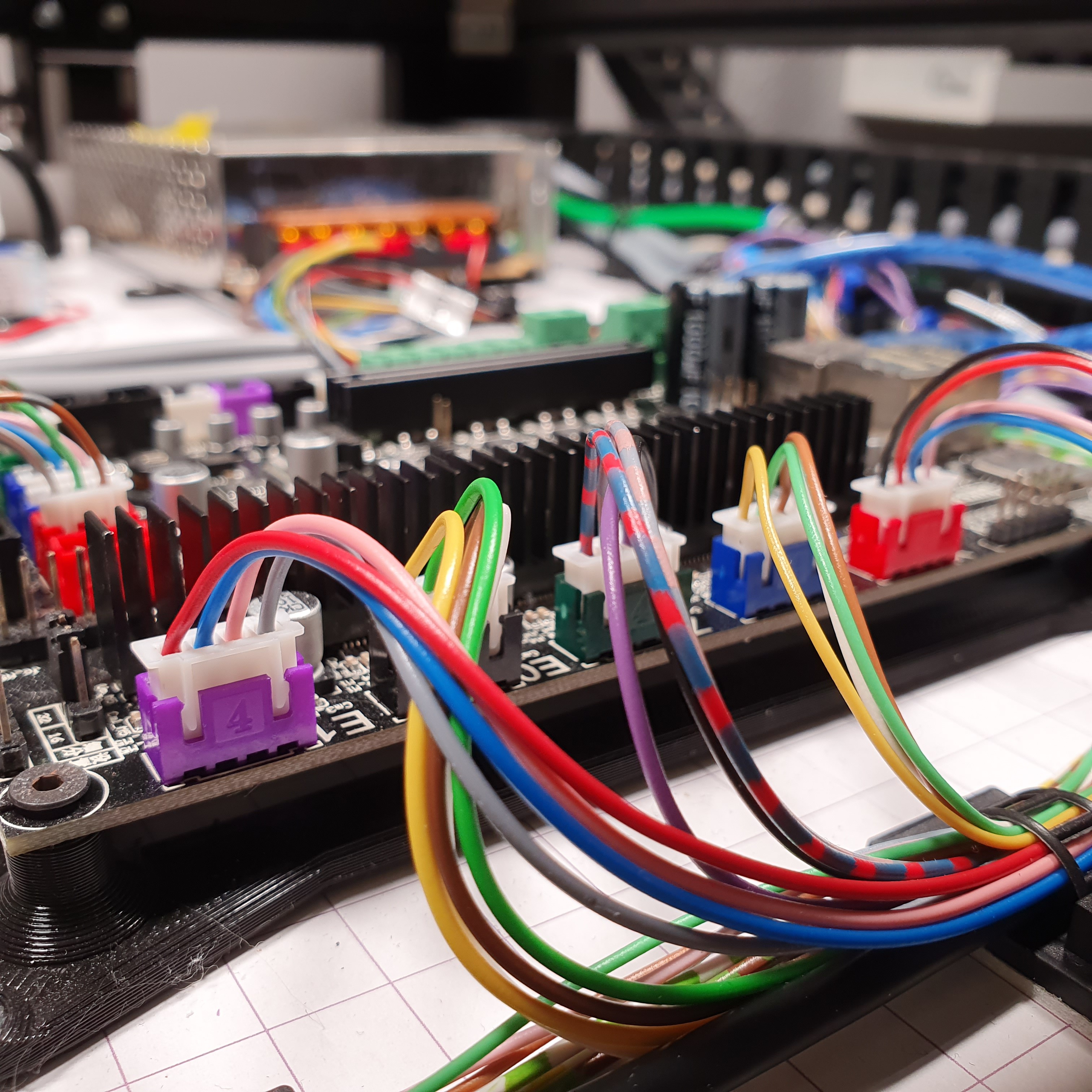

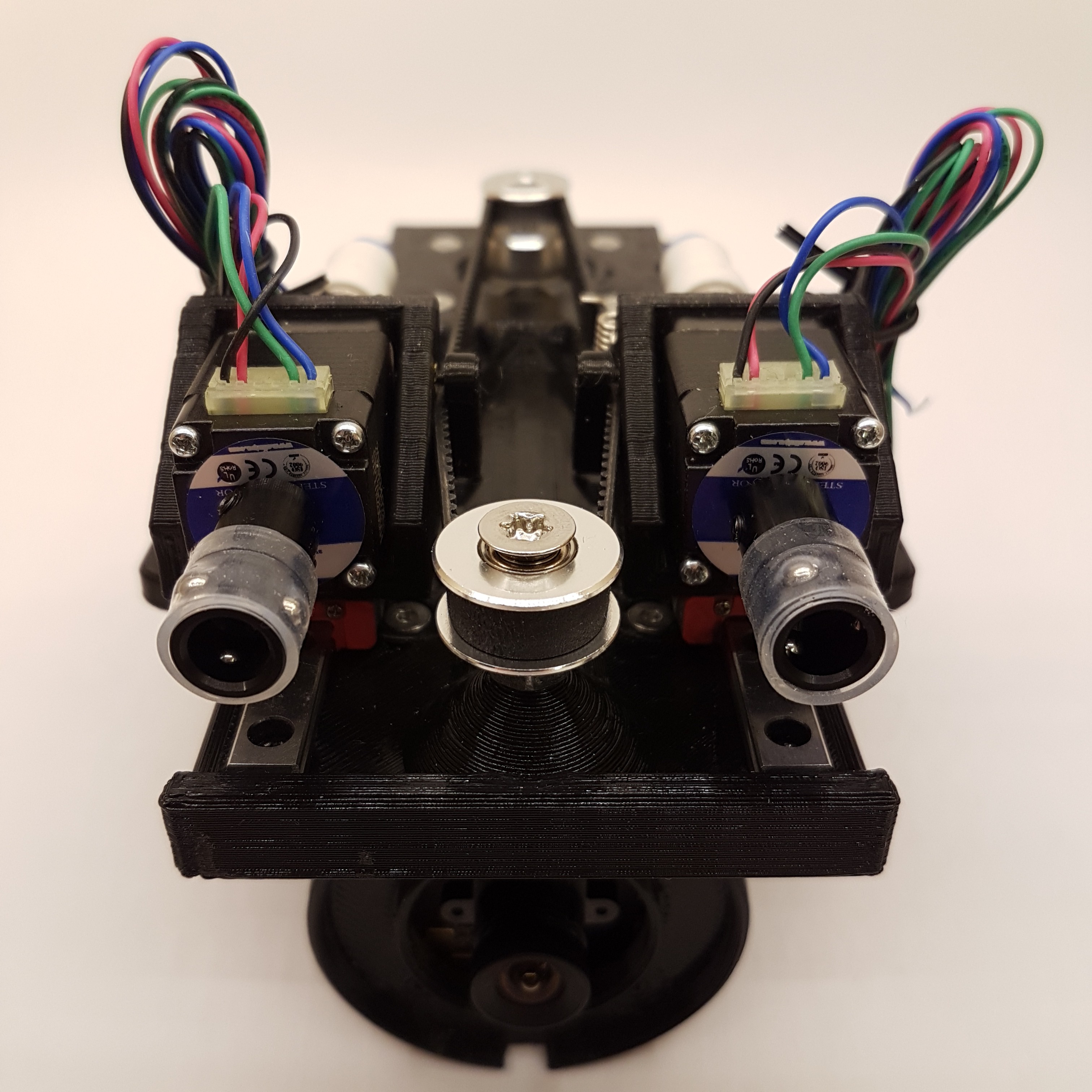

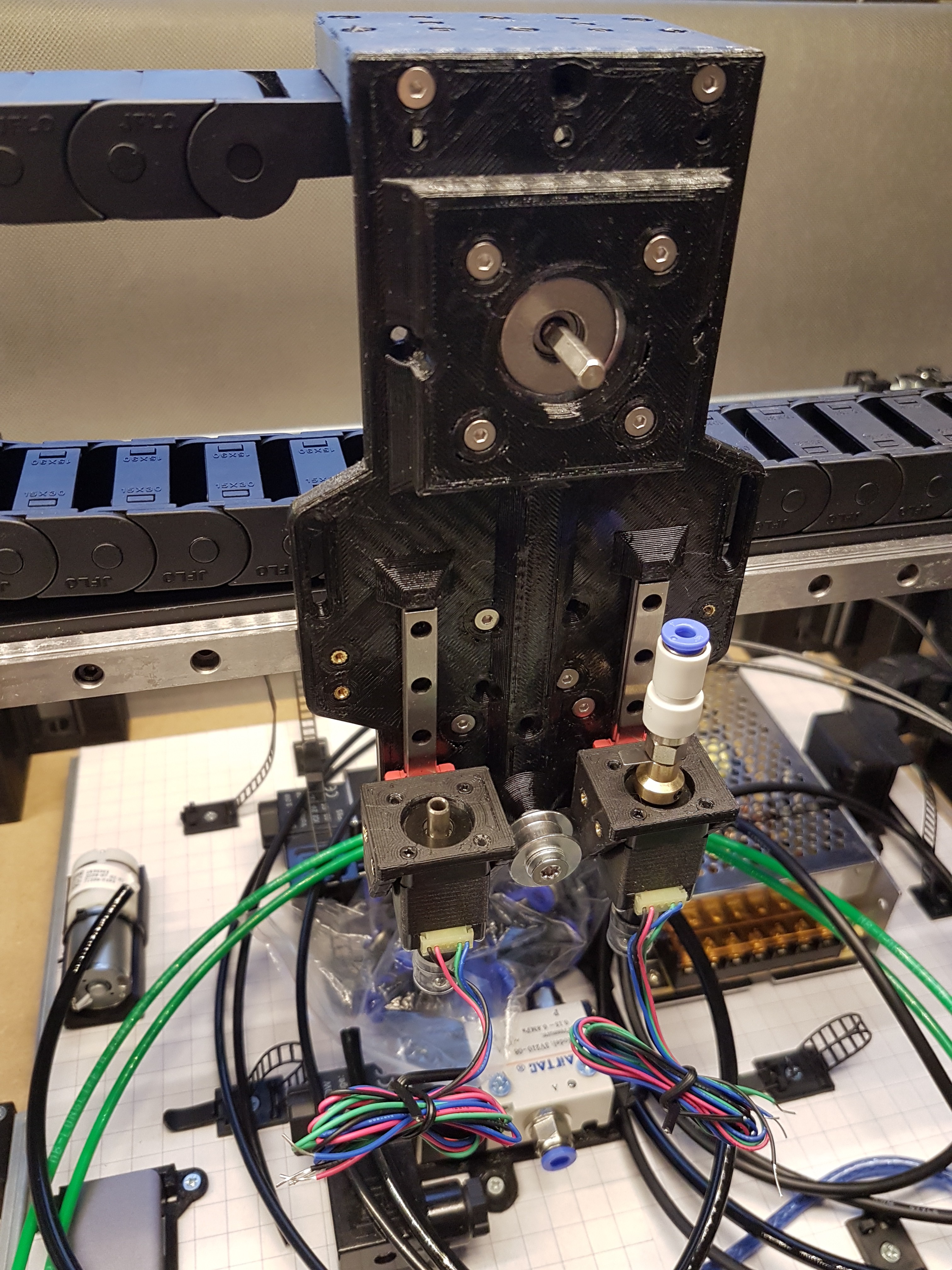

First overview of the installed components.

