General Features

- Closed loop system with gyroscopes.

- Complete system simulation in MATLAB for PID tunning.

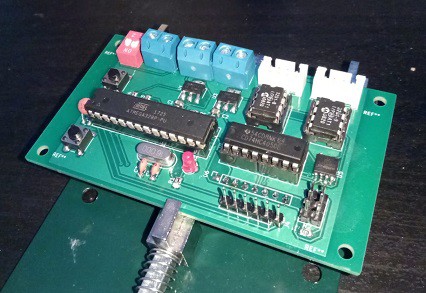

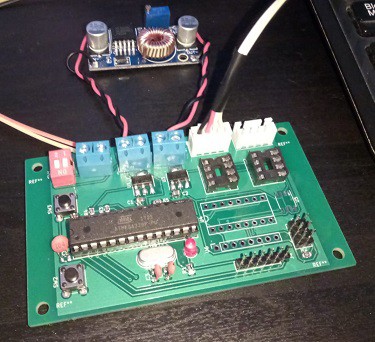

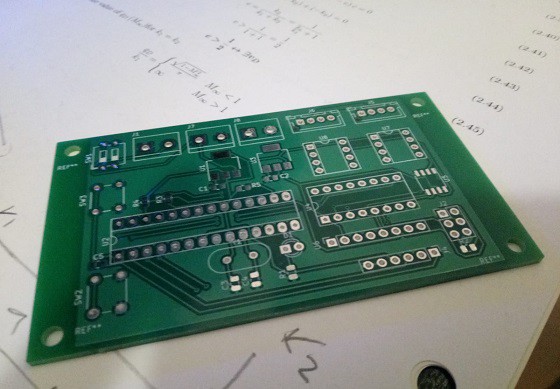

- Custom made PCB for control.

- Remote emergency deployment of parachute.

- Without fins.

- Simple parachute deployment with commercial electronics.

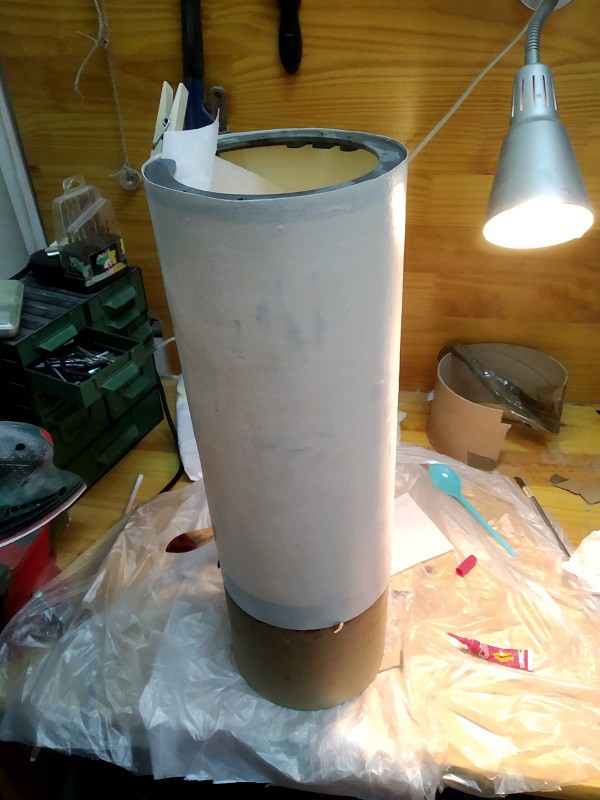

- Fiberglass body tube with wood reinforcements.

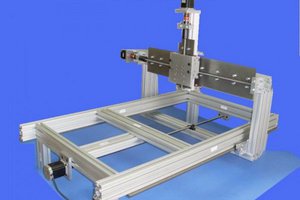

- Two DOF motor vector system.

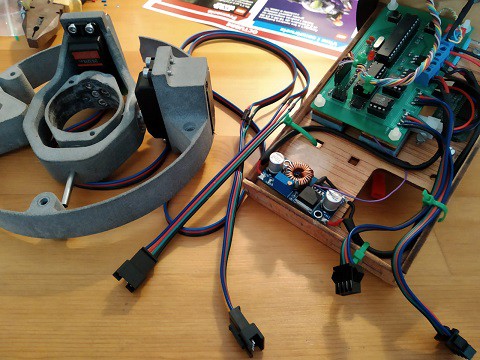

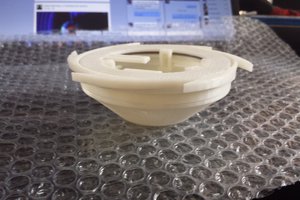

- 3D printed gimbal with hobby servos.

- Finite Element validated gimbal structure design

Active Stabilization

- Closed loop control system.

- Set point, zero angular velocity in rocket transverse axes (behaviour equivalent to fins).

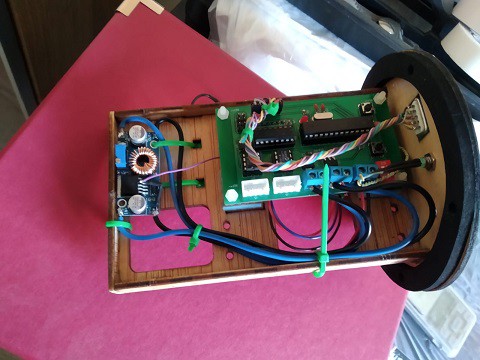

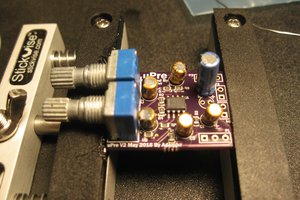

Control PCB Features

- Based on ATMEGA328P

- uC running an 5V and 16 MHz

- 3.3V for some components

- 6.5V for servos by means of an external DC-DC buck

- Reading servos actual position by means of two external MCP3201 12bit ADC's via SPI

- Flight data storage in flash memory Winbond W25Q64

- Inertial mesurement unit GY-91 with BMP280 and MU9050

- PWM control of two servos.

Status

- Feasibility study by means of simulation (COMPLETED)

- Design of the gimbal (COMPLETED)

- CAD (COMPLETED)

- Finite Element Analysis (COMPLETED)

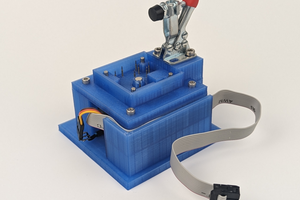

- Static testing (COMPLETED)

- Control PCB (IN PROGRESS)

- Schematic (COMPLETED)

- PCB design (COMPLETED)

- Manufacturing (COMPLETED)

- Programming the control PCB (ALMOST COMPLETED)

- Design of the rocket (COMPLETED)

- Fabrication (ALMOST COMPLETED)

- Gimbal (COMPLETED)

- Fiberglass body tubes and ogive (COMPLETED)

- Assembly (ALMOST COMPLETED)

Rhys

Rhys

Roman V

Roman V

Petar Crnjak

Petar Crnjak

AVR

AVR

This is super awesome! I am curious how you got the Mass Moment of Inertia to PID value relation which is what I am struggling with due to my lack of knowledge