The purpose of this project is to develop, study, and refine the Perturb & Observe (P&O) algorithm for use in a charger that behaves like an automotive charging system: one that works to maintain a constant bus voltage with the battery charge dependent on load.

This is done to support applications where the PV charging system & battery are connected to constantly varying loads. Depending on the load and available PV energy, the charger may support the entire load & charge the battery or support only theload (or partial) with no battery charge. Hence, no battery charging algorithm is included (nor intended) in the design.

Specifications:

- PV input voltage: 15 - 25 volts

- PV input current: maximum 7A

- Charging voltage: 14V (adjustable)

- Charging current: 7.2A (max)

- Maximum continuous power: 100W

- Bias supply: 10 - 15V (provided by battery)

- MPPT algorithm: Perturb & Observe (P&O)

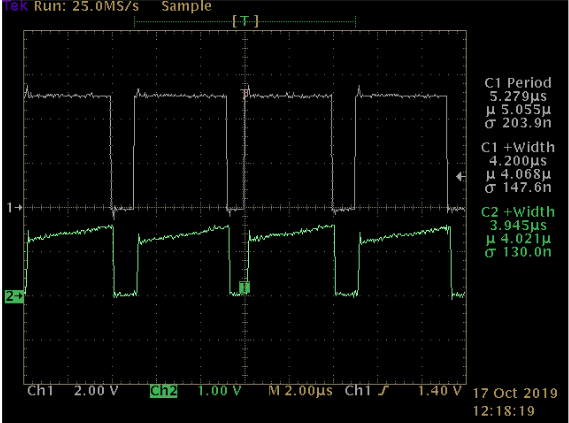

- Switching speed: 200kHz

- Cooling: natural convection

- Operating temperature: -20 - +50C (not validated)

- Bias current: 53mA running, 26mA idle

- Efficiency >95% (@ 90%+ loads)

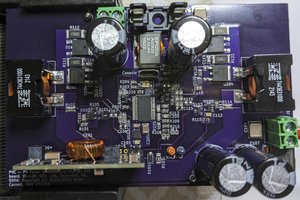

This design is based on the 12 to 5V USB charger and uses the same PCB, PIC, and switching core. PCB modifications have been made with hand wire traces, trace cuts, and glued components.

The switching core of the charger remains a non-isolated synchronous buck with limited low-side control. Unlike 125vbuck, Current mode control with slope compensation is employed. A type 2 error amp in the outer control loop

regulates the charger voltage.

An RS232 interface shared with the ICSP circuit provides a console interface with a robust command set to allow experimentation without firmware modification. Many parameters are stored in Non-Volatile Memory (NVM).

RS232 settings: 115.2kbps, 8 data bits, 1 stop, no parity

This console port is accessed over the micro-USB connector on the PCB and is optimized for use with a GBIB-style control program. A query command is also provided to support the rs232-44780 display unit. This command responds with a packet of binary data that is rendered on a Hitachi 44780 style LCD indicating unit status, battery, and PV output.

The console / display interface is optional and the unit will operate without it provided that the proper options are set (e.g. closed loop and autostart).

A status LED on the PCB indicates if the charger is running (Green) or in a stopped or fault state (RED). There are no flash sequences used to communicate a status code. The LED is managed by the Initialization and Charger on/off functions.