Background:

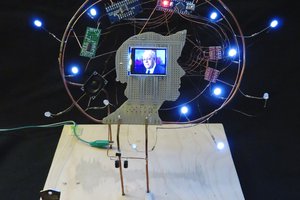

When hackaday announced the circuit sculpture challenge in august I was very excited. I was already impressed by Mohit Bhoite's sculptures on hackaday and his interview on embedded.fm (ep 314) really encouraged me to give it a try. So what better excuses than a hackaday contest.

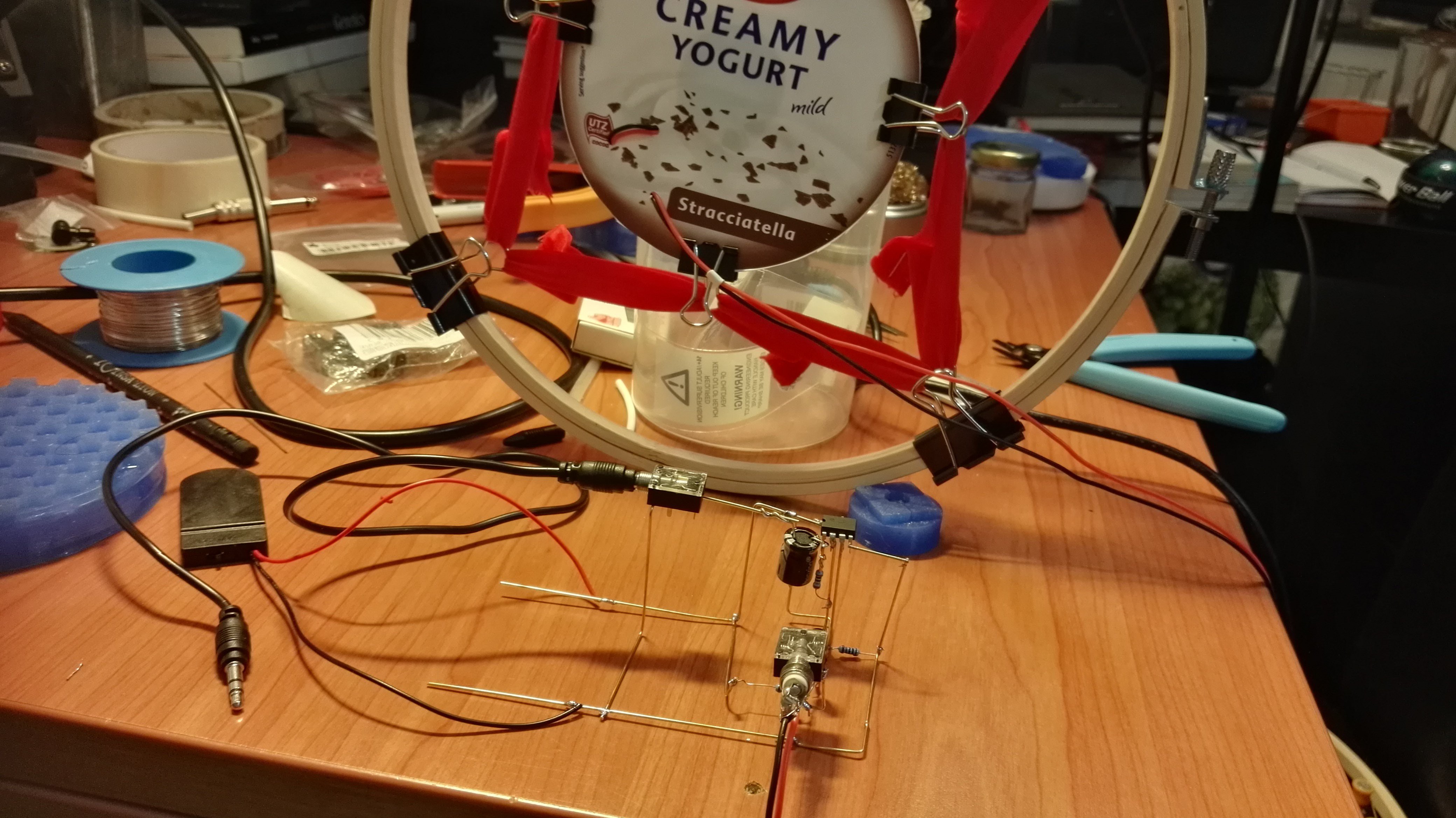

Never having made a sculpture before I thought it be wise to do a basic tutorial for one first (the link in the embedded.fm shownotes was very helpful). Trying things for the first time not being challenging enough I thought it would be fun to try this as a date.

