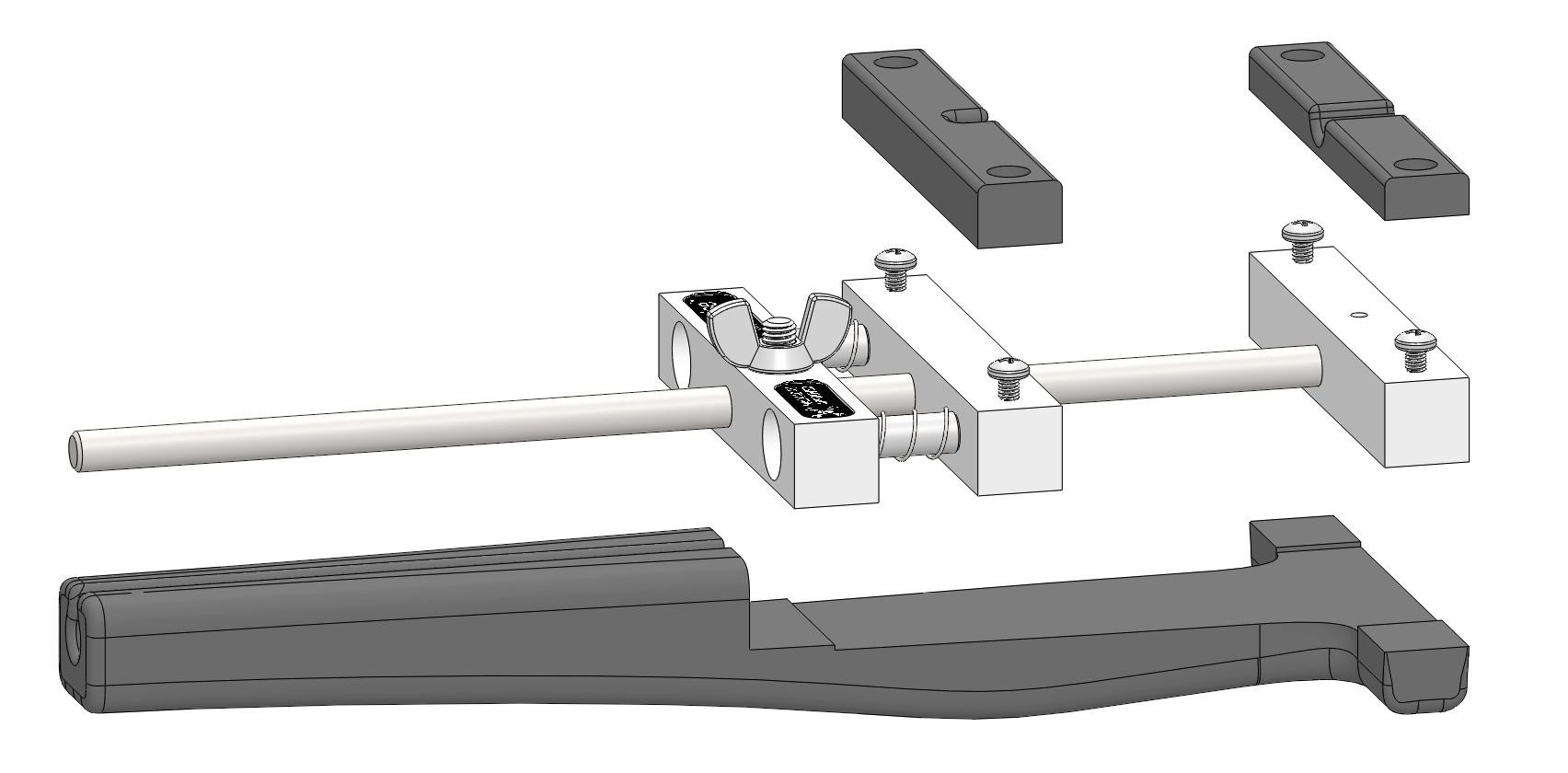

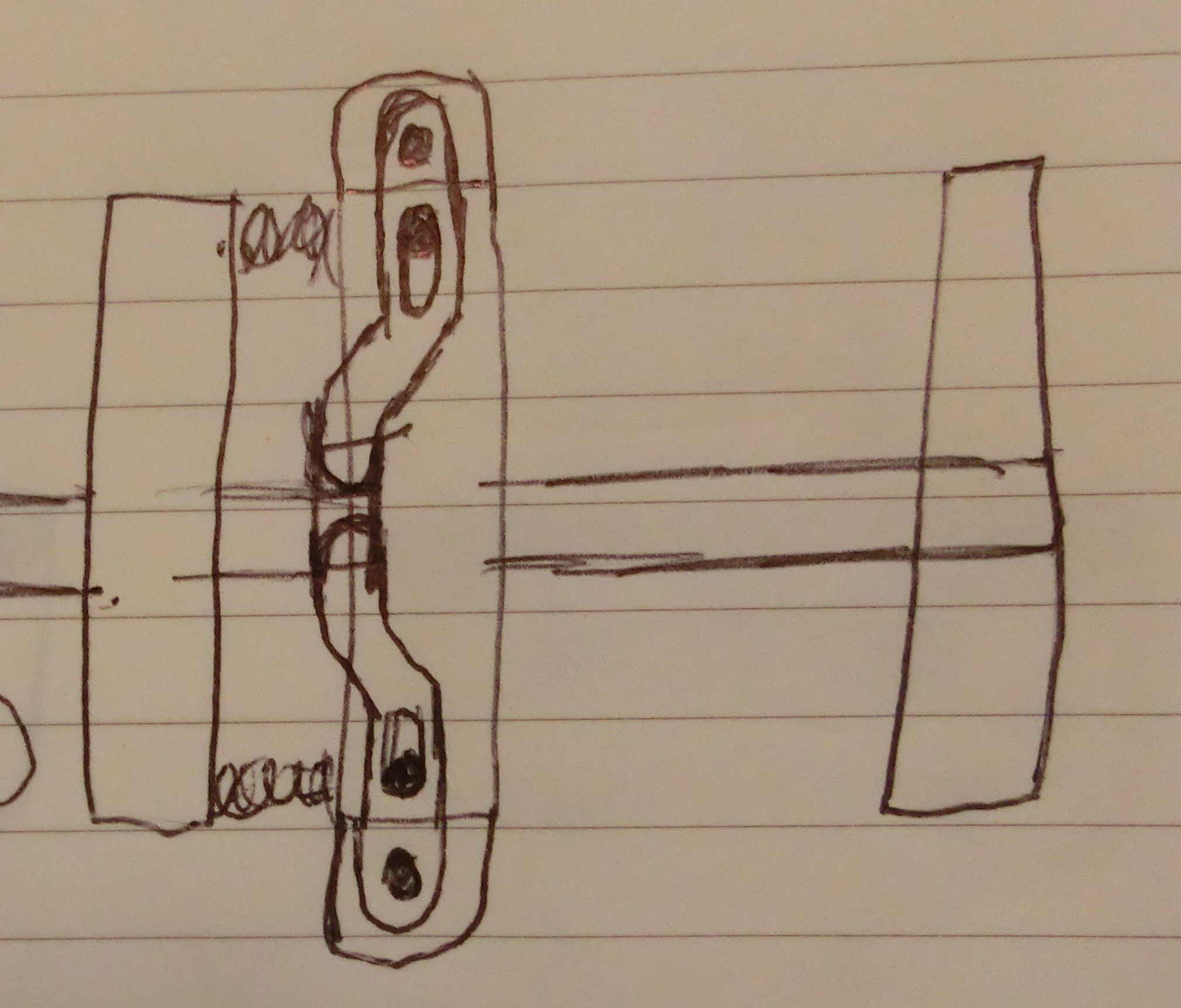

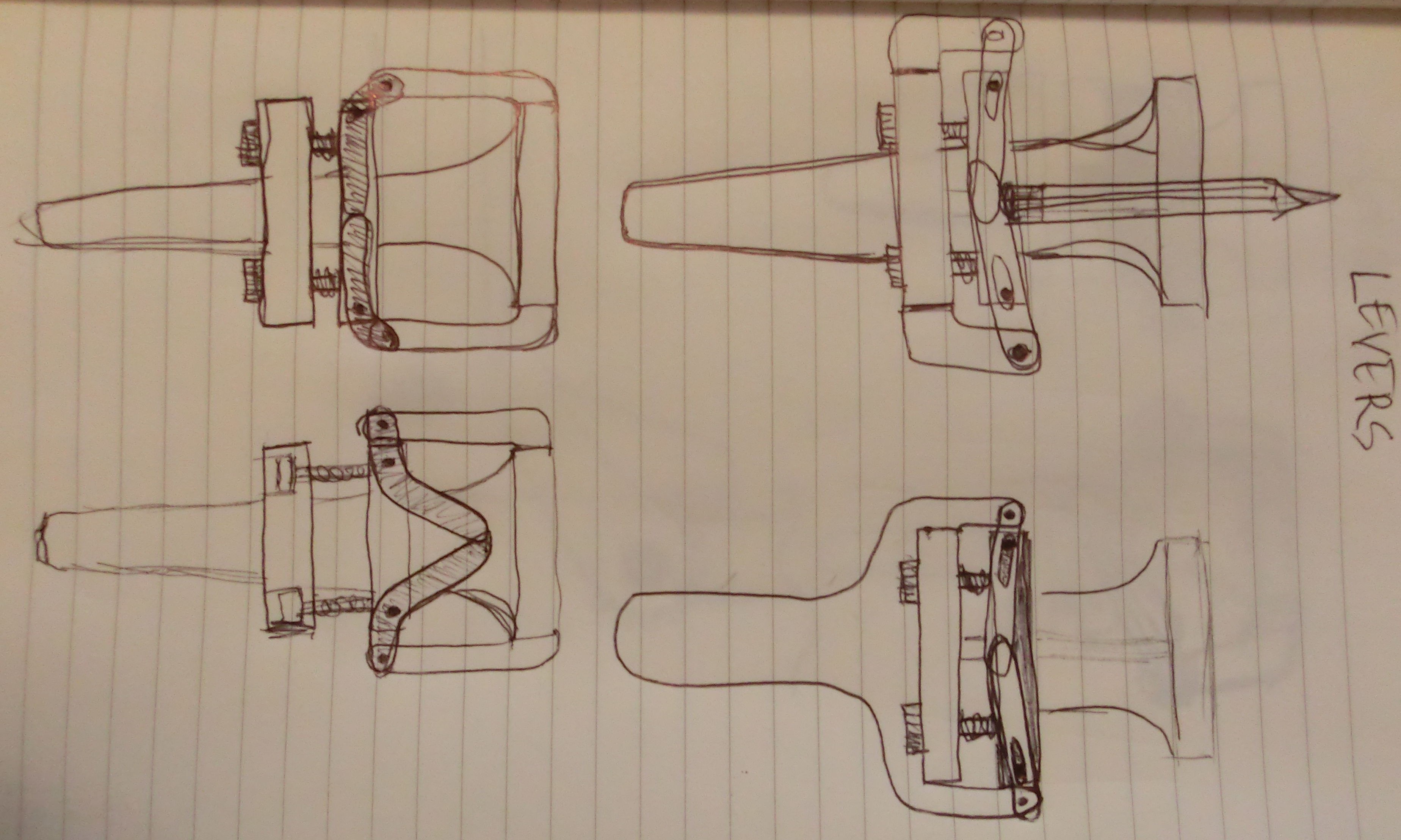

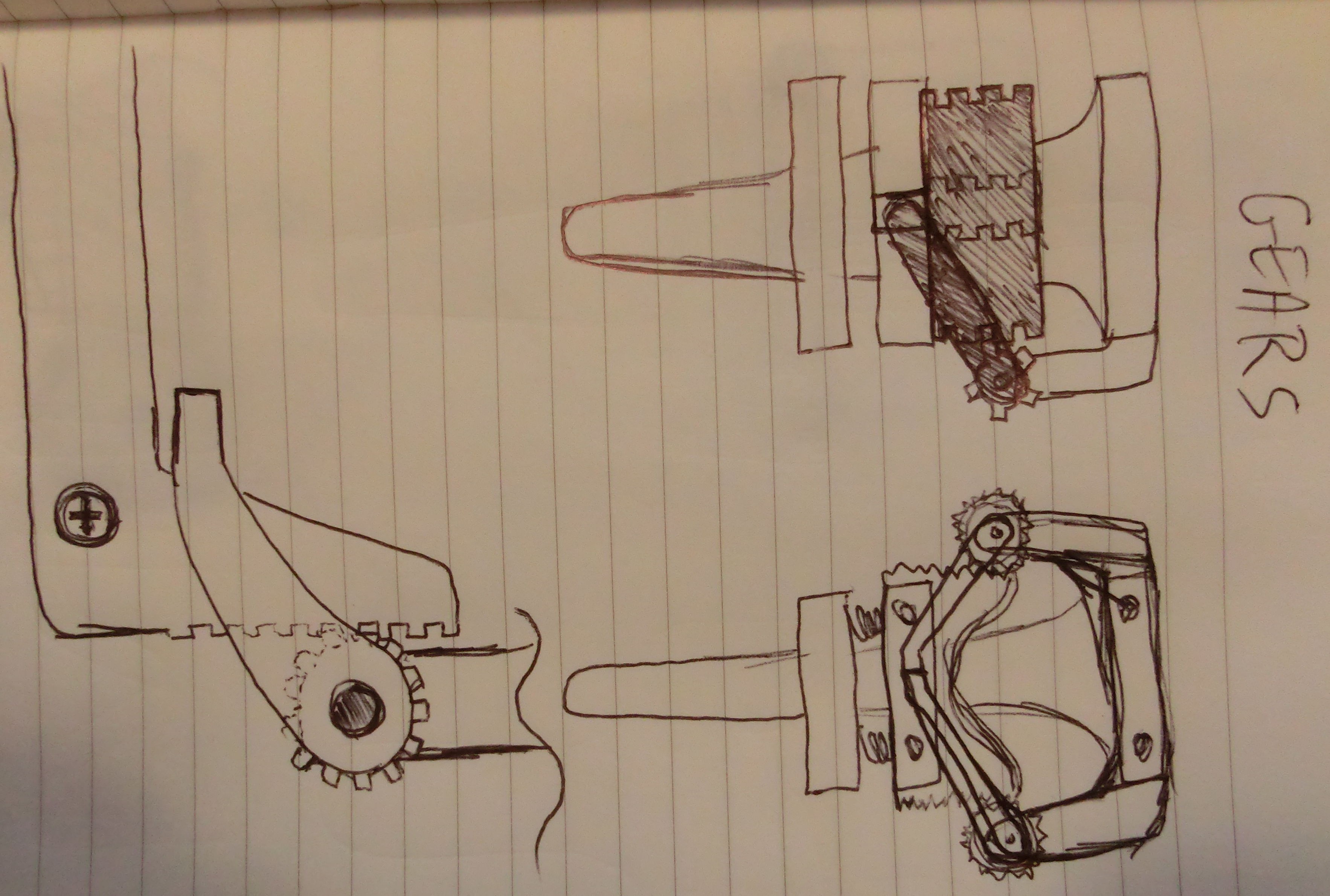

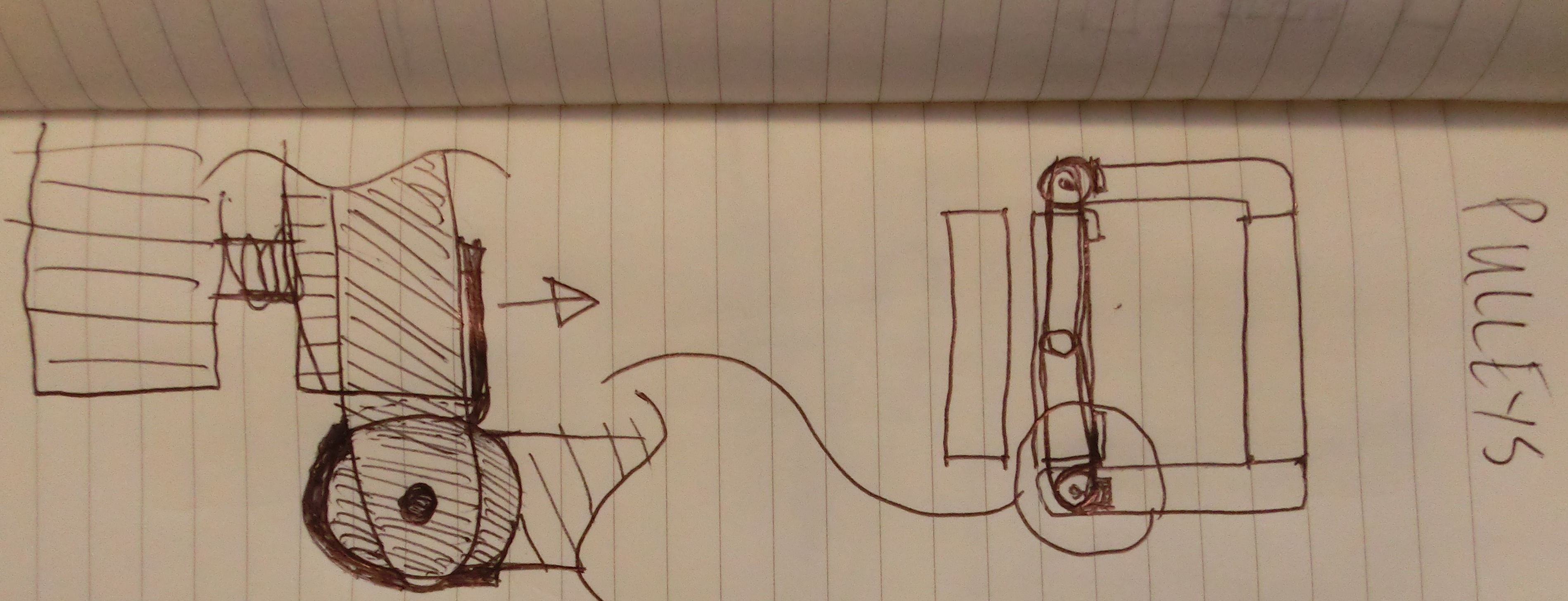

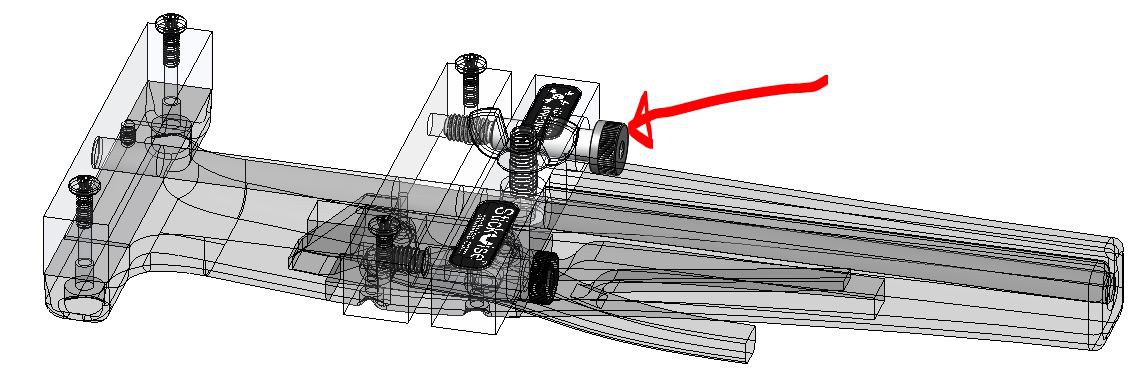

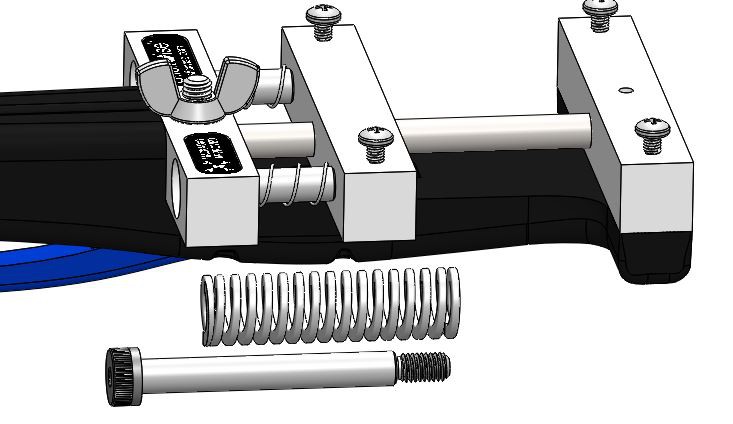

