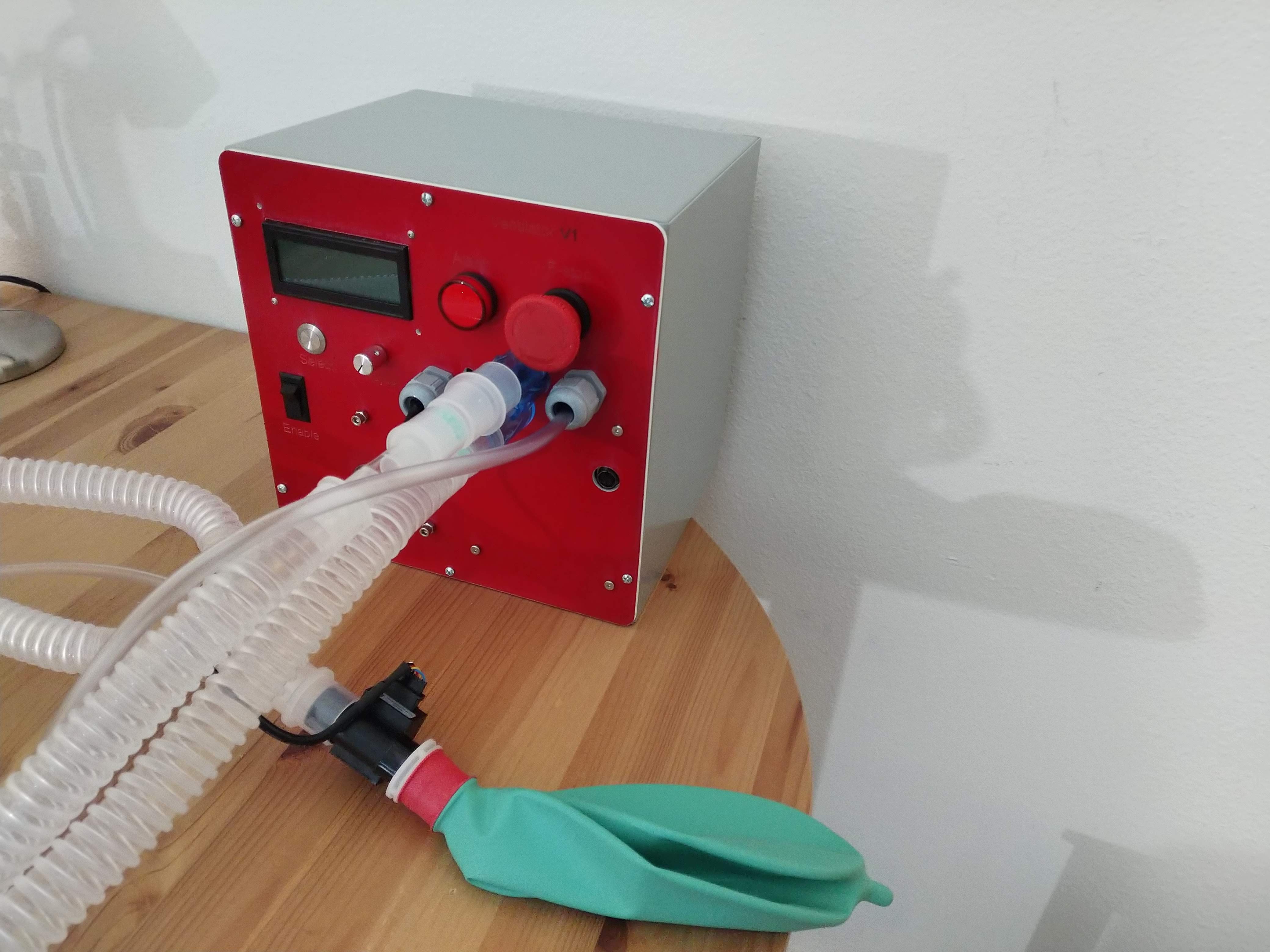

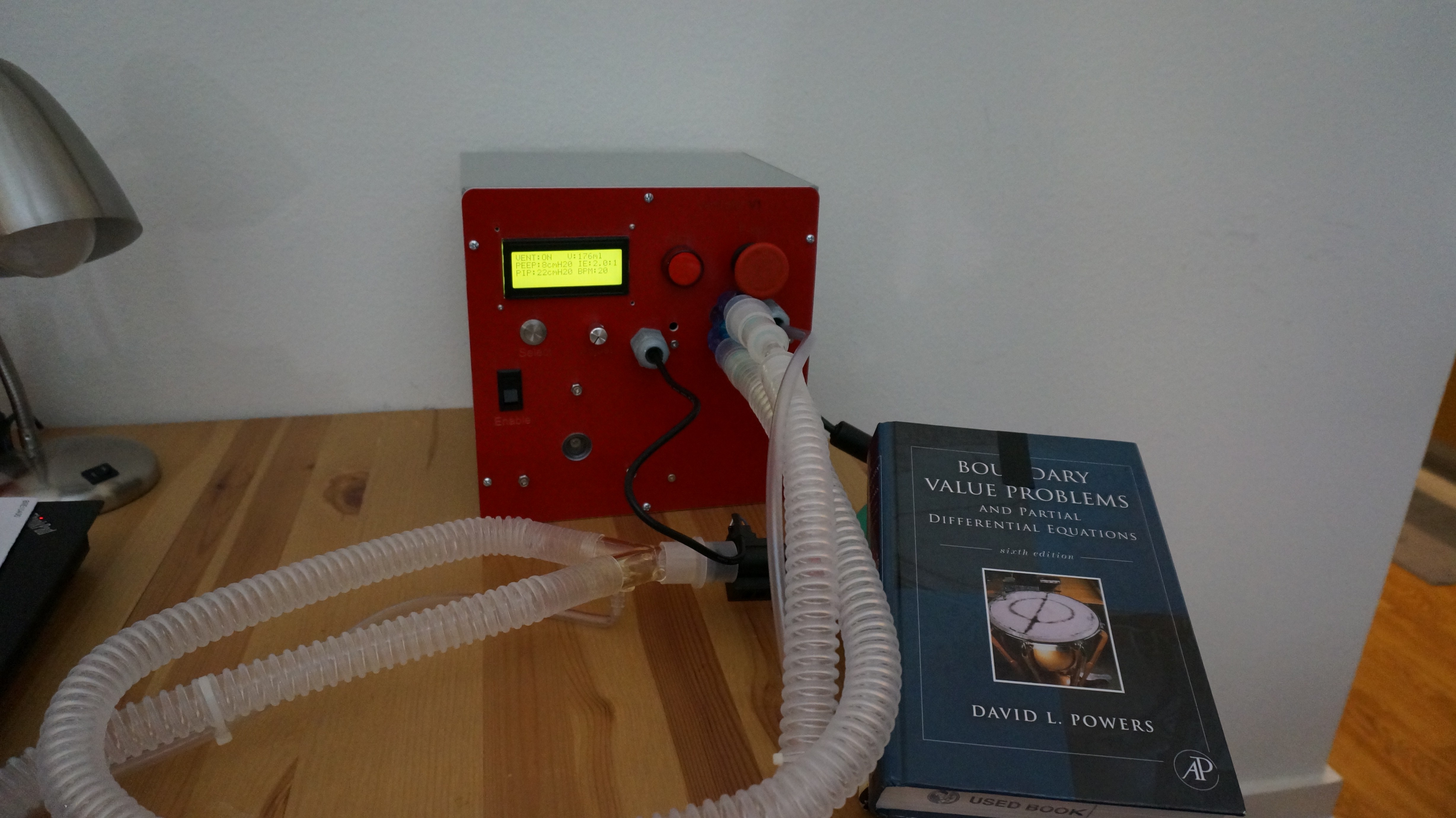

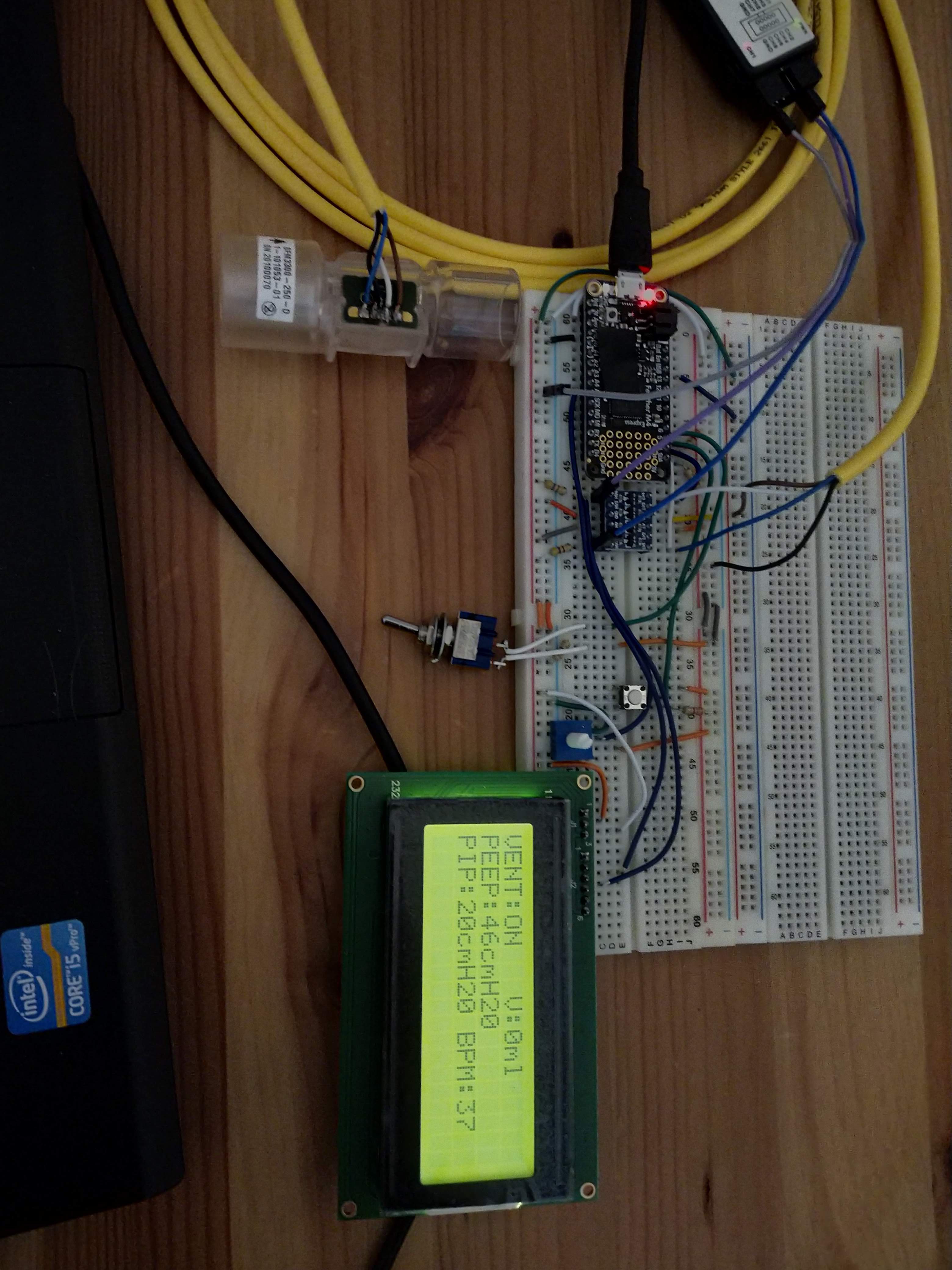

This is a medical ventilator designed to be used for Covid-19 patients if there are a lack of ventilators.

Goals of the project are:

- To provide a cost effective option < $1000

- To provide the patient with a safe ventilation option.

- To make the design as simple as possible to purchase all of the parts and assemble.