On this date we learned the following:

- Cutting mats are not heat resistant

- You will need up to 4 hands to complete some connections

- Double sided tape is not ideal.

- SMD LEDs like to stick to soldering iron tips

- Soldering is a fun date activity

Most circuit sculpture tutorials recommend holding parts in place with double sided tape. However the heat of the soldering iron will reduce the stickiness of the tape (to not sticky at all anymore). So the need for a solder-able hold in place method was born.

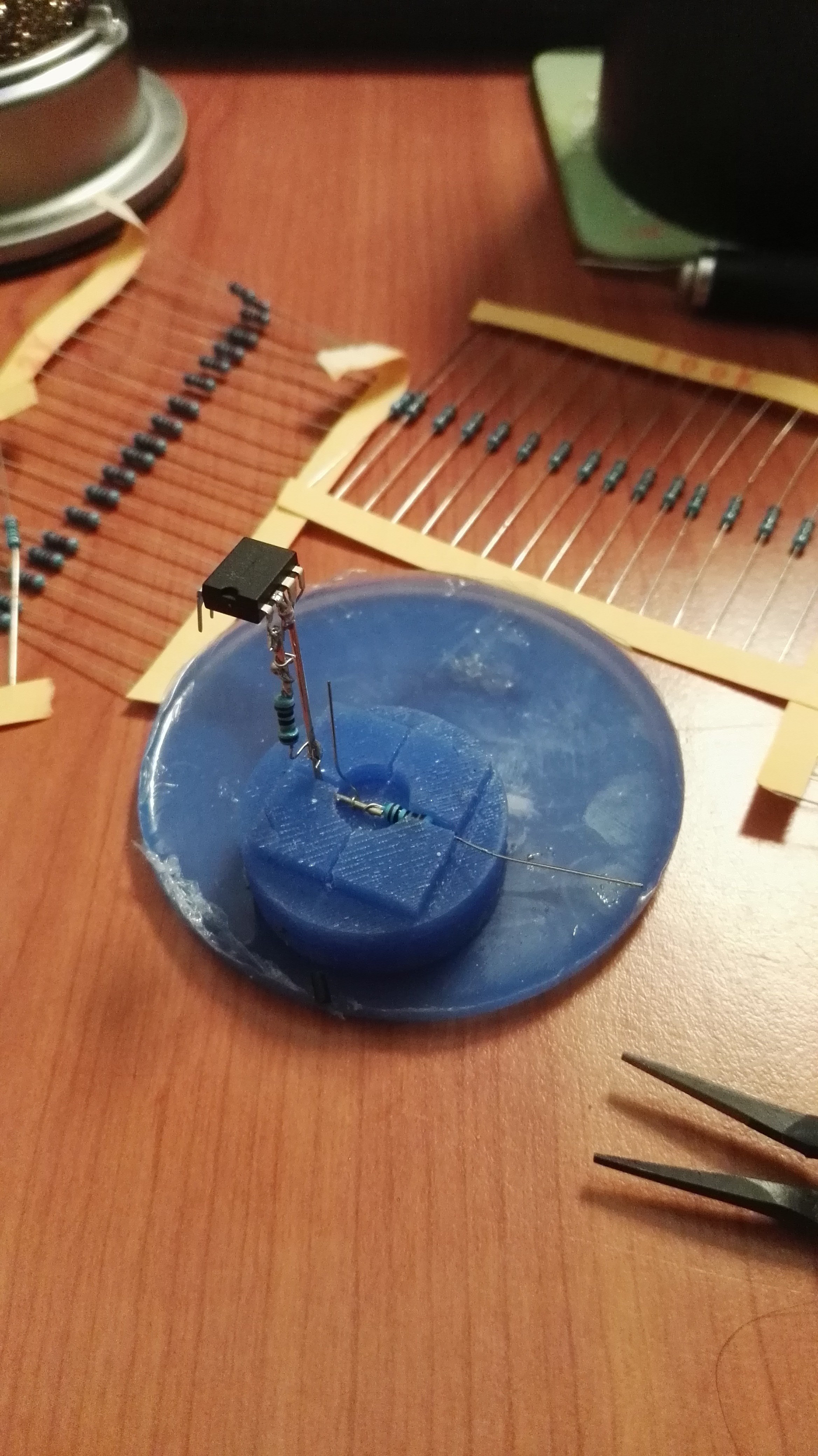