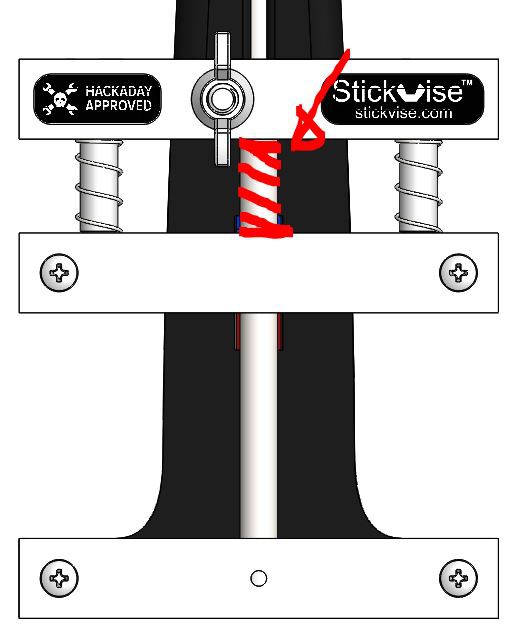

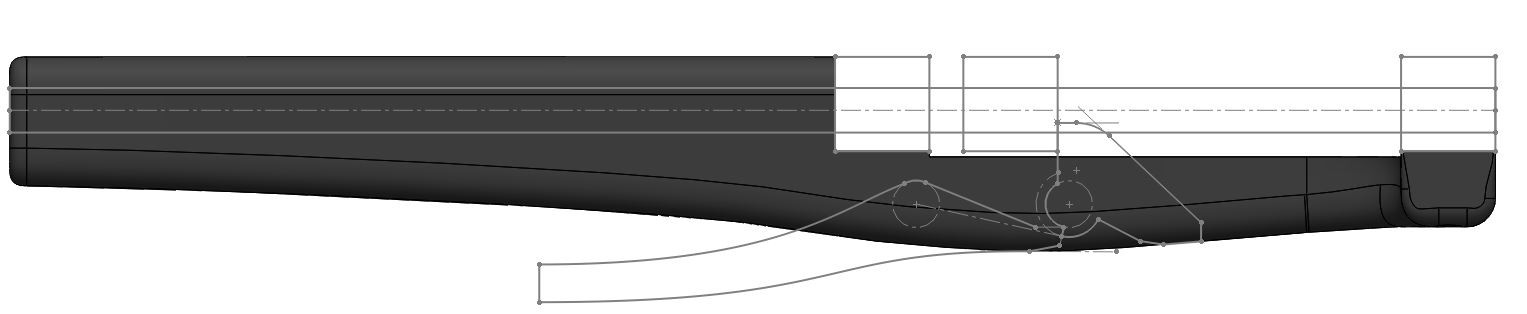

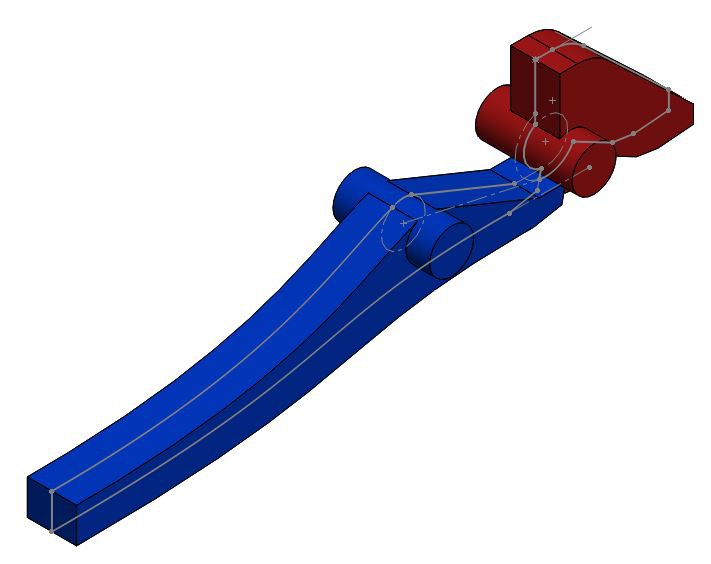

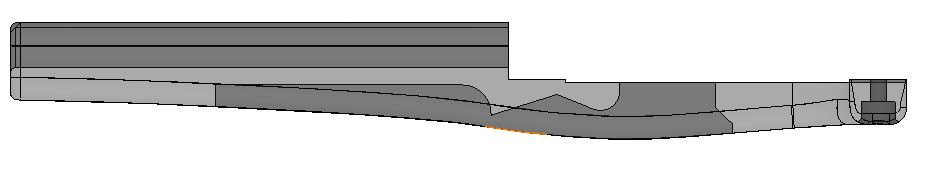

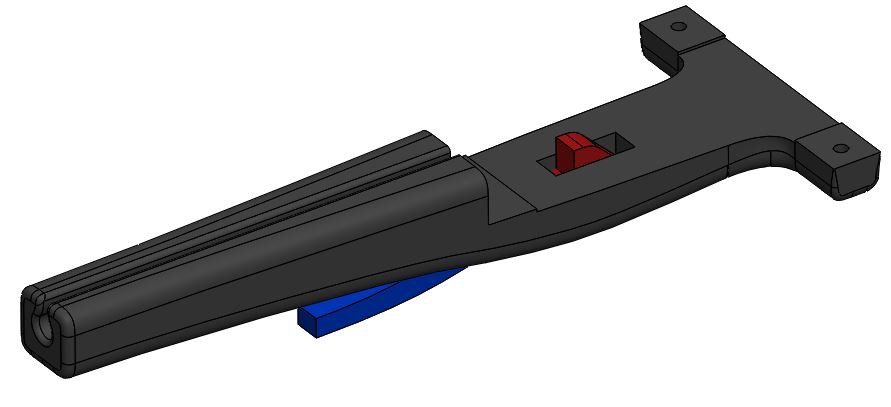

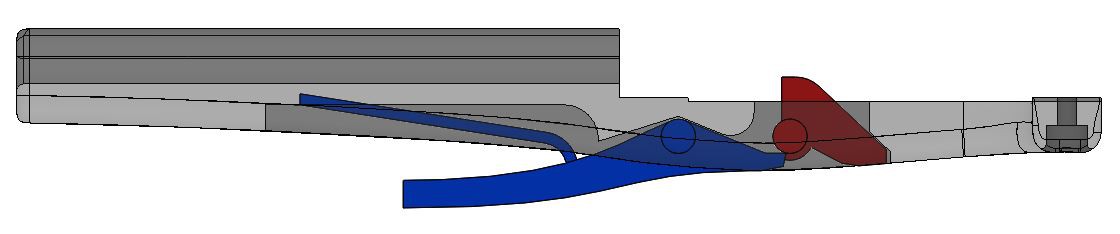

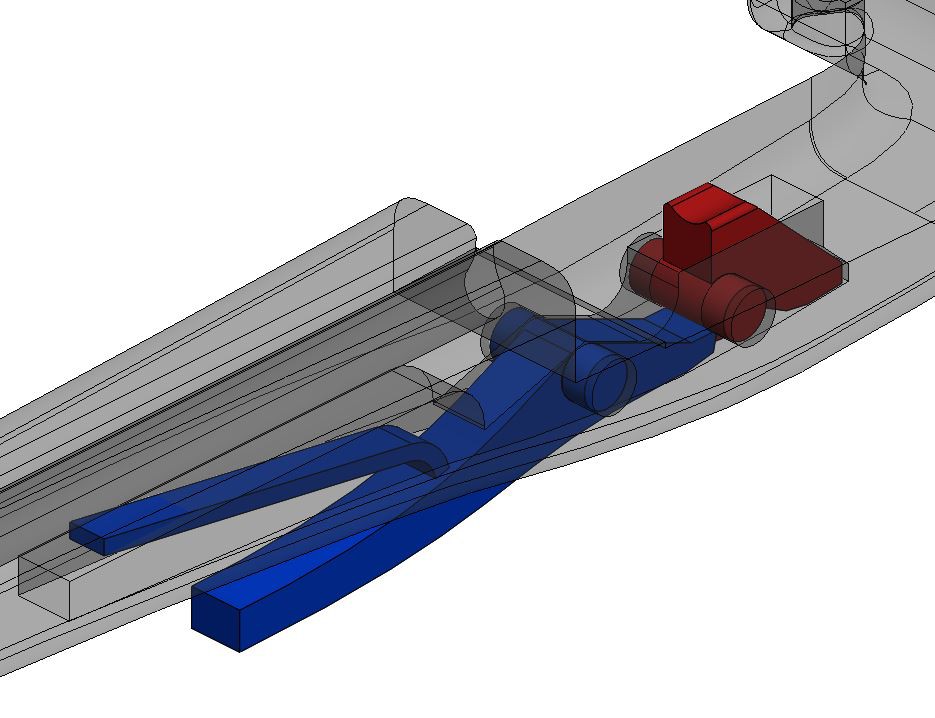