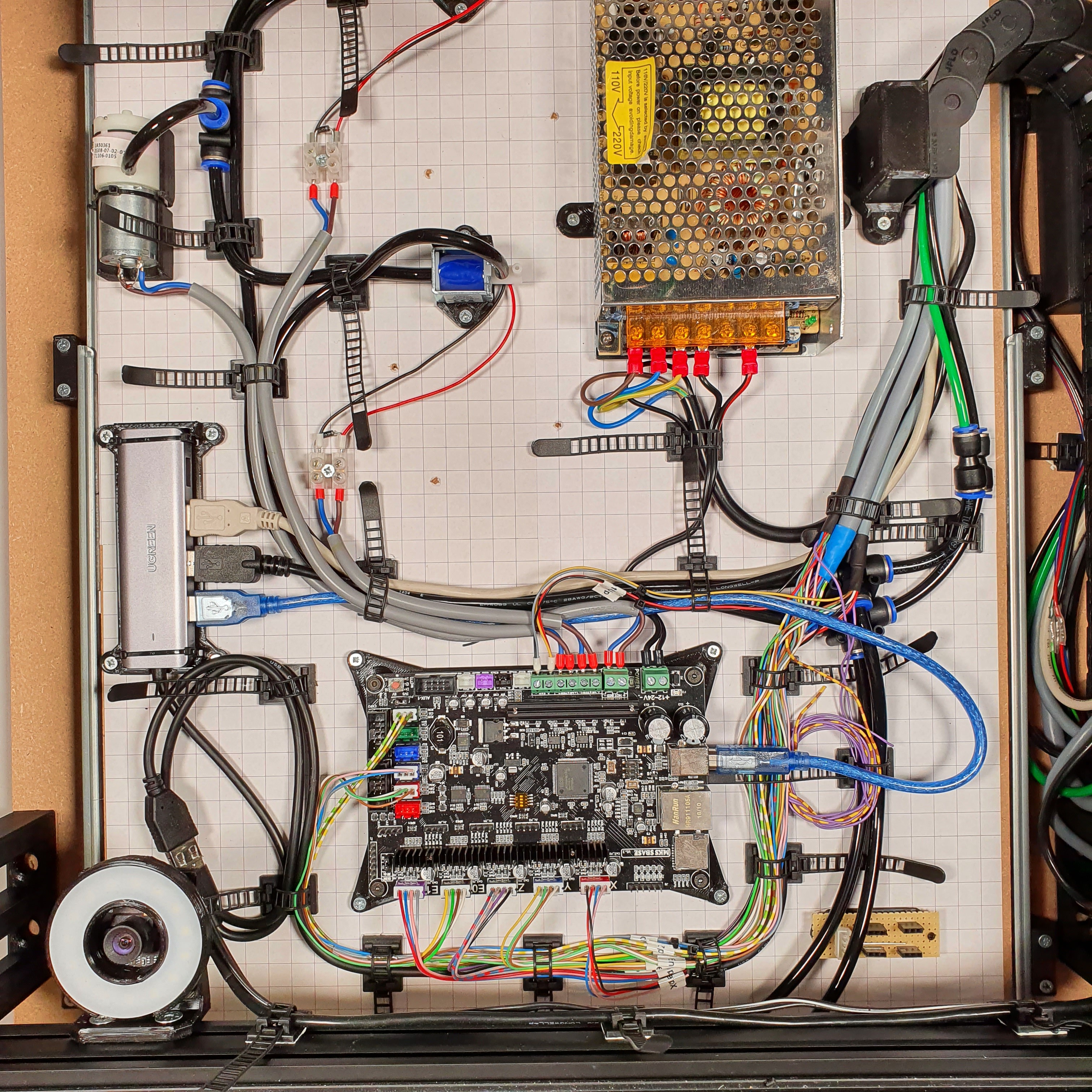

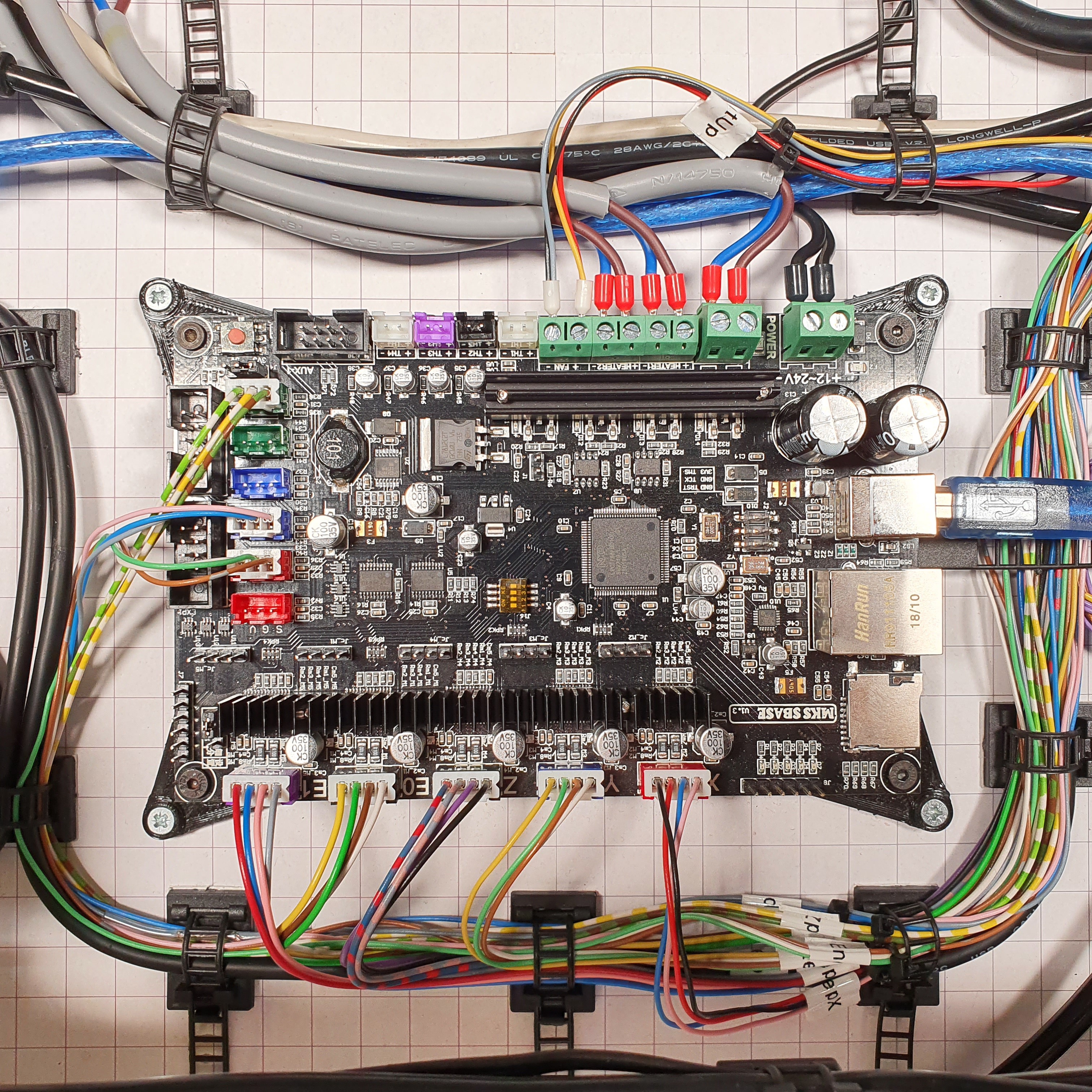

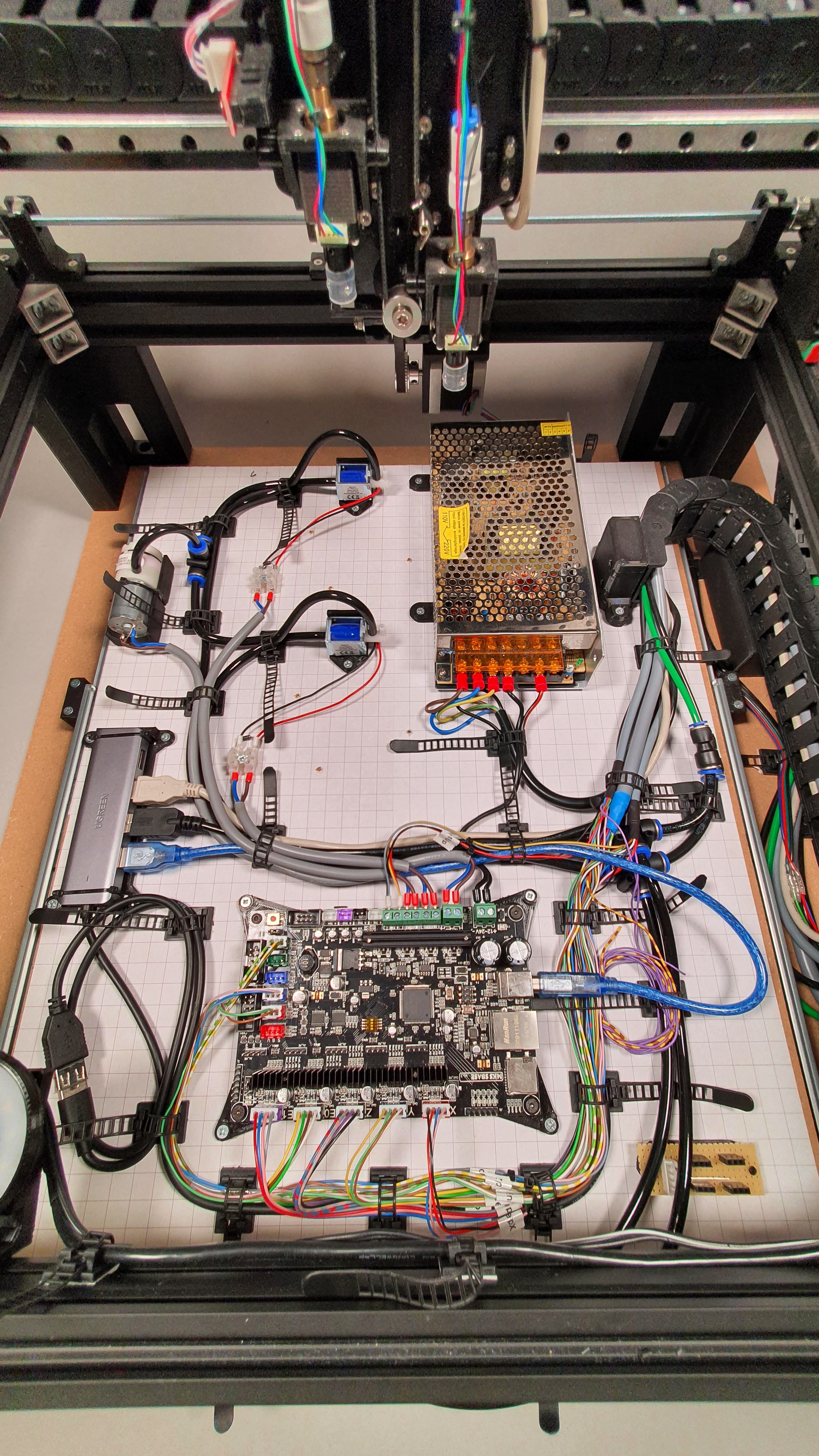

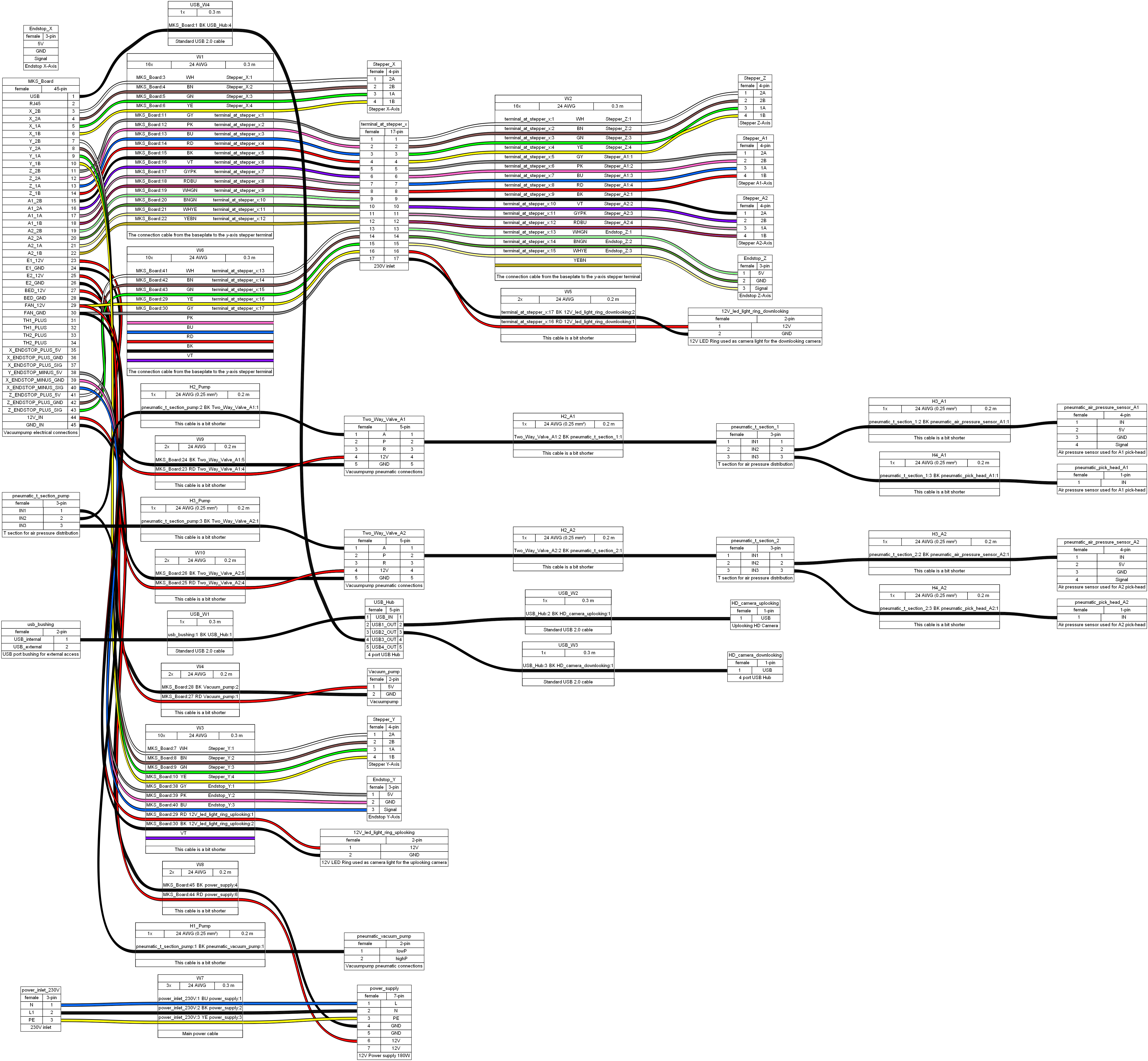

