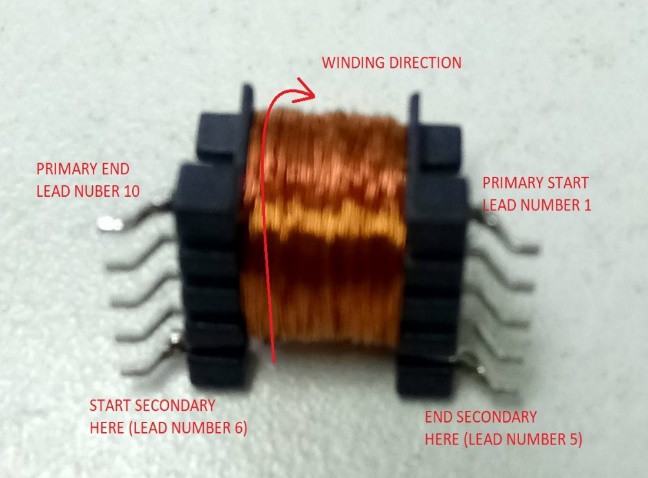

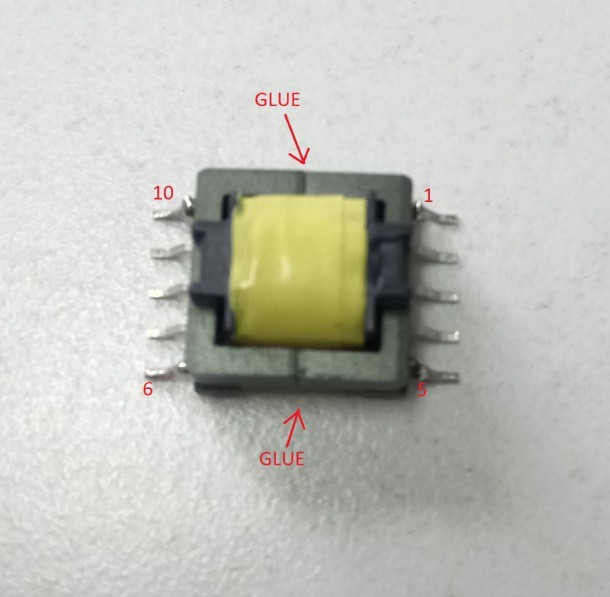

Hello! I was wondering whether you have had a chance to publish anything on the HV transformer? I put everything together except the winding of the HV transformer, so any bit of information would be insanely helpful! Thank you so much!