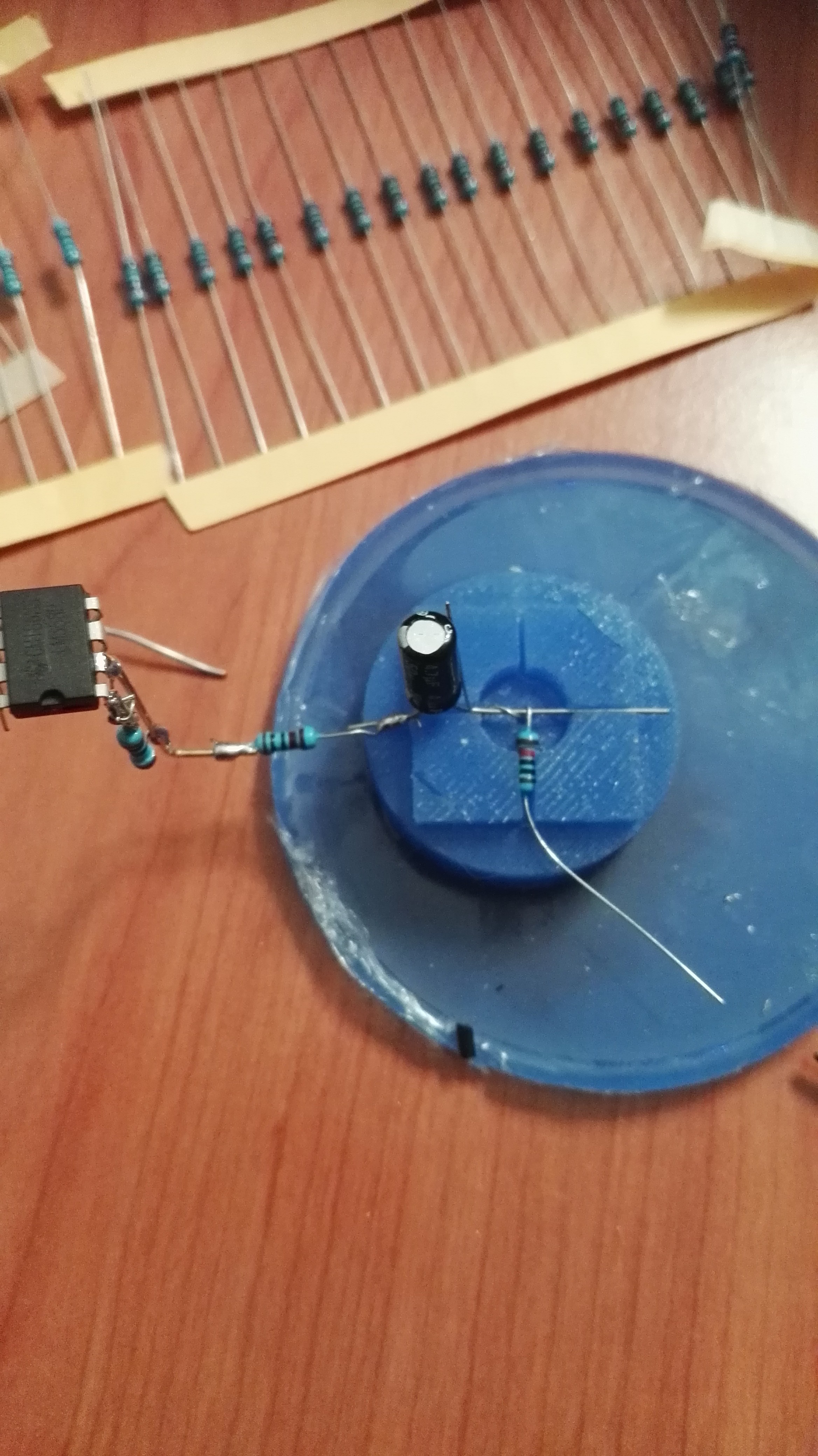

I like to hobby a lot with soft robotics projects which (for me) are made of silicone. Because silicone is quite heat resistant the idea of using as a jig cam e to mind. When pouring silicone you will almost always have a little left over which pools at the bottom of your mixing cup. When this eventually sets it forms a nice round complementary soldering pad. Trying to make another one of Jiří Praus' LED jewelries, but this time on my own, worked quite well even with just a flat silicone pad.