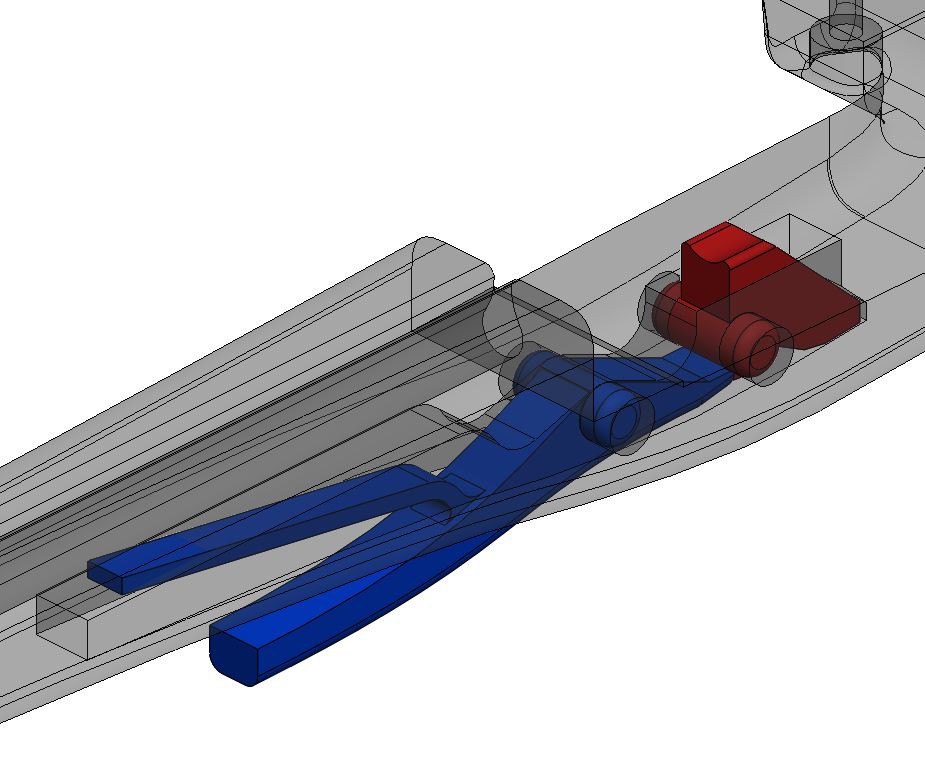

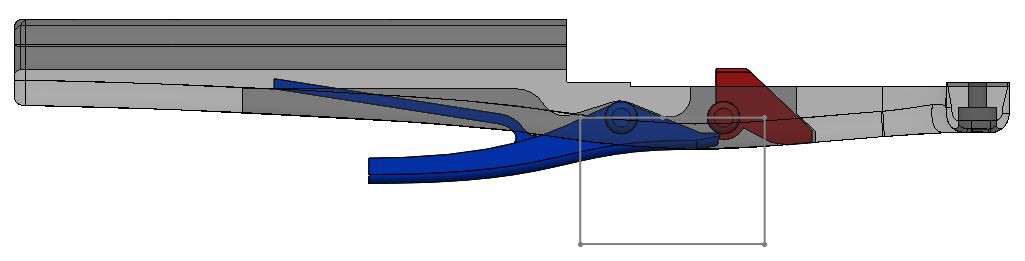

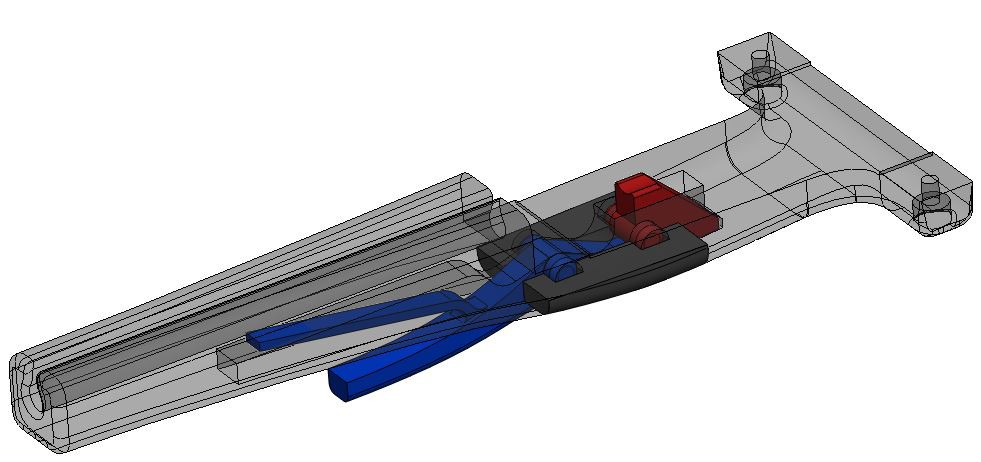

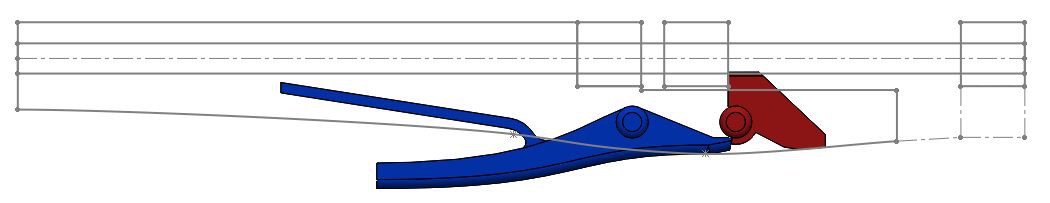

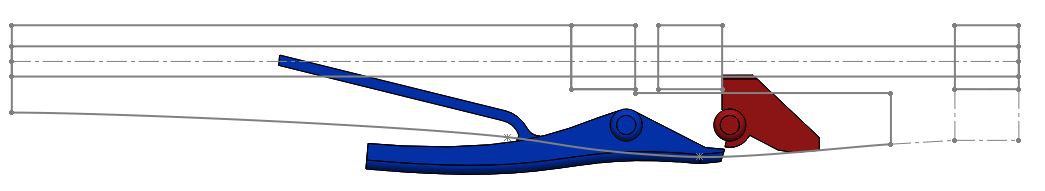

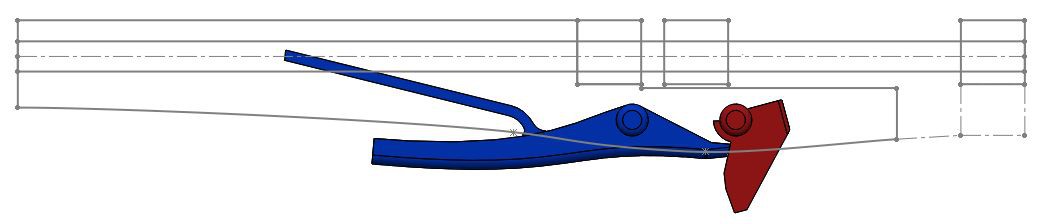

