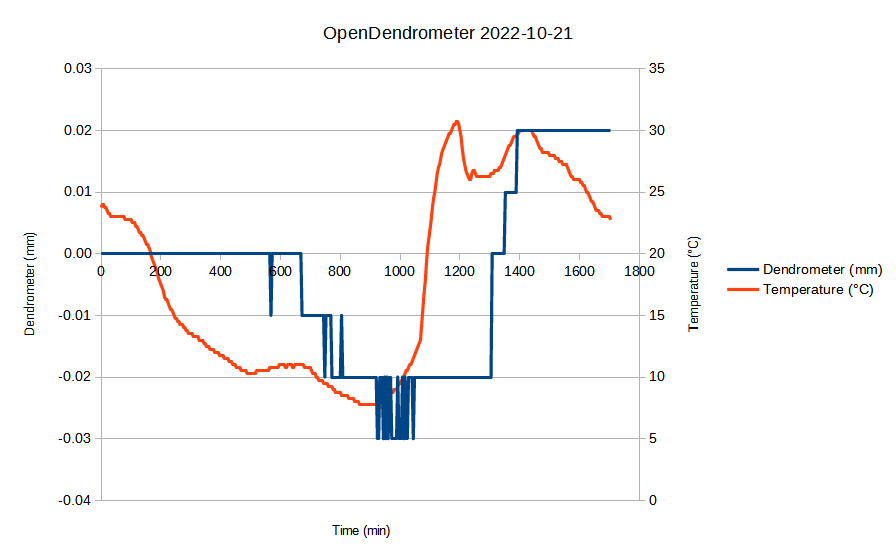

A dendrometer is an instrument used to measure diameter changes of trees and fruit. Small micrometer changes in diameter occur in trees and fruit throughout the day as part of healthy water transport processes. Comparisons of these daily changes in diameter can help predict the onset and occurrence of water stress. In addition, diameter measurements collected over weeks and months can reveal the rate and magnitude of plant growth.