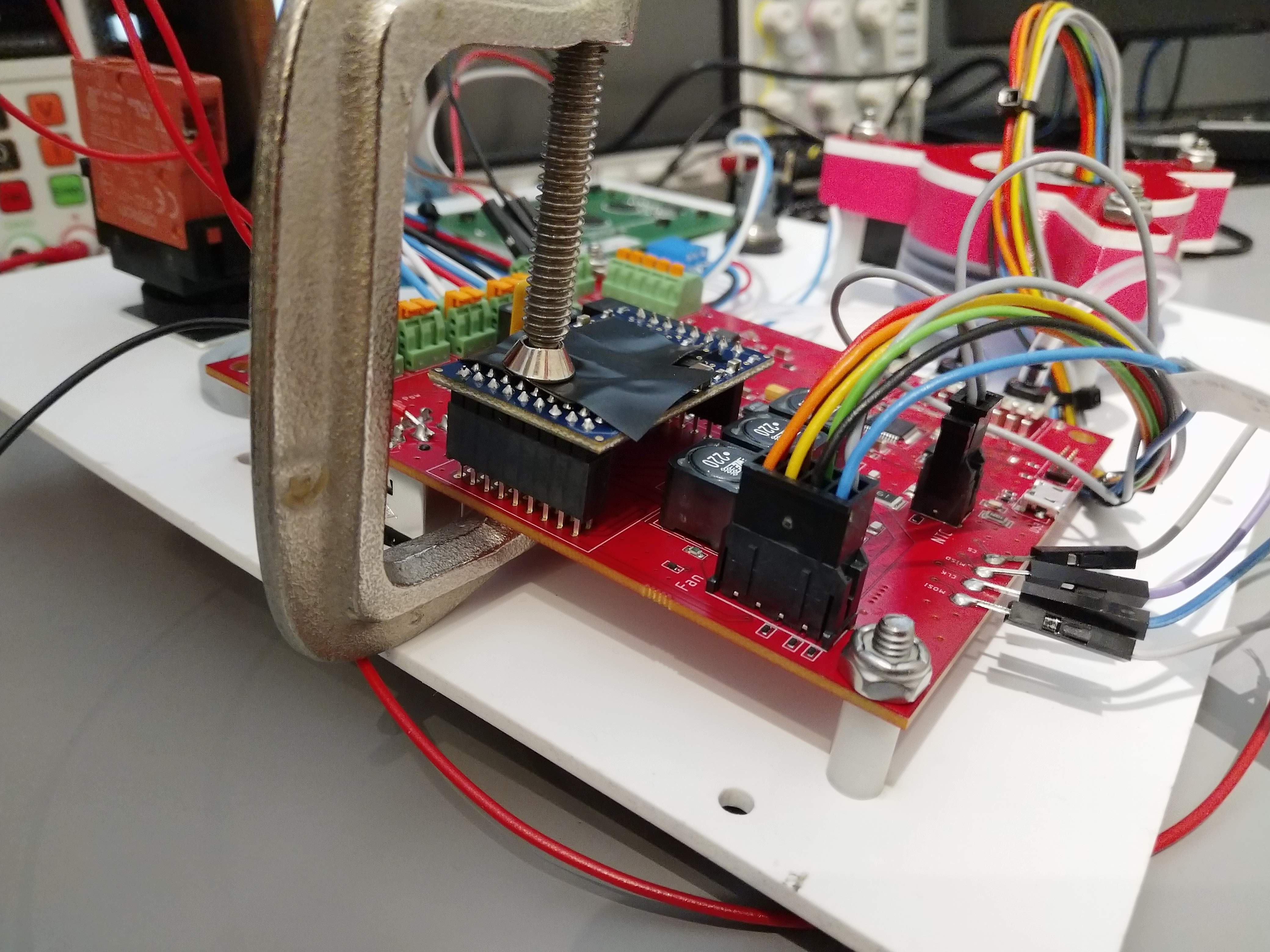

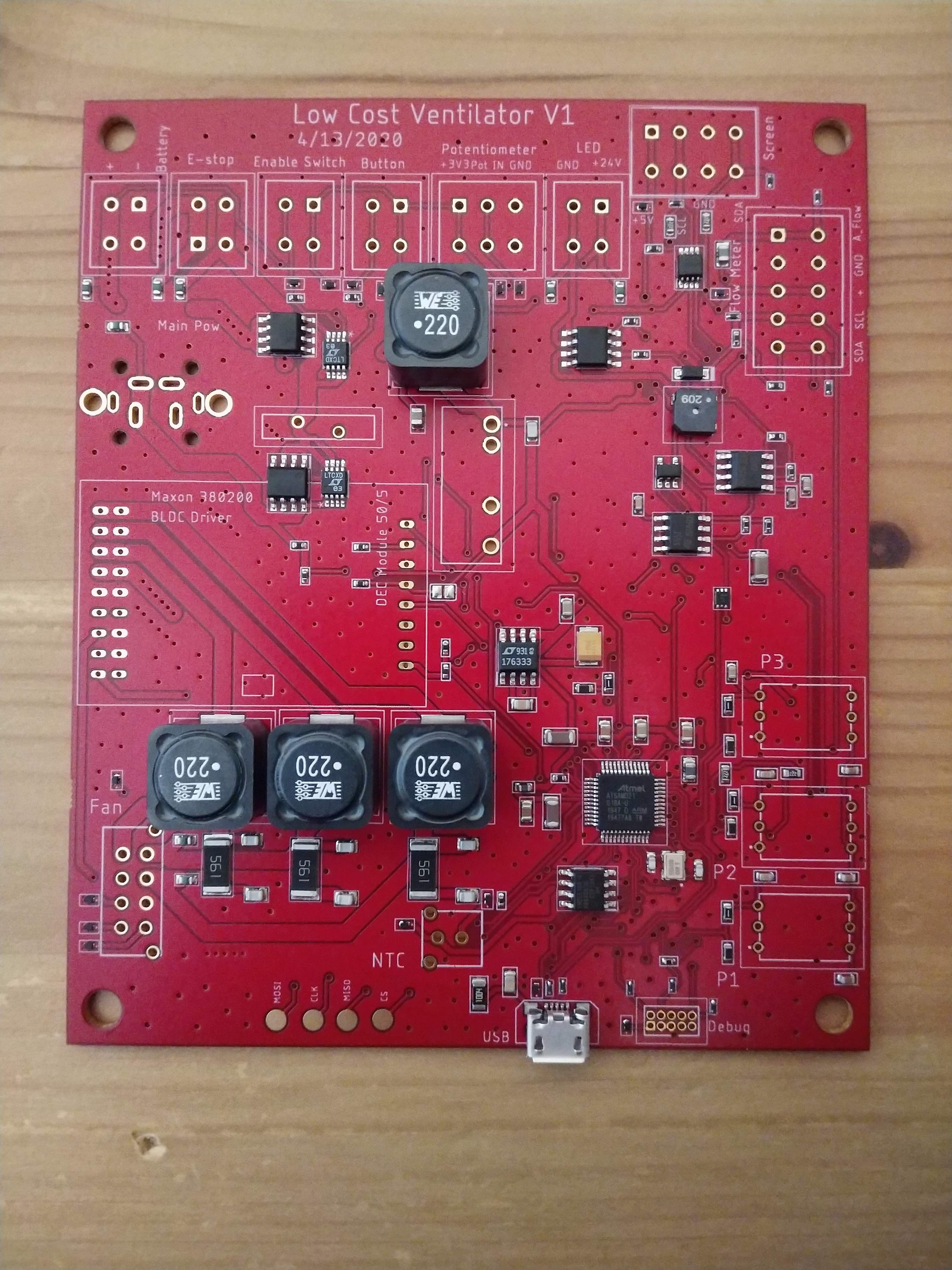

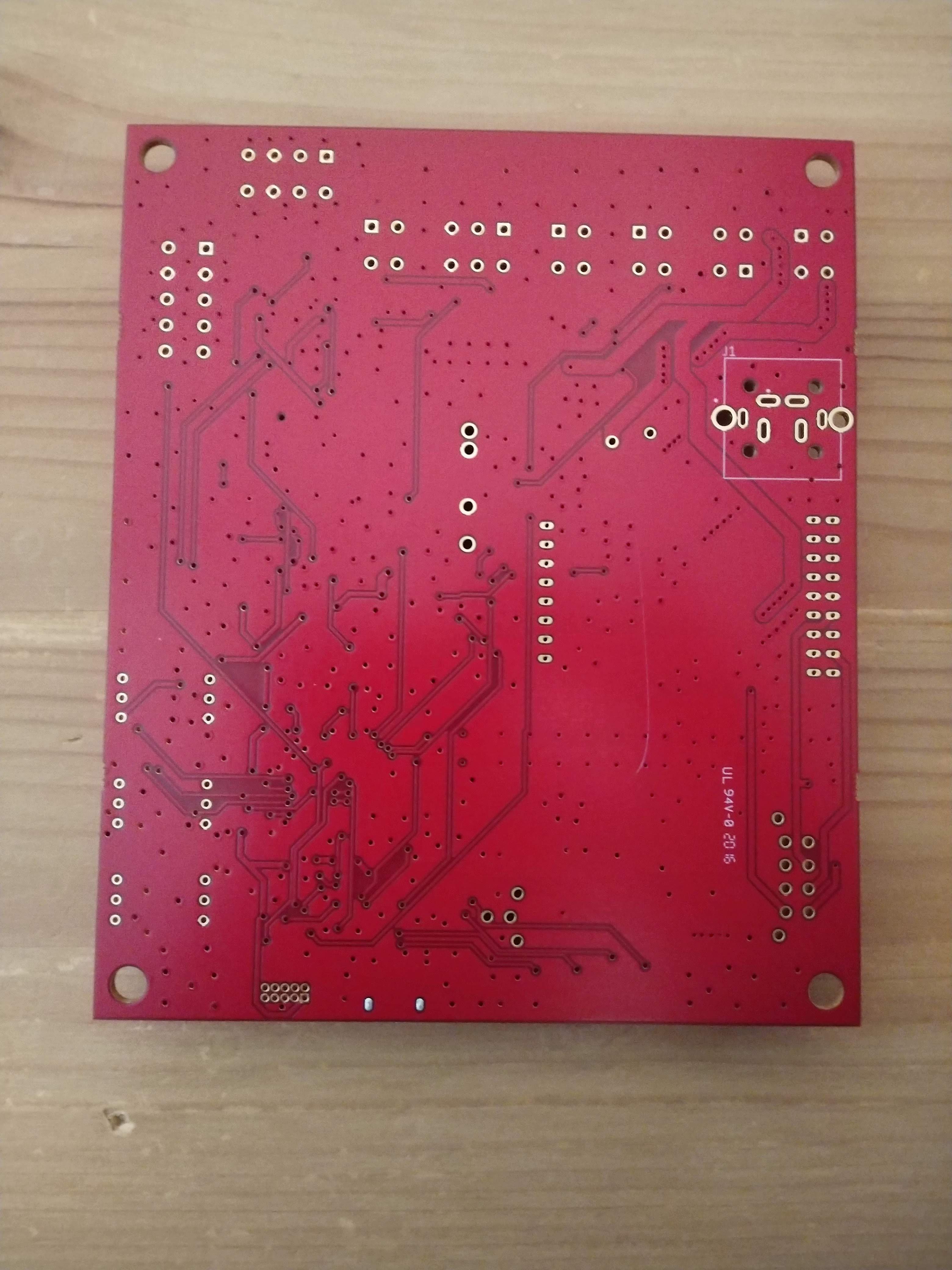

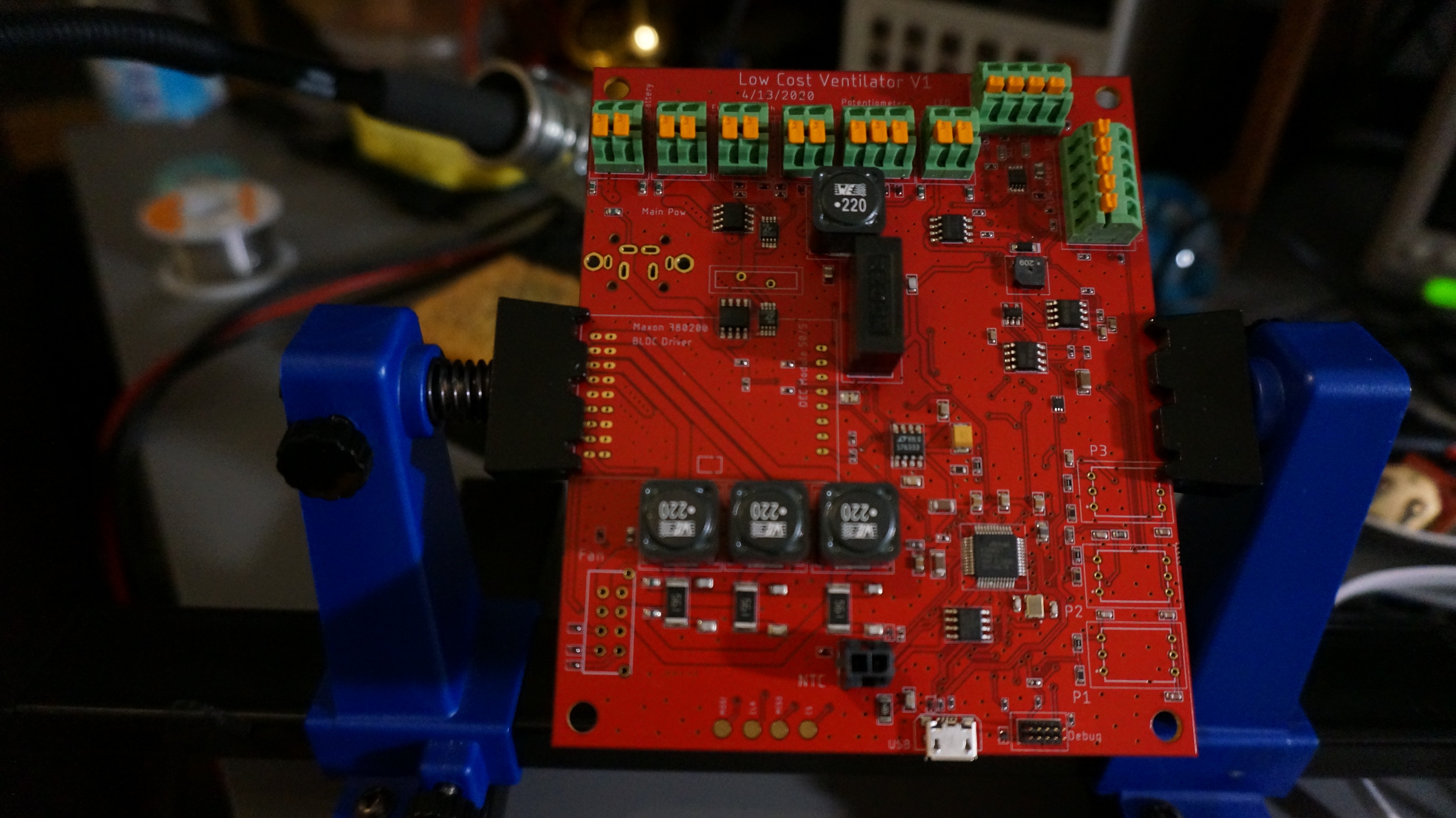

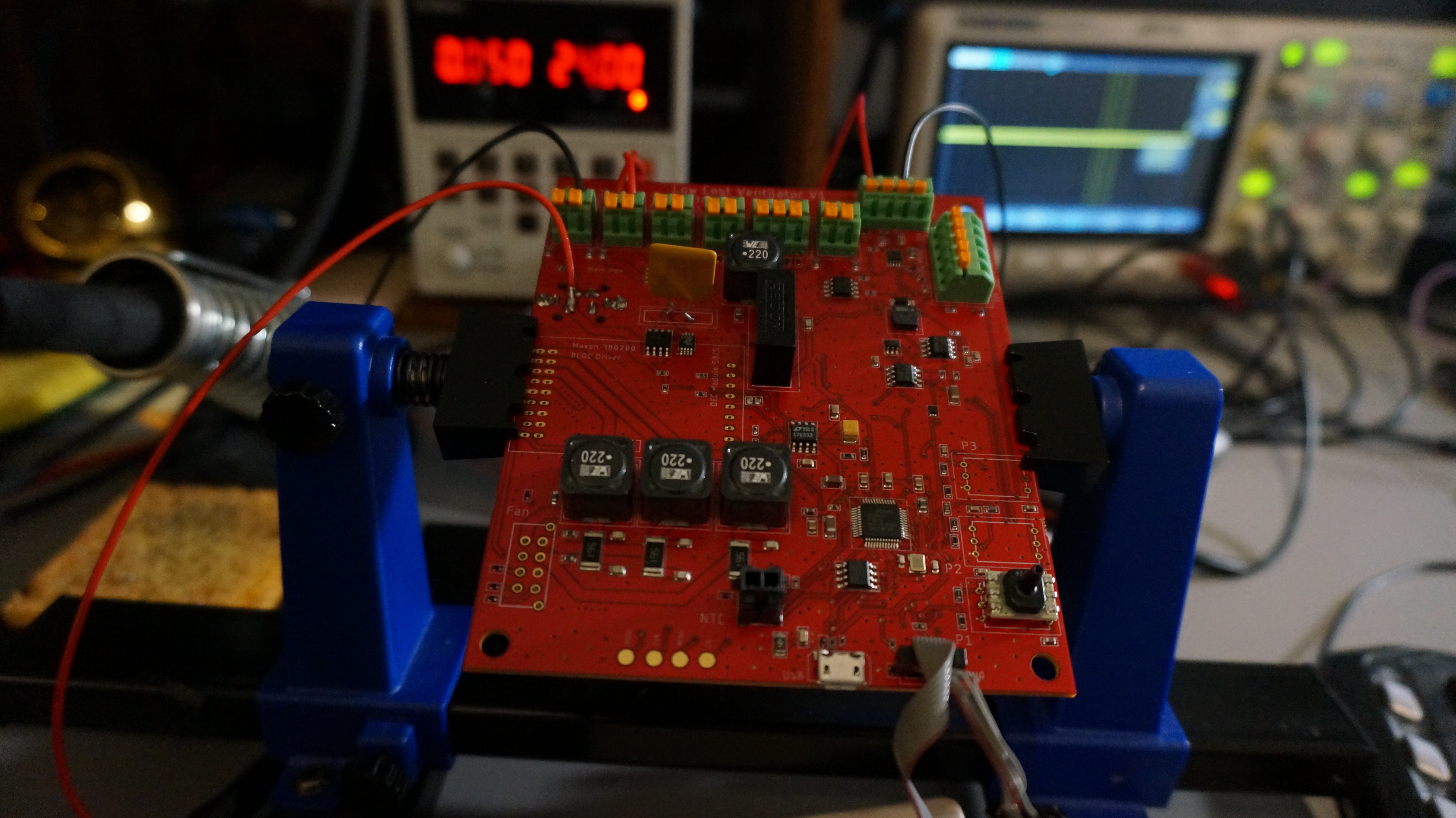