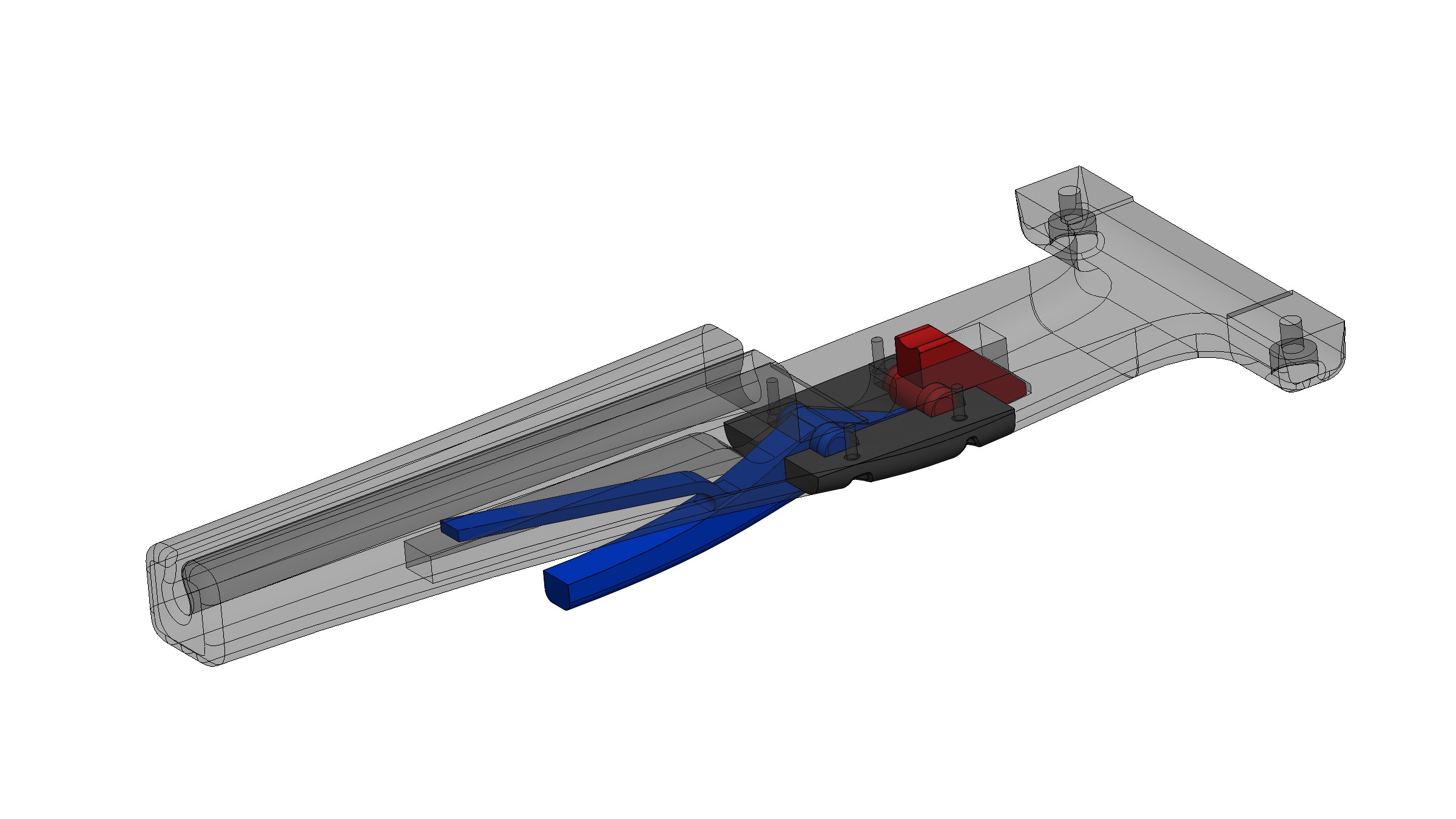

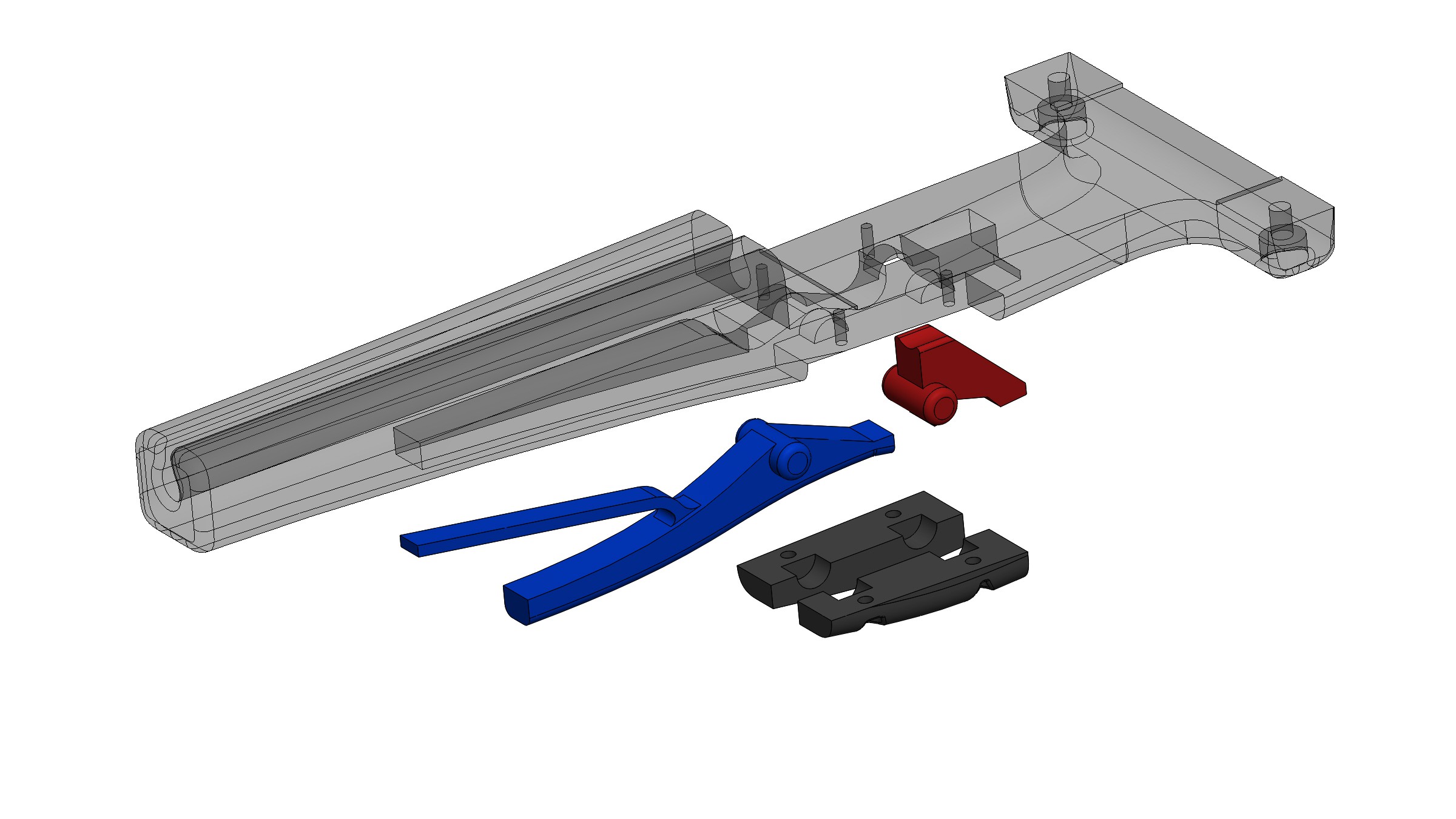

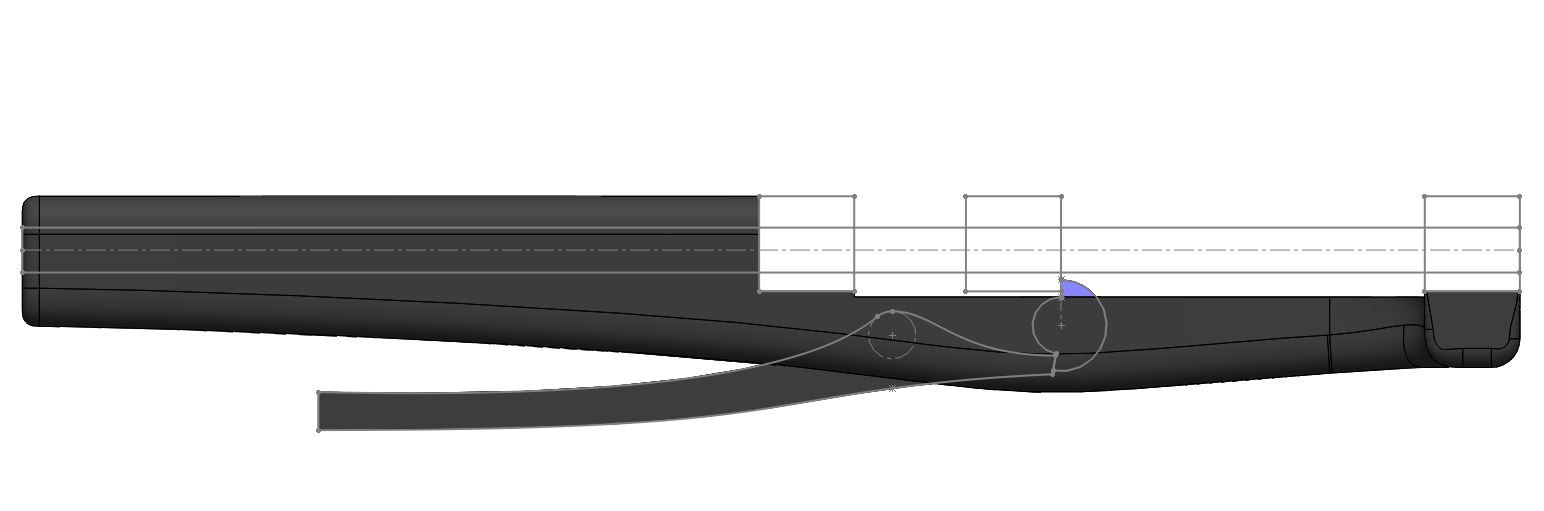

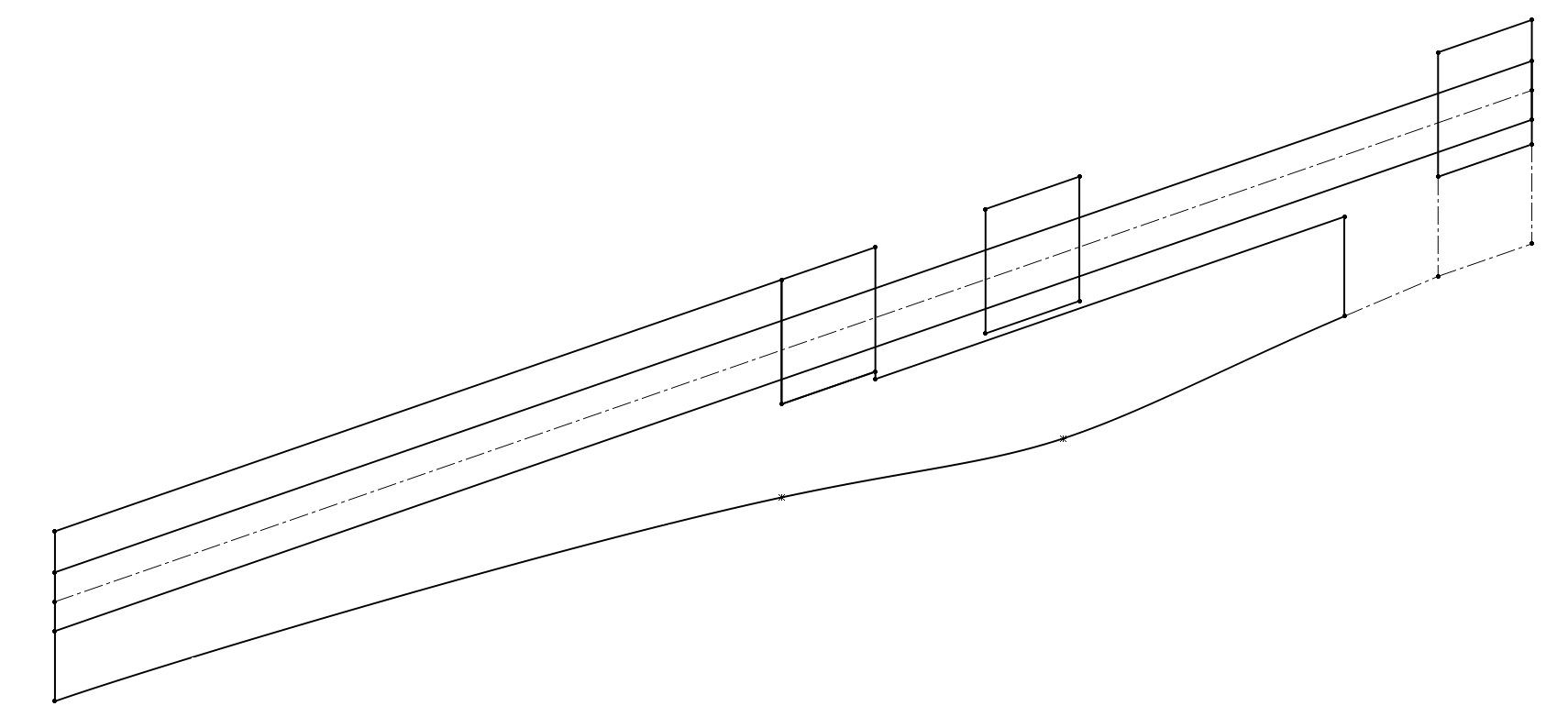

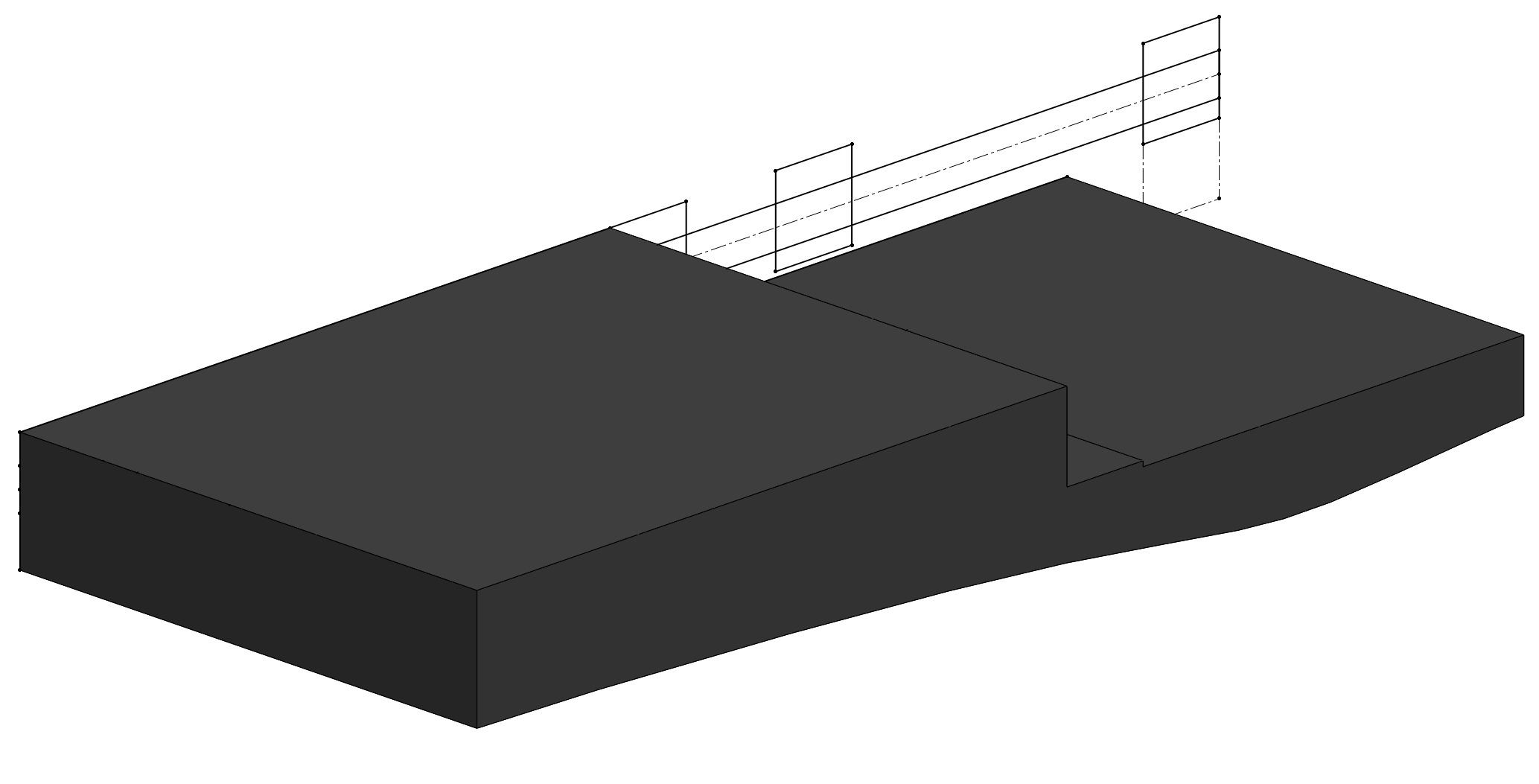

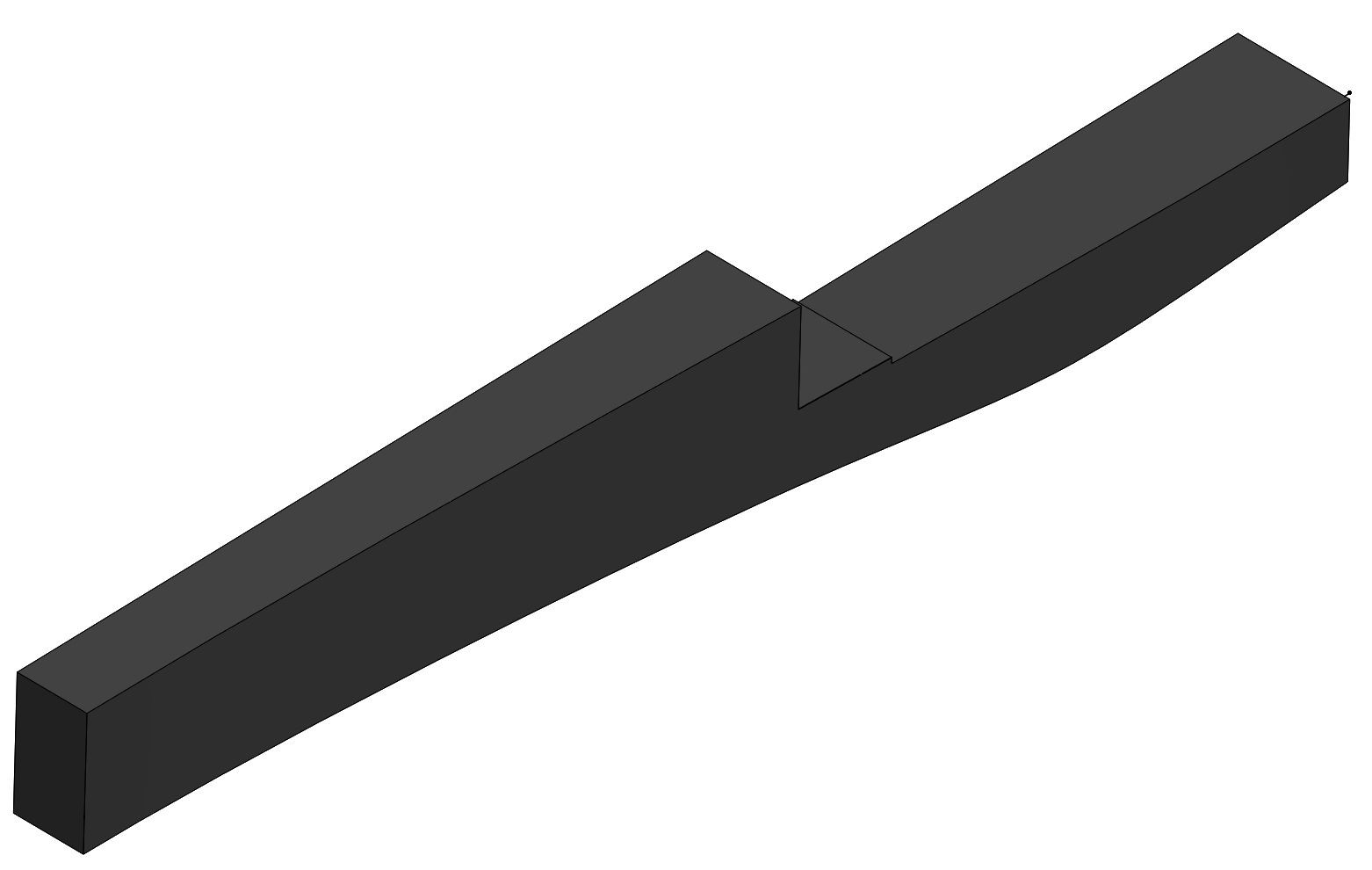

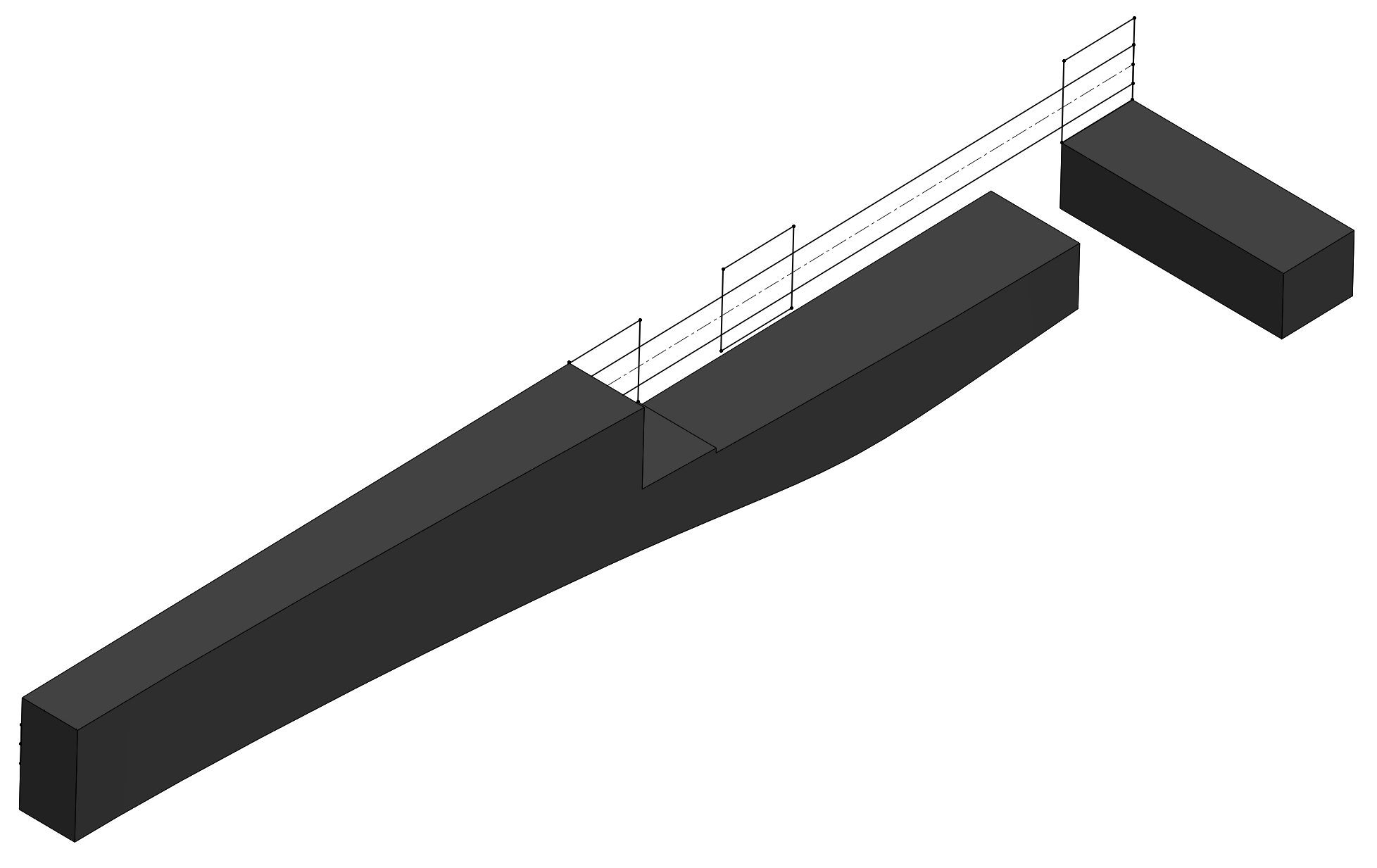