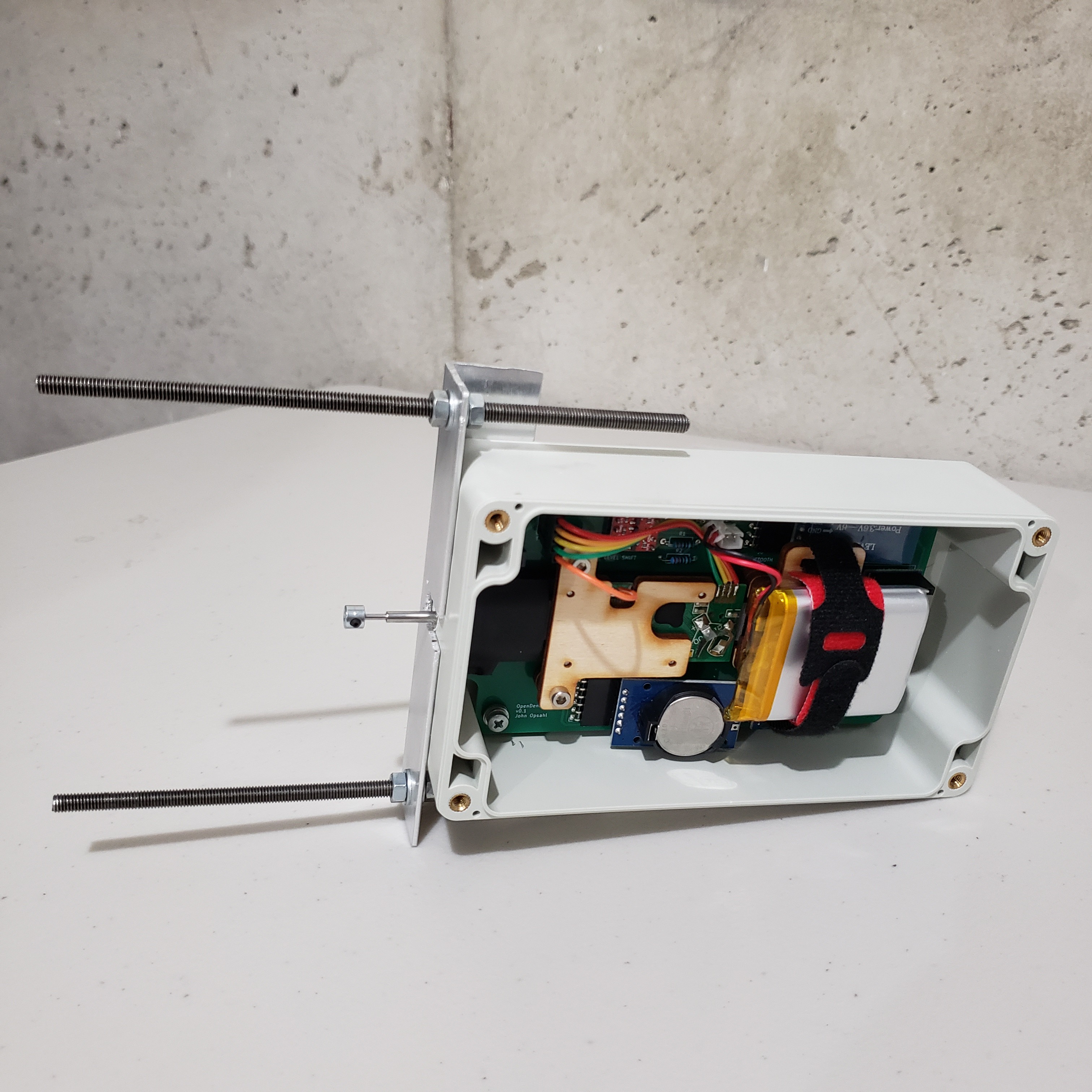

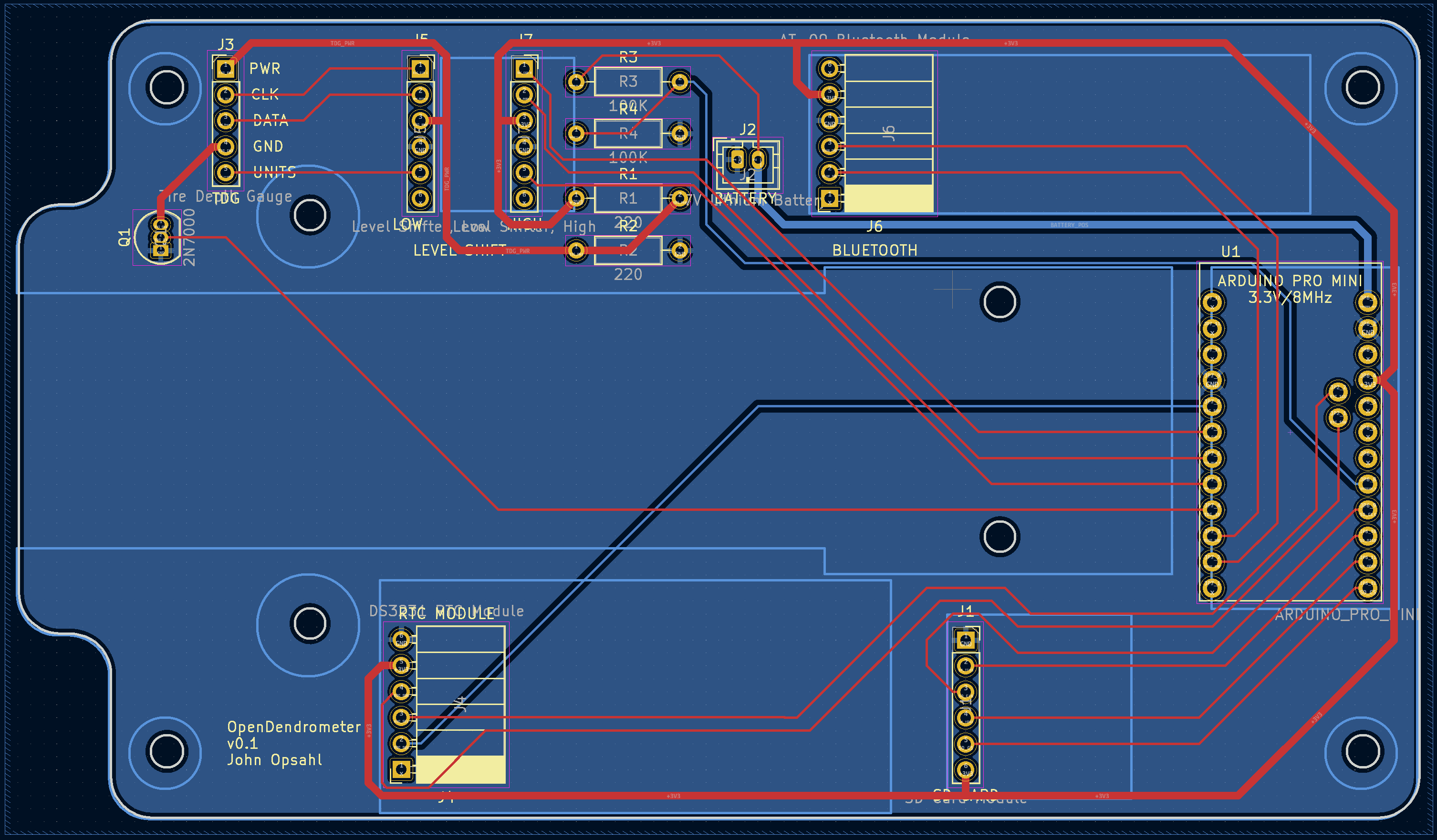

The OpenDendrometer is a low-cost digital dendrometer with wireless data transfer capabilities. In simplest terms, it is device that measures, logs, and wirelessly reports changes in linear displacement. It uses commonly available electronics components and fabrication techniques to ensure that others can easily build their own OpenDendrometer. All design files and information are shared freely.