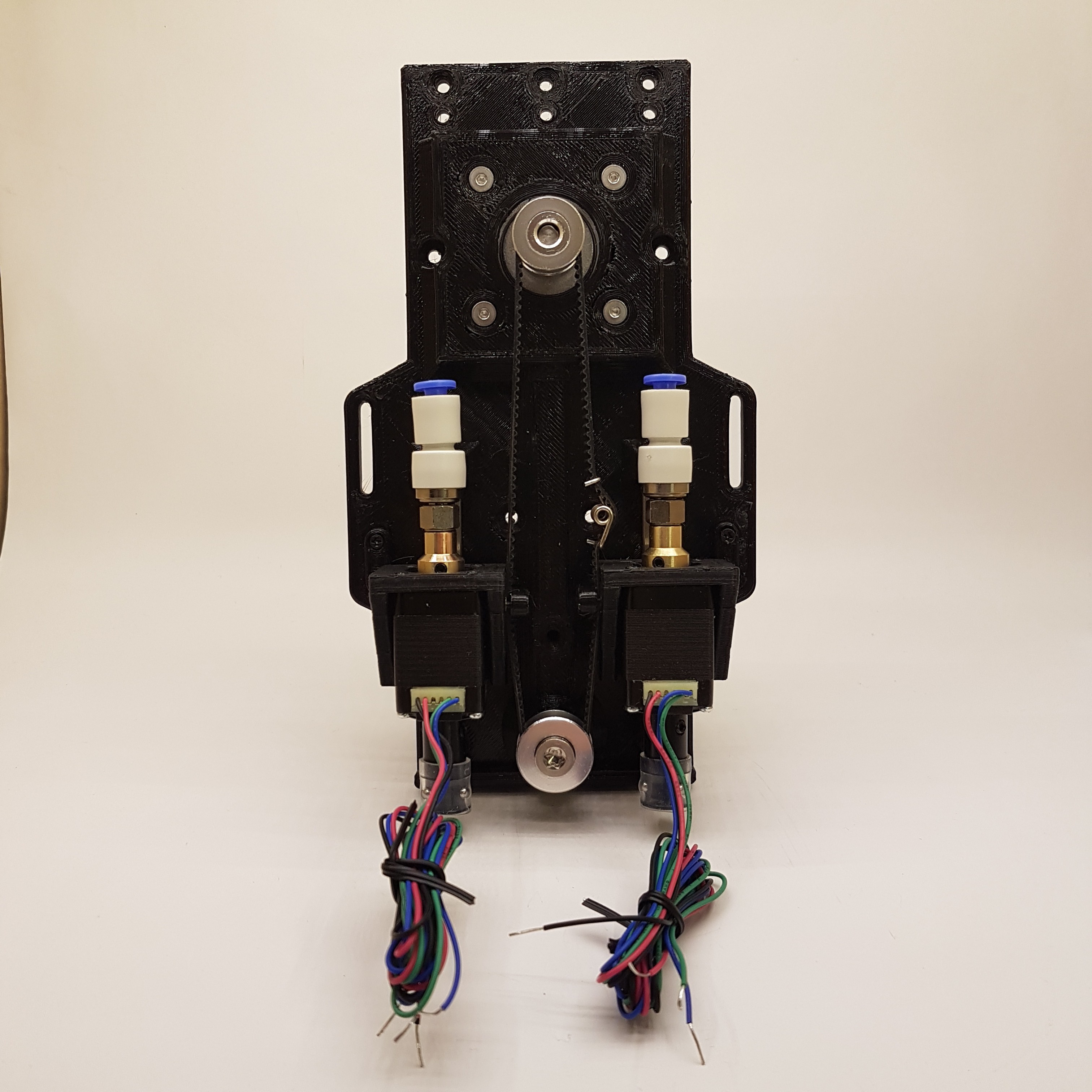

The main components are installed on a slidabble baseplate. This way It's possible to access the components under the main "pick and place"-plate.