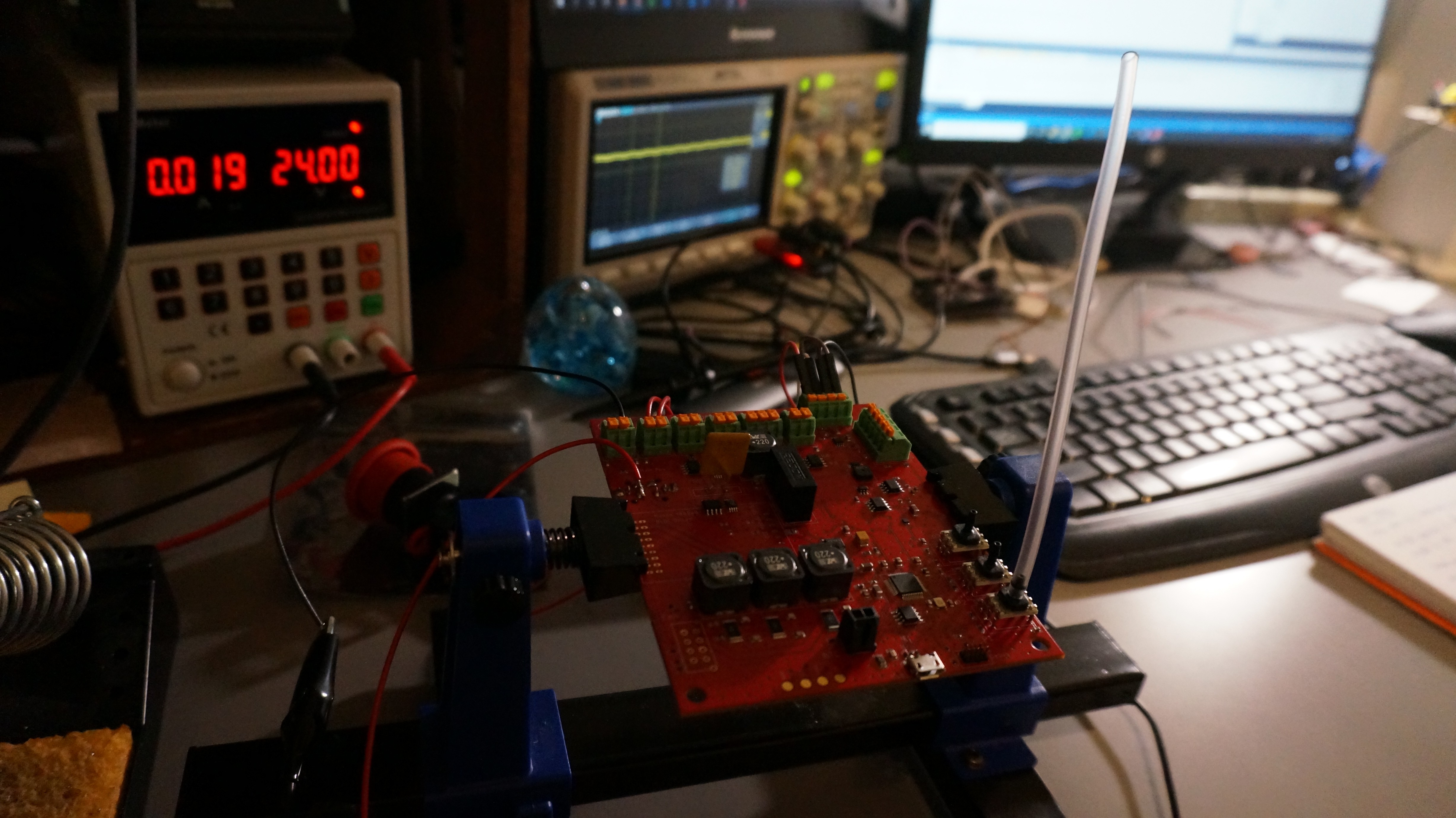

- Controller mostly SMD to simplify electronics build and ensure quality.

- Few, if any, custom components to ensure availability and quality.

