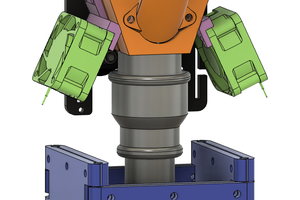

Back when Ninja (https://www.ninjakitchen.com) got their start, they had only one product - a top-drive food processor system where you'd put a blade in your vessel, put a lid on that, and then clap a power pod on top to blend everything. They still sell a version as the "Master Prep Pro System" (https://www.ninjakitchen.com/exclusive-offer/QB1004WBKT/ninja-master-prep-pro-system/). It would seem that, over the years, there have been a couple of variants. They're mostly compatible, but for whatever reason, appear to have different spindle sizes.

My household has two systems, an (older, I suppose?) gray one, and a black one that I can only assume matches the current unit. Unfortunately, I lost the black motor, rendering all those black blades useless. So I decided to draw up an adapter that I could 3D print, making all the mismatched parts useful again!

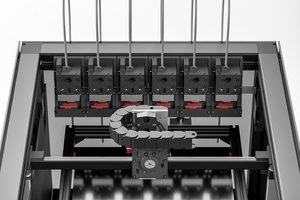

Note about 3D printing this: because the sleeve needs to fit relatively tightly over the spindle, your 3D printer's dimensional accuracy needs to be pretty good. If it's a little tight, there's nothing wrong with pounding the sleeve on with a mallet (but make sure it fits loosely in the drive unit first). But if your printer has any sort of problem with elephant's foot, it'd be best to tune that out before trying to print this part. Also, printing with a brim will likely cause problems, since it's tough to get inside the splines with a deburring tool or anything like that. Though since that'll only be on the outside, it might not cause problems with fitting over the small spindle.

alexwhittemore

alexwhittemore

Otto Gloeckner

Otto Gloeckner

Marc Schömann

Marc Schömann

Tim Wilkinson

Tim Wilkinson

Chris

Chris