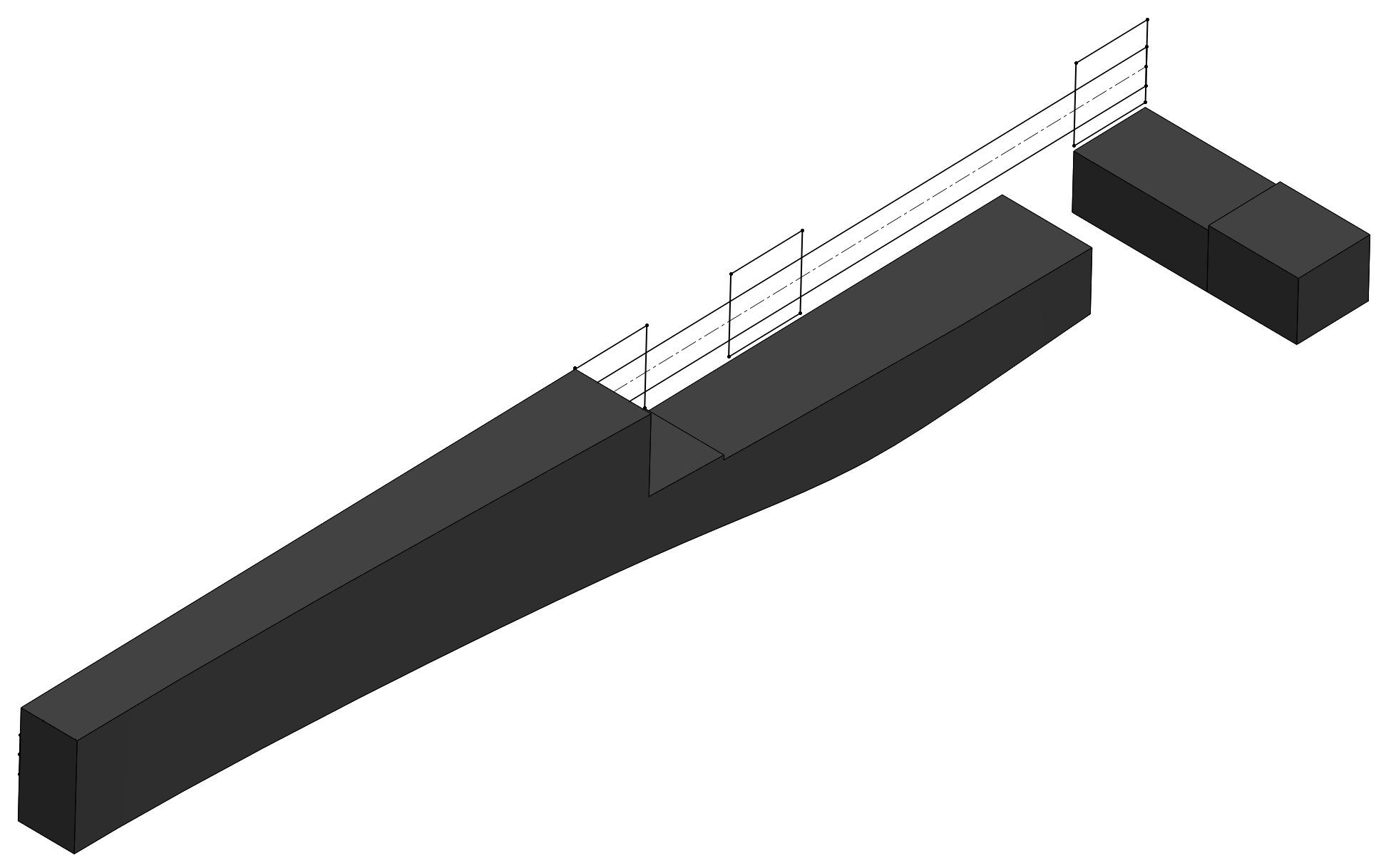

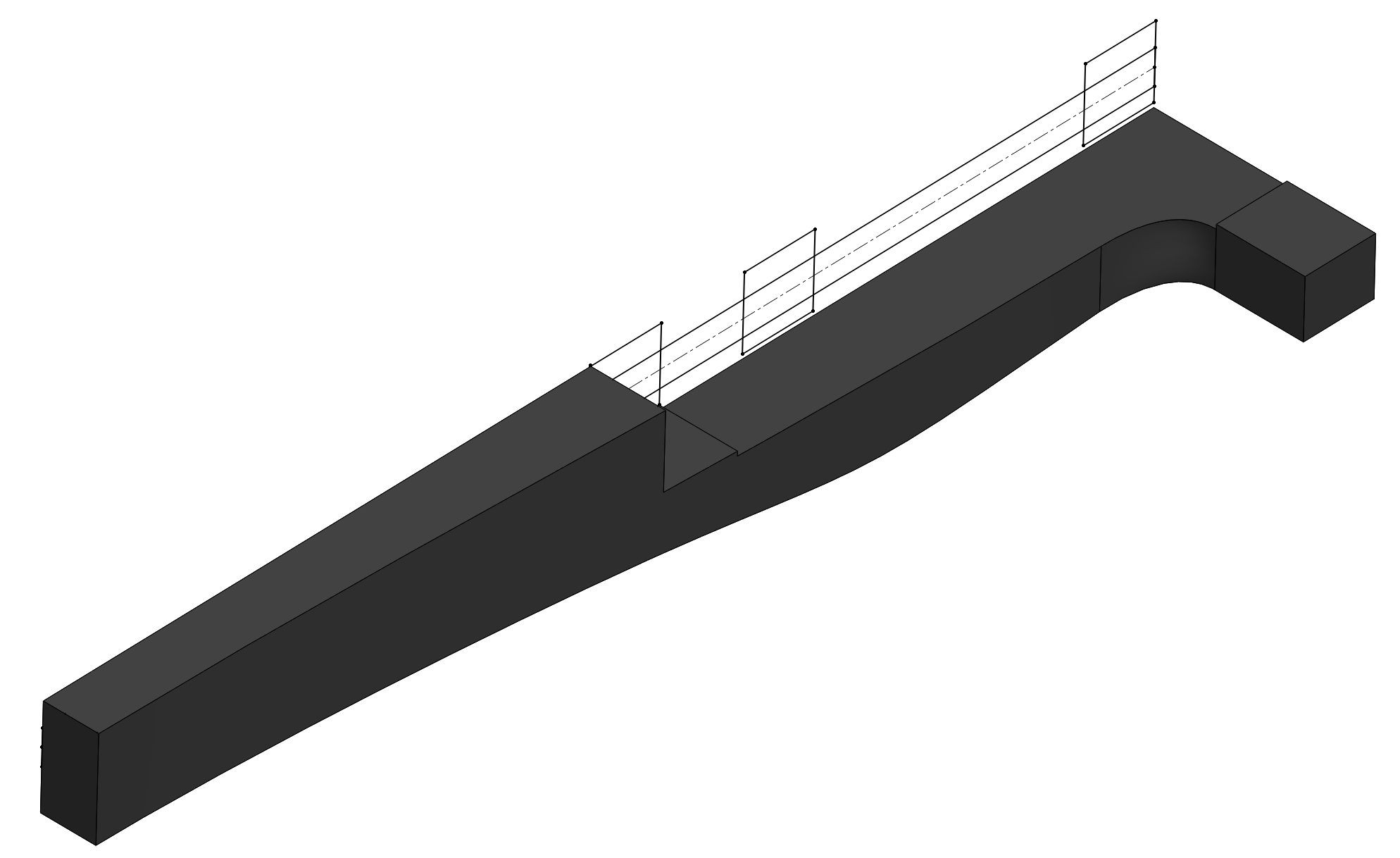

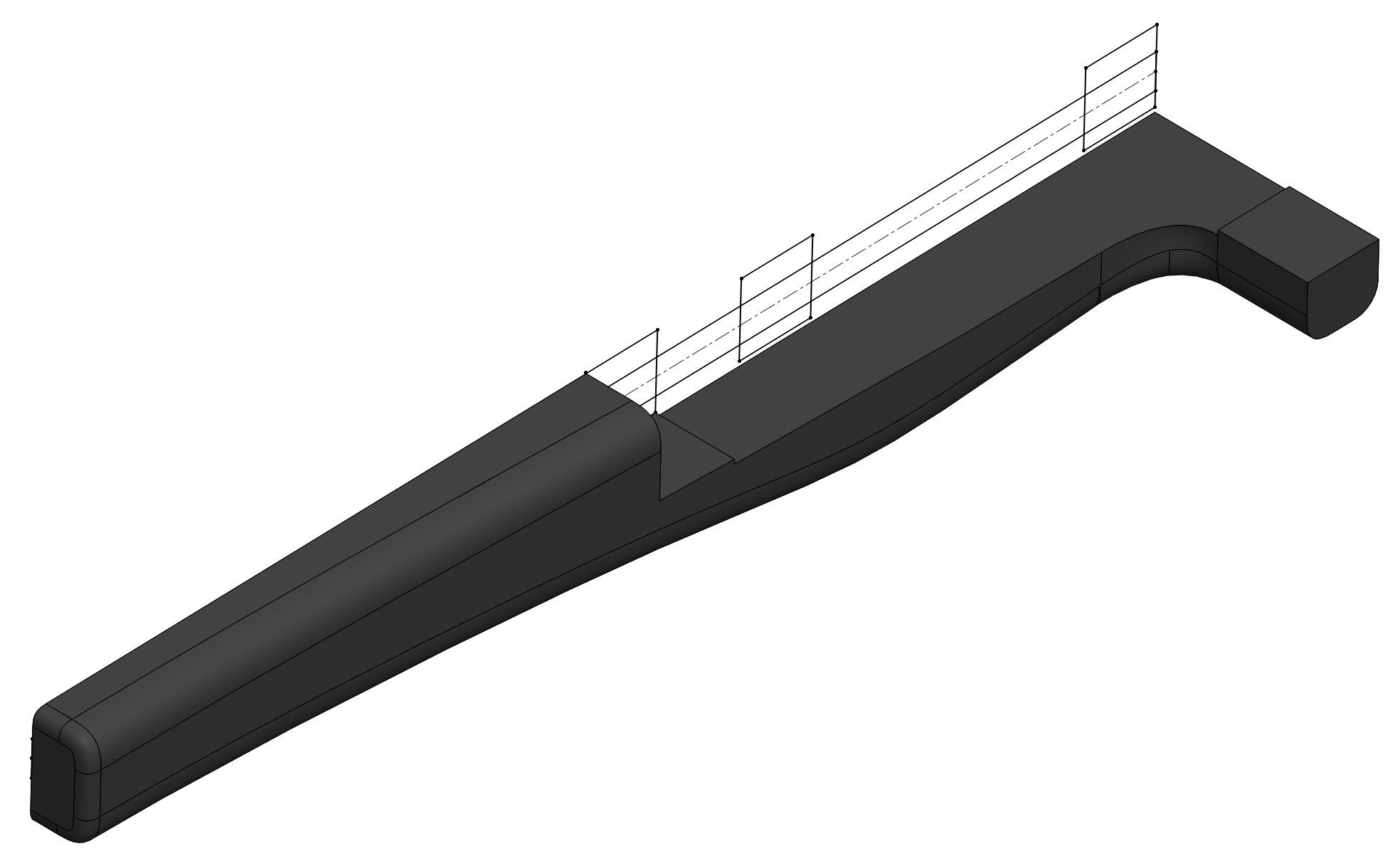

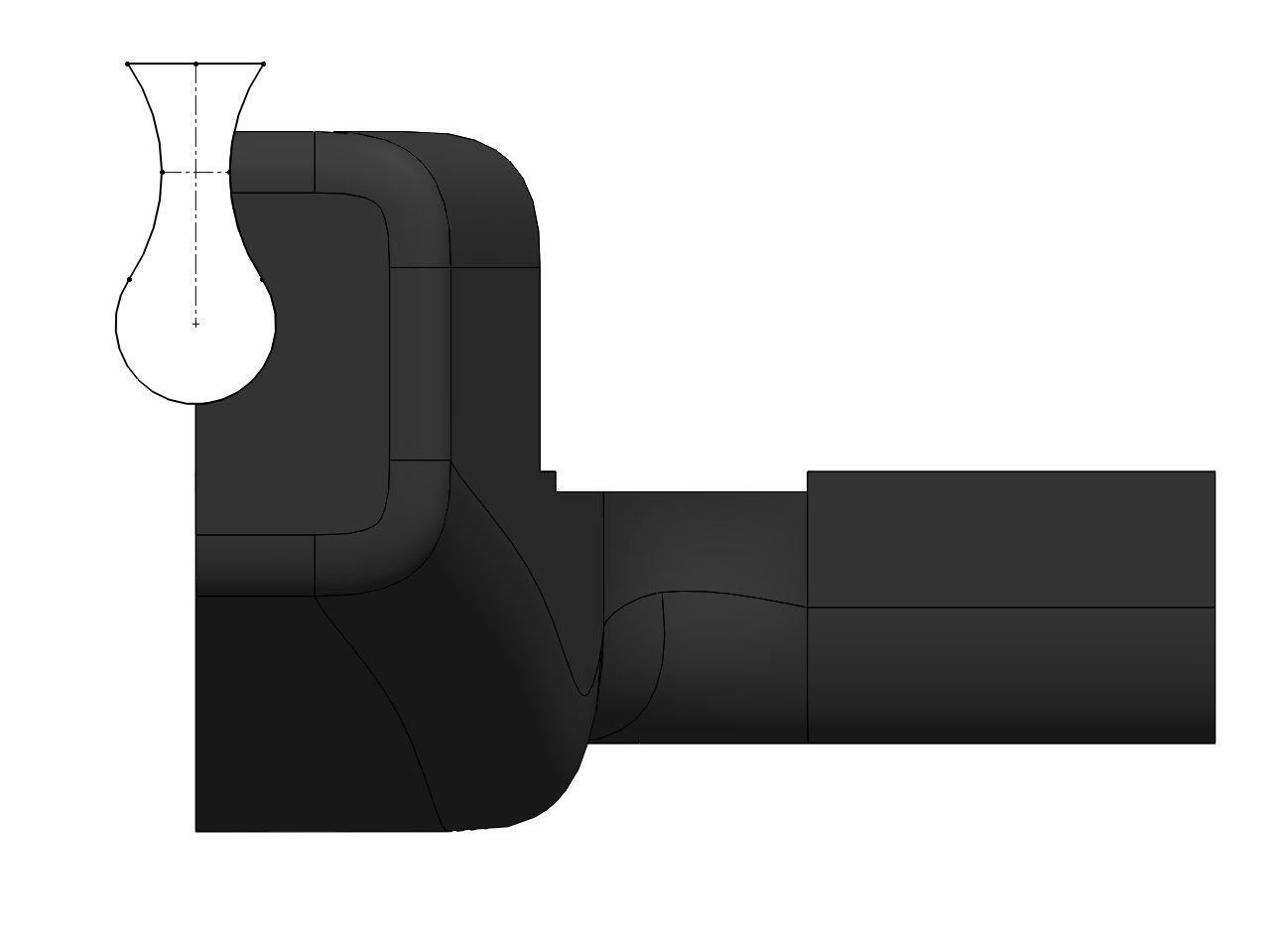

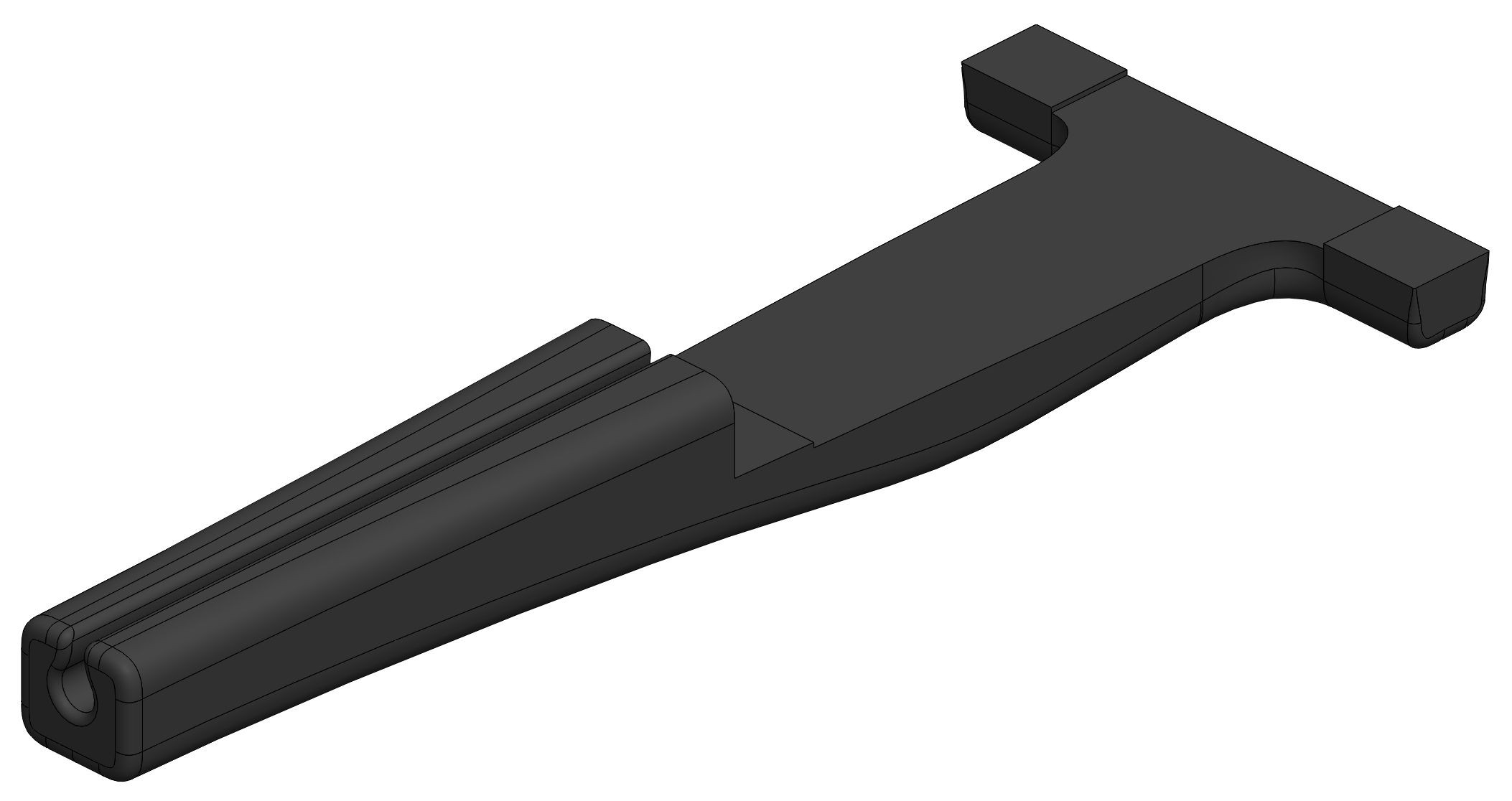

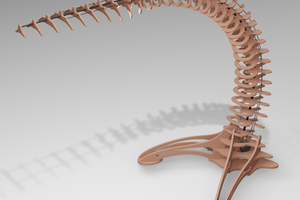