John Opsahl

John Opsahl

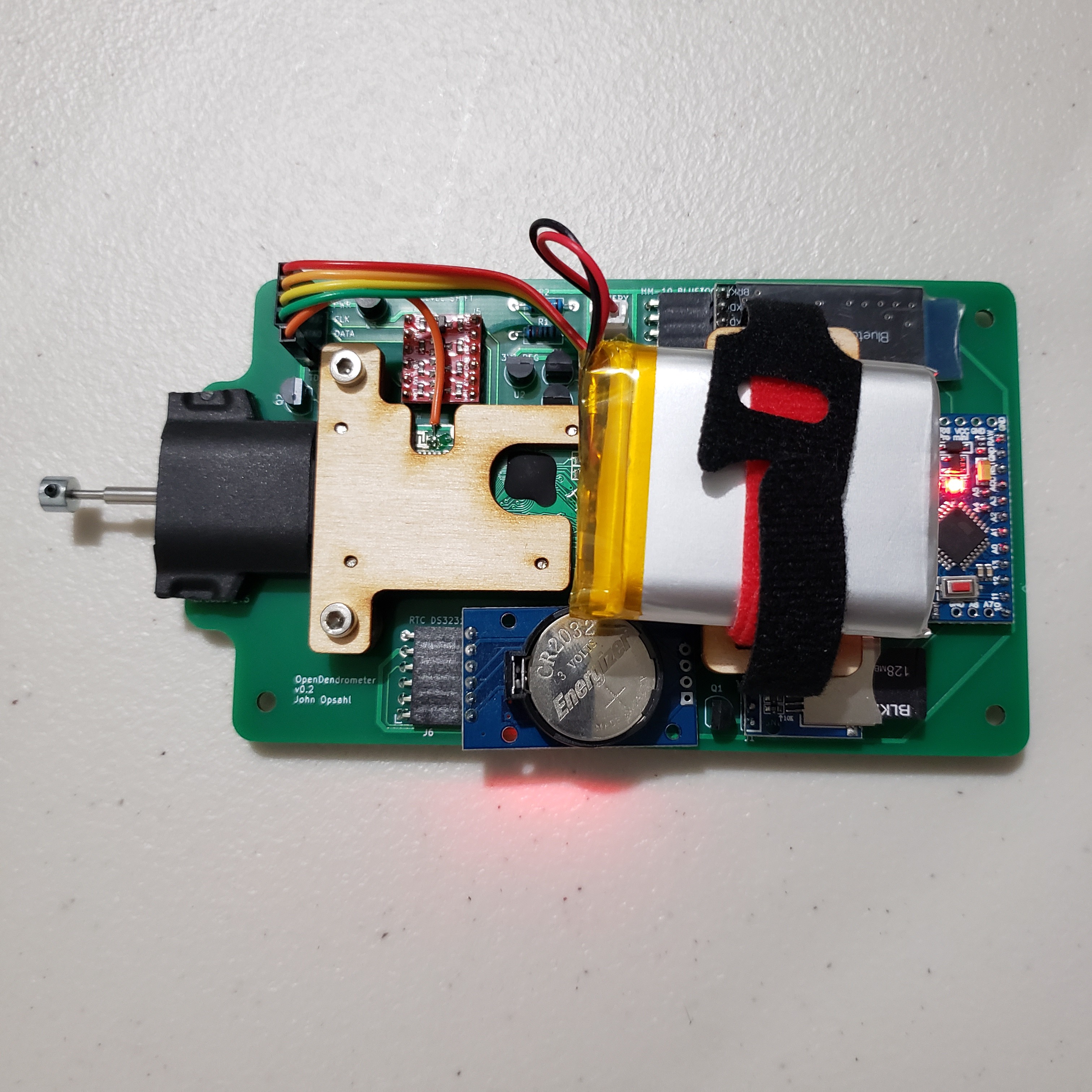

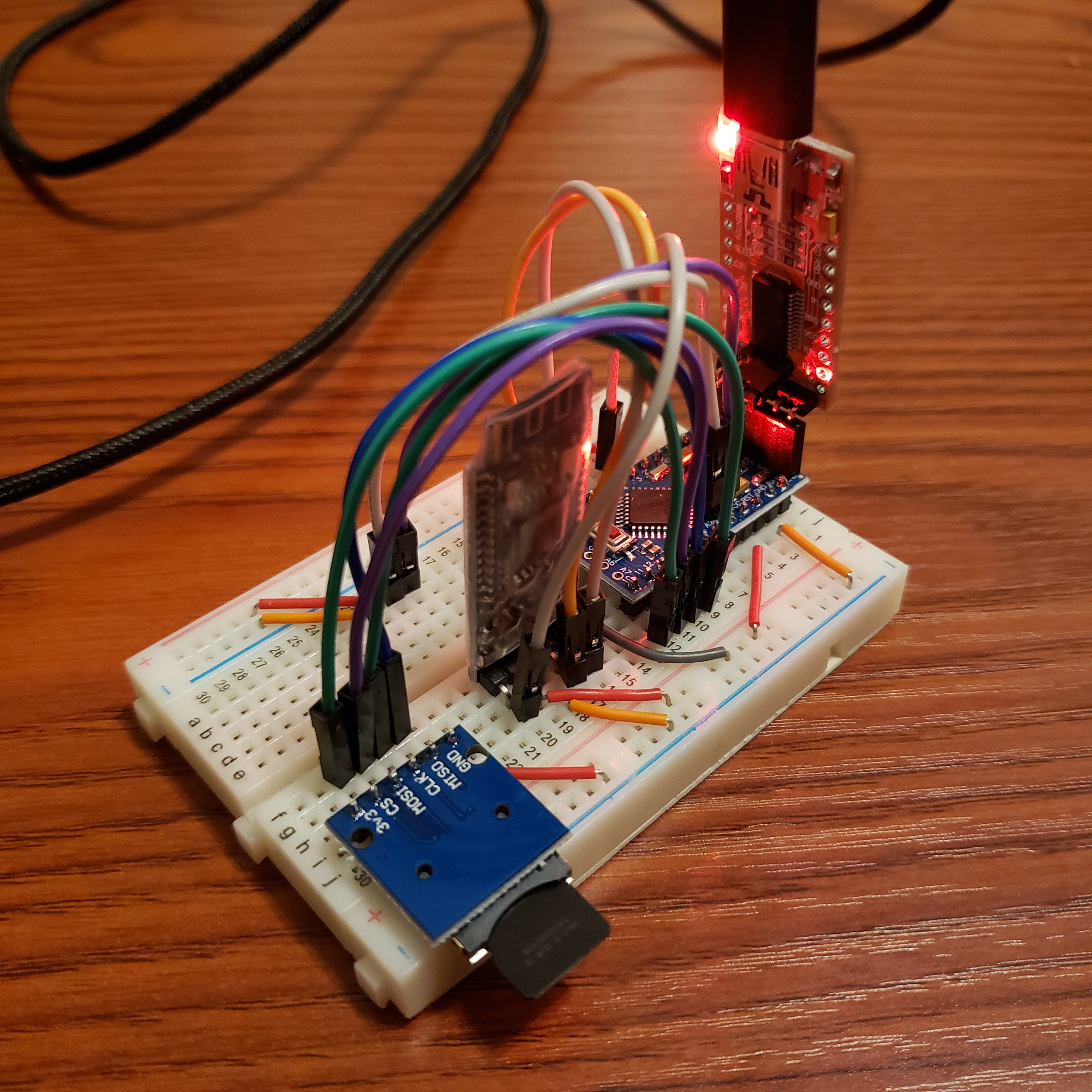

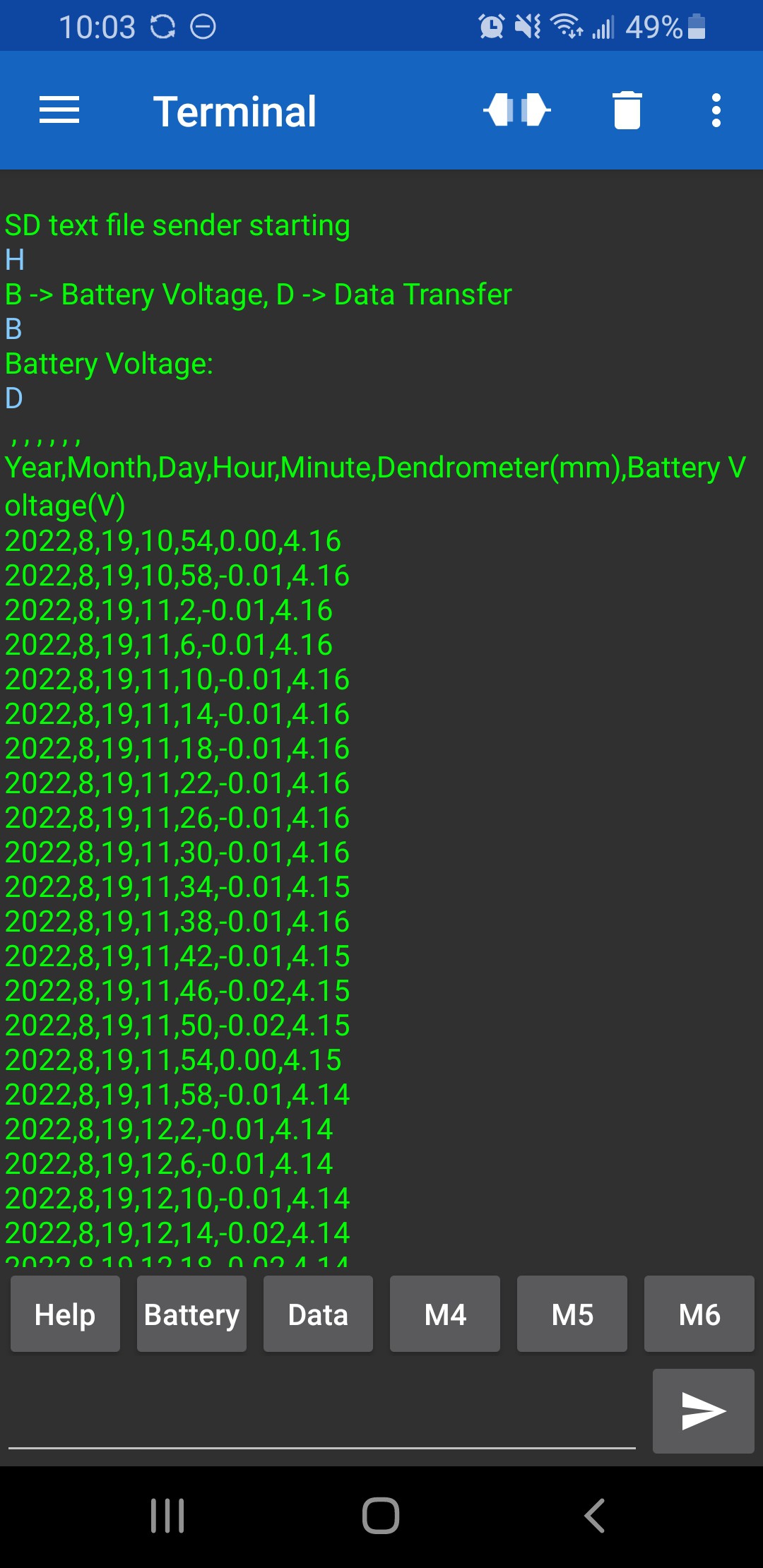

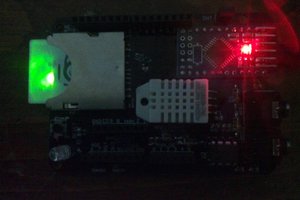

I was able to make significant progress towards adding wireless data transfer with Bluetooth this weekend. The image above is the breadboard unit used for Bluetooth testing.

I was able to make significant progress towards adding wireless data transfer with Bluetooth this weekend. The image above is the breadboard unit used for Bluetooth testing.

Daniel

Daniel

jlbrian7

jlbrian7

YJ

YJ

Clovis Fritzen

Clovis Fritzen

haha gotta love the breadboard, ship it!