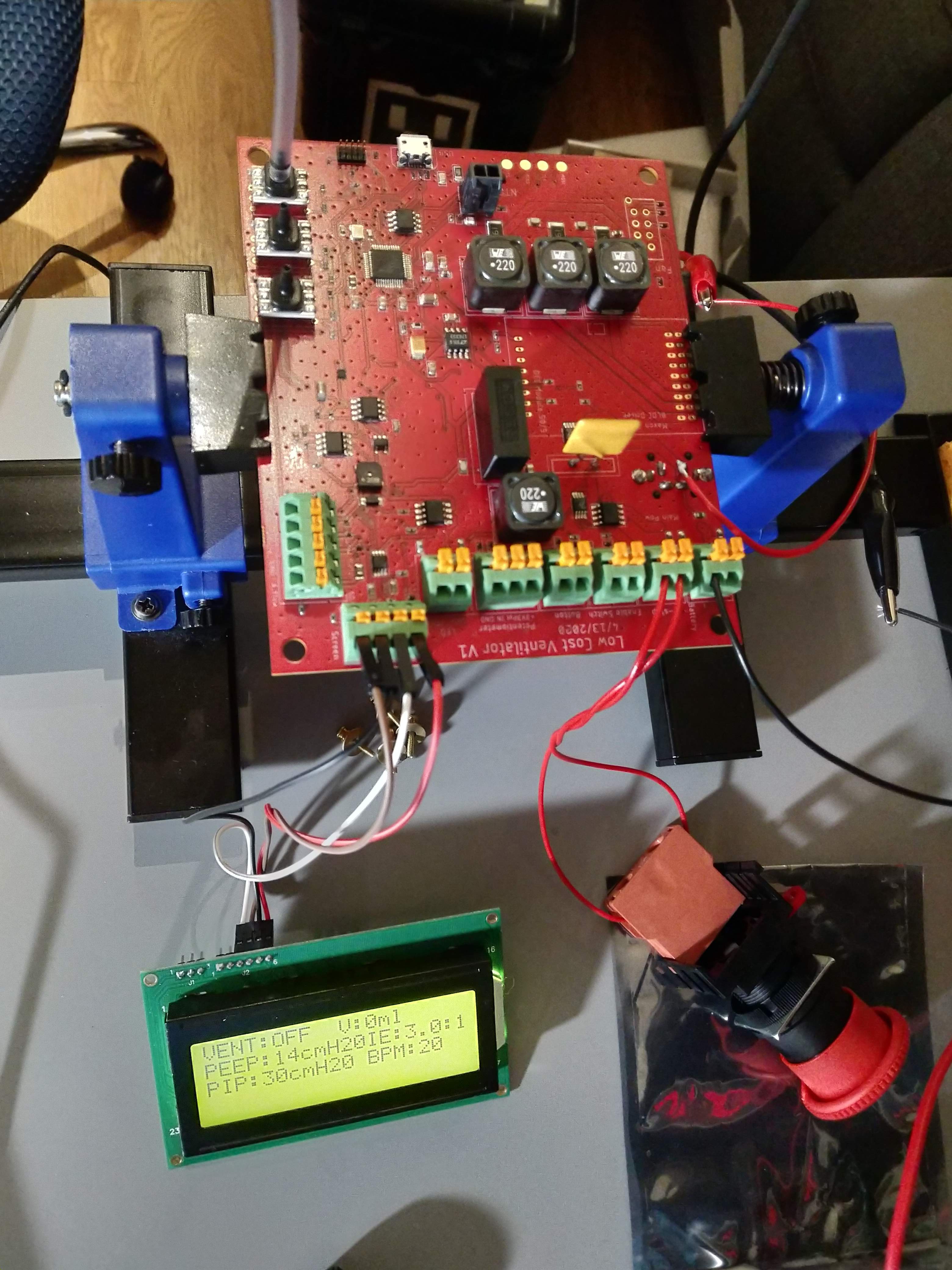

- To provide the necessities. These include the following:

- Option to add oxygen.

- Simple pressure control.

- Flow information for the operator of the ventilator

- Safety for patient and operator - IE Virus filter.

- Covid-19 ARDS pateints are almost alway intubated so additon of an off the shelf humidifier is necessary.