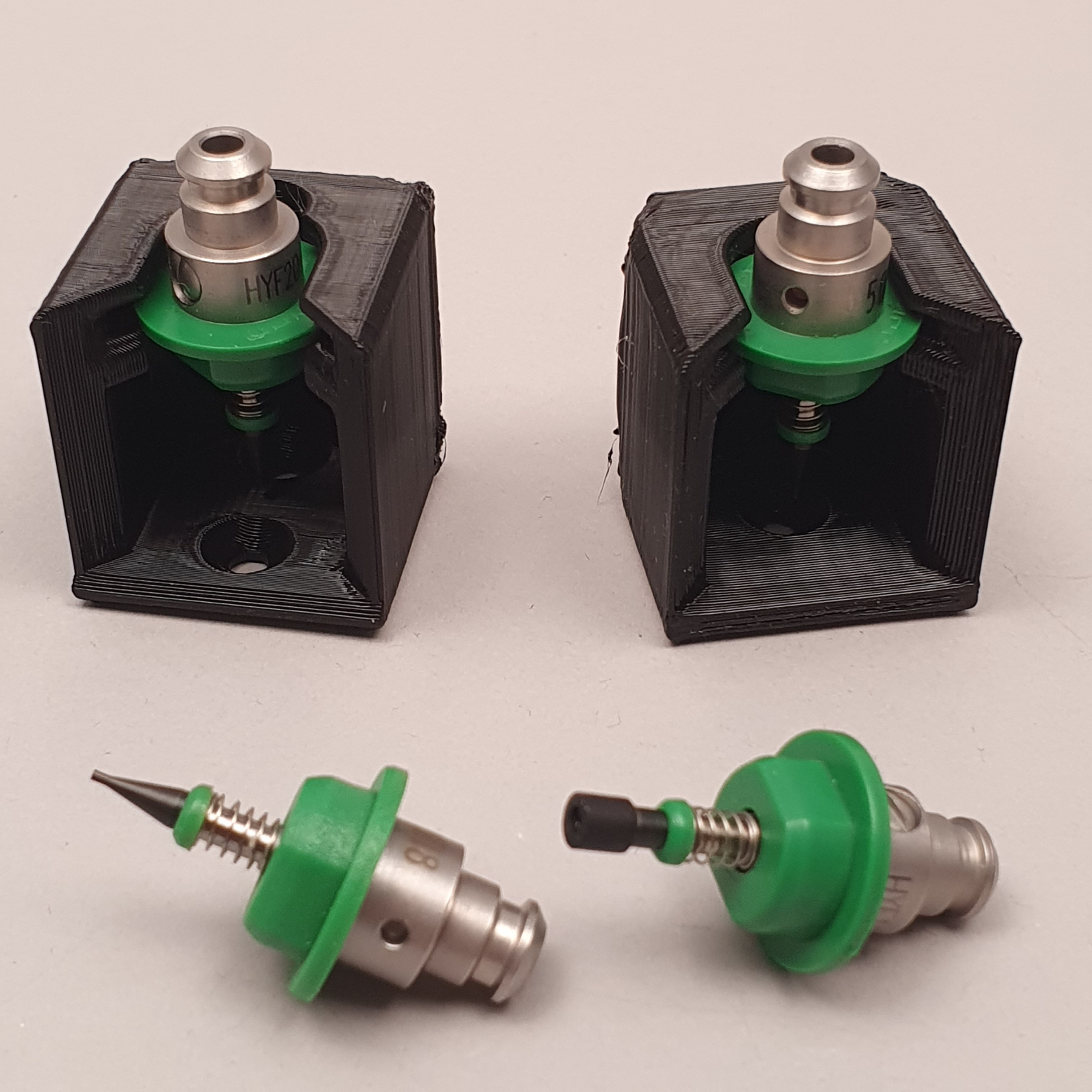

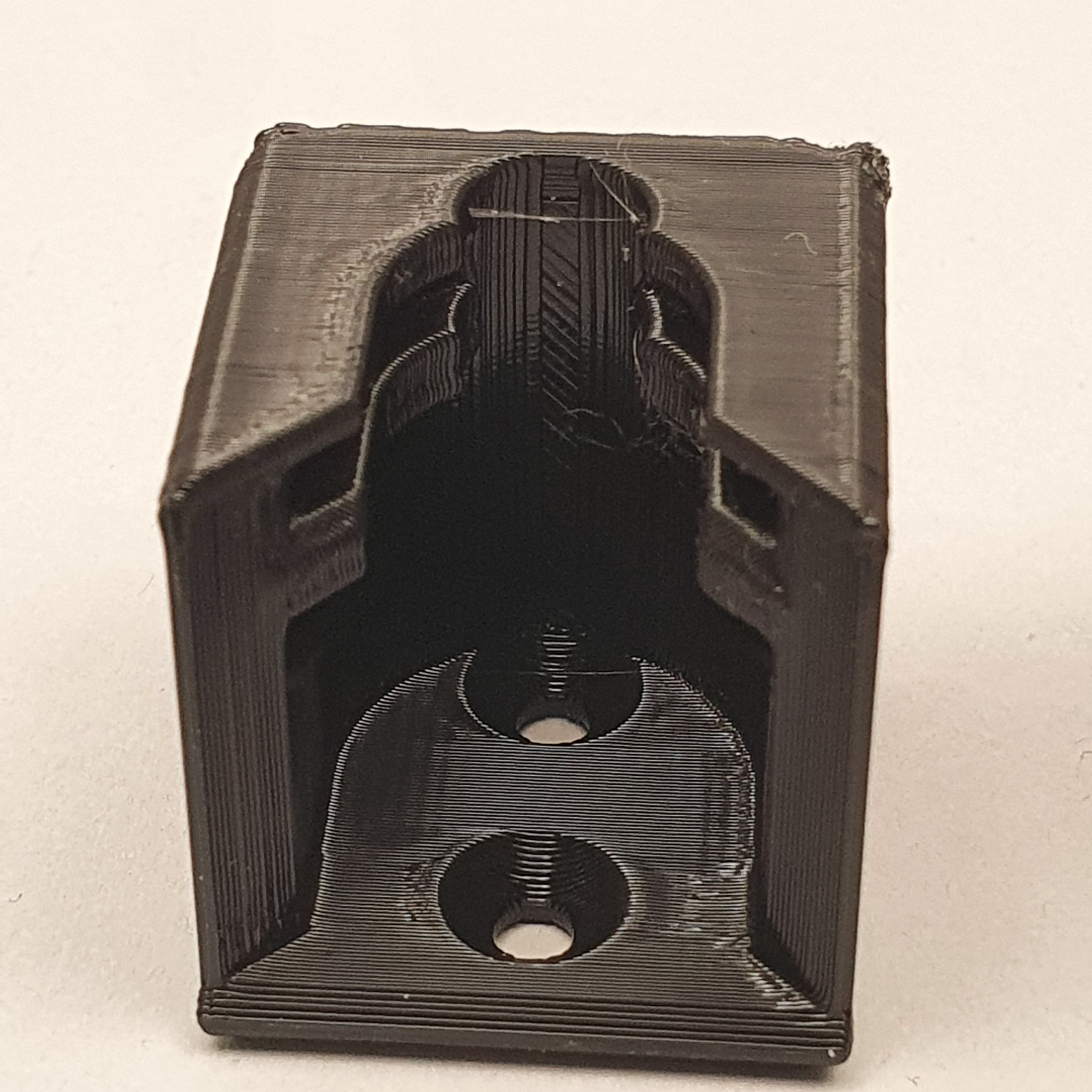

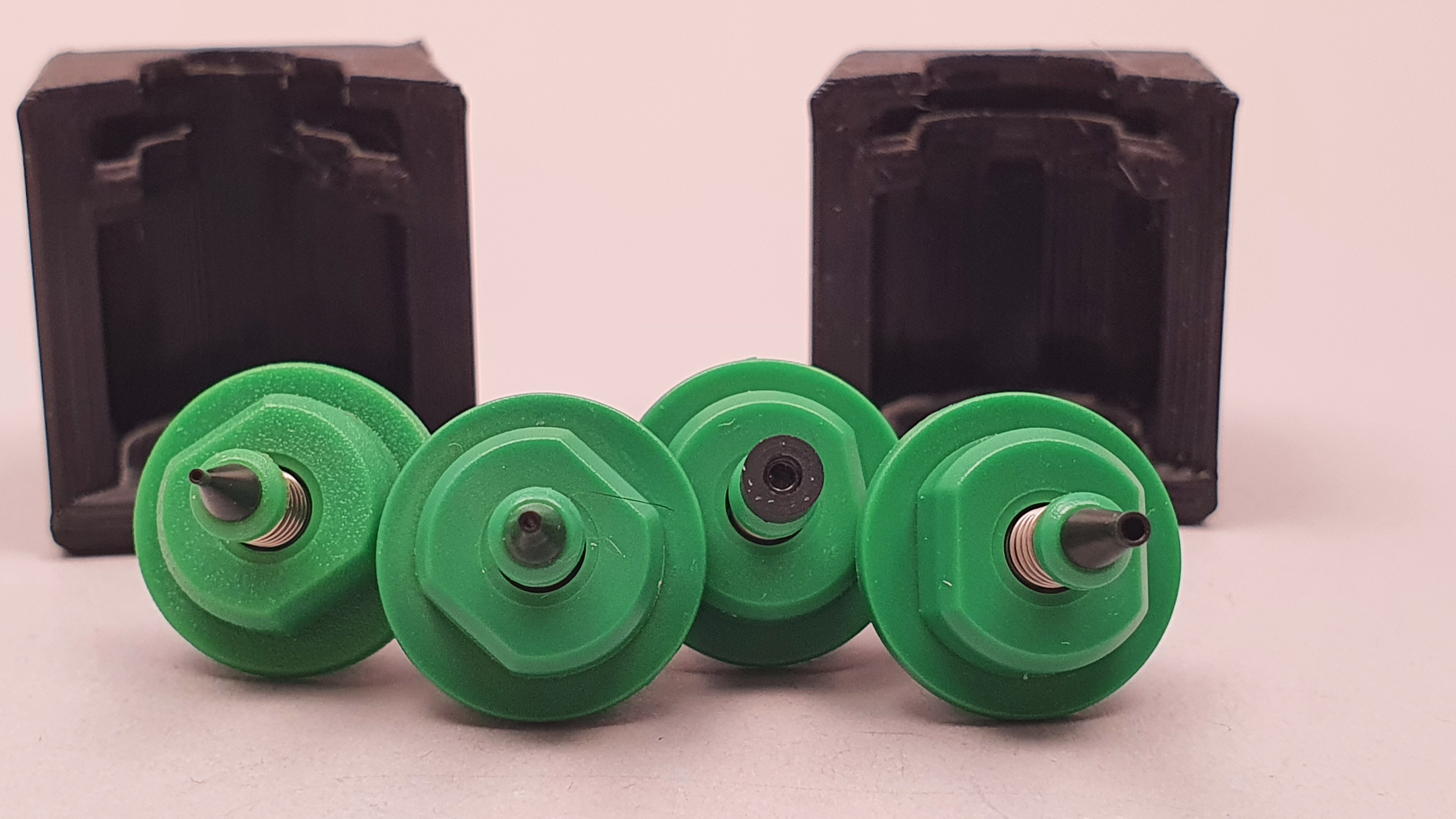