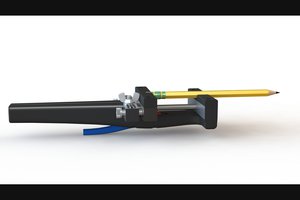

Since its possible to shape silicone in many ways when you actually pour it into a mold (instead of leaving it in the cup); the idea of making a pattern to hold the brass rods in place started to form. Later the realization came that the air pumps I was using for my soft robotics project could be used to create suction to keep SMD components in place.

Leading to the project page we are on now. I had a complicated idea for a circuit sculpture in mind for the contest, however working on the jig itself became quite interesting and challenging. I also hope that by making this project page I can receive some input from other circuit sculpture builders. Mainly about what parts are often used and difficult to work with without a jig, also for which orientations solder support is appreciated. Plus feedback on the OpenSCAD is also appreciated. I am really curious what people think about the variable naming scheme, since I'm personally really fond of it.

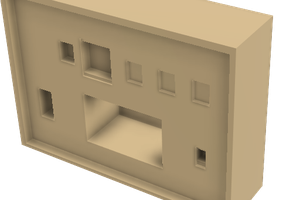

OpenSCAD file

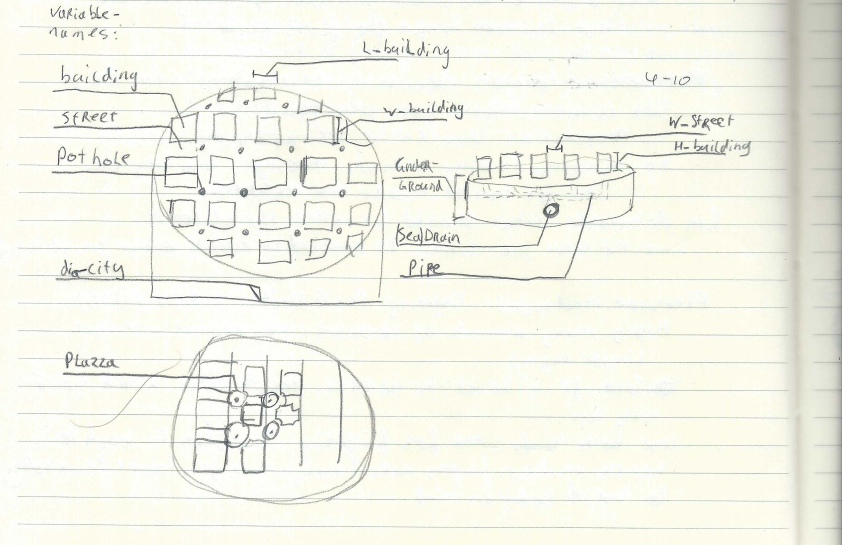

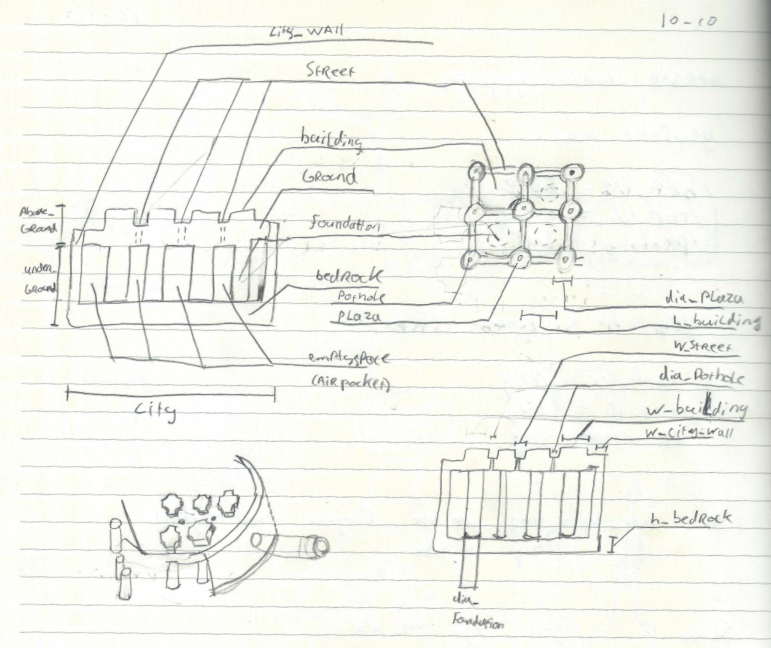

Naming scheme for variables is based on parts of a city. Code is now on Github, though it still needs development in order to produce a useful jig.

| Variable names above ground | Variable names underground |

|  |

Keep in mind that the current physical build is far from perfect. The 3D model code is also quite inefficient since it takes both a long time to render as well as to preview. The concept of this jig is great, however there is a lot to improve before it's ready help anyone. But I believe the soft soldering jig can help with circuit sculptures.

