The main functional stages to consider include:

1. Preparation (removal of bottle bottom)

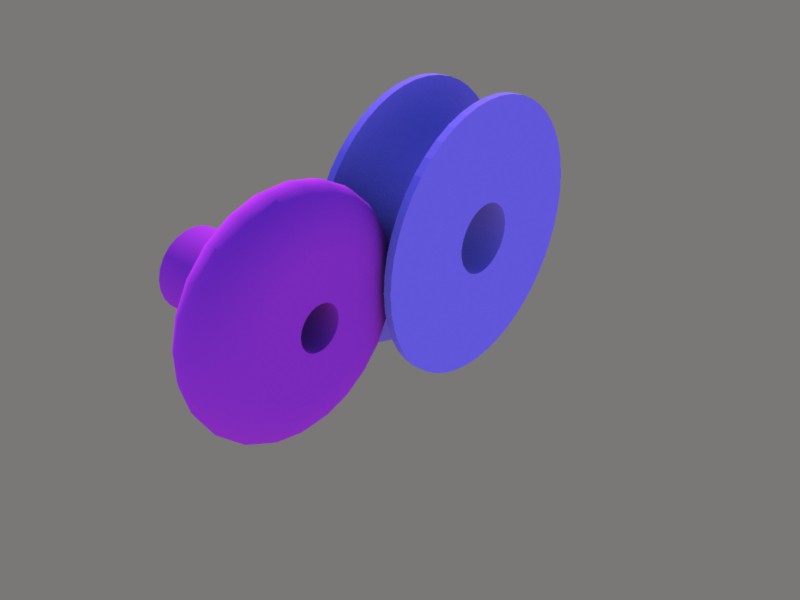

2. Ribboning (cutting strips of plastic material)

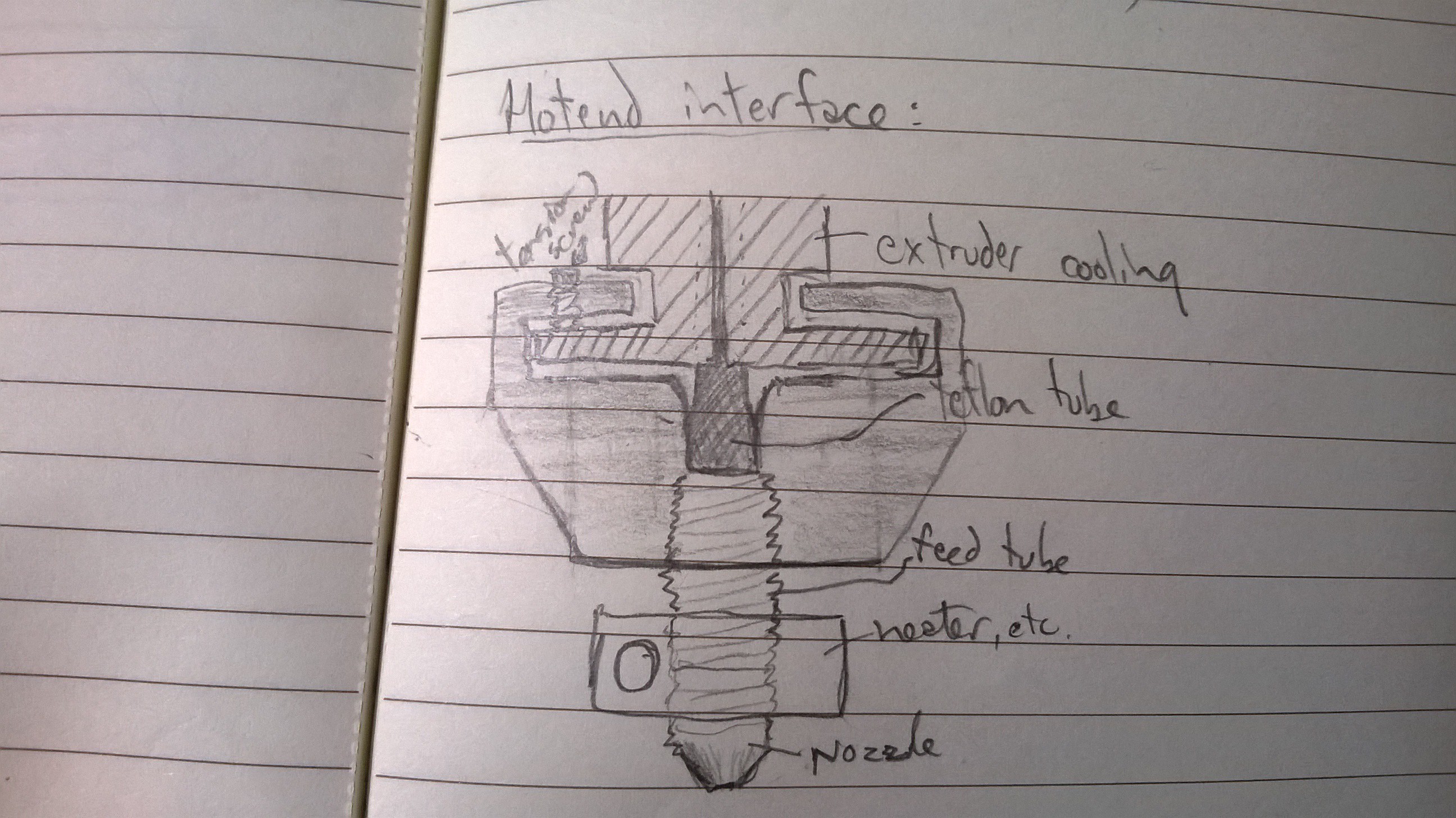

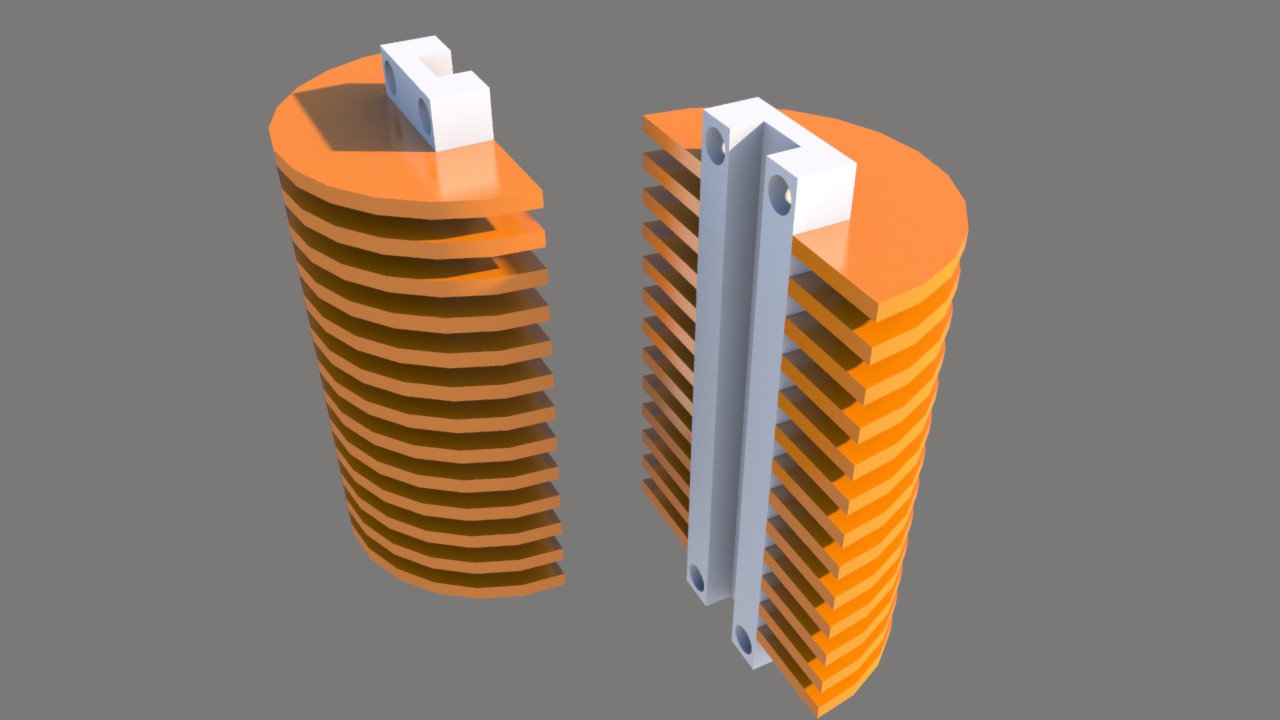

3. Feeding (starting the ribbon feed into an extruder and pushing it into a hot end)

4. Deposition (heating formed ribbon to malleable state, and fusing of this material)

I believe that this can be accomplished inexpensively and in a relatively simple manner. The goal is to keep it simple so a single machine can be sent into an area that has access to the raw material (plastic bottles) and can reuse this raw resource for making useful, educational, and artful objects, as well as new 3D-printer parts, all of which can improve the quality of life.

I think the most difficult challenges to overcome with this system will be changing and starting the bottle feed mid-print, and building a hot end feed tube that can accommodate the formed ribbon. Not insurmountable issues, but to be considered for sure...

ken.do

ken.do

JP Gleyzes

JP Gleyzes

EM

EM

Norbert Heinz

Norbert Heinz

Nice 3d work, how can i integrate this to https://indirminecraftapk.com