So, I am starting this project at the second iteration. The first can be found at the thingiverse link to the left. The prior design is simple and should work fine, but lacked many features I wanted.

Here are my design goals (may get updated):

1. Can be printed on a standard home 3D printer

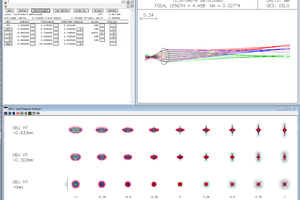

2. Sets the diode approximately 30mm from the material for optimum power and smallest beam diameter

3. Snap in to the portrait or cameo cutter with no modifications necessary

4. Ability to adjust the focus while in the holder

5. Would like to allow for a heatsink/cooling/air-assist for the laser so a more powerful diode can be used

If you are familiar with 3D printing, accomplishing number 1 can be quite the challenge with something like this. I would very much welcome any tips or suggestions.

Some technical details:

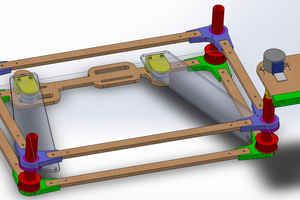

The dimension from the platen to the top of the tool clamp is 34mm when the pen is up and 29mm when the pen is down. The tool clamp is 17mm deep and tools are 14mm in diameter. The flange on the various OEM tools is 17mm in diameter and about 1.5mm high. Anything above the flange must fit within an 9.5mm radius in the back half. The front half is relatively free.

Since the cutter brings the pen down when it wants to cut, our laser will be turned on when the pen is down. To accomplish this, I am stealing the clever trick used by [Peter] before and featured on HaD here: in http://hackaday.com/2015/01/31/paper-cutter-becomes-a-laser-engraver/

Essentially, a switch is mounted over the flat portion of the carriage which gets pressed when the pen is down. It looks fairly simple to actually tap right in to the solenoid, but that requires modification of the Portrait machine.

The flange on the tool sits approximately flush with this flat area when the pen is down.

Retroplayer

Retroplayer

Jason Cho

Jason Cho

Timo Birnschein

Timo Birnschein

Chuck Glasser

Chuck Glasser

helge

helge

also you may make laser engraved photos like this: http://endurancelasers.com/laser-engraving-of-halftones-how-to-print-beautiful-photos/