Model versions

V0

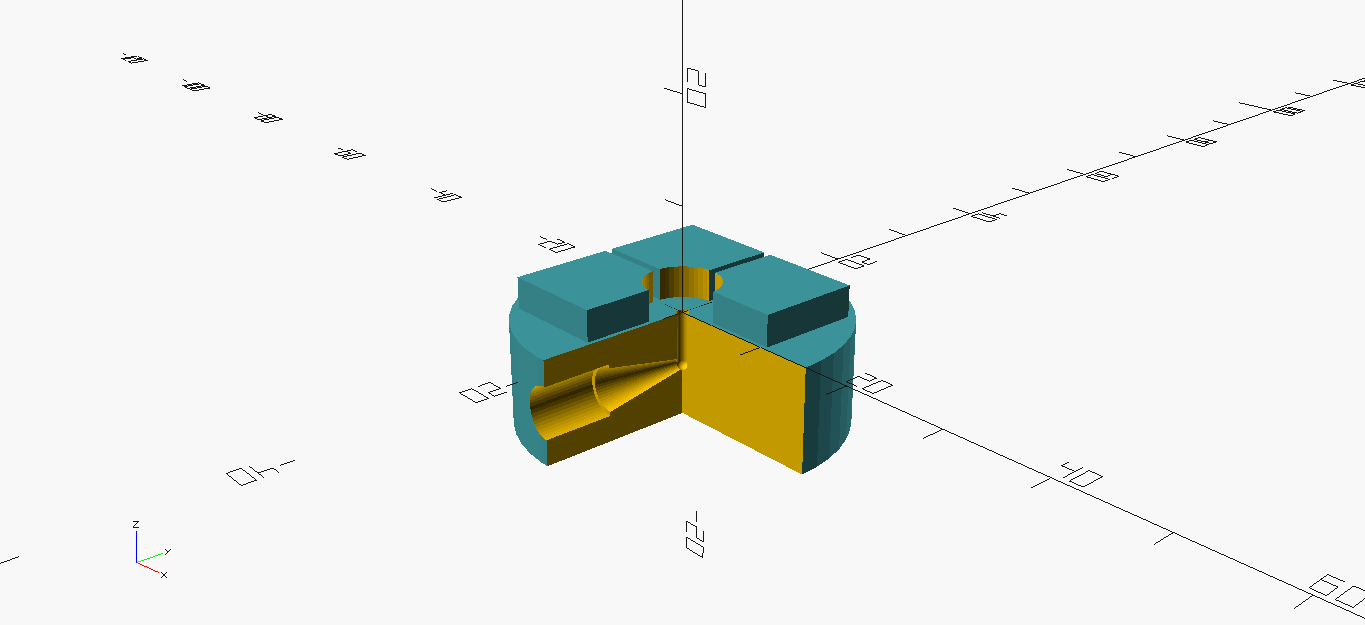

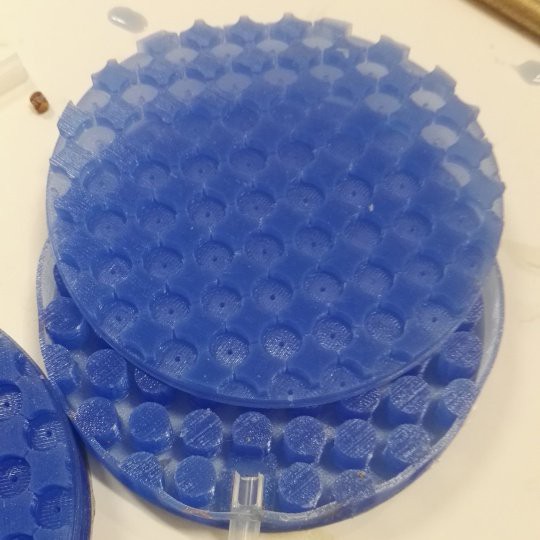

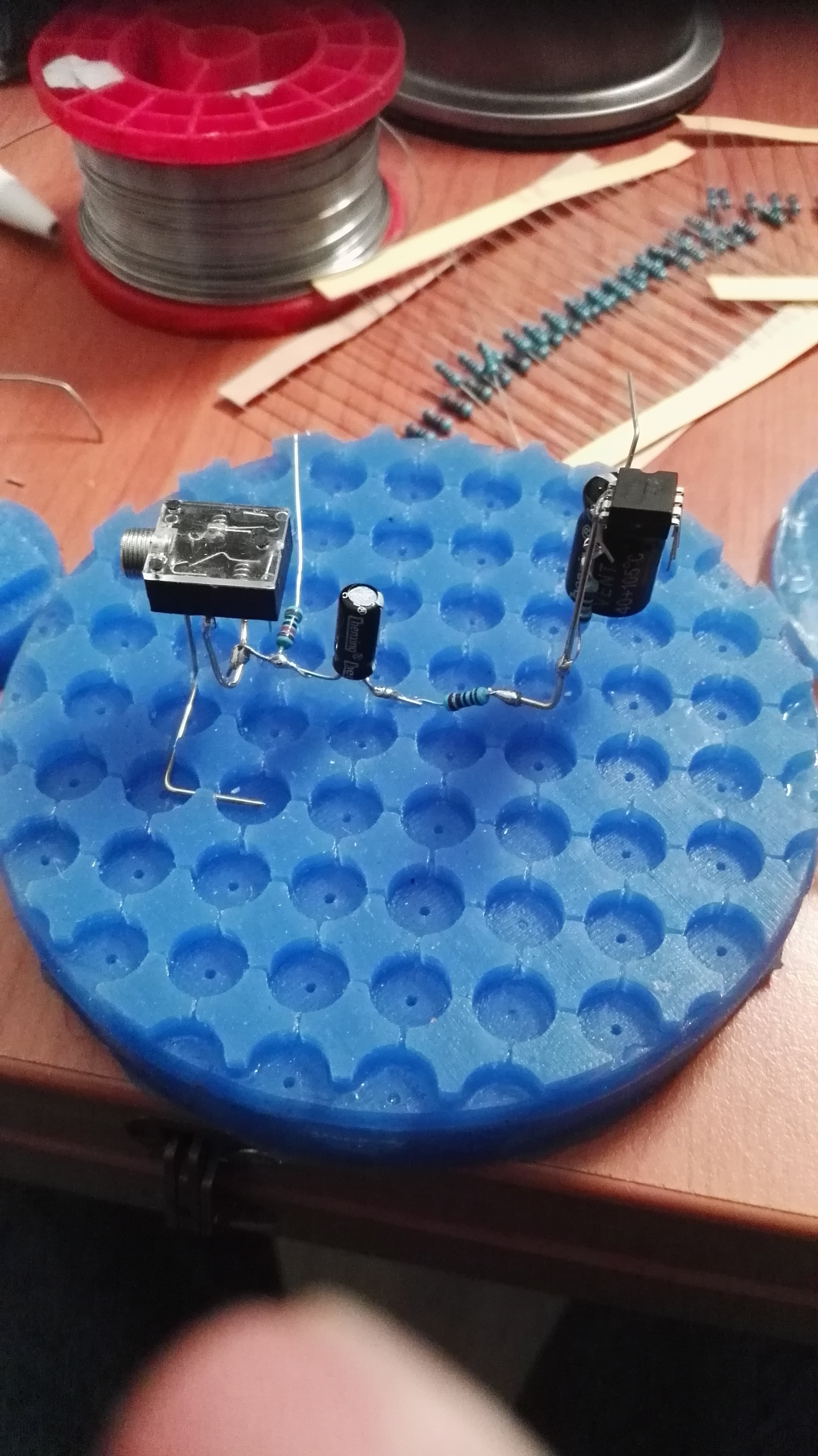

This was the prototype version, to see if the concept even works. Area is deliberately very small for rapid printing and less silicone use. The airflow works and keeps 1206 LEDs in place. This jigs is surprisingly useful already. Even for non circuit sculpture stuff like soldering wires to each other.