------------------------------------------------------------------------------------------------------------------------------------------------

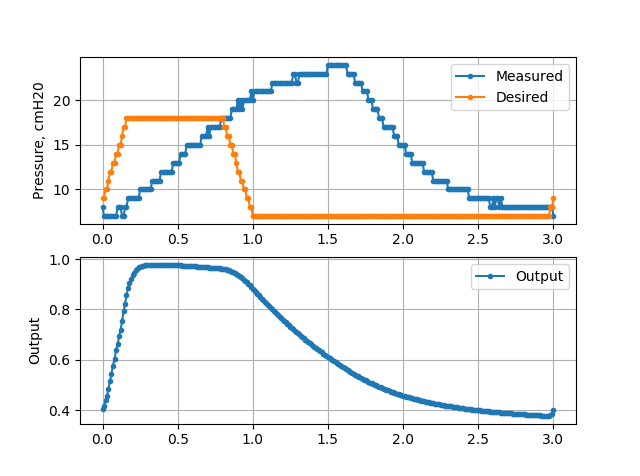

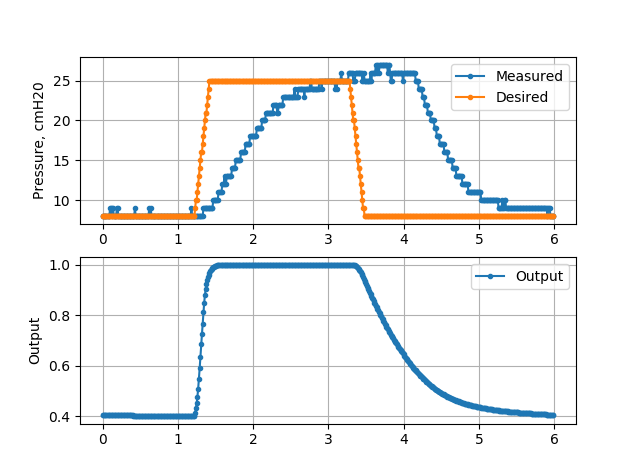

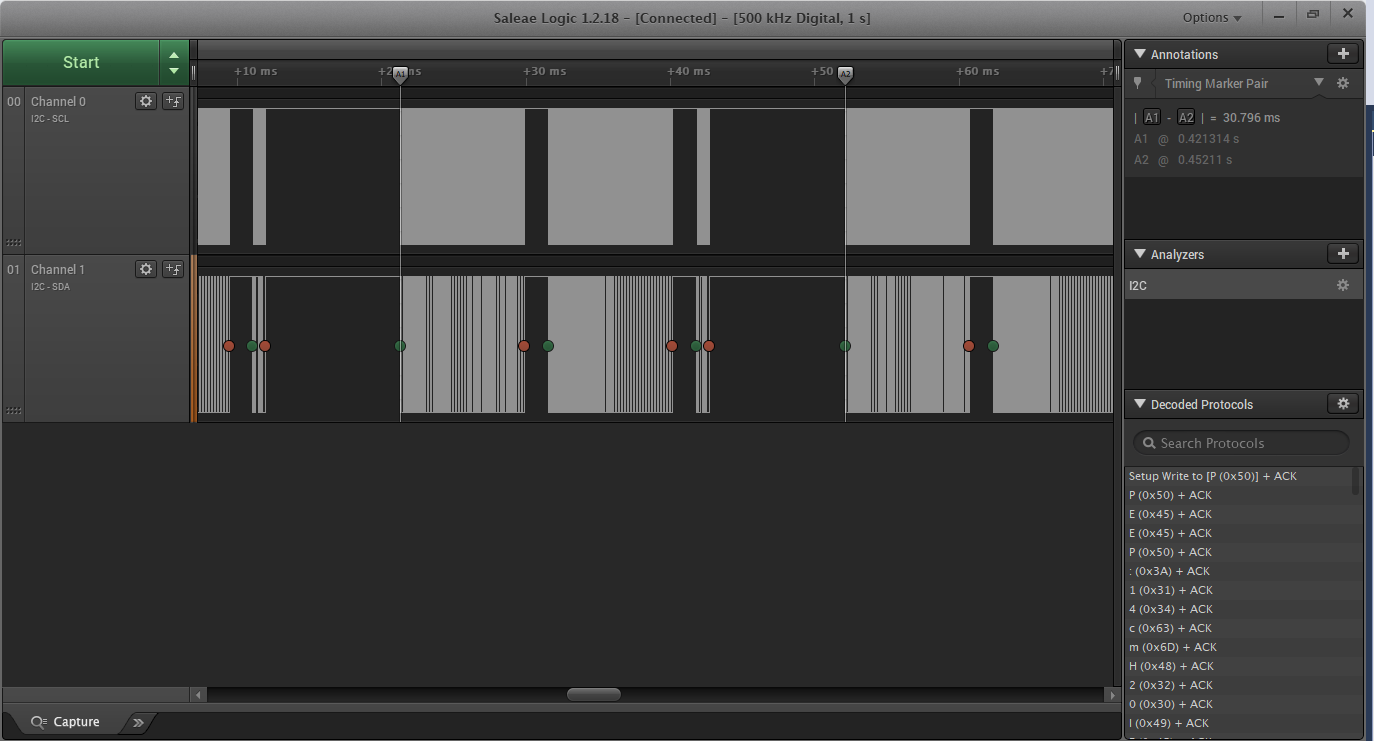

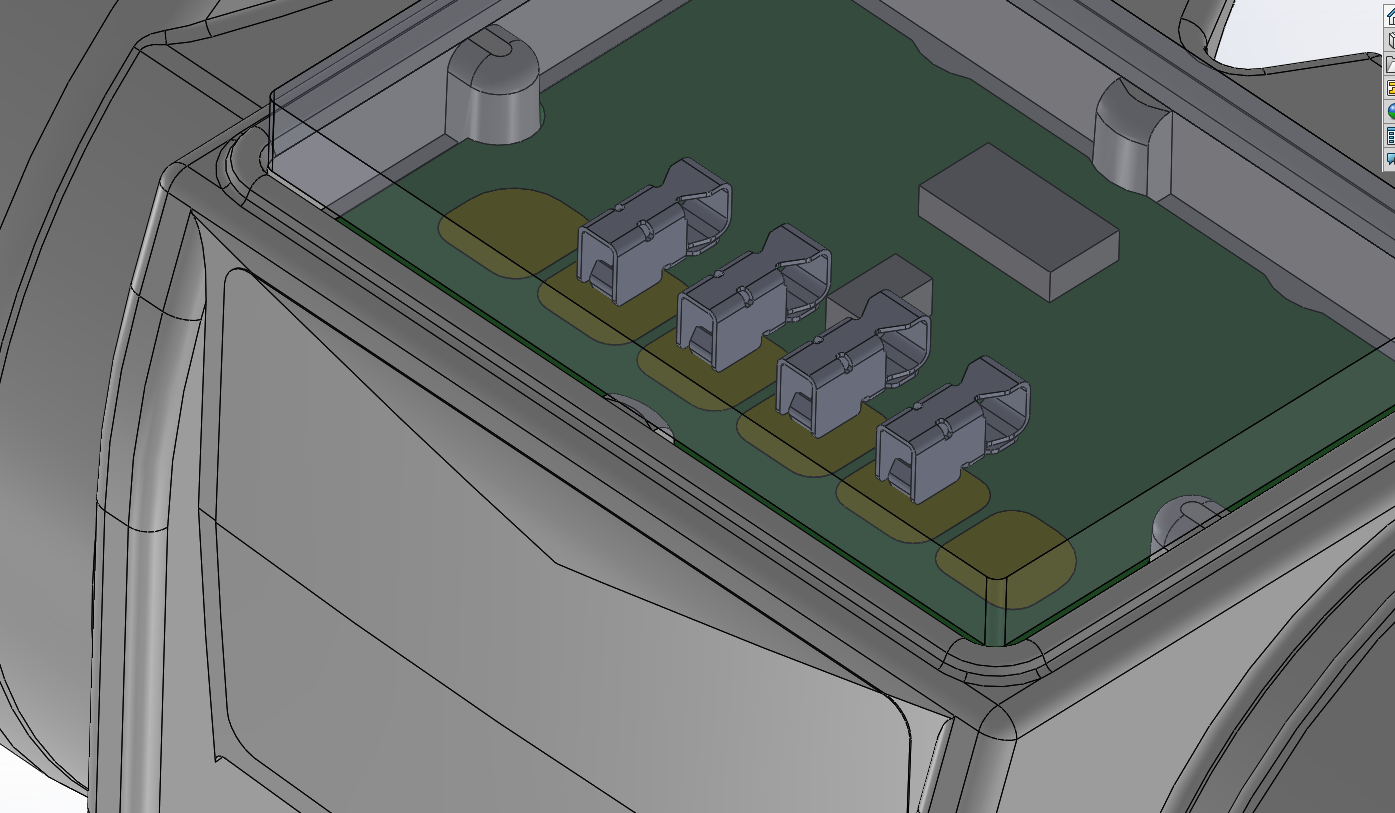

Details on pressure feedback:

The system pressure is monitored with 3 pressure sensors. This is to ensure patient safety and reliability of the system. The system is averaged and voted. This is done so that even if one sensor drops out, the system can still run. This is done in many mission critical systems.

The pressure sensors chosen are Honeywell ABPDANT005PGAA5's which will measure 0-5 psi gauge. These sensors were chosen because they have the maximum availability. Originally we were going with a sensor perfect for the application, but if you can't get them, they aren't perfect.

--------------------------------------------------------------------------------------------------------------------------------------------

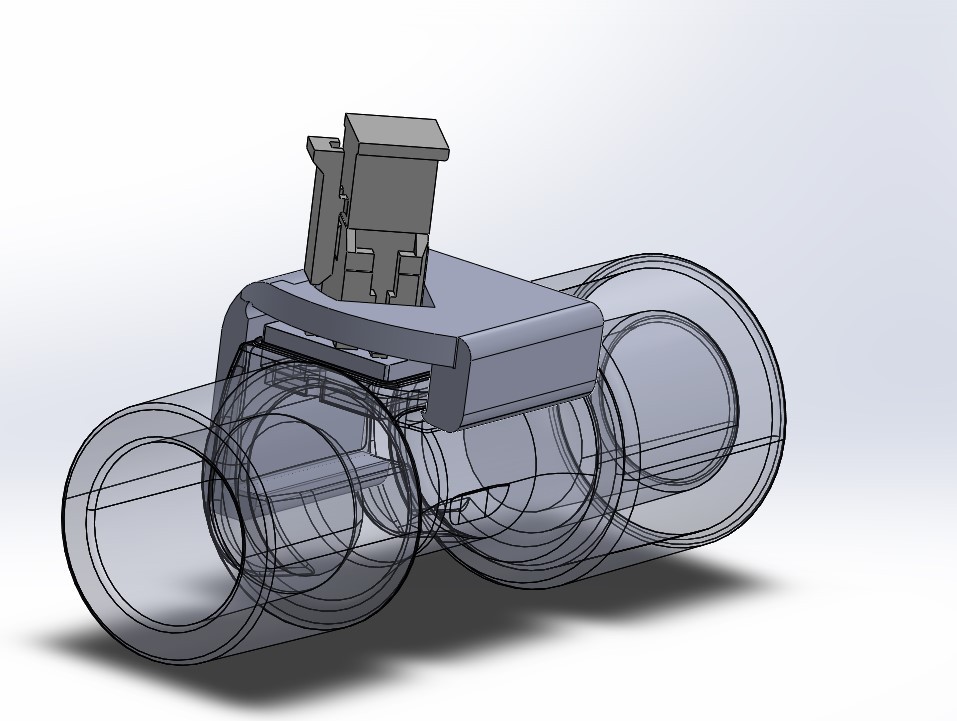

Details on flow monitoring:

The Inspiratory and Expiratory flows will be measured via a Siargo Ltd FS6122-250F250-0P0-0. These are accurate flow meters which will give accurate information to the individual running the ventilator. The Tidal volume or amount of air that goes into and out of the lungs per breath is critical with a Covid-19 ARDS patient who may have decreased Tidal Volumes for the same input pressures. This could eventually lead to hypoxia if not corrected. Without knowledge of the flows there is no way to know and correct this ahead of time. Currently, it is not in the works to control the ventilator based on flow, this will be for monitoring only.

---------------------------------------------------------------------------------------------------------------------------------------------

Details on air moving choice:

A Micronel U65MN-024KD-5 centrifugal blower was chosen as the air mover of choice for several reasons. It is a fan and thus inherently not a positive displacement pump. This is an engineering control to limit the possible pressure delivered to the patient's lungs. This is a quality blower from Switzerland and will not disappoint.

Mark Atherton

Mark Atherton

Jason

Jason

Josh Pieper

Josh Pieper

Paul Gould

Paul Gould

Thanks for sharing such a great info. i thing i am searching for things like this. Thanks

<a href= "https://motivation.how/about"> Don't let your dreams drift away </a>