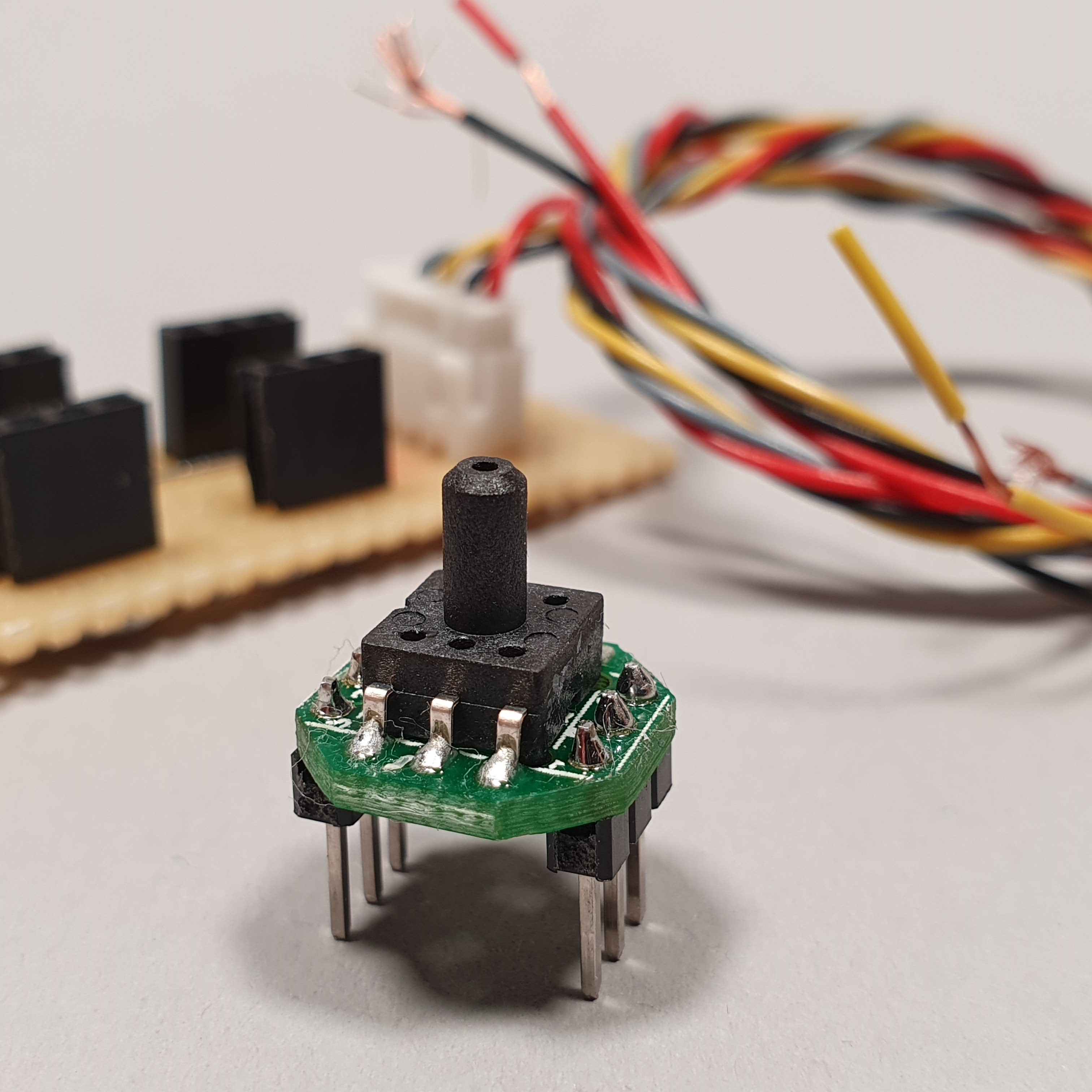

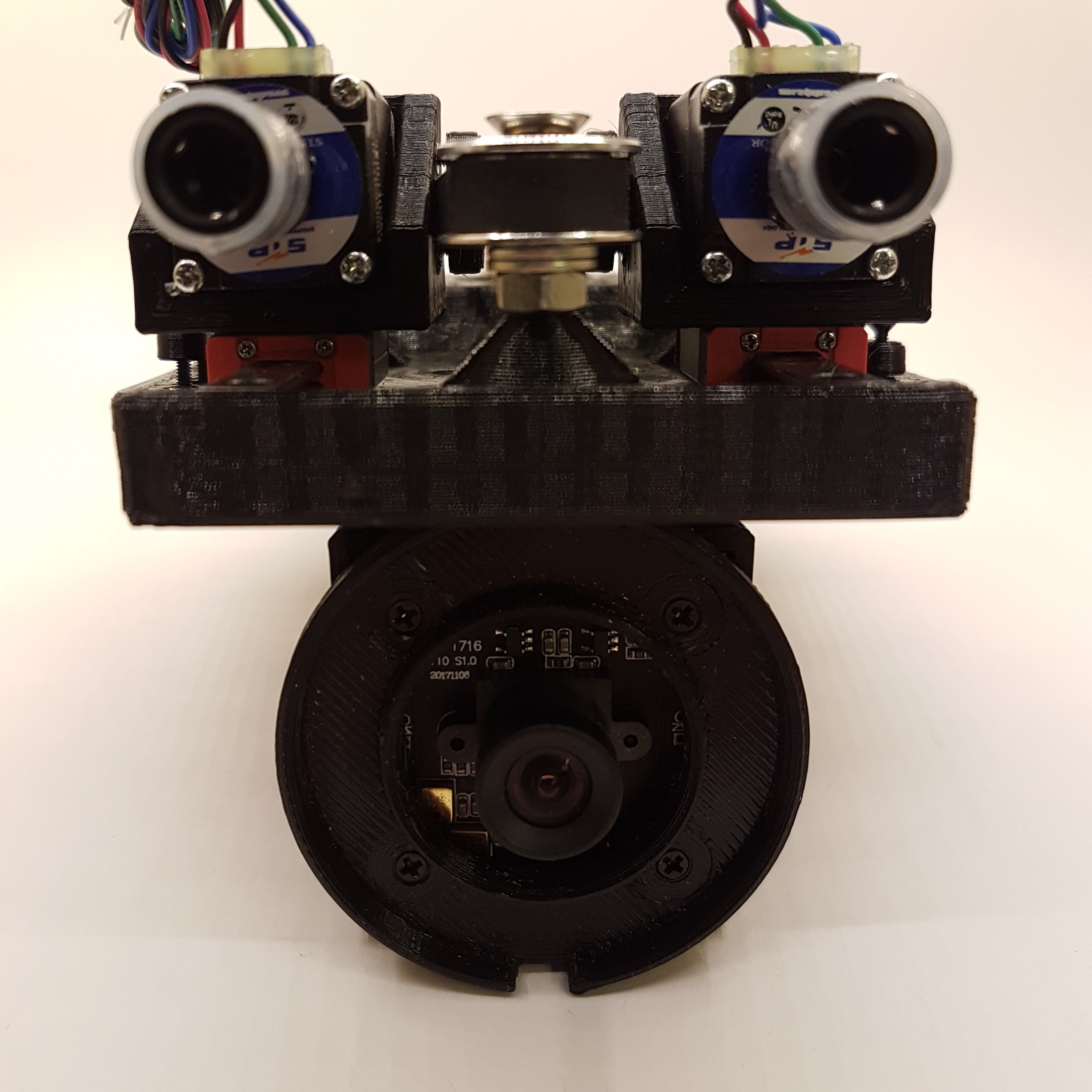

Assembly of the NEMA 8 stepper that is used for rotating the picked components.