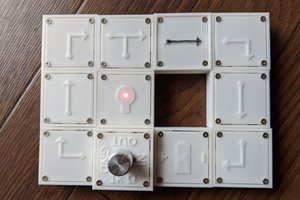

Mold consist of 2 parts. The cylinder containing the city topology and a plug to be inserted to claim the space later occupied by the air tube. Plug can be held in place by elastic band.

| V0 jig model | V0 mold and result. |

|  |

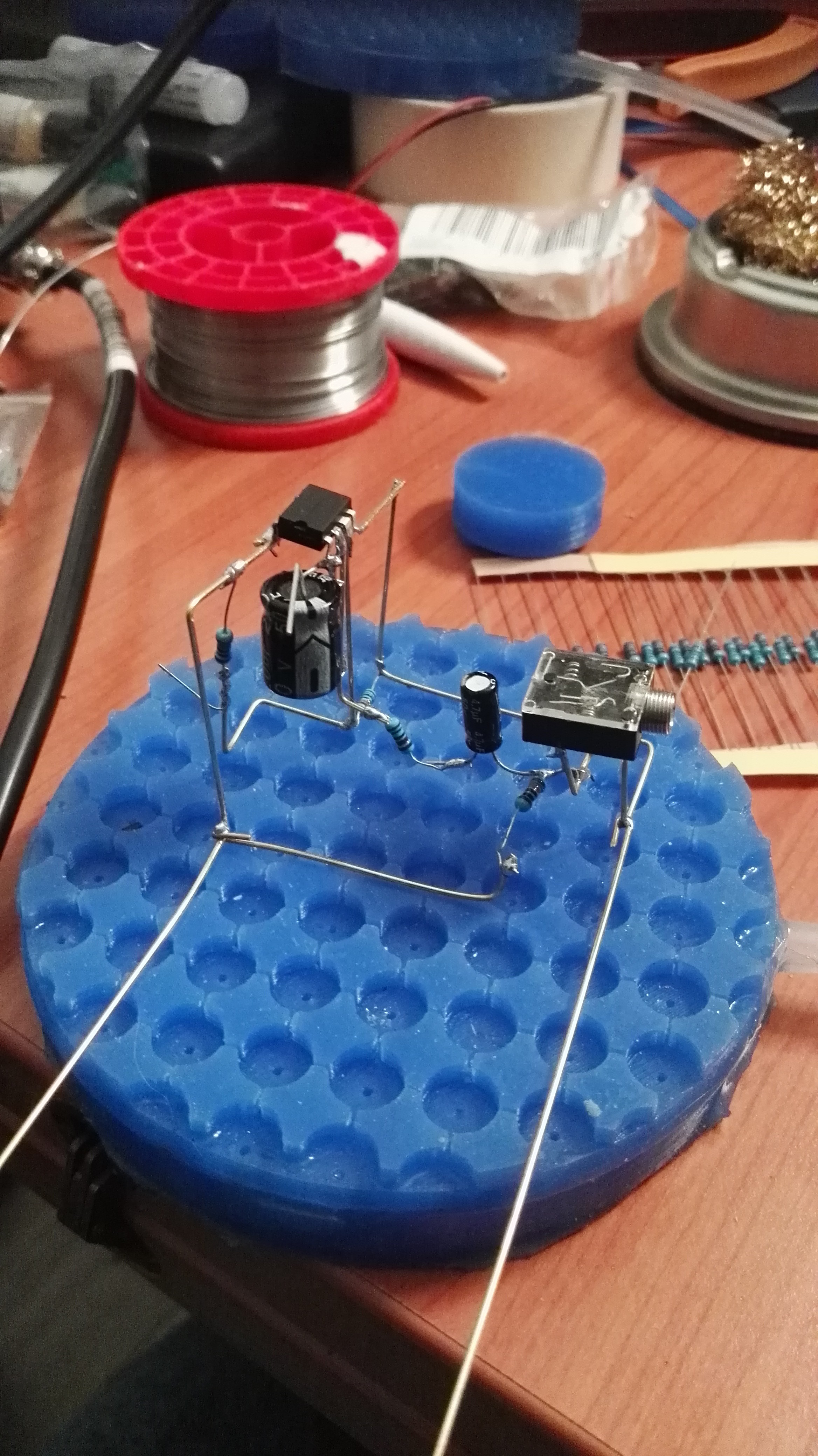

V1

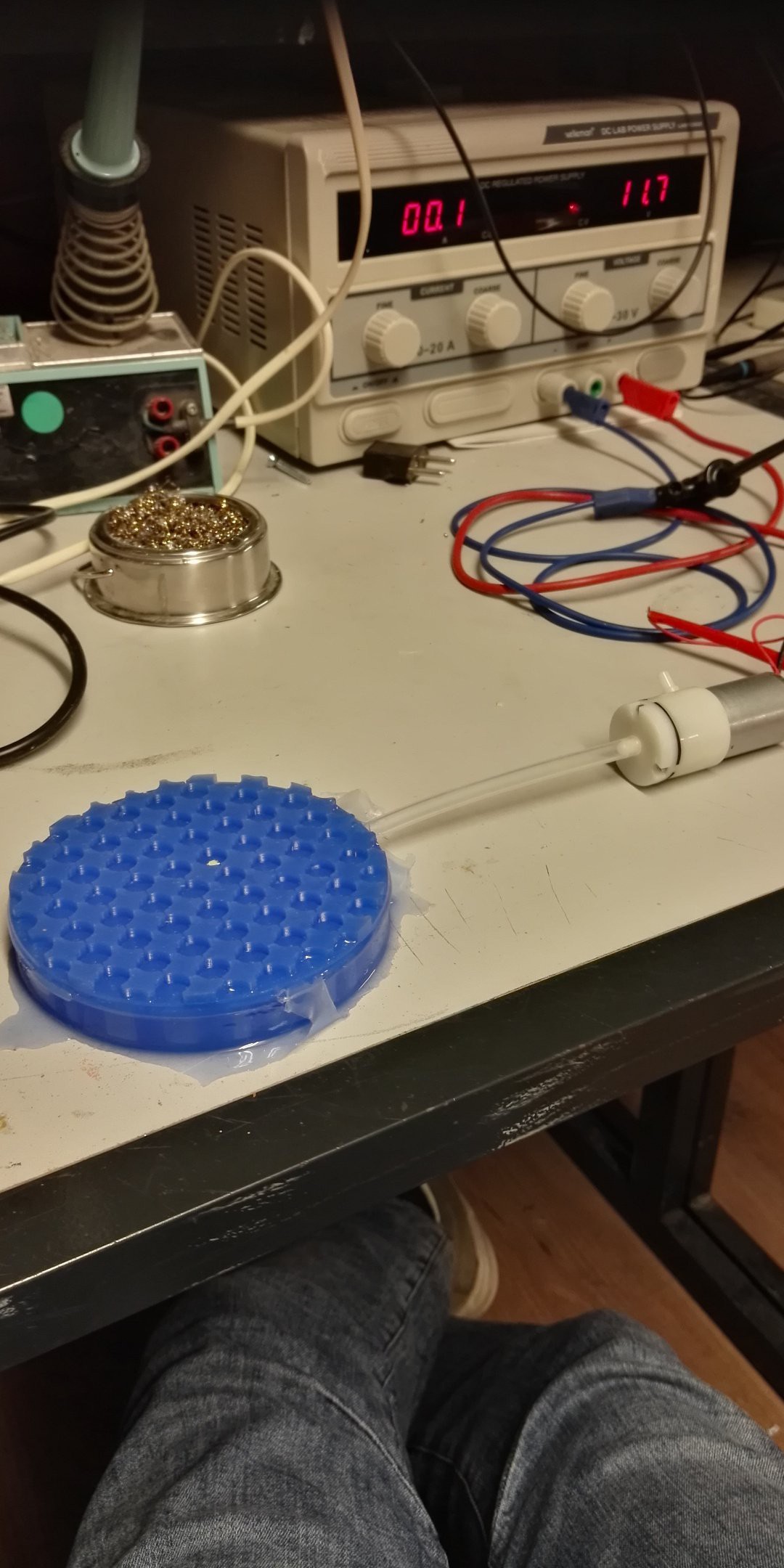

First full scale design. with lots of manholes for air intake. Unfortunately it could not create any suction since there where to many manholes. The bigger surface is great to keep longer rods in place.

Made with both shore 8 and shore 15 silicone. Both having a nice firmness. Though people seem...

Read more » Inne

Inne

Alain d'Espaignet

Alain d'Espaignet

Daniel Domínguez

Daniel Domínguez

Alex Rich

Alex Rich

You might ask yourself, as I did: "How about Silly Putty? Isn't that a silicone-based thing that might hold up to soldering temperatures long enough to be useful for tacking things in place?"

The answer seems to be "No", at least WRT the sample I tried (it was actually a "Chameleon" "Thinking Putty" that I happened to have around, so it might not have been the best choice...) :-(