Current design includes handle as well as the jaw plates that will push / guide the projectile. All I need to do now is design the trigger parts.

Stickvise Crossbow

Every electronics bench should have a crossbow. First crossbow project on hackaday.io

Alex Rich

Alex Rich

Theoretical results:

Theoretical results:

David Troetschel

David Troetschel

zapwizard

zapwizard

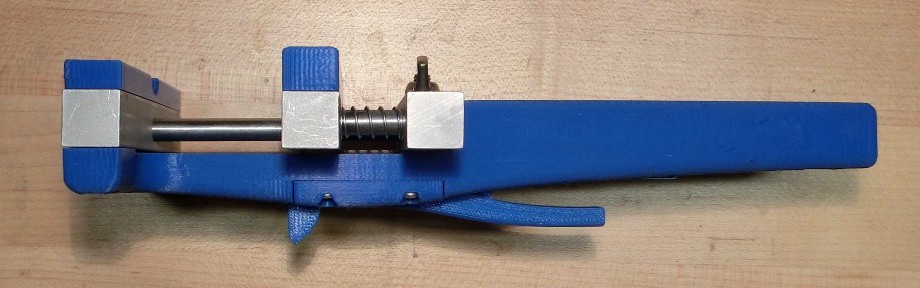

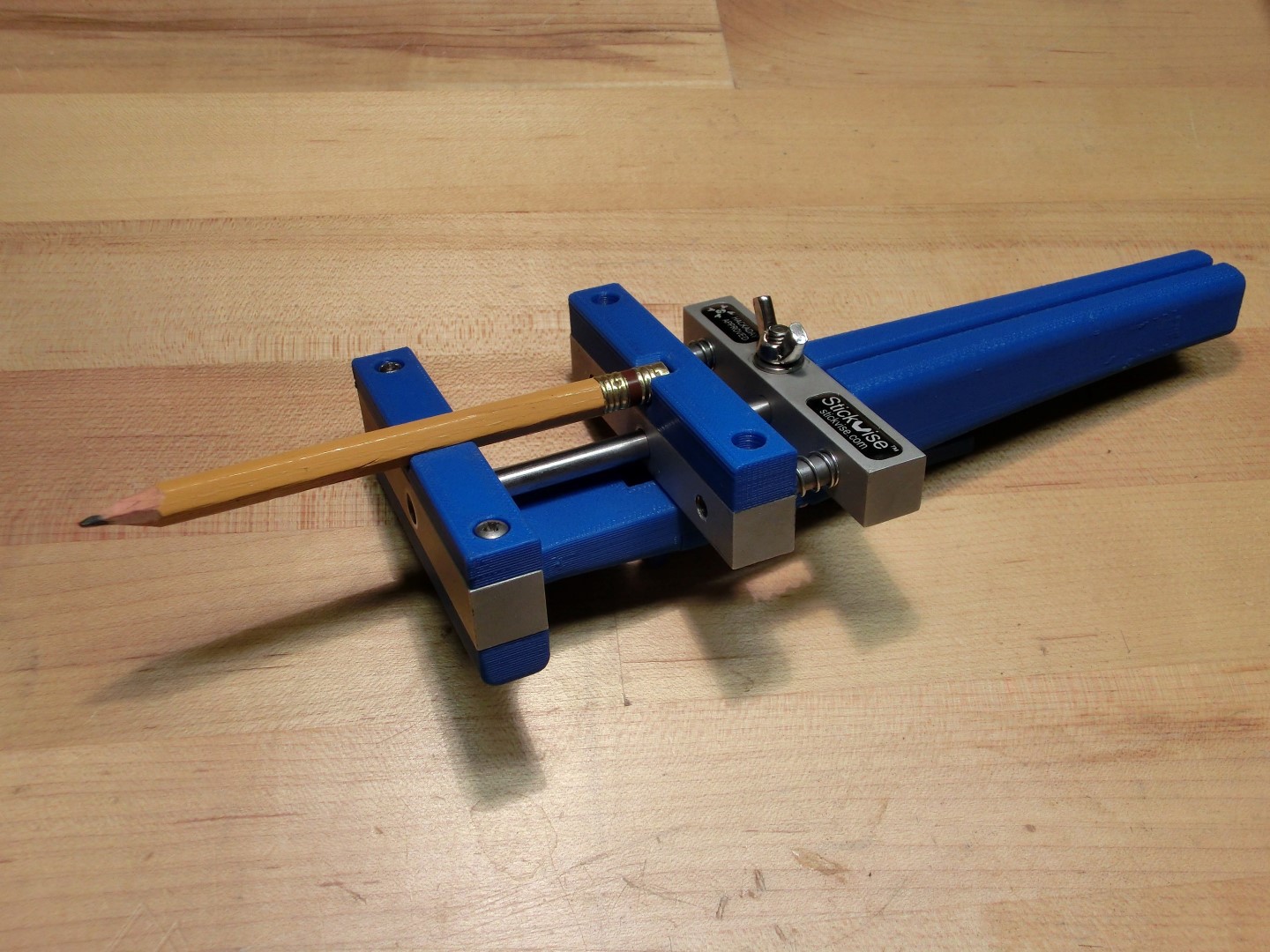

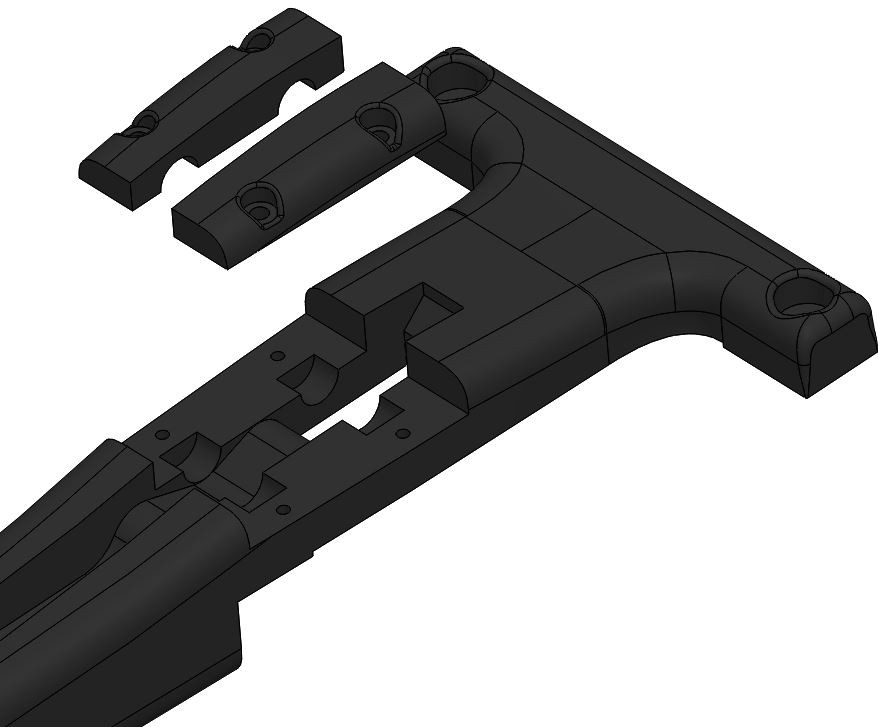

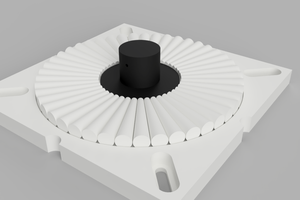

The Stickvise is a device used to hold electronic components or small circuit boards during soldering or other electronic work. It consists of two parallel, adjustable metal jaws that hold the component in place while leaving the operator's hands free to work on the component. <a href="https://gbwhatsapp.net/gb-whatsapp-pro-apk/">GBWhatsapp pro</a>