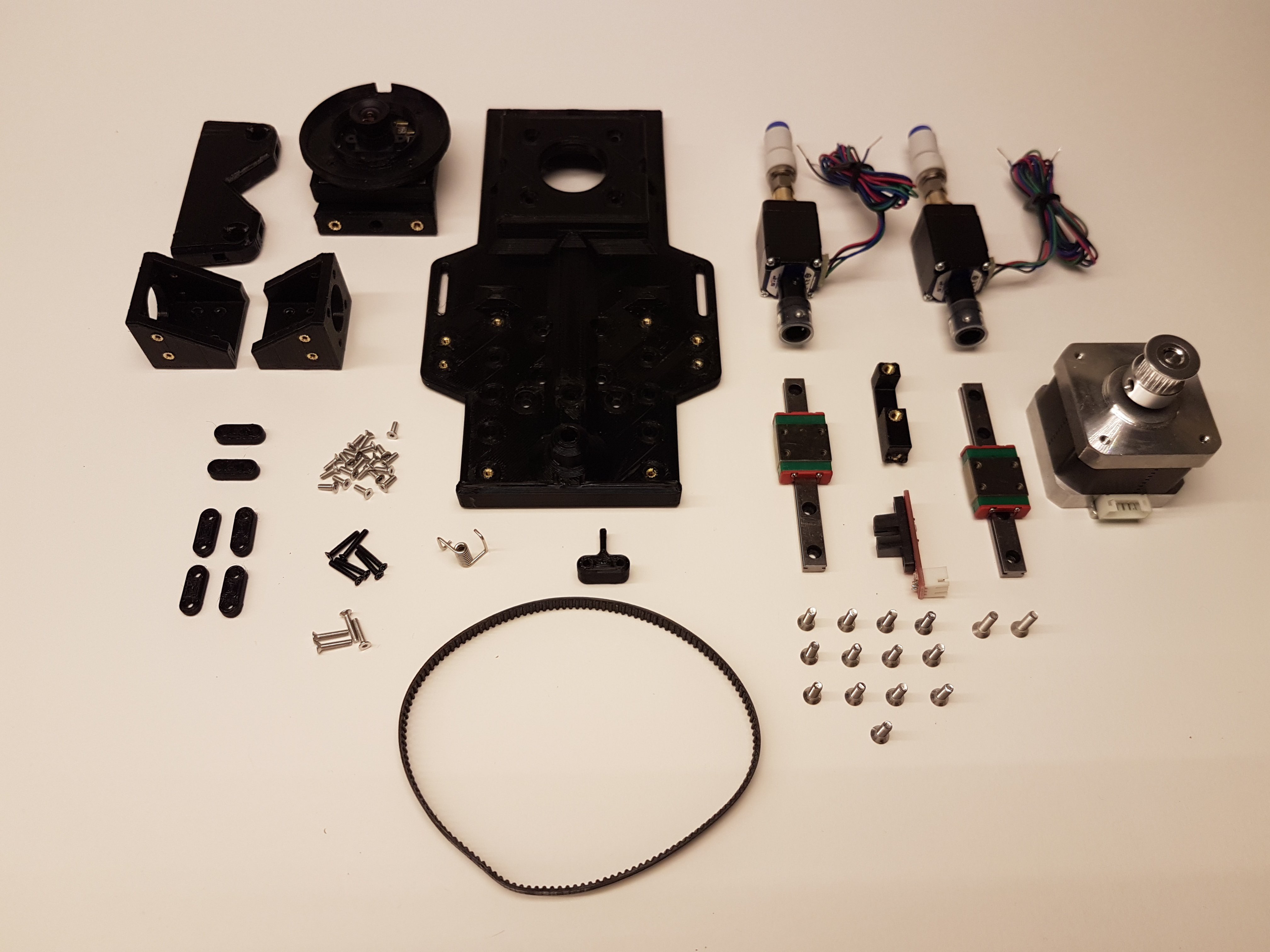

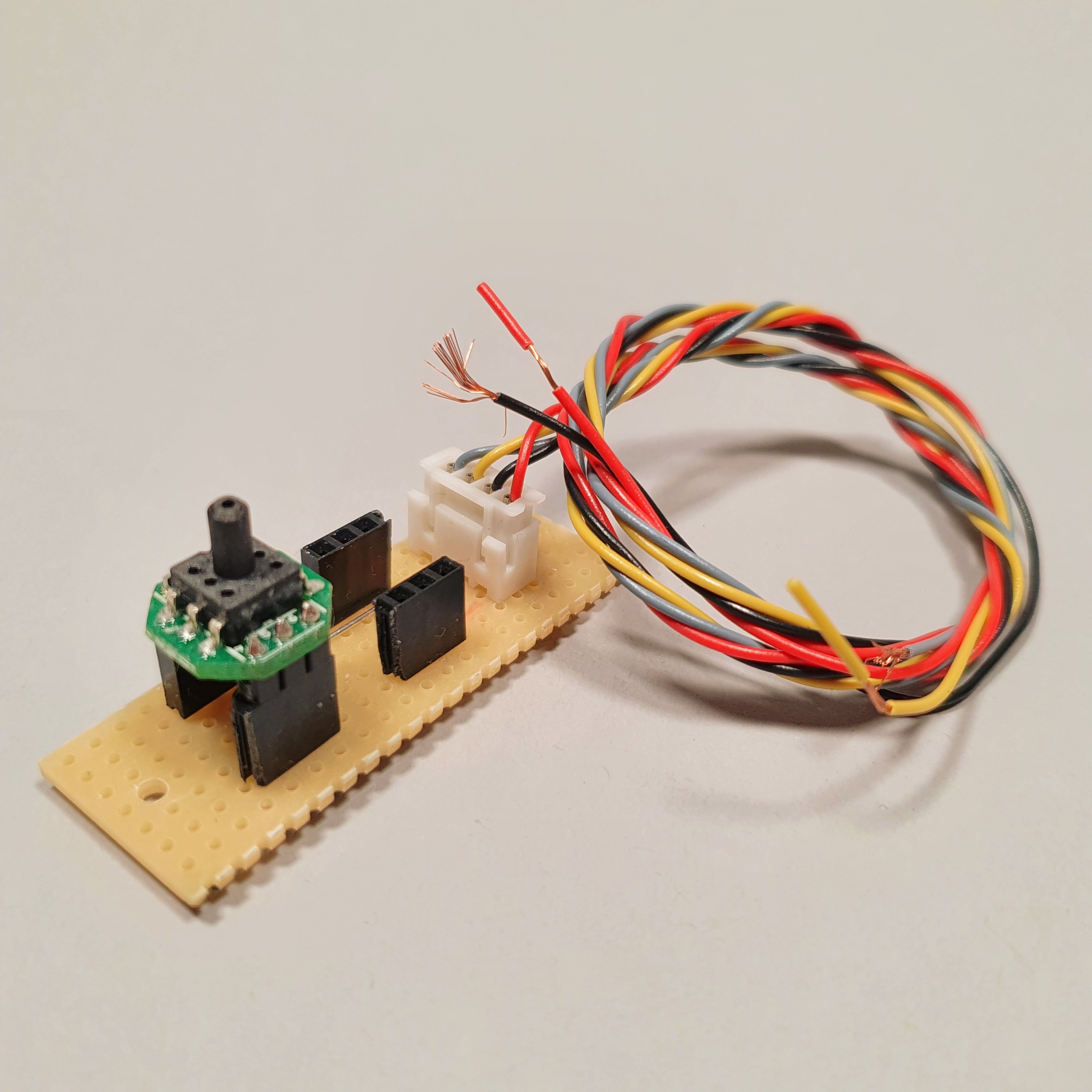

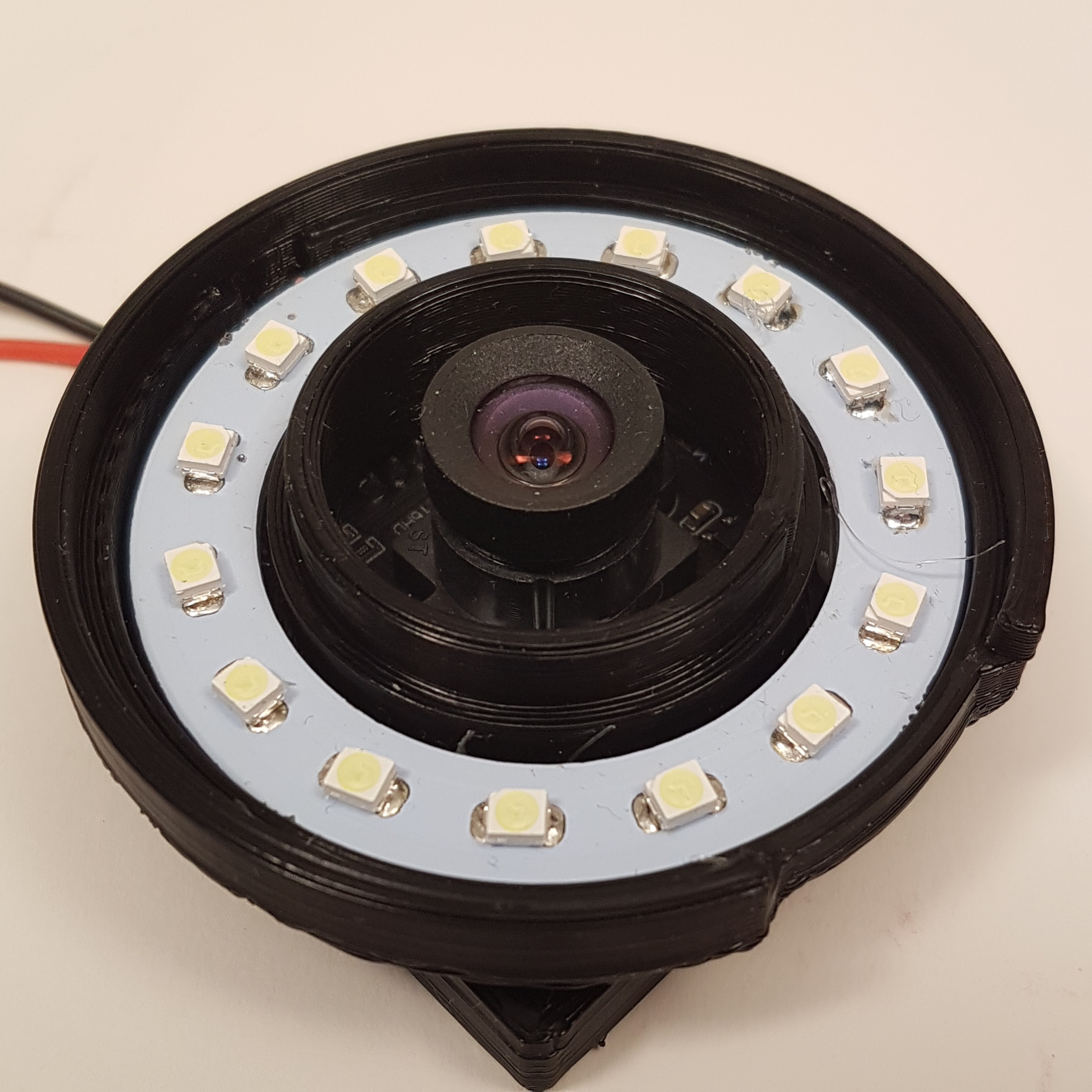

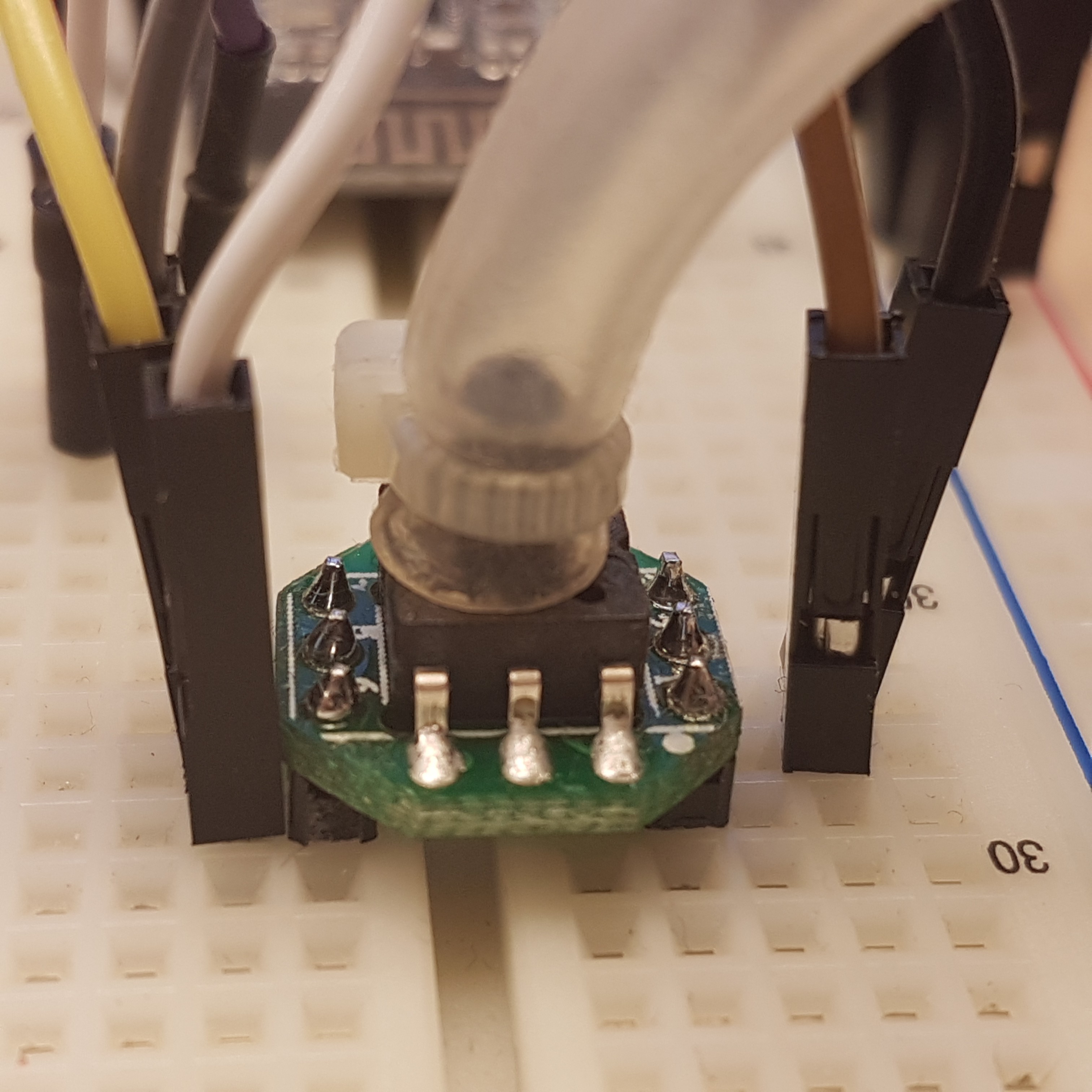

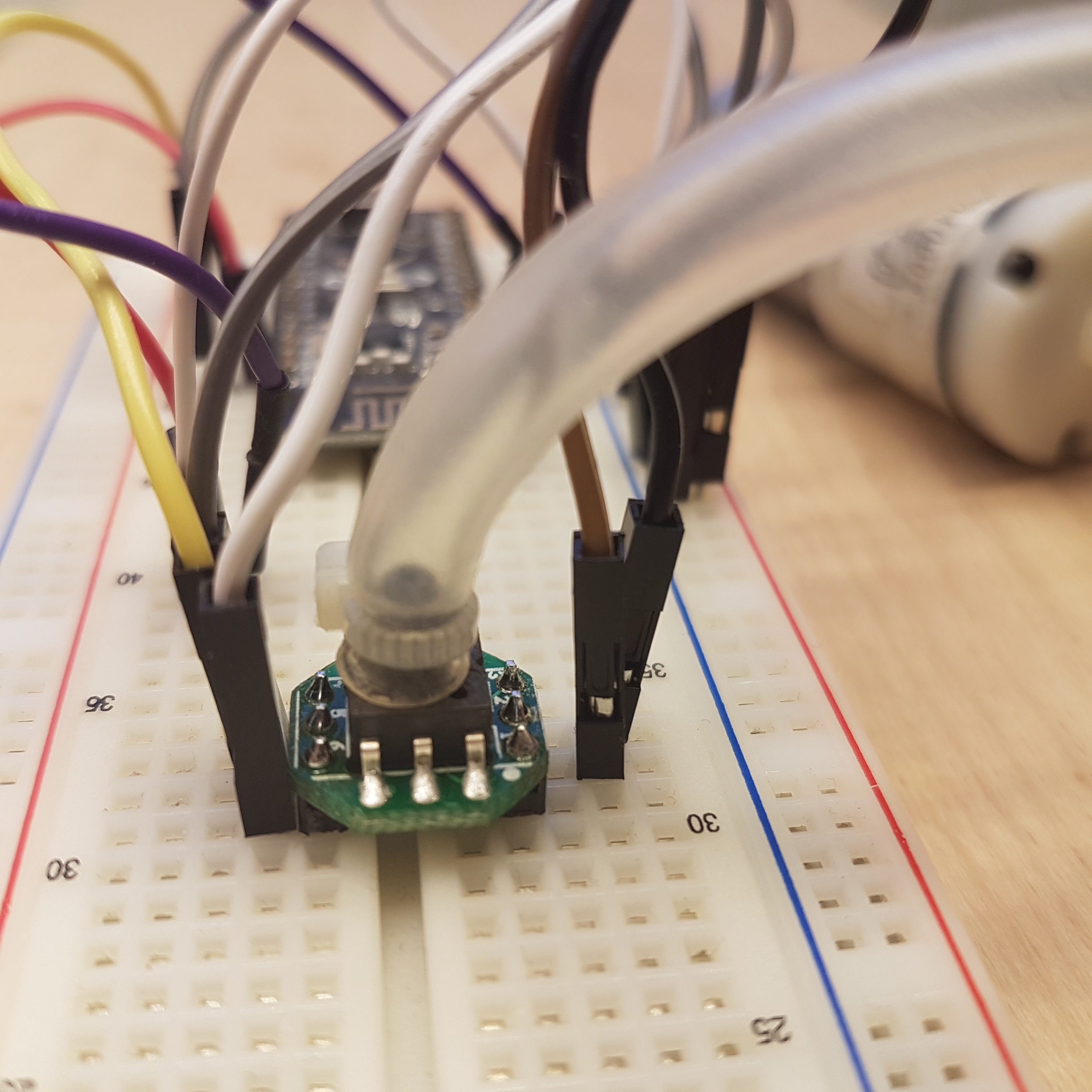

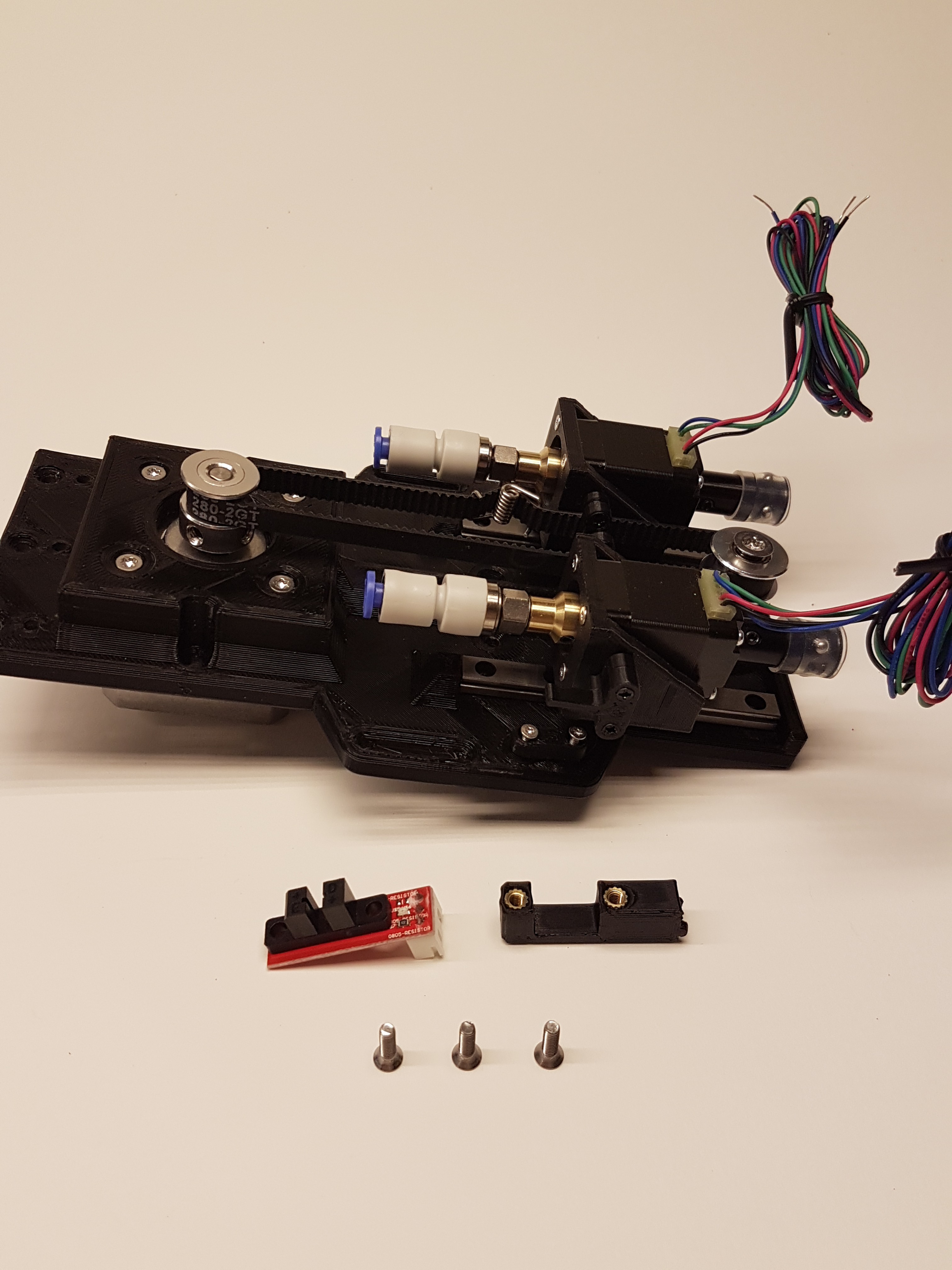

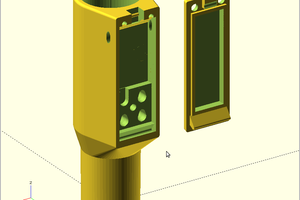

Pick head components "knolling":

Most of the mechanical parts finished (15.01.2021):

Support:

If you want to support me, you can do so by a like this project page, on Instagram or by donating a coffee. :)

Fabian

Fabian

Daren Schwenke

Daren Schwenke

xpDIY

xpDIY

Les Hall

Les Hall

Mika Heikkinen

Mika Heikkinen